We build a change house with our own hands - step-by-step instructions for building

Many novice summer residents often ask themselves: what is the best thing to do, buy a ready-made change house or make it yourself? As practice shows, finished products often turn out to be of poor quality and short-lived. Therefore, we definitely recommend self-construction. You can learn about all its nuances and subtleties from this article.

Why do you need a home?

Before proceeding with the design and construction of a change house, it is necessary to decide on its purpose, because its dimensions, layout and other points largely depend on this. As a rule, the change house performs the following functions:

- residential premises - the building can be used as housing for the period of construction of the main house. Subsequently, it will not be difficult to re-equip it for other household needs, in addition, the change house can serve as an additional summer house, for example, for meeting guests;

- economic - in the room you can store summer equipment, work clothes, etc .;

- sanitary and hygienic - a change house can be equipped with a bathroom, for example, here you can perform an outdoor shower and install a dry closet.

If desired, a country change house can be equipped with a bathhouse or other functions. The main thing is to think carefully about all your needs and wishes in advance, so that later you don’t have to do alterations, as is often the case.

Design - we create a change house on paper

Having decided on the requirements for the change house, you need to create a plan on paper and indicate the dimensions of the structure. Most often, the building is a trailer 2–3 m by 5–6 m. Of course, it is not at all necessary to make it elongated. The main thing is that the shapes and sizes allow you to implement all the intended functions.

In order not to puzzle over the layout, you can take ready-made drawings as a basis. Adjust the dimensions if necessary. The only thing, we note that it makes no sense to make a building too large, since it will no longer be a change house, but a capital structure with completely different construction costs. As a rule, a building measuring 6x3 m is quite enough for all household needs.

Next, you need to decide on the design and materials. Since the change house is an inexpensive and lightweight building, which, if necessary, can even be moved from one place to another, we recommend making it out of wood. Next, consider two construction technologies using this natural material:

- frame - this is the cheapest, fastest and easiest way to build, however, keep in mind that the strength and durability of frame change houses is not their strongest point;

- from a bar in the form of a log house - like log houses, such change houses are strong and durable, but more expensive than frame counterparts.

The basis of the frame structure, as you might guess, is a frame made of timber. It consists of racks located in increments of 600 mm, and connected to each other by the lower and upper strapping (horizontally arranged boards or timber). To strengthen the racks, braces and horizontal lintels are additionally used. The frame space is filled with insulation and sheathed.

The distance of 600 mm between the racks is indicated for a reason - it is for this step that heat-insulating boards, as well as OSB, are designed. If desired, the step can be changed, but in this case you will have to cut the insulation and sheathing.

Before you start building a frame change house, draw up a diagram of the walls and floors, indicating the dimensions of all the details. This will allow you to calculate the amount of lumber and make an estimate. More details about the materials that will be used in construction, we will talk below.

Calculating lumber for a bar change house is even easier: to find out the number of crowns, simply divide the height of the wall by the height of the bar section. The length of each crown is already indicated on the plan. Therefore, an additional project can not even be done.

Foundation - even a change house needs a good foundation

If you install a change house for a month or two, then it is not necessary to build a foundation for it. It will be enough to add crushed stone, aligned in a horizontal position. To protect the bottom of the building from moisture, several bars or bricks / blocks should be laid on the bedding.

If the change house will be used as a permanent structure, you can’t do without a foundation. Of course, in our case, there is no need to carry out a massive tape structure. It is more expedient to make a lightweight base in the form of separate columns interconnected by beams (grillage). Construction begins with the preparation of the site: we get rid of the vegetation layer of soil, after which we mark the site according to the design dimensions of the building.

Then it is necessary to prepare holes for posts with a depth of about 40 cm, located at a distance of one and a half meters from each other along the length and width of the building. Cover the bottom of the holes with a layer of sand and gravel 150–200 mm thick. Be sure to compact the bedding well and align it horizontally. Then build columns of blocks or bricks 30-40 cm high above the soil level. Treat the surface of the posts with bitumen, then cover with several layers of roofing material.

Next, you need to lay the beams (beam 150x150 mm) around the perimeter of the columnar foundation. To fasten the beam to the posts, use special fasteners, the so-called studs. When laying the grillage, make sure that the beams are horizontal. If necessary, you can align the position of the beams by laying bars or boards under them, but in general, try to ensure a horizontal plane even at the stage of erecting the columns.

