Types of door seals and methods of their installation

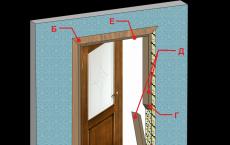

(1

ratings, average: 5,00

out of 5)

The level of protection of the house from street noise and cold is affected not only by the quality of the entrance doors, but also by the material that contributes to their tight fit to the frame. The absence of gaps creates good tightness, preventing drafts from roaming: in this case, sounds and smells from the outside will not be able to penetrate inside the house.

The classification of materials for sealing doors is carried out according to some basic characteristics. First of all, we are talking about the dimensions, material of manufacture and types of doors for which this seal was developed.

For example, wooden and iron doors are decorated with different types of tapes, although outwardly they are very similar. To choose the right equipment for your door, it is important to navigate this classification.

Sealing tapes by types of doors

For each individual variety, its own sealant was developed.

Input

Most often, the finishing of entrance doors is carried out with a dense material in the form of a tube, inside of which there is a void. Significant thickness and bubbling of the material create a secure fit of the door to the frame. How to choose reliable and warm doors to the house.

Of particular interest is the internal structure of these rubber bands for door insulation. Due to the presence of internal pores, a multiple increase in the warming effect is achieved. Most often, the seal for the front door has a self-adhesive base, which makes its installation very fast.

On the other hand, over time, the adhesive loses its characteristics, and the strips begin to lag behind along the perimeter. You can.

Interroom

The seal for interior doors is not assigned the function of protecting the room from the cold outside, as in the previous case.

This allows you to make it more aesthetic by using more elastic and soft silicone instead of dense rubber. The method of installation of these products may differ, as will be discussed below.

If during the repair process you decide to change the doors, then be sure to read.

Plastic

This group of materials is characterized by a high rate of laying and dismantling. Grooves are usually applied to plastic doors along the line of contact with the box, so the seals are given a special shape that repeats the configuration of these grooves. Due to the presence of walls on the sides of the fixing point, the sealing strip receives additional protection from external aggressive influences. The sealant for plastic doors is not afraid of moisture and temperature changes, so it can be used both outdoors and in interior doors without much difference. It is important to keep in mind that this rubber seal has been designed specifically for grooved plastic doors, so it is not recommended to seal other types of doors with it. In addition, different manufacturers complete their plastic doors with individual seals: this should also be clarified when selecting a suitable material.

glass

In the manufacture of a sealant for glass doors, silicone is used, equipped with a special profiled notch. During the installation of the strip, it is necessary to first moisten the area where it will be placed: this will make the connection as strong as possible. Since the design of glass doors can be very different, therefore, a special seal is developed for each of them.

What are door insulation made of?

In order to choose the most suitable door seals for your home, you should also be guided by the materials of their manufacture.

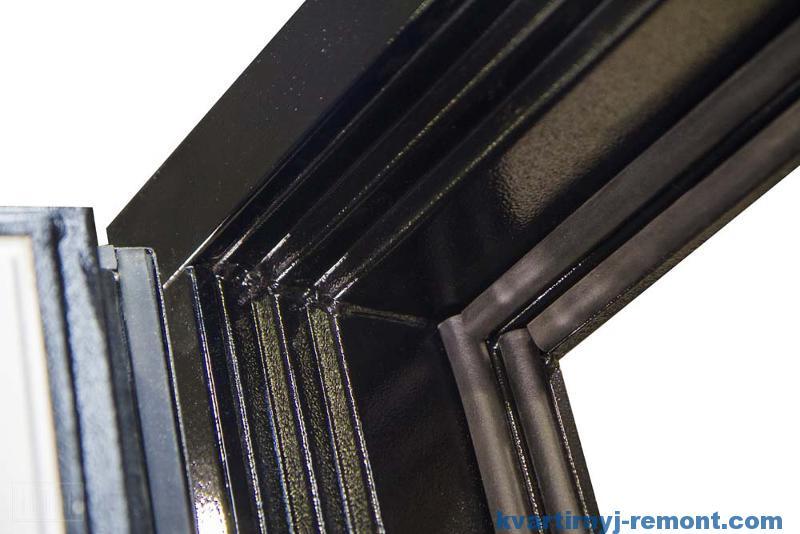

Rubber

Most often, entrance doors are equipped with a rubber seal. Moreover, the material of manufacture is not simple rubber, but its modified varieties that can withstand the most extreme operating conditions, including severe frost and heat. Besides the draft.

Silicone

The performance characteristics of silicone products are slightly lower than those of rubber. This is due to the fact that silicone cannot be given additional resistance to aggressive external influences even by introducing appropriate additives into its composition. For this reason, silicone liners are mainly produced for wooden interior doors, which are operated in comfortable conditions.

Foam rubber

It is the material for the manufacture of the cheapest door insulation, which fails within one year. The reason for this can be temperature fluctuations, dirt and moisture, which provoke crumbling and disintegration of foam rubber. The material gradually loses its original volume, which affects the functionality of products made from it.

