Do-it-yourself attic ladder mechanism with a hatch. How to make a folding or retractable ladder to the attic with your own hands. Finished aluminum ladder

Or a cottage there is no need to explain what an attic is. Often, the layout of the internal space does not allow equipping a stationary staircase for climbing to the named room. This circumstance is due to a rare visit, the theft of quadrature and clutter of the interior. Of course, many will say that they do a good job with a stepladder, however, regular trips for this device, as well as its unsteadiness, make many owners think about building a compact ladder structure. To solve this problem, it is necessary to understand the variety of types of the named element and find out how to make a staircase to the attic without resorting to the help of specialists and without wasting a huge amount of money.

General rules for the construction of attic stairs

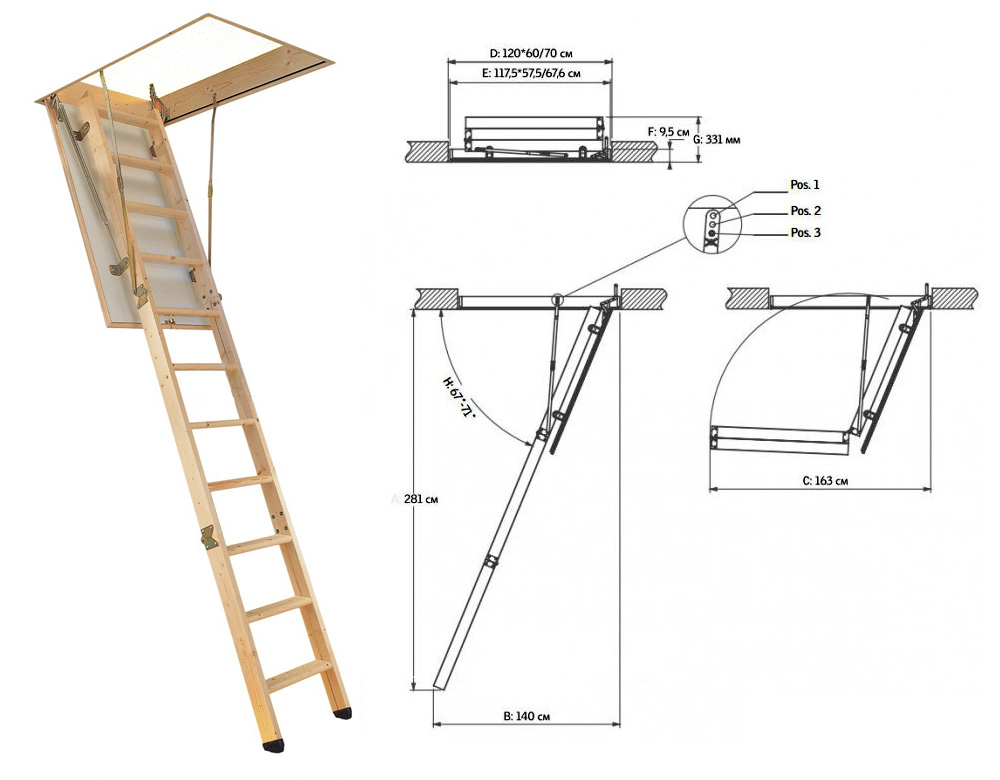

When arranging structures of this type, it is important to know a number of basic recommendations and advice from professionals, which will subsequently help to quickly and efficiently perform assembly work, as well as ensure reliable operation over a significant period of operation. The main ones are:

- the width of the stairs is not more than 65 cm;

- height no more than 3 m;

- the optimal number of steps is up to 15 pcs.;

- the distance between the steps is not more than 19 cm;

- step thickness from 2 to 2.2 cm;

- classic tilt angle from 60 to 75°;

- the design is made with a margin for more weight;

- the position of the steps at the time of opening must be strictly parallel to the floor;

- standard hatch dimensions - 120 × 60 or 120 × 70 cm.

Compliance with all of the above requirements for the arrangement of stairs to the attic room will allow you to perform work with proper quality and focus on durability of operation, as well as eliminate excessive heat loss in winter periods.

