Tile adhesive: which is better?

A huge assortment of goods of the same type is simply confusing and makes it difficult to determine the only right choice - this is exactly the case when abundance is not in favor of the buyer. Well, how do you choose tile adhesive if that one is good, and this one is even better?

Neither intuition nor managerial advice will help here. Because in the first case, not intuition is needed, but experience with similar material, and in the second, you will be praised for everything, just to sell the goods.

Therefore, before you go to the construction market, arm yourself with information. The most important thing for you now is to know by what criteria to choose an adhesive so that the tile lasts the entire period promised by the manufacturer.

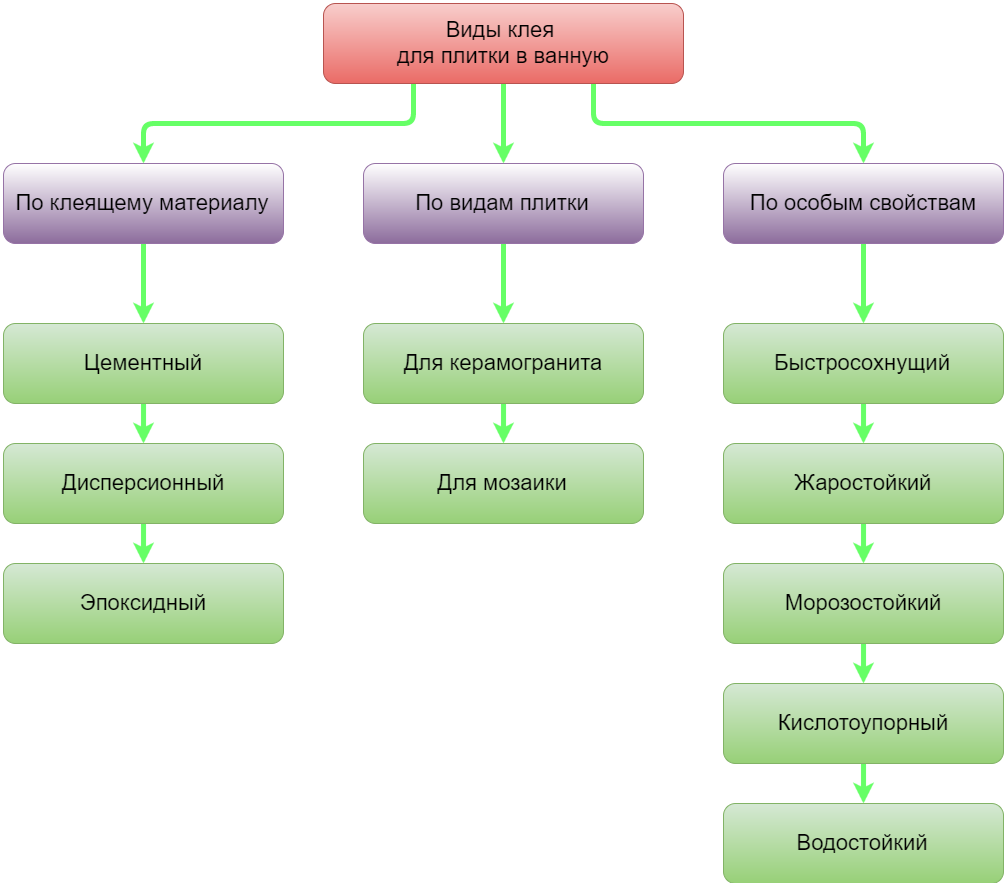

For various kinds of work and for different types of tiles, there is a special adhesive. But, if you do not delve too deeply into the classification, you can immediately identify two main types of glue, widely represented in specialized building materials stores.

Dry mixes for tiles, based on cement, are diluted with plain water and kneaded

- Dry mixes. Sold in bags, they require "bringing to condition" immediately before use, by adding liquid to the mixture, the basis of such glue is cement. Budget.

- Ready mixes. They are sold in buckets, they do not require any additional actions before use, they are made on a polyurethane basis, they belong to the group of expensive building materials.

Note! To choose the right tile adhesive: which one is better, expensive or cheap, it’s not enough to navigate like this - by price. After all, what costs less is not always the worst quality. We repeat: it all depends on what kind of work you are going to carry out and what type of tile to use.

Tile laying with polyurethane adhesive will last longer than cement-based adhesive

Returning to the question of quality: who said that the budget must necessarily be fragile, weak and, in general, have disadvantages? It all depends on what goals the master pursues, using a certain adhesive mixture.

What are the qualities of a good adhesive?

