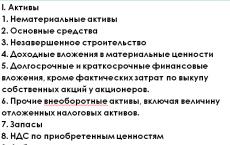

Waterproofing with reinforced film. How to choose the right protective film for foundation and floor waterproofing Reinforced waterproofing

It is a type of protective layer that serves to protect buildings from moisture penetration. It is applied in construction, to isolation of walls and the whole rooms of any buildings under construction.

Waterproofing improves not only the technical characteristics of the structure, but also serves as a guarantee of long-term operation.

Reinforcement can exist as a separate method of waterproofing, and can serve as an auxiliary material to improve the strength of the main insulating layer.

Reinforced waterproofing as a method of initial waterproofing

Reinforced waterproofing, as an independent protective layer, can be plaster.

The plaster reinforced waterproofing is applied to isolation of buildings, rooms and constructions. With it, you can perform:

- foundation waterproofing;

- waterproofing of floors;

- facade waterproofing.

There is another type of reinforced plaster that affects the way it is applied - coating.

It is distinguished from plaster by the method of device. Use this material in the insulation of porous surfaces of materials in construction. Due to its binder composition, coating waterproofing is able to close all cracks and existing voids in the structure.

It is thanks to these properties that coating reinforcing waterproofing provides more reliable protection against moisture. It can also be used as another separate product for additional protection against moisture.

Before applying the reinforced waterproofing, the surface must be cleaned of dirt, dust and then lightly moisten the surface to be insulated.

Reinforced waterproofing as a way of additional protection

Reinforcement in waterproofing can be used as an additional protection of the main surfaces of the applied waterproofing. There are several types:

- diffusion and superdiffusion membranes

- polymer films

- reinforced mesh

Diffusion and superdiffusion membranes are presented as a material consisting of three layers with a reinforced mesh based on polypropylene fibers. They are used in pitched roofs and ventilated facades. The advantages of such additional waterproofing include:

- ease of installation

- impenetrability

- thermal insulation

- long-term operation

- light weight.

Cons: it is undesirable to use euroslate and metal tiles in sealing.

Polymer films are both reinforced and non-reinforced. They are applied with a special solvent, forming a monolithic connection. They are used as pools.

- do not let water through

- serve up to half a century

- easy to install

- can be applied to old materials.

Of the minuses, it is worth noting the expensive installation, which requires specialized fasteners and equipment.

The reinforced mesh is made on the basis of fiberglass treated with a primer. The mesh, after application, hardens and forms a reinforcing layer, which serves from cracks and deformations. Reinforced mesh is an excellent material for waterproofing balconies and terraces.

Reinforcement materials must meet certain requirements:

- adhesion to mastics

- elasticity to follow the contours of irregularities

- resistance to mechanical damage, biological and chemical properties

- glossy surface

During the construction of buildings, waterproofing plays an important role, which helps to keep building elements and materials from rotting and destruction longer. Special protective coatings exclude penetration into the room and into the built walls of moisture, condensate or precipitation. The material with which the waterproofing will be made is selected at the design stage. Well-selected and properly executed insulation work allows the use of technical rooms located in the attic or basement as domestic ones. Considering the options for materials used for these purposes, first of all, attention is drawn to price and quality. The simplest and cheapest of all is polyethylene film for indoor waterproofing.

- Polyethylene is a good vapor and water insulator, providing protection against moisture infiltration both in one direction and in the other. This property is especially useful when insulating pools.

- The width of the film covers a large area, which saves time.

- The film is easy to glue, and sealed joints are formed.

- Polyethylene is elastic and thinner than roofing material, this allows you to use it more flexibly when sealing corners and inconvenient places.

- The film does not rot and is not destroyed by bacteria for a long time.

- Environmentally safe and odorless during operation.

When applied to freshly laid concrete, it helps to improve hardening, which increases the strength of the matured concrete.

This is due to the fact that the film does not allow moisture to evaporate from the surface. At the same time, there is no need to constantly moisten the concrete, which saves both money and time.

Cons of using polyethylene

- Polyethylene is not durable in open space, as it is subject to destruction when exposed to sunlight. This does not allow it to be used as a coating for more than a year.

- A thin film is easily torn with minor damage, and even a small break can negate the entire waterproofing system arranged with polyethylene. Therefore, additional security measures are needed to prevent damage to it during construction work.

- The film is the “favorite delicacy” of rodents, so it’s not the best option to leave it within their reach.

Types of waterproofing films

Polyethylene film for waterproofing, suitable for this role, is produced in various versions by both Russian and foreign manufacturers:

Produced in several colors, different thicknesses and with the addition of reinforcing bases, the film will successfully perform its functions.

Plain transparencies in sheet, sleeve and semi-sleeve form

Such films have a thickness of 0.6 to 2 mm. They are used more often in the subsidiary farm, for sheltering greenhouses and greenhouses. Less commonly, due to fragility and easy damage, it is used as an insulating material for roofs and foundations. In the ground, without exposure to the sun, it will certainly last a long time, and the cheap price is attractive, but if special measures are not taken to ensure its integrity, then the foundation waterproofing film is likely to be damaged when pouring concrete or when shrinking an already finished foundation. Manufacturers add various additives, stabilizers and fillers to manufactured products, which give it a little more strength and increase its service life.

