How to make a sewer well in a private house: materials and construction technology

When planning and building private houses, their owners make a lot of efforts to improve the comfort of their homes. Particular attention is paid to water supply and sewerage systems. It is important to design them correctly so that the house becomes cozy and all the needs of the residents are satisfied. For the operation of the wastewater disposal system, it is necessary to build various types of sewer wells. What are they like? How to make a sewer well with your own hands?

- Lookouts. They are necessary for free access to communications. Structures of this type are installed in places where it is especially important to control the condition of sewer systems. These are sections where pipes of different diameters are connected; where the direction or slope of the pipeline changes. You also need to have access to systems on too long straight pipe runs.

- Variable. Structures of this type must be built in areas where there are differences in the level of pipes. Thanks to the overflow well, the owner of the house can control the speed of movement of drains through the system; equalize the sewerage outlet with the water level if treated wastewater is discharged into a reservoir. This design is needed if the height of the drop exceeds 300 mm. If it is less, you can get by with a manhole.

- Swivel. Thanks to the structures of this type, you can get free access to sections of the pipeline that have bends. In such areas, there is always a high risk of pipe blockages and there is a need for enhanced control.

- Filtration. The structures are designed for post-treatment of wastewater. They are equipped only in areas with permeable soils - sandy or sandy loam. Pay attention to the depth of groundwater. The aquifer must be located at least 1 m below the structure. Otherwise, the drains are poorly filtered. An alternative to such structures is underground filter fields.

- Cumulative. Tanks of this type are improved cesspools. Their main advantage is environmental safety. The structures are completely sealed. Accumulating in them, runoff does not penetrate into the soil and aquifers. Minus - the containers need to be pumped out regularly. It is necessary to correctly calculate the volume of the tank in order to contact the sewage services as rarely as possible.

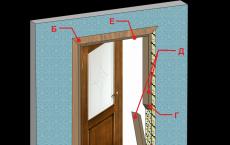

Operating sewer well

Scheme of the design of the inspection sewer well

What materials can be used

To make a sewer well in a private house, you can use concrete, reinforced concrete, wood, plastic. The two best options are to build your own from concrete rings or buy and install an industrial plastic structure. Plastic structures are factory blanks. They are easy to install, but inferior to concrete rings in many ways. To make a choice, it is worth understanding the features of both types of devices.

Plastic sewer wells

What are the advantages of plastic structures

Until recently, plastic was little used in outdoor sewage systems. The reason is low frost resistance. Structures burst in severe frosts and began to leak. Now this problem is solved. New varieties of polymeric materials have appeared that can operate in the temperature range from +70 to -50 degrees Celsius.

Manufacturers have taken care of the release of models of various diameters, so the owner of the house can only calculate the required volume and choose a product of the right size. Plastic blanks are much lighter than concrete rings. To properly make a well for sewage, it is enough to mount the tank. This can be done even alone.

Plastic products are absolutely impervious to water, perfectly withstand the effects of chemicals, and do not rust. All these are definite pluses. But there are enough cons. The material does not cope well with mechanical loads, so it may not withstand the pressure of the soil. Structures must not be installed in places where vehicles can pass. In terms of durability, they are significantly inferior to concrete.

Concrete rings - reliability and durability

If we compare the characteristics of strength, reliability, durability of concrete and plastic structures, then the conclusions are obvious. Tanks made of concrete rings can serve for several decades. In the event of a malfunction, the wells can be repaired. In this, plastic cannot be compared with concrete.

In some respects, concrete rings are still inferior to plastic. They are much more expensive, but this is not the only drawback. To independently build a sewer well from them, you have to make a lot of effort. The structures are very heavy, they can sag under their own weight. Installation requires special tools.

When choosing, it is important to find products made of high quality waterproof material. You will also have to spend extra money on good waterproofing of the joints. Otherwise, the structure will begin to leak. Contaminated water will enter the soil, and water from the surface may seep into the well itself.