The optimal solution for the arrangement of the structure under study, which allows taking into account all household aspects, is the manufacture of a folding ladder. This type can be built both in the external version and in the internal one. The only fundamental difference is that the latter option is more comfortable to use, since it eliminates the need to go outside, which sharply makes itself felt in the cold season. In addition to this, in internal version it is protected from external influences external factors and is a kind of gasket between the cold air masses of the attic and the adjacent room.

In the assortment of modern stores there are many options for the execution of stairs, but it is more expedient to single out the most common types:

- scissor - is a ladder made of metal and, when folded, is a kind of accordion;

- folding (retractable) - includes several retractable sections, which, as they open, fold into a single structure thanks to hinge mechanisms and hinges;

- telescopic - consists of several flights of stairs, which at the time of assembly are stacked one on top of the other (aluminum is usually used as the fundamental basis of this design).

Making a folding ladder to the attic with your own hands is a simple event that does not require deep knowledge in the field of construction, so you can cope with this task without much difficulty.

Before starting any activity, you should prepare tools and acquire material. The tool kit does not provide for the availability of expensive equipment and includes a list of available tools familiar to each person:

- saw or jigsaw;

- drill or screwdriver with a set of bits;

- roulette;

- wood screws;

- anchors, corners and hinged hooks;

- one-piece staircase design with a margin of 20–25 cm for the length of the side bases;

- 4-6 card-type loops;

- timber with a thickness of 3-4 cm.

The diversity of this element allows the homeowner not to be strongly attached to traditional ways and choose the type that is best for you, depending on the available square footage, interior and other important characteristics. However, with little building experience, it is more expedient to make a ladder structure for the attic on your own with simple accessible ways, which are represented by hinged and folding types.

hinged view

The named type of stairs can be easily made in 3-4 hours. To make it, it is enough to take two beams with a section of 50 × 50 and a length of 70 to 100 cm. We attach one of the beams to the wall, directly under the equipped hatch using dowel-nails or self-tapping screws, and the second - on the lower points of the ladder supports. Further, from the upper edge of the prepared wooden stairs, we measure 2/3 and make a cut. Then we fasten these components and the top with the upper support beam with the help of loops. The design is ready, it remains only to equip a hook in the wall in the place where the lower section is folded so that the ladder is securely fixed to the wall.

It would be useful to reinforce the upper support partition with steel corners or anchors, since most of the load will fall on this element.

When equipping a folding staircase, you can choose a classic wooden staircase, sawn into several components, as the basis. To do this, you need to take 2 bars with a length that provides passage to attic hatch, and fix them on the upper and lower edges of the prepared structure, respectively, by means of loops and nails. Next, measure from top to bottom 1/3 of the total length and make cuts. The components are also fastened together with card loops.

In order to avoid spontaneous opening of the resulting staircase, a bar located on the upper edge of the structure should be equipped with a hook.

Before fixing the hinge devices, additionally check the correct opening of all components. It would be useful to install a sheet of plywood on the back of the stairs, so that when closing the stairs completely folded into the gap between the hatch and the common surface of the ceiling.

Photo of a folding wooden structure

The photographs show the sequence of manufacturing a folding ladder for the attic:

In conclusion, I would like to note that the independent arrangement of auxiliary structures from time immemorial has been the subject of attention of most owners of private houses. sticking to general rules construction and following the presented simple recommendations, you can easily make an excellent staircase to the attic without spending a lot of money on it.

Video

The provided video material, consisting of two parts, tells in detail about the manufacture of the attic stairs:

A photo

The photographs show various options attic stairs:

Scheme

If you decide to make a staircase yourself, then below are a number of schemes that you can take as the basis of your design:

This article provides step-by-step instruction to create a folding attic ladder. You will learn how to correctly assemble the main hinge element, what to make sections of the stairs from and how to securely fix the structure in the mounting position. The article contains diagrams and drawings.

The inventory factory ladder to the attic is a fairly common product that can be purchased at many hardware stores. However budget options not always reliable, and strong branded products cost accordingly. Making the necessary item or device with your own hands from improvised materials is very popular among home craftsmen. The attic stairs are no exception.