Between themselves, the beam can be connected "in half a tree" - in this case, even grooves are made at the junction of the beams with a depth of half a beam. The grooves must be reciprocal, i.e. in one beam, the groove is cut from above, and in the second, respectively, from below. Additionally, joints can be strengthened with self-tapping screws and steel corners. In the same way, floor beams are laid and cut into the extreme bars.

We build a change house quickly and cheaply - the nuances of frame technology

To build a frame change house, you will need the following materials:

- timber 100x100 mm;

- boards 35x100 mm;

- mineral mats with a thickness of 100 mm and a density of 25–35 kg / m 3;

- vapor barrier;

- wind and moisture insulation;

- finishing material - lining, block house, etc.

We begin the construction of walls with the installation of corner posts, which are made of timber 100x100 mm. To fix them, use the corners and screws, strengthen them with braces. After making sure that all the racks are vertical, connect them with an upper harness, which use a 35x100 mm board.

If the roof of the change house is single-pitched, do not forget to make one long wall 30-40 centimeters higher than the other.

Then you can install intermediate racks made of boards. They are attached to the upper and lower trim with metal corners. To give the structure rigidity, fix horizontal jumpers between them in a checkerboard pattern. In addition, install horizontal strips from the same boards above and below the openings.

If the roof of the structure is gable, lay the floor beams on the frame of the walls. Since the beams will carry practically no load, the same boards of 30-100 mm can be used. Install them with an edge on the harness and secure in this position with the help of corners. The step of the boards can be made about 40 cm.

After that, you can proceed to the insulation and sheathing of the frame. It is better to start from the roof, but we will consider this stage separately, and now we will insulate the floor and walls. Thermal insulation of the floor begins with laying the rough flooring on the floor beams. Since it will not perform a supporting function, any boards can be used for these purposes. Waterproofing is laid on top of the rough flooring, and then floor logs are installed. Do not forget to align the logs in a horizontal plane.

All roll materials, i.e. vapor barrier, wind protection and waterproofing, are mounted with an overlap of 15-20 centimeters. Moreover, it is desirable to glue the joints of the canvases with butyl rubber double-sided sealing tape, which will ensure complete tightness of the joints.

Next, the lag space must be filled with heat-insulating material, for this you can use both mineral wool and any other insulation. The surface of the log and thermal insulation must be protected from moisture with another layer of waterproofing film. Then you can install the boardwalk.

The ceiling ceiling is insulated in approximately the same way - the space between the floor beams or rafters is filled with insulation (if the roof is shed). To fix the plates, you can zigzag a wire or a nylon cord between the beams. Then, from below, a vapor barrier film is attached to the floor beams with a stapler. On top of the vapor barrier, a crate is made of a 20x30 mm lath, to which a lining or other finishing material is attached.

If the thickness of the rafters is not enough to fix the insulation between them, build them up with a bar or boards.

One of the most important points is the insulation of the walls. Not only the comfort of staying indoors and the energy efficiency of the building depend on it, but also the durability of the entire structure. We start thermal insulation with the installation of a vapor barrier film, which is attached to the frame from the inside of the walls. Previously, it is desirable to stick a sealing tape on the racks so that later there is no depressurization of the circuit in the areas where the film is attached to the frame. The vapor barrier is fixed using a stapler - the staples are driven in increments of 100-150 mm.

Then the frame space must be filled with mineral mats. In the process of insulation, observe one main rule - there should be no gaps anywhere in the walls. If cracks have formed, they need to be filled with scraps of mineral wool, otherwise cold bridges will form. Upon completion of the thermal insulation of the frame, fix the moisture-wind protection on the outside. The membrane is mounted according to the scheme described above.

A crate is attached to the frame over the windscreen. As a rule, the rails are arranged vertically. To fasten the crate, use self-tapping screws, screwing them in 25 mm increments. Then the wall cladding is done outside the OSB. The plates are also attached to the crate with self-tapping screws. In order not to cut the skin in advance, door and window openings can be cut with an electric jigsaw in place, i.e. after installation of plates. Keep in mind that 5 mm thick expansion joints must be provided between the plates. Be sure to fill these seams with building sealant or mounting foam.