Polyethylene film for waterproofing is an inexpensive and durable material.

Reinforced films

Polyethylene multilayer fabrics, the middle layer of which consists of a non-woven material or a polypropylene mesh, sealed with outer layers. Foreign manufacturers do not use, unlike ours, a reinforcing mesh made of low-density polyethylene. Such films of the perforated type and non-perforated are produced. Films have different quality, and, of course, the price, so you will have to decide on the use of one or another type, manufacturer and quality yourself.

The perforated type of films has micro-holes for moisture permeability and is intended for roof waterproofing when constructing pitched roofs, while non-perforated films are used specifically for vapor barrier. The reinforcing layer prevents the film from deforming and stretching, which increases its service life.

The applied reinforced PVC film for waterproofing the roof or foundation is produced in rolls up to 4 meters wide, it can have a combination of different colors on different sides. It is customary to measure not the film thickness in mm, but the surface density, so you need to look for films with a density of 100 to 250 g / m2.

Important! Some manufacturers call reinforced films membranes because of the perforation that exists on them, which can pass moisture. But this is wrong. Membranes have a different principle of operation.

In some models, special anti-combustible fillers are added, which make it a material that does not even support smoldering.

Diffusion membranes

Polyethylene multilayer films capable of passing water vapor, but at the same time are moisture resistant. Such films have different names - breathable, vapor-conducting, windproof and others.

There are three degrees of steam transmission per day:

- 20-300 g/m2 – pseudodiffusion membranes;

- 400-1000 g/m2 – diffusion membranes;

- over 1000 g/m2 - superdiffusion membranes.

Important! They produce both one-sided membranes, which have a throughput only in one direction, and two-sided ones. When conducting installation work, it is important not to make a mistake with the side that can be laid one-sided.

Pseudo-diffusion membranes have a low vapor permeability, but it is completely insufficient for the use of such a film as a membrane in waterproofing in the construction of buildings.

Diffusion membranes are used for under-roofing waterproofing of the second level of protection of facade or roof insulation from moisture and wind blowing. The ability of such a film to remove water vapor from the layers of thermal insulation to the outside helps to keep the cake of the mounted roof from destruction, fungi and leaks.

The overlaps of the membrane rolls are welded together with hot air or joined with a special glue for soft PVC (so-called "cold diffusion welding")

Superdiffusion membranes are used in the construction of buildings with deliberately increased humidity in rooms - baths, kitchens or restaurants. In addition, the declared figure during operation is always less due to temperature fluctuations in the external environment. The price of these films does not vary much, so the use of the latter type of membrane will be a reliable guarantee of the correct and long-term operation of the building insulation structure, even if there are possible defects in the insulation system.

Polyethylene film in modern construction has taken its rightful place among various insulators. Regardless of whether the film is used for waterproofing the floor, roof, walls or foundation, it is possible to choose a specific type of material with the necessary properties for this type of work. High-quality, and especially imported materials are not cheap, but long-term and good protection of the building will be provided.

.

.

A reliable concrete base is the unchanging basis of the strength of any building structure, no matter if it is a residential building, municipal institution, shopping center or other structure. In order to make it such, it is important to take care, first of all, of protecting the foundation from the harmful effects of various adverse conditions and natural phenomena: decay, precipitation, and accumulated condensate. Properly selected waterproofing will help prevent the penetration of harmful moisture. The simplest and most inexpensive type of it is a reinforced polyethylene (PVC) film for waterproofing the foundation.

What is reinforced waterproofing film? Pros and cons of its use and features of the laying process

Reinforced film for foundation waterproofing is a fabric made of non-woven material (polyethylene), which consists of three layers. The top and bottom are the usual film, which each of us has seen more than once, for example, in garden greenhouses. The middle layer is not a hollow space, but a mesh made of polypropylene, which performs a protective function. Reinforced waterproofing films are produced in wide 4-meter rolls, varying in thickness from 0.6 mm to 2 mm, and they can be used not only to protect the foundation from moisture, but also for walls or roofs.

How to work with waterproofing film? The first stage of construction work will be cleaning and leveling the surface on which you are going to lay this material. Then a layer of cement mixture is placed on the foundation, and already on it - the film itself. Do not panic if its width is not enough, the reinforcing film can also be overlapped, while it is important to remember that the width of the joints should be at least 30-40 centimeters. To glue the film at the joints, you can use a special construction adhesive. As for the corners, a layer of polymeric elastomer (polyurea) can be manually applied here.

After the film has been laid, a second layer of mortar should be applied, on which bricks, concrete or the building material chosen for laying the walls of a particular building will subsequently be laid.

Like any material, a reinforcing waterproofing film for a foundation has its own advantages and disadvantages. It makes sense to get to know them better.

Film benefits include:

- Low cost of the product;

- Durability;

- Environmental safety - the coating does not rot and does not decompose;

- High level of isolation of both water and steam;

- Elasticity;

- Ease of use - working with such a film is very easy, much easier than with other waterproofing materials.