Material for work

To assemble an analogue of a factory product, you will need high-quality materials that may be available, especially during construction:

- Bar 50x50 (pine) grade 1 - 20 linear meters m. The frame of the cover and opening will be made from it.

- Plywood 8-10 mm - 2 sq. m. Needed for covering the lid.

- Board 100x25-30 mm - 15 linear meters. m. Will go to the steps and bowstrings.

- Steel strip 3-4x20 mm - for movable fastening of knees.

- Corner and plate 3-4 mm - for the main mechanical element.

- Bolts, nuts, washers, grovers M12-M14.

- Self-tapping screws.

Tool:

- Carpenter - saw, screwdriver, goniometer.

- Locksmith - welding machine, electrodes 3-4, grinder.

- Workbench and clamps.

Operating procedure

First of all, you need to choose a place for the stairs and make an opening. If necessary, cut and install intermediate beams in the ceiling - 6-7 mm larger than the size of the intended cover. Next, according to the size of the hatch, you need to assemble the lid itself - from a bar and plywood. The design can be arbitrary, but must be reliable (it is better to glue the joints). The bar on one of the short sides should be rounded - so as not to interfere with the lid to open.

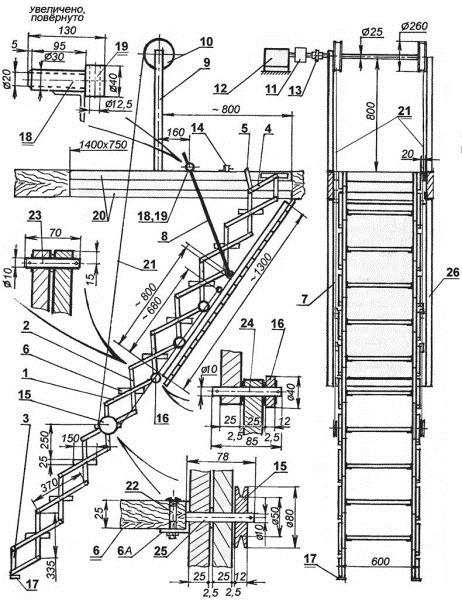

Hinge Assembly

This is the most critical element of the design. For its manufacture you will need: a steel corner, a plate and strips with a thickness of at least 3 mm. The shape of the parts is clear from the diagram, but the dimensions of the drilling site should be determined individually, based on the situation at the site. Manufactured parts must be of high quality, they should be cleaned and edged.

1 - thrust plate; 2 - corner, top view; 3 - short wings; 4 - long link

1 - thrust plate; 2 - corner, top view; 3 - short wings; 4 - long link

The key point is to determine the opening angle. This angle is very important and appears in the manufacture of the plate. In order to set it correctly, project the future march on the ground - stretch the thread and empirically (selecting the best position) set the desired angle. Attach it securely to the goniometer - it will be needed in the manufacture of steps.

The resulting angle must be transferred to the part, namely to the plate. To do this, set the mechanism to its original position, attach the goniometer and move until the angles of the angle and goniometer shelf coincide. Then mark the plate along the resulting trajectory and cut out the part travel area.

Holes must be pre-drilled in the plate for mounting to the beam. We assemble the mechanism on the bolts through the washers.

After a rough assembly, you need to try on the knot in place, bait and exactly reproduce the procedure for opening and closing the hatch. If shortcomings are found, correct them.

Then you need to make a response mechanism. It should completely repeat the first one, but in a mirror image. Use clamps and a workbench - by clamping the parts together, you will achieve complete identity in size.

Empirically make the adjustment and final installation. The cover in the open position must exactly follow the angle projected by the cord.

Section manufacturing

Calculation of the length of each section:

- 1st - opening length minus 10%

- 2nd - the length of the first minus 10%

- 3rd - the length of the march minus the sum of the first two

Let's assume that the length of the march is 2500 mm. Based on an opening length of 1200 mm:

- 1st - 1080 mm

- 2nd - 972 mm

- 3rd - 448 mm

We mark the whole boards according to the calculation and transfer the march angle to the bowstrings.