Concrete rings come in different sizes. When calculating the volume of the tank, it should be taken into account that the optimal height of the structure is 2.5 m. Most often, wells are made from products of the KTs-10, KTs-20 types. There are rings of non-standard sizes, but finding them can be difficult.

For ease of installation, many products are equipped with a so-called. locks, thanks to which you can install them without displacement. The more accurately the rings are fitted to each other, the tighter, stronger, more reliable the finished structure.

Scheme: dimensions of concrete rings

How to make a sewer well with your own hands

How to make a sewer well? When choosing the type of construction, consider the volume of drains. If their number does not exceed 1 cubic meter. per day, the structure may have an outlet for wastewater into the soil. Bacteria living in the soil are quite capable of coping with the processing of a small amount of organic matter.

If there are more than 1 cubic meters of wastewater or they contain aggressive chemicals from detergents, washing powders, etc., then the design must either be completely sealed or have a contaminated water treatment system. In this case, it makes sense to choose a plastic container, and the concrete one will have to be carefully waterproofed.

Often they make structures with a filtering bottom. They are suitable for wastewater without chemicals. Waste, passing through the filters, is cleaned to such an extent that there are no problems with their further decomposition. The depth of such a well depends on the permeability of the soil and the level of groundwater. If an inspection, nodal, differential or rotary sewer well is planned, it must be airtight.

Scheme of a well with a filter bottom

Requirements for the construction of wells for sewerage

The size of the structure depends primarily on its purpose. If we are talking about a storage facility, then the larger it is, the less often you will have to call for sewers. On the other hand, too much drain can cause an unpleasant odor in the area.

The standard rate that is used in volume calculations is 150-200 liters of water per person per day. However, water consumption often significantly exceeds these figures. For example, in houses where many plumbing fixtures and household appliances that use water are installed, the consumption can be 240-250 liters per day per 1 person.

To determine the desired volume, 200-240 liters (depending on consumption) are multiplied by the number of people living in the house. The result will show the average water consumption of all residents per day. It should be multiplied by 3. This will be the optimal volume of the well. Next, calculate the height of the structure, taking into account the standard sizes of the rings.

The layout of the well for sewerage

Stages of construction of sewer wells

- Excavation. How to dig a sewer well - open or closed? Since the structure is shallow, the first method is preferable: first they dig a hole of the required depth, and then they mount rings in it. Even if the soil is loose, it is not necessary to resort to complex technologies, it is enough to install temporary formwork to strengthen the walls.

The closed method is used less often. In this case, a hole is prepared for one ring, and it is installed. Then they continue to take out the soil. The ring is gradually lowered. When it is at a sufficient depth, the next one is mounted on it and work continues.

- Construction bottom. First, they equip the mounting pad - they fill the bottom of the pit with rubble. The layer must be at least 40 cm. The bulk material is compacted, the finished concrete bottom of the structure or slab is installed on top. If the structure must be completely sealed, then only the bottom of industrial production, made specifically for rings of the desired diameter, will do.

- Wall construction. The rings are installed on a cement-sand mortar. It is important to mount them exactly one on top of the other. When the solution dries, the seams and joints are waterproofed. The well is connected to the sewer, the pipe entry points are also sealed.

- Completion of work. Lastly, install a cover with a hatch, insulate it. Install the ventilation pipe. It should rise above the ground by at least 60 cm.

Important! Pay special attention to the ventilation system. During the decomposition of organic substances, an explosive gas is formed. It is necessary to ensure that it does not accumulate in the tank. This can lead to negative consequences.

Stages of making a well from concrete rings

Video: how to make a sewer well

How to make a sewer well and what it should be, each homeowner determines for himself. The article provides general recommendations for the arrangement of the structure. If you are not sure that you can do everything yourself, contact the experts. In almost every area there are companies involved in the design and installation of sewerage systems. In the absence of proper skills, it is better not to experiment and contact such a company.