However, there are also disadvantages to using a reinforcing film as a waterproofing material. First of all, they include a high probability of mechanical damage. Any break, no matter how small, can adversely affect the entire waterproofing system. Of course, ordinary polyethylene films that are not supplemented with a reinforcing layer, and therefore have a lower density, are more likely to suffer from this trouble, but even if reinforced ones are used, you may encounter a similar problem.

In general, reinforced film material for waterproofing is a fairly reliable thing, tested by thousands of builders around the world. It is only important to know how to work with it correctly, as well as strictly follow this technology.

Where to buy reinforced film for foundation waterproofing?

Despite the fact that this product is widely distributed, it makes sense to purchase it from trusted suppliers so as not to stumble upon low-quality, which is produced almost in a handicraft way. One of the permanent leaders of the Russian construction market is StroyBusinessAlliance.

In our online store you can always purchase a wide variety of building materials at an affordable price. Unlike most wholesale and retail outlets, our range is really wide, and so much so that even the most picky buyer can choose exactly the building material that is needed.

What advantages, in addition to a rich assortment, await all our customers?

- Convenient delivery to anywhere in Russia;

- Consistently low prices;

- Efficiency, starting from placing an order, ending with its transportation to your city. Be sure: your order will be delivered within a few days;

- Competent consultations, which you can always ask for from our operators;

- Individual approach;

- High quality. All supplied materials are subject to mandatory certification.

Sales leaders.

MARISEAL DETAIL npolyurethane mastic for waterproofing roof elements, pipes, chimneys is a high quality, always highly elastic, thixotropic and fibreglass-reinforced, liquid-applied and cold-applied, one-component cold curing polyurethane membrane used for permanent waterproofing of roofing elements. The MARISEAL DETAIL membrane is based on a pure, highly elastic hydrophobic polyurethane resin, resulting in excellent product properties such as mechanical, chemical, thermal, UV and weather resistance. Dries when interacting with moisture contained in the soil or air.

| color |

package kg | price up to 1 t. | price 1-10 t. | price over 10 tons. |

|

black gray |

6 | 894 rubles/kg | 801 rub/kg | 740 rubles/kg |

APPLICATION of waterproofing elements and joints of the roof Marisil Detail: to create waterproof seals for such complex and composite roofing elements: wall-to-floor joints, aprons and 90o corners, shades and skylights, chimneys, pipes, air conditioning units, photovoltaic systems, siphons, downspouts, gutters, etc. .

Waterproofing elements and joints of the roof Marisil Detail can be applied to surfaces such as

- Concrete

- Lime-cement mortar

- Brick

- Ruberoid with mineral coating

- Simple roofing material

- PVC and EPDM membranes

- Metal

- PVC and aluminum profiles

- Wood

ADVANTAGES of waterproofing elements and joints of the roof Marisil Detail:

- easy application (brush)

- fiber reinforced

- forms a seamless membrane without joints, which does not allow leakage

- resistant to water, rain and frost

- retains mechanical properties in the temperature range from -30 °С to +80 °С

- provides vapor permeability

- full adhesion to the surface without additional fixation

- in case of damage, the membrane can be easily repaired on site within a few minutes

- low cost

EXAMPLES OF WATERPROOFING OF ROOF JOINTS AND ELEMENTS

Roof skylight waterproofing with waterproofing MARISEAL DETAIL

|

|

|

|

|

If necessary, for aesthetic purposes, you can additionally sprinkle the not yet dried coating with asbestos chips. Lightly press down on the asbestos chips with your hands to even them out. |

Waterproofing the pipeline passage on the roof with waterproofing MARISEAL DETAIL

|

|

|

Measure the edges of the area where the waterproofing will be applied with masking tape of the required size. Prepare the surface according to the surface preparation table |

Apply the first coat of MARISEAL DETAIL with a flat brush and spread it evenly |

|

|

|

Apply a second coat of MARISEAL DETAIL with a thicker brush and remove masking tape |

If necessary, for aesthetic purposes, you can additionally sprinkle the not yet dried coating with asbestos chips. |

MARISEAL DETAIL

Polyurethane waterproof membrane, applied in liquid form, reinforced with glass fiber, for the joints of roof elements.

Product description

MARISEAL DETAIL is a high quality, always highly elastic, thixotropic and fibreglass-reinforced, liquid-applied and cold-applied, one-component cold curing polyurethane membrane used for permanent waterproofing of roofing elements. The MARISEAL DETAIL membrane is based on a pure highly elastic hydrophobic polyurethane resin, resulting in excellent product properties such as mechanical, chemical, thermal, UV and environmental resistance. Dries when interacting with moisture contained in the soil or air.

Advantages

- Easy application (brush, trowel or roller).

- When applied, it forms a seamless membrane without joints.

- Water resistance.

- Frost resistance.

- Resistant to root penetration, therefore can be used for green roofing.

- Water vapor permeability, so the surface can "breathe".

- Frost resistance and heat resistance, never softens.

- Good adhesion, excellent bonding to almost any type of surface.