Attention! Bowstrings must be installed mirror! Keep this in mind when marking and drilling.

At the joints of the sections, we drill holes Ø 25 - mirror through one.

All parts need to be processed with a sanding tape with high quality, chamfers are rounded in order to bring the quality as close as possible to the factory one.

Then we cut along the grooves for the steps. We select wood with a chisel.

The design of individual sections is assembled on 65 mm self-tapping screws with a press washer through D-3 carpentry glue.

Knee loops can be made from the same strip as the opening mechanism. To do this, cut 4 strips of 160 mm and 4 of 120 mm, round the ends. To four of them we weld the paws to a length of 160 mm with a hole of 8 mm. You should get 8 parts of the same length, but 4 of them with a step.

Assemble individual plates into hinges using bolts.

Assembly of sections and installation of stairs

Lay out on a flat plane and install the finished sectional hinges so that the mounting bolts fall into the holes in the tree. Install the hinges on the M8-10 bolts.

After assembling the first knee, check the system for operability. Eliminate distortions if necessary.

Then attach the lower short leg and test the system.

Now it remains to mount the ladder in the design position - on the hatch cover. For installation, use bolts (self-tapping screws are not reliable). If, after installation and testing, everything works without distortions, the structure can be dismantled for painting. Use varnishes and spray paint for metal.

Subsequently, the design can be complicated and made more convenient by adding to it:

- Additional hinges to eliminate backlash.

- A spring to support the structure to make opening easier.

- Lock-lock.

- Handrails.

- Use decorative trim and extra insulation.

Finished stairs:

The issue of finishing and insulation is decided locally, based on needs. You can finish the cover with any material that fits into the ceiling. Basically, it is plastic - light, inexpensive and having an additional layer of air. The difference in price between the "home" and "shop" version of the folding ladder is about 90% (80-150 USD). The work required only a few new boards, a coating for them and hardware.

Almost all country houses have attics. To organize a comfortable and safe ascent there, it is necessary to equip a ladder.

It can be made from various materials, but the most common and convenient wooden stairs. Let us consider in detail their types, and tell you how a staircase to the attic can be made from wood with your own hands.

Finished building

Structures for lifting to the attic can be capital and removable. Their type depends on the available space for installation, ceiling height and frequency of use.

Indeed, often the attic is used as a utility room, and there is no need to install a complex architectural structure. However, even among simple designs there are those that will harmoniously fit into the interior, and will not take up much space.

When choosing a type, you do not need to think about the possibility of moving large objects on it or finding two people at the same time, since both of these situations are unlikely to arise.

Stationary types

All structures, according to the type of attachment to the supporting base, are divided into the following types:

- On strings.

Such structures are two bearing bowstrings, straight or curved, between which steps are located in the grooves.

On bowstrings

- On stringers.

They are a bit like bowstring systems, but the difference lies in the fact that stringers serve as a support beam. The steps are attached to them from above, so that they seem to lie on supports. Usually one or two stringers are used.

On kosoura

- On the pains.

AT this case, steps on one side are fixed with pins to the wall, or to a load-bearing beam built into the wall. Such a system of steps looks very stylish.

Boltsevaya

- On a support pole.

This design has found application in the device of screw types. One, tapered end of the step is fixed on a vertical bearing support, and when properly positioned, all steps form a helical march. A big plus in such a system is that it does not take up much space.

screw

- Combined designs.

Such structures can be manufactured using all of the listed types of fasteners.

On the vertical support and bowstring

Stationary types are the most visually attractive, convenient and safe to use. However, for the installation of capital attic systems, it is not always possible to find a suitable free space.

Portable options

They are quite inconvenient to use for interfloor movements:

- Attached. This is the simplest device for ascent and descent. It can be used as a temporary, bring and take away at any time. Attachments are suitable for a rare visit to this room. Such a device can be left in place, but it will not add any aesthetics to the interior. In addition, the shakiness and instability creates problems with the safety of the person using it.

Attached

- Everything that has been said about the attached variety can be repeated about this type - with the only difference that stepladders are a little more convenient and safe to use.

Most often, portable options are used when access to the attic is from the street.