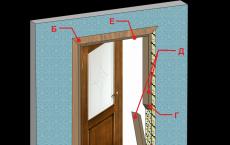

Next, you need to finish with clapboard, corrugated board, siding or any other facade coating. Install doors and windows immediately. On the inside, a crate is attached to the frame in the same way as on the outside, after which the walls are sheathed with clapboard or even drywall.

As necessary, you can complete the frame structure, expanding its area, or even build another change house nearby and connect it to the first one. In this case, you get a whole house of change houses, which can be used for any of your needs.

We make a Russian folk change house-log house

If you want to make not a temporary structure, but a change house "for centuries", then it is better to build it from a log or timber in the form of a log house. For this we need the following materials:

- timber 150x100;

- wooden dowels;

- interventional heater.

Lay the first crown of the house on the grillage. Be sure to align the beam with the grillage, and also make sure that the corners are 90 degrees. Connect the beam to each other "in half a tree" according to the scheme described above. Immediately lay the first crown of partitions, and in the same way cut it into the first crown of the outer walls. Then, on the first crown, fix the interventional insulation with a stapler.

Lay the second crown in the same way. To connect both crowns to the grillage, drill vertical holes according to the diameter of the dowels. To do this, use an electric drill and a special long drill. The holes should reach the middle of the lower beam and be located in the walls in increments of one and a half to two meters. Carefully hammer the dowels into the holes obtained.

Then two more crowns are laid and in the same way they are connected by dowels to the lower pair of crowns. The only thing is that the pins are installed with an offset, i.e. in a checkerboard pattern, as shown in the diagram above. According to this principle, the walls, together with the interior partitions, "rise" to the design height.

The result is a box without windows and doors. Therefore, you need to mark the door and window openings on the walls, and then cut them out with a chainsaw. First, to the left and right of the opening, temporarily fasten all the bars with boards. After making the openings, immediately install window frames made of boards. They will fasten the trimmed bars of the crowns together, preventing them from crumbling.

I must say that it is possible to make openings in the process of building walls. In this case, the bars are fastened to the left and right of the openings with dowels. You can use any option you like.

As for the floor and ceiling, all work is carried out in the same way as during the construction of a frame change house, so we will not repeat it.

If you decide to finish the change house, please note that you can start this operation no earlier than one and a half to two years after the completion of construction, i.e. after the structure has collapsed. The exception is change houses made of profiled glued laminated timber, which practically do not shrink.

Installation of the roof, or how many slopes do you need for complete happiness?

The type of roof construction depends on the purpose of the change house. If it will be used in the summer, it is better - it is easier to perform and cheaper. For its construction you will need the following materials:

- timber 50x150 mm;

- super-diffuse moisture-proof membrane;

- slats 20x30 mm;

- boards 100x20;

- roofing material.

Step-by-step instructions for installing a shed roof looks like this:

- 1. Rafters are laid on long walls that have different heights. You need to put them vertically, i.e. to the edge. To fix the rafters in the Mauerlat (the upper crown of the walls or trim), you can make grooves. Additionally, use corners and screws. Since a shed roof will carry a large snow load, do not make the distance between the rafters more than 40–50 mm.

- 2. Fasten the moisture-proof membrane over the rafters, and then fasten the counter-lattice - slats 20–30 mm. The counter-lattice should be parallel to the rafters.

- 3. Next, boards are mounted on the counter-lattice perpendicular to the rafters. The step of the lathing depends on the type of roofing material, but in any case, the distance between the boards should not exceed 15-20 cm.

- 4. Now we lay the roofing. Since the roof will be flat, overlap the sheets more, for example, when installing slate or tiles, it should be not one wave, but two.

If you plan to use the change house not only in the warm season, but also in winter, do it better. It is based on roof trusses, i.e. isosceles triangles formed by rafter legs. From above, i.e. at the top of the triangles, a ridge run is mounted - this is a beam that connects all the roof trusses to each other. In addition, reinforce each truss truss with puffs - horizontal jumpers connecting two rafter legs between themselves.

Waterproofing and laying of roofing material is carried out according to the instructions for a pitched roof. The only thing is that if the change house is winter, it is advisable to insulate not only the ceiling ceilings, but also the roof itself. This operation is carried out according to the same principle as.

So we built a change house with our own hands, now it remains only to conduct communications to it. As you can see, there is nothing super complicated in this work. And it’s not for nothing that the popular proverb says: they don’t mold holy pots.