- Waterproofs old glassine and tar paper by covering them without the need to remove them prior to application.

- Retains its mechanical properties in the temperature range from -40oC to +90oC.

- The waterproof surface can be used for domestic foot traffic.

- Resistant to synthetic detergents, oils, sea water and household chemicals.

- Even if the membrane is mechanically damaged, it can be easily repaired in that place in a few minutes.

- Does not require the use of an open flame (torch) during application.

- Receives positive reviews all over the world for over 10 years.

Application

The MARISEAL DETAIL membrane is mainly used to create waterproof seals for complex and composite roofing elements such as:

- Joints wall with ceilings

- Aprons and 90o corners

- Plafonds and skylights

- Chimneys

- Pipes

- Air conditioning units

- Photovoltaic systems

- Siphons, drain funnels

- Gutters, etc.

Consumption

1.5-3 kg/m2 when applied in two or three layers.

surfaces

The MARISEAL DETAIL membrane is used to create waterproof joints between various building materials such as:

- Polyurethane membranes

- Ruberoid, PVC membranes

- Concrete/Cement-lime mortar/Cement screed

- Various metals

- Tree, etc.

Colors

The MARISEAL DETAIL membrane is available in white and light grey. Other colors can be supplied on request.

Certification

The MARISEAL DETAIL membrane has been tested by the German State Testing Institute for Building Materials in accordance with the European directive for the technical certification of liquid applied roof waterproofing materials ETAG 005 and found to be in conformity with this directive. The MARISEAL DETAIL membrane has been certified by the German State Institute for Building Technology Berlin, receiving the European Technical Certificate (ETC) and CE marking, as well as certification according to the requirements of EOTA (European Organization for Technical Approval). The MARISEAL DETAIL membrane has also been tested and approved by various laboratories around the world.

European Technical Approval: ETC 09/0241 of the German State Institute for Building Technology. Use category levels according to ETAG005, for liquid applied polyurethane waterproofing materials:

- Service life: W2 10 years

- Climate zone: M and S All

- Roof pitch: S1 to S4<5o до >30o

- Lowest surface temperature: TL3 -30oC

- Highest surface temperature: TH4 +90oC

- Reaction to fire: Class E EU regulation

- Wind load resistance: ≥ 50 kPa EU regulation

Specifications (property / results / test method)

- Elongation at break > 250% ASTM D 412 / DSI 52455

- Tensile strength > 2.5 N/mm2 ASTM D 412 / DSI 52455

- Water vapor permeability > 20 g/m2/day ISO 9932:91

- Resistance to mechanical damage due to static impact High stability (class P3) EOTA TU-007

- Resistance to mechanical damage due to dynamic impact High stability (class P3) EOTA TU-006

- Hydrostatic pressure resistance No leakage (1 m water column, 24 hours) German Standards Institute EN 1928

- Adhesion to concrete >2.0 N/mm2 (concrete surface fails) ASTM D 903

- Tarpaulin adhesion >1.0 N/mm2 (concrete fails) ASTM D 903

- Strength (Shore A) 65 ASTM D 2240 (15”)

- Thermal stability (80oC for 100 days) Passed - no significant changes EOTA TU-011

- Accelerated UV aging, in the presence of moisture Passed - no significant changes EOTA TU-010

- Resistance after water aging Passed EOTA TU-012

- Hydrolysis (5% KOH, 7 day cycle) No significant change in elasticity In-house laboratory

- Fire class of building materials Class E EN 13501-1

- Working temperature -50oС to +90oС Own laboratory

- Dry coat resistant to rain 4 hours Conditions: 20oC, 50% RH

- Walking time without load 12-24 hours

- Final curing time 7 days

- Chemical properties: Good resistance to acidic and alkaline solutions (5%), synthetic detergents, sea water and oils.

Application

Surface preparation

Careful surface preparation is an important process for quality application and long-term application. The surface must be clean, dry, free of damage and contamination that could adversely affect the adhesion of the membrane. The maximum moisture content of the substrate must not exceed 5%. The compressive strength of the surface should be at least 25 MPa, the strength of the cohesive bond should be at least 1.5 MPa. New concrete surfaces must be cured for at least 28 days. It is necessary to mechanically remove the previous loose layers, dirt, fats, oils, organic matter and dust. It is necessary to level the existing surface irregularities. It is necessary to completely clean the surfaces and remove the dust left after grinding.

Table of preparation of different surfaces for waterproofing roof elements

|

surfaces |

Note |

Primer |

|

Copper, Zinc, Rigid PVC, Acrylic glass, Glass |

not necessary |

|

|

Wood |

not necessary |

|

|

Painted surfaces |

not necessary |

|

|

Polymer roofing felt (APP (atactic polypropylene) / SBS (styrene-butadiene-styrene), Ruberoid coated with crumbs (APP / SBS ),Oxidized ruberoid coated with crumb |

not necessary |

|

|

Simple oxidized ruberoid |

not necessary |

|

|

Steel, Aluminum |

1, 3 |

not necessary |

|

EPDM Membrane, PVC Membrane, Polyester |

1, 6 |

not necessary |

|

Concrete, Lightweight concrete, Gypsum, Screed, Brick, Stone |

2, 5 |

not necessary |

- Before application, sand the surface with sandpaper or before application, sand the surface with paper with a grinding wheel and remove dust.