Folding types

This type is very convenient and functional for rooms of a small area, and "not suffering" from excessive luxury. They are compact, with a slight movement of the hand they fold and stow away in the hatch. Despite the apparent primitiveness of the design, they can withstand decent loads (150-250 kg).

Manufacturers offer big choice. They consist of 3-4 spans and easily adjust to any ceiling height. However, the price of these structures is quite decent.

Manufacturing

If the question arose about manufacturing, wood is the most suitable material for these purposes. There is no need to buy a ready-made design, as it is quite simple to make it yourself.

The production process of the attic stairs can be viewed on the video in this article:

Manufacture of a stationary ladder on bowstrings

Do-it-yourself capital construction: stages of work. In the manufacture of the structure, you will need bars for the manufacture of bowstrings, boards for steps, a set of screws and anchors for fastening, varnish or paint for finishing.

Tools needed for work:

Manufacturing instructions:

- A design drawing is being prepared.

- Bowstrings and steps are cut in accordance with the drawing.

- In bowstrings, according to a pre-prepared stencil, grooves are cut to install steps to a depth of 15-20 mm. The accuracy of cutting grooves and maintaining geometry are the most important part of the whole process, because, otherwise, the steps will loosen, and the staircase will quickly become unusable.

- All parts are polished with sandpaper.

- Before assembly, the parts are treated with an antiseptic.

- The grooves are coated with glue. Steps are being installed. For greater reliability from the outside, they are fixed with self-tapping screws. Hats are better to drown and putty.

- If necessary, you can install balusters and railings.

- Finishing treatment with paints and varnishes.

- The structure is anchored to the supports.

The result is a simple but reliable and secure system.

Option on bowstrings

Production

Requirements for folding structures:

- step width - 65-110 mm;

- the number of steps - no more than 15;

- distance between steps - 16-20 cm;

- step thickness - 18-22 mm;

- height - no more than 3.5 m;

- load capacity - not less than 150 kg;

- tilt angle - 60-75 degrees.

Consider how to make it yourself:

Important! In the production of the structure, and especially during its installation, you will definitely need an assistant.

- A drawing is created.

- Details are being prepared. All places of cuts are carefully cleaned.

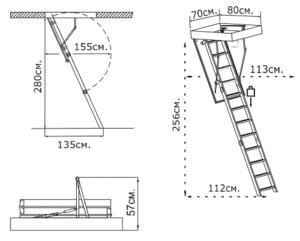

- Manhole frame is being made. Standard size hatch 120x60 or 120x70, however, you can make it in accordance with the existing opening.

- With the help of bolts and metal inserts, the frame is installed in the opening.

- The manhole cover can be made from 2 sheets of plywood 10 mm thick, laying polyethylene between them for vapor barrier. You can use a furniture board. We mount the handle to the lid.

- The cover is hung on the frame.

- On the prepared bowstrings (on the inside), which will be used as supports, grooves are made (about 5 mm deep) for installing steps.

- The ends of the support beams are sawn off so that they are stably placed on the floor. It is best to install plastic tips.

- For simplicity, you can use the design, sawn into 3 fragments.

- With self-tapping screws, the crossbars are fixed at times between the bowstrings. For strength, we recommend additionally applying glue to the joints.

- The parts are connected to each other with loops.

- The design of the sections, the corners are attached to the cover (as in the photo).

- Gate valve is installed.

- For more convenient opening of the door, we recommend installing a lever-spring mechanism.

- The entire system is treated with a protective compound.

Important! Before attaching the system to the hatch, check that all elements are functioning properly.

The result is a design that will provide safe access to the attic, and will not take up space in the house.

We examined what wooden attic stairs are, their types, options for use. They gave advice on making a comfortable and functional staircase with their own hands. Now it's up to you!

The attic is a traditional room in almost every country house. Its functionality is extremely wide. For example, this room is used as a storage room or workshop, some homeowners even design the attic as a living room or bedroom. In fact, the functional purpose of such a room depends solely on your own imagination, as well as financial capabilities. However, despite the wide variety of attic space design options, it is worth knowing that an attic staircase with a hatch is an integral part of it. If you do not build this structure, then you simply cannot get into this room. Creating an attic staircase is a fairly simple matter, in connection with which you do not even have to turn to professionals in the construction industry.

