Do-it-yourself wooden paths in the country house

Anyone, even a beginner lover of digging in the garden, planting vegetables and fruits, thinks about how to make it more comfortable to move around your garden plot. To do this, you have to make paths from various hard and durable materials, such as stone or concrete. One of the reasons for this lies in the durability of such buildings made of durable natural and artificial material that does not collapse from moisture.

Garden tools and other goods in this Chinese store.

But with the advent of effective means to protect building materials from moisture and other destructive factors, the popularity of wooden sidewalks has increased, which can serve almost as long as their stone and concrete counterparts, while not inferior to them in beauty, but in some ecological sense, even surpassing them in design and motivating gardeners to make a beautiful one in the country with their own hands. Ideas in the video below - also highly recommended to watch.

Self-construction of tracks is justified. With it, there is no need to constantly clean shoes, experience difficulties when moving, it is easy to move from one area to another, regardless of weather conditions.

What's more, beautifully crafted paths are a great addition to your landscape, especially when you consider how they look and fit in with your design.

When choosing material for the construction of paths, it is customary to observe the general style of garden design and the budget that is calculated for work. A feature of wood as a material for building paths is its versatility. The tree is in perfect harmony with lawns, flower beds, terraces; on its basis it is not so difficult to make paths even for an inexperienced master. A wide price range of boards, depending on the quality and degree of processing, allows you to save money significantly. Therefore, many lovers of rest and work on their site choose just this way of giving a civilized look to the paths in the garden.

Advantages, disadvantages and manufacturing methods

Wood as the basis for the manufacture of garden paths is not yet such a common material, but it is quite popular among gardeners due to its beautiful appearance, relative strength and affordability. If you do not use a processed board, the cost of which is quite high, then building residues can become a good alternative material, which significantly reduces the price of the issue.

But even if you plan to use new boards, the simplicity of working with wood reduces costs compared to other materials. There are two options.

Walkways

The surface is raised above the soil level, the frame is installed on the base. The flooring is raised above the ground so that air can freely flow under the track. In this case, the service life of the pavement will be significantly extended and there will be protection from moisture. A small slope specially created at the same time will drain water from the surface, so that even after heavy rain the tree will dry out faster.

The base for the flooring is a frame made of longitudinal varnish, on which, with the help of fasteners, crossbars from a board or timber are placed. Alternation of identical in length but different in width segments is allowed, depending on the design. To avoid warping, a wide board is installed on several self-tapping screws or nails; for a beam, you can limit yourself to two self-tapping screws. At the same time, the hats deepen and hide to ensure safety for the legs when walking on the flooring.

The width of the wooden board track depends on the design intent. For normal movement along it, a width of 80 to 100 centimeters is sufficient with a thickness of 25-50 millimeters. Such parameters will allow you to easily miss each other in oncoming traffic. If it is assumed that people with a sufficiently large weight will walk along the path, or the carriage of weights in a trolley along it will be used, another one is added - the middle log. To protect the lamps from moisture in places of contact with the ground, they are treated with liquid bituminous mastic or other means. The crossbars are treated with antiseptics, after which they are dried and mounted on the frame.

There are two build options. Tightly without gaps and with the same intervals between the parts. The wrong side of the flooring must be treated with mastic, the outer surface is covered with paint or varnish. A much better effect is obtained if parts of the structure are processed in advance than using bitumen and tinting after assembly. While the flooring can be laid on a flat surface and operated without any protection of vodka, it is better to follow the correct technology already.

There are two ways to prepare. Under logs or on all width of a flooring.

Preparation is carried out in several stages: a layer of soil of 20-30 centimeters is removed, the bottom is carefully compacted. Sand is poured, it is also tamped, watered with water, small gravel is poured on top and tamping is performed again.

If conditions allow, geotextiles are placed between the layers. This allows the materials to not mix and increases the drainage capacity of the pillow. If the sidewalk is laid temporarily, then a pillow is not required, just geotextiles, roofing material and similar materials are placed under the logs. To protect against weeds, the soil under the flooring is treated with herbicides.

Budget wood flooring for a summer residence

The most economical budget option is the manufacture of flooring from pallets. A pallet with a narrow span between the parts is used. Such a wooden path does not differ in special beauty, but it requires a minimum of time and effort for laying. To make the flooring obtained from pallets look decorative and durable, the pallets are divided into segments, treated with protective materials and a full-fledged flooring is made. The only thing is that you will have to spend more time and effort, but the result is much more interesting. But the cost here remains very low.

The opposite option is decking paths - wooden modules from a decking board. The boards are laid on a flat base and look much more interesting in design than homemade ones, but the cost of such a design is quite high, therefore this method is used infrequently.

dug in

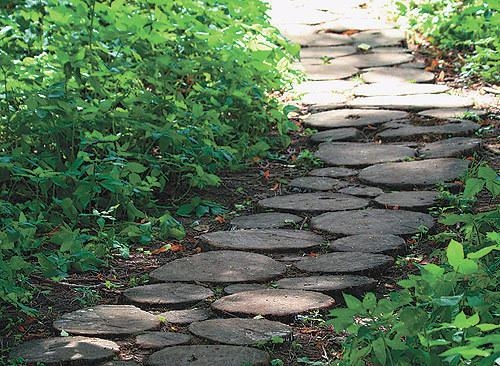

The wooden parts in such paths are immersed in the ground at the same level with the surface or rise slightly above the ground, the voids are filled with drainage materials - sand, gravel. Boards are used on the flooring, a thick beam from 10 to 15 centimeters long. Since the wooden materials in this case are in contact with the ground, there is a need to protect them from water. To do this, you need to use an antiseptic or hot drying oil, cover the bottom with bitumen, the upper part can be varnished or waxed.

For beauty, small ones are installed between thick rounds. When using a bar, imitation of a brick is of interest.

The flooring can be laid directly on the ground, but dug-in paths need special preparation of the base, since the logs will be immersed in the ground.

So that the water does not stagnate and the sidewalk does not wear out, a drainage system of sand and gravel with a height of more than 10 centimeters is installed.

After the trench is marked, rammed, sand is poured, which is also rammed and wetted with water, a layer of crushed stone is poured, and finally, another layer of sand.

The cut is put on a substrate, to give decorativeness, the dimensions in diameter alternate. The gaps are filled with rubble, sand, clay.

One of the best materials for wooden pavement is larch. Softwoods and oak can also be used, but their service life is not very high. However, modern protective materials greatly increase the service life of the wooden parts of the tracks. Therefore, one can only proceed from the cost and availability of wooden blanks.

Once again, it is important that the sidewalk looks in harmony with the overall style of the garden area, so you need to think about the design of wooden paths right away if you want to plan and do it yourself.