- Residual moisture of mineral substrates - no more than 5% The age of new cement surfaces should be at least 28 days. Remove the protruding remains of the old coating mechanically.

- Always remove old paint.

- Melt the surface to a liquid state with a burner and immediately pour a sufficient layer of dry quartz sand (0.4-0.8 mm) into it.

- Before applying the coating, clean the surface with a wire brush to make it rough.

- Always carry out an adhesion test before application. For surface treatment of materials not listed here, please contact MARIS POLYMERS Applications.

Attention: All information regarding surface treatment is indicative according to the current state of laboratory conditions and the level of practical experience. Deviations are possible due to the variety of materials on the market. Therefore, we do not guarantee the absolute accuracy of the information provided.

Due to the varying requirements of the treated objects and changing conditions, adhesion tests must be carried out to ensure that the coating is suitable for a particular task.

Therefore, it is recommended to pre-test the coating for adhesion in all categories. If there is any doubt about the suitability of the coating for your surface, we will gladly test your surface samples.

Padding

Surface preparation and priming is the same as for standard liquid mastics.

Waterproof membrane

Stir MARISEAL DETAIL slowly and thoroughly with a wooden tool before use. Do not use a mechanical punch. Apply MARISEAL DETAIL to the prepared and/or primed surface with a roller or brush until the entire surface is covered. If necessary, apply a second layer. For more detailed instructions please contact our R&D department. RECOMMENDATION: Strengthen critical elements with MARISEAL textiles. To do this, apply a correctly cut piece of MARISEAL textile to the still wet MARISEAL DETAIL membrane, press it to wet it, and saturate it again with a sufficient amount of MARISEAL DETAIL. For more detailed instructions on how to apply MARISEAL geotextile, please contact our R&D department. ATTENTION: Do not apply MARISEAL DETAIL at an ambient temperature below +50C during application and 4 hours later, on surfaces with a temperature below +50C, on frozen surfaces, during rain or fog, on a wet surface of MARISEAL DETAIL and on surfaces with high humidity. Do not apply "MARISEAL DETAIL" thicker than 1 mm in one pass. Low temperatures slow down drying, while high temperatures speed it up. WARNING: The MARISEAL DETAIL membrane becomes slippery when wet. To avoid slipping, dust the damp coating with quartz sand to obtain a rough, non-slip surface. Please contact our R&D department for more information.

Package

The MARISEAL DETAIL membrane is supplied in 6 kg metal pails. Buckets should be stored in a cool, dry place for no more than 24 months. It is necessary to protect the product from moisture and direct sunlight. Storage temperature: 5 - 30C. The product must remain in its original unopened packaging containing the manufacturer's name, material designation, batch number and labeling with storage precautions.

Precautionary measures

The MARISEAL DETAIL membrane contains isocyanates. See information provided by the manufacturer. Please read the product data sheet. FOR PROFESSIONAL USE ONLY.

Our company can offer you cars of various carrying capacity, which allows you to choose the option of loading that you need.

- Delivery of materials in Moscow and Moscow Region, when ordering a minimum lot:

- Delivery of materials to other regions of Russia (with the exception of Moscow and the Moscow region), when ordering a minimum lot:

- Delivery of materials to the CIS countries, when ordering a minimum lot:

Maximum delivery rate in Moscow

| № | Carrying capacity (tons) | Volume (cubic meters) | Cost, rub.) |

| 1 | up to 1.5 | 7-10 | 2 000 |

| 2 | 1,5 | 7-10 | 3 000 |

| 3 | 3 | 15-17 | 4 000 |

| 4 | 5 | 15-20 | 7 000 |

| 5 | 10 | 30-40 | 8 000 |

| 6 | 20 | 75-96 | 10 000 |

Maximum delivery rate outside the Moscow Ring Road in the Moscow region

| № | Carrying capacity (tons) | Volume (cubic meters) | Cost per 1 km (rub.) |

| 1 | up to 1.5 | 7-10 | 28 |

| 2 | 1,5 | 7-10 | 30 |

| 3 | 3 | 15-17 | 32 |

| 4 | 5 | 15-20 | 35 |

| 5 | 10 | 30-40 | 40 |

| 6 | 20 | 75-96 | 50 |

Additionally:

Entrance to the interior of the Third Ring Road - 1500 rubles. for the car.

Entrance to the inside of the Garden Ring - 2500 rubles. for the car.

We can offer you the option of delivery by manipulator. Load capacity of the manipulator is 15 tons. The use of a manipulator greatly simplifies the unloading of products at your facility, helps to get rid of the search for unloading equipment, and also significantly saves on unloading.

The price of unloading 1 pallet is 250 rubles.

Delivery of regional orders is carried out to the transport company chosen by the Customer within the city of Moscow or the Moscow region at the above rates, or by the transport of our partners in agreement with your manager to the facility in your region.