Structure classification

Actually, the most time-consuming process in the organization of the attic space is the design of the stair segment. Before creating a project for a specific staircase for your home, you must first determine the design category. There are such options:

- folding;

- stationary;

- portable.

Temporary solution

Portable models will be singled out in a separate category, however, it is quite extensive. The variety of portable products is simply incredible. Meanwhile, do not forget that the daily use of such a product can never become safe or comfortable enough, and the ladder itself is not able to compete with stationary and folding models in terms of operational and technical characteristics.

Selection of building materials

In the process of creating an attic staircase with your own hands, namely, its preliminary drawing, you should pay attention to what building materials are commonly used in this case. Despite all the variety of products in the building materials segment, any experienced builder will tell you that there are certain types of products that perform best during operation. As a rule, all the main structural parts are made mainly of wood, while fasteners and fixing elements are made of metals. Thanks to the competent selection of materials, a do-it-yourself attic staircase, the drawing of which was made by a non-professional, will be an order of magnitude stronger and more reliable.

How to make your choice?

Due to the fact that building materials for folding stairs to the attic are presented in a variety of price segments, source material and characteristics, it is quite easy to drown in a sea of information about them. To minimize the time spent on searching and choosing the best options, you should be guided by a number of rules:

- Specify the type functional purpose structure, as well as its main parameters, including structural features, sectionality, width, etc.

- Choose building materials in strict accordance with how the product will be actively used and in what conditions.

- Identify the negative factors that can reduce the life of the product.

The main thing is to correctly define the function

Any specialist who has the necessary level of qualification and experience in working with such types of objects will tell you that the final result largely depends on the competent definition of the functional purpose of the product. construction works on the construction of stairs to the attic with their own hands. This parameter allows you to calculate the allowable load indicator for each step of the product. The standard value of this indicator for a metal product reads about 250 kgf, but wooden models are designed for only 150 kgf. In addition, it is worth considering that the above indicators are valid for products made by professionals, while home-made objects have somewhat lower parameters. In general, the indicator of permissible pressure on a step does not mean that it cannot withstand more stress. However, if the structure is overloaded too often, then it will become unusable in a fairly short period of time.

So, the main criteria by which the choice of the optimal option is carried out are as follows:

- the area of free space in the room;

- functional purpose of the object;

- desired angle of inclination.

Figure 9

What to consider when designing?

Most General requirements normative and technical documentation can be reduced to a number of simple and understandable conditions:

- the ergonomic range of product width is from 60 to 100 centimeters;

- the best height is three and a half meters;

- the maximum number of steps is 15 pieces;

- the distance between adjacent steps should be about 20 centimeters;

- the step height comfortable for a person reaches about 20 centimeters, a deviation of 2 centimeters is allowed;

- if we are talking about a folding structure, then when creating a project, a permissible load of 15 kilograms is taken.

Tools

Having decided on the independent implementation of construction work, it is very important to stock up on a certain set of equipment so that in the process of implementing the product project, you do not stop due to the banal lack of a screwdriver or tape measure. So, the standard set of tools consists of the following items:

- mounting foam;

- bars;

- self-tapping screws;

- electric screwdriver;

- hacksaw;

- yardstick;

- anchors;

- screwdrivers.

Building a staircase is not a difficult task.

Building a staircase is not a difficult task. Location features

All the nuances of the location of the object in the room will become visible during the construction process. This is especially true if you are engaged in the creation and subsequent implementation of the project yourself. Remember that the product can in no way reduce the comfort of the room. That is why stairs with a hatch are not located in bedrooms, living rooms and kitchens. However, if necessary, you can diversify your staircase project with an interesting design. Thanks to this, the product will be able to harmoniously fit into the overall interior of the room.