Criteria for choosing a quality adhesive remain traditional. In addition to what we know about adhesive mixtures from the time when they began to be actively used for professional and household repairs (the percentage of spreadability and stickiness), modern tile adhesive has a number of other characteristics - new - let's call them that.

New compositions are enriched with some substances that affect adhesion, plasticity and color of the adhesive. In fact, nuances play a role only in certain conditions. If you need to finish the walls with mosaics, then there can be no question of any cement gray mixture - only white polyurethane.

Advice! If you are looking for tile adhesive in the bathroom, then you need to focus on mixtures with water-repellent properties.

And another tip: when studying the characteristics of the adhesive placed on the packaging, labels or catalogs, do not get too excited about them - you will not be able to determine the features of the adhesive composition. If for the first time you are faced with the problem of choosing this building material, consult with experts, or carefully study these characteristics of high-quality glue:

- glue for wall tiles must have moderate plasticity - otherwise it will simply spread over the surface, and the lining will have nothing to hold on to;

- when choosing an adhesive for floor tiles, the requirements are completely opposite - this one should spread. And not just spread, but fill everything, even the slightest voids, otherwise, a part of the tile that is not supported by glue threatens to break when a heavy object falls on it;

- any of the adhesive compositions must have high adhesion and the ability to quickly adhere to the surface, according to the indicated properties, a certain type of adhesive must hold a tile of a certain parameter and weight;

- high-quality adhesive composition never hardens quickly: the master should have time to correct poorly placed cladding elements; and experts say that the slower the glue dries, the stronger the tile adheres to it;

- when choosing an adhesive composition for your repair, consider the operating conditions of the tile: adhesive for ceiling tiles differs significantly in properties from adhesive for floor or wall tiles, and adhesive for outdoor work is completely different from that for interior;

- an important role in the choice of glue is played by the material and quality of the surface intended for cladding - all adhesive compositions have a certain level of adhesion with certain materials;

- don't forget to consider the size of the tile when choosing an adhesive for it: experts say that the larger and heavier the tile, the more adhesive hold it will require.

Varieties of adhesive for ceramic tiles

Dry and ready-made adhesive mixtures, which we talked about at the beginning, are just, if I can say, a dividing barrier between all existing types of glue. According to the internationally accepted classification, tile adhesives are divided into five large groups.

- Glue mixes for internal works. The cheapest of all existing ones are used mainly in the process of finishing household premises. Despite the fact that the content of additives that improve the properties of the adhesive in such mixtures is very low, they do their job pretty well and stick the tiles firmly, provided that the tile size is standard: 20x30. In the absence of temperature changes and the negative impact of the environment, this type of glue can last a very long time.

- Glue of the increased fixing. Withstands high loads, and this indicates the scope of its application: for facing surfaces subject to thermal and dynamic influences. Typically, such adhesive mixtures are used for laying large-format tiles or natural stone. And what is more valuable in this mixture is that it can be used for laying tiles on the old cladding, the main thing is that the old tile should hold on very tightly and not think of collapsing along with the fresh one.

- Standard adhesive mixture, it is also universal - the most common among tile installers. It is used both for internal and external work, it is considered universal, but it is not recommended to use it for tiles with dimensions exceeding 30x30, as well as in rooms where there are heavy loads on the surface of the floor (walls) or high humidity. Although ... if you buy Ceresit tile adhesive, then these restrictions do not apply to him.

- Adhesive for floor tiles. The main feature of this type of adhesive mixtures is the presence of a plasticizer in their composition, which allows the solution to penetrate into all voids, filling them and not leaving the slightest vacuum. In no case should such glue be used for wall cladding - it is too liquid, it will not hold the tile in an upright position.

- Moisture-repellent glue - was developed specifically for finishing pools and fountains, it is used with pleasure by the owners of apartments and private houses for bathrooms and outdoor terraces. In its composition, this is the same strong fixation adhesive, but with an added modifier that gives the mixture hydrophobic properties.

Another nuance is the temperature at which you work. The higher it is, the faster the moisture evaporates from the mixture and the more glue is needed.

Qualification of the master ... you have no doubt that a lot depends on professionalism, including the amount of consumables? Experienced tilers have a trained eye so much that they won’t put too much on, but there won’t be enough glue either - with a reasonable consumption of the mixture, the cladding will hold securely.