Transport companies with which we work for the delivery of materials in Russia:

- Business Line

- PEC

Delivery of orders to the CIS countries is carried out to the transport company chosen by the Customer within the city of Moscow or the Moscow region at the above rates, or by the transport of our partners in agreement with your manager to the facility in your region.

Upon delivery to the CIS countries, we carry out the necessary customs clearance, which is processed by our partner LLC "Corporation VED-CENTER"

The success of each shipment depends on competent planning, so for each cargo we select the most suitable transport, the best route and delivery cost.

You have excellent buying conditions! We did the finishing of the basement in our house, we were looking for materials. I drove to the office by car, chose a stone grout and glue. Everything was in stock and the guys shipped everything immediately. Very fast and coherent. I thought it would be closed on the weekend, but it turned out that they are open. Later, I had to buy more grout for the Parel stone. All without problems. I am completely satisfied with the quality of materials and services. They work very professionally, quickly and loyally to the client. Therefore, if you also need various building materials, I highly recommend it. Yes, and I myself, I believe, I turn not the last time.

Victoria Medyanik

My husband and I decided to finish the facade of the house with thermal panels. It is very cold in the house in winter. We have been looking for quality materials at the right price for a long time. As a result, I came across your company on the Internet, called back, clarified the details, ordered 30 bags of Perel thermal panels with delivery. Thank you for helping me choose the most suitable material, calculating the right amount and quickly delivering it on the same day. I am very satisfied with the quality of the service and the panels themselves. And yes, the price is great. We are currently in the process of decorating. Thank you for your efficiency and professionalism. This is very important for buyers today.

Marina Abidova

I independently decided to start building a house from Braer ceramic blocks. Fortunately, I have construction experience, and quite good. It was only necessary to buy Perel 8020 masonry mortar, and it is in short supply in many stores. I called back, consulted, said how many blocks I had and ordered the right amount of solution. Managers very accurately calculated the quantity, delivered the very next day. Before that, I could not find it anywhere at all, but here the right amount was right in the warehouse. They also gave me a nice discount. It is very pleasant and convenient to work with you.

Sergei Simonov

He began to build a new house of ceramic blocks. It was necessary to buy an inexpensive material - warm masonry mortar HAGAst - 720 bags. At first I called local shops in Tver for a long time, but if I was anywhere, then in insufficient quantities. And there was no point in buying less, so that later the work would become. As a result, I contacted your company, told me how many blocks I had, they provided me with a consultation, calculated the required quantity, promptly delivered it at a discount. The material is really great. Especially for its price. I am 100% satisfied with the cooperation and the level of service.

Andrey Ermak

This is not the first time I have been building a house from ceramic blocks and I always face the same problem - finding a warm Perel 2020 masonry mortar. It is difficult to find it, and if it is somewhere, then this is not enough. As a result, I called your company, consulted, asked for a miscalculation of the required amount. I needed a little, but even this I could not find in local stores. I was pleased that you ship any volume, everything is very fast and at a nice price. The material is just excellent. I checked it myself, and I understand this well. Therefore, I recommend you to everyone.

Roman Radchenko

Very fast work and quality materials. For now I am building a house from ceramic blocks and will finish it with clinker bricks. I didn’t want to spend extra money on already expensive materials, so I first came to the office, consulted, looked at samples. As a result, I ordered a system for paving paving stones, drainage mortar and grout. I was pleased that the office had all the samples, they gave me a good discount as a wholesale buyer, they delivered it inexpensively by a manipulator. Plus, you can pay by card through the terminal.

Anton Marchenko

I recently laid paving stones near my house, I needed high-quality materials at a low price. I hoped it was real. I'm glad I turned to you. Right in the office, they showed me suitable samples, suggested what was best to choose. I ordered a paving system, drainage mortar, glue and grout for paving stones. The materials are very high quality, plus they helped me calculate the right amount. It's great that you can see everything right in the office, ask any questions and clarifications. And for large orders, they also give a good discount. Great job!

Mark Nikipelov

The husband was laying stones on the paths in the yard. He asked me to find on the Internet where to buy a mortar for laying stone QUICK-MIX NLV 300. I quickly found exactly your store and decided to call back. As a result, the husband spoke, said the area, the size of the stone. We fully calculated the required amount of solution and completed the delivery. It's great that this solution is both glue and grout. The material is really high quality and reliable. It's been holding up just fine for six months now. And the cost is more than reasonable. Highly recommend to anyone doing any construction or renovation work. Price and quality at the level.

Maria Kostina

This is not the first time I have been cladding a house with clinker bricks. Often made to order, and this reached his hands and to his house. Called back, consulted, asked a couple of questions. I completely calculated everything, took the order and completed the delivery. I bought a solution of QUICK-MIX VZ white. The material is excellent and the price is justified. Thank you for quickly and accurately calculating everything, delivering it directly to Velikiye Luki (we found a good delivery service) and always informing where the car is now. Delivered on time, safe and sound. All perfectly. Satisfied with the result.