Project implementation technology

Following a certain technology, you can quickly and efficiently implement even a complex project. So, if you have chosen metal as the main material, then remember that the following steps are carried out:

- the drawing is applied to sheets of cardboard;

- cardboard elements of the future product are cut out;

- hinge marking is applied on metal strips and special holes are prepared;

- prepared parts are fixed to each other;

- the required angle is measured and the structure is moved apart in accordance with the parameters obtained;

- on metal sheets, markings are applied to those places that will subsequently be covered with corners;

- elements are cut using a special tool;

- given aesthetic appearance object;

- existing corners are rounded;

- workpieces are fastened in pairs.

As you can see, the technology for working on the implementation of the staircase project with your own hands is quite simple. It applies not only to metal objects, but also to wooden products.

In order for the appearance of the attic stairs to be as attractive as possible, do not be too lazy to carry out preparatory work on the surface building material. It's about, for example, about applying a special primer before covering the surface with a coloring matter.

Do not be afraid of difficulties, because the technology for the construction of stairs only at first glance may seem problematic to you and require experience in the construction industry. Applying the optimal amount of effort will help you achieve maximum results.

Folding loft ladder is convenient option that doesn't take up much space.

It is not difficult to make such a ladder on your own.

To do this, you do not need to have special talents, you do not need to be a professional carpenter, but you need to have some materials, free time and, of course, a bit of patience.

Which ladder is best?

The attic can be a place littered with old junk and make for a great Halloween decoration.

You can equip a creative workshop or an office for work in the attic, you can equip a cozy children's room there.

But no matter how different purposes an attic space serves, no matter how it is equipped, all the attics in the world are united by one fact: it is impossible to get there without a ladder. Of course, if the owner of the attic is not a superhero.

So which ladder to choose for climbing to the attic? Is it possible to make it with your own hands? The answer to the second question is simpler: everything can be done with human hands! The first question will have to be dealt with in more detail.

The type of stairs should be chosen depending on the purpose of the attic and the availability of free space below.

All types of stairs can be divided into three types:

- attached;

- permanent;

- folding structures.

The easiest option is, of course, a ladder. This type includes both ordinary wooden drabins and metal ladders.

Benefits of a ladder:

- light;

- does not take up space;

- You can use one ladder to climb in different places.

In the economy, this option is undoubtedly indispensable. With the help of a ladder, you can change light bulbs, cut trees on the site, repair the roof, etc.

However, it is convenient to use it to climb to the attic only if the attic is planned to be used from time to time.

This is ideal if old things are stored in the attic, that is, they will go up there a couple of times a year.

If the attic is planned to be converted into a useful, functional room that will be used frequently, then the way to get there should be appropriate.

A fixed ladder is ideal.

This option has many advantages:

- stable;

- reliable;

- it is easy to climb it for both a child and an elderly person;

- it is easy to arrange in the style of the room;

- can be supplemented with railings;

- the space under the marches can be functionally used, for example, to arrange a pantry there.

This is the only acceptable option if the attic is supposed to be converted into a children's room. Metal spiral staircases with wrought iron railings also look very impressive.

But all the advantages of this staircase are crossed out by one fat minus - it takes up a lot of space. What to do for those whose place does not allow to make a stationary staircase?

Is it really necessary to abandon the idea of converting the attic space?

For those who want a reliable and safe ladder, but do not have free space for its installation, there is a third option - a folding design.

This option is slightly inferior in safety to the stationary one, but after use, the ladder will be removed and not take up space. In addition, it is easy to do it yourself, taking into account all the individual nuances.

Folding structures

There are many options for folding ladders.

This type includes the following structures:

- suspended;

- retracting upward.

Both options are easy to make with your own hands. The difference between them is that the ladder can be folded and removed into the attic hatch or folded and hung on the wall.

The hanging option is only suitable if the hatch is located directly against the wall. In addition, hanging on the wall under the ceiling, albeit folded wooden structure, will not fit into any interior.

Therefore, the best option is a ladder that will be removed to the attic. Depending on the size of the hatch, it can consist of two, three or even four sections.

Taking measurements and building drawings is the first step in making a staircase with your own hands.