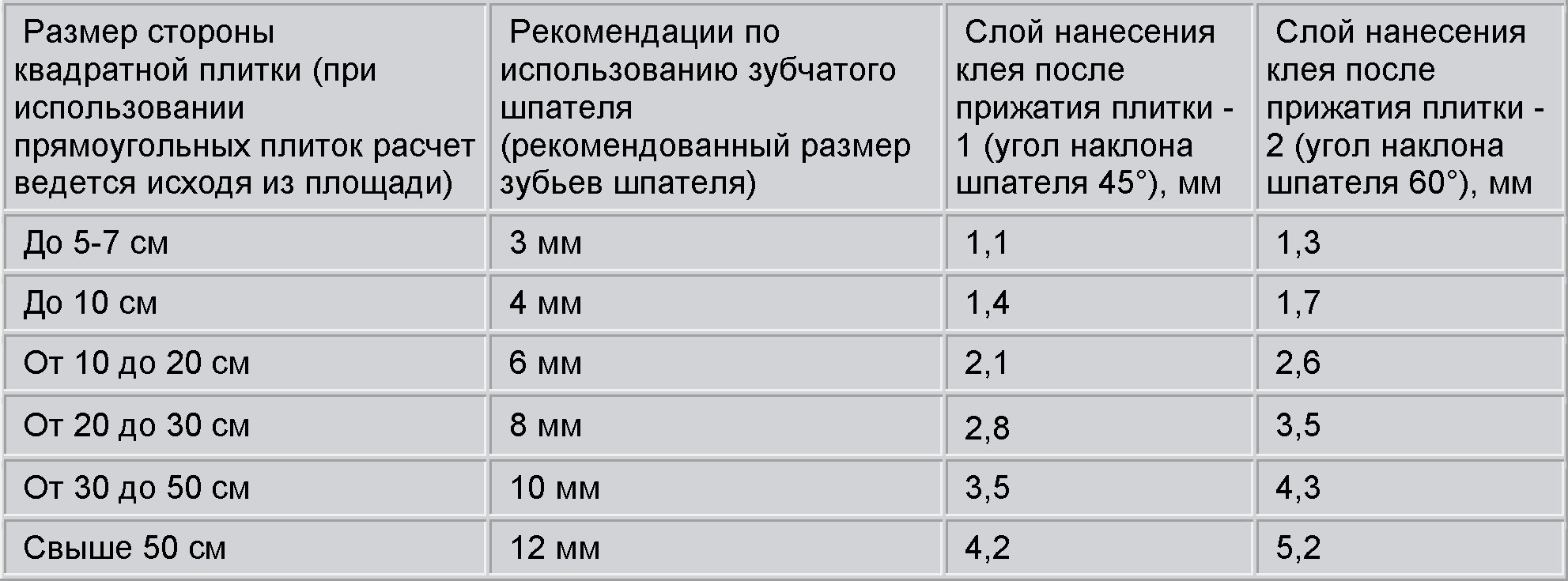

An approximate calculation of the required volume of the adhesive mixture

Everything is simple here: for example, let's take cement-based tile adhesive. Under the most favorable working conditions, the material consumption will be 1.3 kg, this value must be multiplied by the thickness of the layer that the master applies to the surface (with standard tile sizes, it will be 4 mm).

Result: 5.2 kg/m2. For ten squares, you will need 52 kg of glue, for twenty - 104 ... well, and so on.

When calculating, consider the size of the tile - in accordance with it, the indicator of the thickness of the adhesive layer changes.

The provided calculation sample cannot be called a reference, but can be taken as a basis.

Selection Options

You already know about different types of glue, but how not to get lost in such a variety and buy exactly what you need? When choosing, you should be guided by three main parameters, which are described below.

- Material and dimensions. These two factors affect the weight, which in turn determines the choice of adhesive. It is logical that for a heavy tile it is necessary to choose an adhesive that has an increased adhesion strength to the surface. In the construction industry, this property of the adhesive mixture is called adhesion. Its quantitative value is usually indicated by the manufacturer on the packaging. This indicator also affects the price: the higher the adhesion value, the more expensive the adhesive composition will cost you.

- Operating conditions. This is one of the decisive factors, so it should be given special attention. Here you must take into account absolutely all the features of the room in which the repair is planned. It is important to foresee every detail: the temperature regime of the room, air humidity and permeability. For example, to work with refractory tiles, you need to use a heat-resistant adhesive that can withstand operation at temperatures up to 100 degrees. Frost-resistant glue is used in unheated buildings, and acid-resistant glue is used in rooms where there is a risk of exposure to external chemical irritants on the tile.

- Foundation features. Professional builders conditionally divided surfaces into two types: simple (not susceptible to deformation) and complex (unstable to loads, can be deformed). The former include bases made of concrete, brick or sand-cement screeds, and the latter are surfaces made of plastic, wood, glass and metal. As the name implies, working with them is quite difficult, so you have to find an adhesive designed specifically for these surfaces.