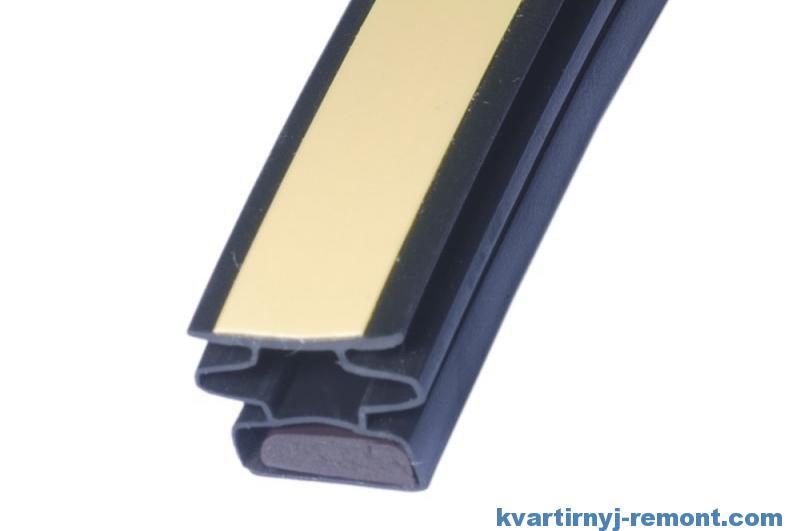

Magnet

An innovative development, with the help of which expensive metal doors are mainly completed. The average layman is familiar with the magnetic sealant from household refrigerators and freezers, in which permanent magnets around the perimeter of the doors are attracted by attraction poles. Most often, metal doors are equipped with three-circuit magnetic seals. The location of the two circuits is the door leaf itself, while the third is mounted on the door frame. The main disadvantage of such products is a rather high pressing density, which a child or an elderly person will not always be able to cope with. If the action of the magnets is weakened, then proper tightness and sound insulation will not be provided.

Advantages of a magnetic door seal

Soft filler is made of thermoplastic, which is characterized by the following advantages:

- Considerable service life.

- Persistent transfer of sharp temperature fluctuations (from -65 to +95 degrees).

- Possibility of recycling after loss of performance.

Felt

Usually they are made out with a felt seal. Such tapes cannot provide special protection against noise and cold. They are used solely to prevent dust from entering the cabinet or room.

Basic ways to install door seals

When starting to install a door seal, the first thing to do is to find out what type of product you have to deal with. This will allow you to choose the most optimal way to glue the seal. The most common sealing gum grooved and self-adhesive types.

Groove seals

The installation of this material is quite simple, so it is most often used for self-repair of doors. The most difficult moment of laying the seal for doors in the groove is finishing the corner sections. Beginners are advised to use accurate trimming of the material. More experienced users achieve continuous laying, without docking sections. The latter option is more preferable, since the level of door sealing in this case is an order of magnitude higher. However, to implement it, you will need to show some skill. Door seals on the bottom are equipped with a special edge on which there is a brush: such a structure of the material contributes to a fairly quick installation into the groove cavity.

In the course of laying both rubber and silicone seals, it is important to avoid even minimal stretching of the tape. Otherwise, an unacceptable voltage is formed inside the sealing layer, which will affect its performance. No matter how high-quality silicone or rubber is, they will gradually stretch, losing their original volume and elasticity. Experienced craftsmen, when laying the seal in the groove, try to compress it slightly, which significantly extends the life of the door insulation. Trimming of excess parts is carried out upon completion of laying. It is more convenient if only one edge of the rubber or silicone tape is left for trimming: in this case, the remaining segment is longer and can be used to insulate another door.

Self-adhesive seal

Laying such material is also not particularly difficult, although a few useful tips should be taken into account. In order for the self-adhesive rubber seal to stick to the seat with high quality and for a long time, it should be preliminarily prepared. This procedure includes several steps. Firstly, all dirt must be removed from the surface of the door: this is done not only along a narrow installation area, but by some expansion to the sides. For these purposes, soapy water or detergent is usually used.

Particular scrupulousness will require the preparation of a wooden surface. It should not be too moistened - it is enough to wipe it thoroughly with a damp cloth. If the seat has roughness, protrusions and irregularities, they must be eliminated. In this case, the operation technology also depends on the surface material. For example, wood can be lightly sanded and puttied; for a metal or plastic surface, a gentle grinding will suffice. Individual protrusions can be carefully removed with a chisel or sandpaper. After the area for laying the sealant is cleaned and washed, it must dry completely. Sometimes, if the work is carried out in a closed room, or when it is necessary to speed up the process, a regular hair dryer is used to dry.

Before gluing the seal on the door, it must be degreased. When choosing a degreaser, it is important to consider the surface material. Most often, this procedure is carried out with white spirit, acetone or ordinary alcohol. However, it should be understood that all these agents are toxic and explosive, and they should be handled very carefully. It is better if it is possible to ventilate the premises well after application.

Useful advice: in cases where the seal is laid where people are at that time, it is better to use a special low-toxic emulsion or an aqueous alkaline solution for degreasing.

As for the direct laying of a self-adhesive sealant, this procedure is not particularly difficult. All that needs to be done is to release the lower part of the material from the protective film, and carefully lay it along the edge of the door. It is more convenient to remove the entire film not at once, but in segments of 10-15 cm, immediately mounting the freed area on the seat. At the same time, it must be pressed tightly against the surface of the door, achieving high-quality gluing. A similar algorithm of actions is maintained throughout the entire procedure. It is more convenient to start work from above, and when you reach the bottom edge of the door leaf, cut the rubber band with a sharp knife or scissors.

When sealing the front door with a protective material, the door frame is also glued. In this case, the material is glued along the outer and inner lines of contact between the two surfaces, which makes it possible to create double protection in the way of outdoor cold and moisture.

As can be seen from the description, any person can seal the door. The main thing is to choose the right material and work carefully.

Under the heading | with labels , |