There are a number of rules that, if possible, must be observed in order for the design to be convenient and safe:

- the width of the stairs should not be narrower than 60 cm;

- in the unfolded state, the angle of inclination must be at least 30 °;

- the depth of the step should be at least 10 cm so that the rising person feels confident;

- the distance between the steps should not exceed 30 cm (preferably less);

- if the attic hatch is higher than 2.2 meters, then it must be equipped with a leash for easy opening;

- with a room height of 4 m or more, it is better to choose a stationary option, since under the weight of a person the structure can “play”, which will significantly reduce its safety.

First of all, you need to decide on the size and location of the future hatch. The longer it is, the fewer sections you will need to divide the stairs into.

For example, with a door length of 90 cm and a ladder length of 240 cm, three sections are obtained: 240: (90-10) = 3.

It is better if the hatch is made of solid wood. In this case, it will turn out to be heavier than from plywood or other materials, but the fasteners in the tree will “sit” much better.

On the ceiling, the hatch must be fixed with reliable fixed-opening door canopies.

Such canopies are fixed with their own hands in the position necessary for opening with the help of special pins.

With further opening of the hatch, it will open only as much as the installed studs allow.

Do not use any other fasteners (for example, window awnings).

It must be remembered that the weight of the hatch itself, the ladder and the person climbing it will fall on the canopies. Therefore, it is necessary to ensure the proper reliability of the design.

In addition, you need to install a lock and, in the case of a hatch height inaccessible from human growth, a leash.

The ceiling side lock can be used for both interior door equipped with an automatic latch. From the attic side, a latch type latch is suitable.

A cable or a lever can be used as a leash. The cable, passing through the roller device from the attic side of the door, actuates the lock mechanism.

However, a cable hanging from the ceiling will not fit into every interior, so a lever is a better solution.

The lever is a plastic or metal rod (it can be telescopic for easy storage) with a recess of the desired shape at the upper end.

This method is suitable when using a do-it-yourself mortise lock in the hatch cover, from which you need to remove the turntable.

A turntable is a plastic nozzle on a non-removable key. It is used for the convenience of opening the lock from the inside.

Under the turntable there will be a metal rod of a square or semicircular shape, on which a lever should be put on.

The hole of the lever should fit as closely as possible to the lock rod, in this case the lock will open easily.

If there is a financial opportunity, then you can install an automatic lock with a remote control on the hatch.

Making stairs

After the attic door is made, you can start making stairs with your own hands.

This will require the following materials and tools:

- two beams, equal in length to the length of the future staircase, at least 12 cm wide and 3 cm thick;

- a board for steps with a width of at least 10 cm, a thickness of 2 cm. The total length of the board is equal to the length of the steps multiplied by their number;

- corners or bolts for fastening steps (4 for each step);

- fasteners for fixing the upper section of the ladder on the hatch cover;

- hinges, two for the number of section connections (4 sections are 3 connections);

- drill;

- screwdriver;

- wood saw;

- a long metal ruler or tape measure;

- protractor or small.

After everything is prepared for work, the primary task is to mark and secure the steps.

It should be remembered that the stairs will be at an angle, and the steps should be parallel to the floor. They must be marked at an angle of 30 °.

After the first step is fixed, you should install the ladder and make sure that the steps are located correctly.

When the ladder is ready, it should be sawn into required amount sections. The cuts should be located at the same distance from the steps. Sections are fastened together with metal hinges or loops.

When the ladder is assembled, its upper part must be tightly fixed on the attic door, stepping back 5 cm from the top edge.

After that, the load capacity of the ladder and its connections should be checked. Do not check the ladder with your own weight by climbing on it!

To soften the harshness of the opening, you can use rubber straps or metal springs, securing one end to the bottom of the manhole cover, and the other to the attic floor.

The staircase is made by hand, and not so much time and effort was spent on its manufacture.

But for greater security and reliability, something else should be done:

- lubricate all moving metal parts (hinges, hinges);

- sand all wooden surfaces with an emery cloth or grinder;

- can be painted if desired acrylic paint or varnish.

In this case, this design will last a long time, will not leave a splinter after climbing it, will not tear clothes and will not creak.

Such a device, made by hand, will become a real pride of the owner. Happy repair!