Sergey Belozertsev

I recently insulated my wooden house in the country - we decided to visit here more often in winter. It was necessary to buy Belarusian thermal panels Belan. I could not find anything suitable or any alternative for a long time until I saw your offer. I contacted the managers by phone, clarified the main points, sent my drawings and in the end ordered exactly what I needed. Thank you for helping me choose the material and its quantity. Definitely liked the price and quality. Delivery is fast and reliable - no delays, for which special thanks to your company and your specialists.

Andrey Bazhan

I needed to buy facade decorative colored plaster Bark beetle. I don't know much about this myself, so I needed to ask. I am very glad that I contacted you. First I called back, found out the main points, then I came to the office and looked at the samples. I am very grateful to your specialists for helping me, inexperienced, to make the right choice, they advised good colored plaster at the price of white. All tinted and delivered right on the day of payment. Excellent professional work and the highest quality. And, most importantly, responsibility. Thanks for being you.

Antonina Makarenko

Recently plastered block walls inside and outside the house. It was necessary to buy warm HAGAst plaster (perlite). Very pleased with the quality of service. I was invited to the office, answered all questions, consulted, showed samples and helped to make a choice. The price is just great and the quality is top notch. This is not the first time I have worked with you and I am always satisfied with the result. Even if the material is not enough, you can always quickly re-order. Delivery is very fast - almost always on the same day, and you can pay already upon receipt. I am sure that I will come to you again and again and recommend to friends.

Artem Senatorov

I am constantly engaged in the type of activity of finishing houses with artificial stone. And I always face the same problem - finding the necessary materials. Fortunately, I found your company and ordered everything I needed: SOREL artificial decorative stone, QUICK-MIX FX 600 stone glue, QUICK-MIX RSS stone grout. Everything is of excellent quality, there are samples for review in the office, consultants are well versed in the materials and are always ready to help. I was also very pleased with the discount for a large purchase. Everything needed was delivered on the same day. Paid by card. Very convenient, fast and high quality. Recomend for everybody.

Maxim Shcherbakov

Recently started finishing the house with natural stone. I had the main material, I had to buy glue for natural stone HAGAst KAS-555. I have worked with him before and have always been happy with the results. But I couldn't find it anywhere at a reasonable price. Or it was out of stock. I am very glad that I contacted you. I called back, clarified whether there was glue in stock, whether there was a delivery. The managers answered all the questions and said that the material was in stock in the right quantity, after which they delivered it directly to me. Thank you for the high quality material and first class service. From now on, I will always turn to you.

Igor Gorelov

I am a foreman and our team of builders are constantly laying marble tiles on the walls and floor. For work we use quick-mix MK 900 marble glue (white). For a long time we worked with one supplier, but in the end he stopped working in the city and it was necessary to look for an alternative. Found you and do not regret. At first they took some material purely for testing, the quality was on the level. Further already ordered for the entire object. The glue is durable, easy to work with and dries quickly - exactly what we need. So we will be applying for new batches soon. Definitely pleased with the fast delivery and quality service. Thanks!

Semyon Lukyanenko

I myself am engaged in the construction of houses, so I know quite well when it comes to choosing materials. And not all of what sellers offer today really deserves attention. This time I needed to buy glue for polystyrene foam, facade glass meshes and dowels. I was looking for something suitable for a long time until I came across your site. Everything you need is there, the price is good, the quality of service is excellent. Especially the speed of delivery. I was advised on the options for choosing the material, calculated the right amount, delivered right on time, as indicated in the contract.

Ivan Artamonov

Our company is engaged in the installation of industrial floors in Moscow (for increased loads). Accordingly, the quality of the materials we use must always be at the highest level. We ordered especially durable industrial floors Reapol 20 from you and did not regret our choice. The material itself performs the functions of a leveling screed and top coat, is very easy to use and has the highest strength. Thank you for clearly calculating the right amount of material, delivering it strictly on time and giving a good discount for a large amount of goods in the order.

Vitaly Zgursky

We are engaged in floor laying in large industrial premises. For us, the quality of the final result is always in the first place. This means that the materials used must be first-class. You ordered concrete floor hardener Reamiks-M - a novelty on the market that completely replaces the topping. The material is more convenient to use and perfectly increases the strength of concrete. Nice to work with you. Specialists are always ready to consult on all issues, give advice and quickly deliver to the place. Good job for reasonable money. We cooperate not for the last time.

Viktor Semagin

I am in the process of laying brick walls. It was necessary to buy mortar for Quick-mix LHM bricks. Searched, I confess, for quite a long time. And at first I didn’t even know for sure whether I needed this solution. Good to be in your office. Here they showed samples, advised what is best to choose and made a miscalculation of the required quantity. After payment, delivered the same day. The material provided is inexpensive and of high quality. Great for laying bricks on your own, even without special building skills. Yes, I enjoyed working with you. You are real pros.

Dmitry Khorolsky

Our small company is engaged in the insulation of facades in high-rise buildings. You bought glue for polystyrene foam, facade mineral plaster bark beetle. All materials are of the highest quality, and the price is more than affordable, which is definitely pleasing. We have been working for the second year and mainly try to find inexpensive, but high-quality material. Just happened to find one here. They called, ordered, took advantage of the delivery to our warehouse. Everything is very convenient. Delivery is generally inexpensive, and deliveries are strictly on schedule. Great job! We will cooperate.

Segey Maksimenko

A rather topical issue at the initial stage of the construction of any structure is the correct foundation waterproofing. Its saturation with moisture, caused by heavy precipitation or rising groundwater, leads to the destruction of the monolithic integrity of the structure's support and corrosion of metal reinforcement. The strength of the foundation largely depends on the type of hydraulic materials used to protect its underground part. Their range provides a wide range of choices, varying in quality, efficiency of use and price. One of the most practical solutions can be a film for waterproofing the foundation, the use of which compares favorably with other methods of protection.

Types and features of building polymer films

In the technical and economic calculations of the erected building structures, the priority issue is the maximum possible reduction in the cost of the work performed and the materials used. At the same time, their low cost should not, to one degree or another, affect the final quality of the finished structure.

In some cases, the use of polymeric film materials as waterproofing allows to partially compensate for the significant financial costs during the construction of the foundation. Their main types are:

- ordinary flat PE or PVC films;

- reinforced;

- membrane.

Building films favorably differ from traditional waterproofing materials, such as roofing material or mastics, primarily by ease of installation and the possibility of combining layers. Such insulation serves as a reliable protection, being impervious to moisture, and its durability has been not only proven by theoretical studies, but also confirmed experimentally in various conditions. The only negative factor is the effect of ultraviolet radiation, which affects the strength of the film, but this can be excluded, since the insulating material is in the thickness of the soil.

Some types of polymer films, reinforced with a rubber or bitumen layer, are highly resistant to acids and salts present in groundwater. The use of the material is focused on waterproofing foundations located on problematic soils with severe geotechnical conditions.

Application of flat films for waterproofing

The most budgetary option for waterproofing the foundation can be a conventional plastic film, which is widely used for household needs. For example, it is often used in summer cottages as a cover for greenhouses or greenhouses. Made from high density polyethylene, it:

- has elasticity and sufficient tensile strength;

- does not rot.

The polyethylene film finds its use as a waterproofing material at the stage of preliminary preparation of the formwork - before pouring the foundation. The bottom and walls of the box are covered with a polymeric material, preferably in several layers, with an overlap of sheets of at least 20 cm.

For waterproofing the foundation, the thickness of the applied polyethylene film should not be less than 0.4 mm.

In addition, polyethylene film coating is widely used as a means of preventing rapid loss of moisture in a poured concrete foundation. This ensures the optimal ratio of the water-cement composition of the mortar in the mixture and ideal conditions for cement hydration.

Reinforced waterproofing films

Unlike ordinary polyethylene film, this material has a multilayer structure. Its feature is the presence of a reinforcing mesh sealed between the outer layers, which ensures increased mechanical strength and resistance to stretching. As a reinforcing layer, non-woven materials or polypropylene meshes are used, less often high-pressure polyethylene. Two types of waterproofing film are produced:

- perforated, with micro-holes over the entire area of the rolled material. It is mainly used for roof waterproofing of buildings;

- non-perforated, used mainly for waterproofing foundations.

Due to the perforation applied to the surface, the reinforced film is sometimes mistaken for a waterproofing membrane. It should be noted that the perforation is primarily designed to drain excess condensate and provide sufficient ventilation for the surfaces covered with a film, but in no way to protect against moisture from the outside.

Non-perforated coating, on the contrary, is used specifically to protect against excessive moisture. When choosing this material, one should be guided not by the film thickness, but by the density indicator indicated on the package, which should be in the range of 100 - 250 g / sq.m.

Film membranes

Such types of film waterproofing are innovative materials that contribute to the most reliable protection of the foundation from moisture. A fundamentally different approach to the device of a multilayer coating ensures the removal of the accumulated hydroid vapor from the covered surface through it. At the same time, the material is completely waterproof from the outside.

There are two types of film membranes:

- flat;

- profiled.

The correct choice of one or another type of waterproofing membrane depends on the geotechnical conditions of operation of film materials. Flat polymeric membranes provide protection against soil moisture for foundations located above groundwater. Profiled waterproofing membranes have a surface reinforced with hollow convex spikes. They are used to protect foundations that are exposed to periodically rising groundwater.

Advantages and disadvantages of waterproofing films

Being a worthy alternative to bituminous coating waterproofing, the presented types of film coating are widely used in the installation of horizontal and vertical protection of foundation walls from moisture penetration. However, before deciding and choosing the most suitable material, you should familiarize yourself with the results of preliminary geological studies of the soil, as well as weigh all the shortcomings of waterproofing films, namely:

- high risk of damage to film waterproofing due to its relatively low mechanical strength;

- careful preparation of the surface before laying the insulating coating on it;

- the presence of connecting seams, which are problem areas in protection;

- possible damage to integrity as a result of chemical impacts of groundwater;

- susceptibility to damage by rodents.

Nevertheless, due to excellent waterproofing properties, as well as relatively low cost, the use of film coatings to protect foundations is popular in the construction of not only private buildings, but also industrial facilities.