What is needed for the production of decorative gravel. The technology of self-painting rubble. Unloading crushed stone from a concrete mixer

Usually crushed stone is used in the production reinforced concrete structures or in road construction. Colored gravel - decorative material from a fine fraction of natural stone. After painting with colored gravel, they finish the interiors, use it in landscape design, line the bottom of aquariums, etc.

Crushed stone is one of the most commonly used materials in construction. It is usually used as a filler for cement-concrete and asphalt mixtures, in the production of reinforced concrete structures and as one of their lining in the construction of highways.

In the last couple of decades, there have been the new kind specially prepared building rubble, which performs a decorative rather than a building function.

Colored gravel: a brief description

Colored crushed stone is a specially colored a natural stone(granite, marble) fine fraction. After painting, the surface of the gravel becomes smooth. The coloring matter does not lose its properties from changes in temperature, humidity, sunlight and other influences.

Other names for colored (painted) crushed stone are colored pebbles, colored gravel, decorative painted stone. It is usually sold in bags. Used in landscape design, for interior decoration, decoration of aquariums, etc.

Consider the feasibility of the production of colored gravel in terms of commercial benefits. The cost of one ton of ordinary crushed stone is 2,000 rubles, and the cost of a bag of such crushed stone is 300 rubles, i.e. Only packing can decently earn. The cost of colored gravel is much higher, so its production will be profitable.

Production of colored gravel

Ordinary granite (marble) crushed stone is painted with special dyes, dried, packaged and sent to trade or to the consumer. A package of painted gravel usually contains 20-25 kg.

Manufacturers of such gravel unanimously declare that acrylic dye is best suited for coloring. However, in the absence of such, it is possible to offer several options for the use of other dyes. Let's start with necessary equipment and tools for staining gravel.

Equipment, tools and materials

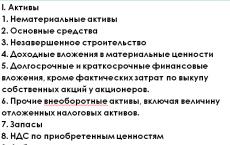

So, for the production of colored gravel you will need:

- Crushed stone - 2-3 tons;

- Paint - 100 kg;

- Installation or room for drying material with good ventilation;

- Vibrating screen VG-1 or its analogues - 1 unit. (from 89,000 rubles);

- Concrete mixer (painting bin) - 1 unit. (from 8,000 rubles)

If there are problems with financing, then at first you can do without a crash. In this case, crushed stone will have to be sieved manually using nets of the outer size. You can also not purchase a drying chamber yet, but dry the rubble directly in the open air. Thus, from the equipment you only need a concrete mixer.

Already by the set of equipment it is clear that this production belongs to a low-cost business. You can get by with no more than 100 thousand rubles to fully equip the production. If this is not possible, it is enough to buy a concrete mixer, sifting sieves, paints and gravel itself.

Gravel painting technology

Name and sequence of technological processes:

1. Sorting of crushed stone in order to separate garbage and separate fractions

With the help of a screen or mesh, crushed stone is sorted into fractions of the required size. As a rule, crushed stone more than 10 mm is used, since it is more convenient to paint it. Sorting is also needed to remove contaminants from rubble.

2. Loading individual fractions of crushed stone into the concrete mixer hopper and adding paint

The paint of the required color is added in the amount of 20% of the volume of the loaded crushed stone.

3. Mixing gravel with paint

Mixing should be 40-60 minutes to completely cover the material with a film.

4. Unloading crushed stone from the concrete mixer

Crushed stone should be removed through the grid above the receiving hopper so that excess paint flows into the hopper and is used for the next painting.

5. Drying of painted gravel

For large volumes of production, it is desirable to use a drying chamber. If at the initial stage there is no such chamber, then it can be dried in the open air.

6. Packaging of painted gravel

Activity registration

For small production best form business registration will be IP -. The registration procedure is simple and does not require large expenses.

The taxation system is better to choose the simplified taxation system (simplified taxation system) with a tax of 15% of profits. To register on this system, it is necessary to submit an application for the transition from the general taxation system to the simplified tax system within 3 days after the registration of the IP.

Economics of colored crushed stone production

Consumption of materials for the production of 1 ton of colored crushed stone:

- Crushed stone from granite (marble). The cost of 1 ton of crushed stone is 2,000 rubles.

- Water paint with a consumption of 20 kg per ton of crushed stone. The cost of the paint is 200 rubles/kg. For the production of 1 ton of crushed stone, you need to buy paints for 4,000 rubles.

Total: the cost of producing 1 ton of colored crushed stone is 6,000 rubles.

The retail price of colored crushed stone is 22,500 rubles per ton. Profit per ton will be 16,500 rubles.

Wages, taxes, advertising and transport costs, packaging costs, rent, etc. remained unaccounted for. However, the figures show that the net profit will be at least 50% of investments. For a low-cost business, this is a very good indicator.

As in any production, the main thing for a successful business is to ensure constant sales of what is produced. Even before production begins, you should conduct market research on the use and need for your products.

Research should be carried out among companies engaged in landscape design, interior design, etc. Part of the product can be sold to building supermarkets, shops, markets, etc. Packing crushed stone in paper or plastic bags of 20-25 kg is convenient for retail distribution.

The business idea for the production of multi-colored crushed stone is based on the acquisition of raw materials of an average fraction of 10-30 mm and its further painting with acrylic paint. As a result of this not tricky operation, a material for landscape design that is very much in demand today is obtained.

The essence of the business for the production of multi-colored gravel

The business of producing colored stone for landscaping is based on painting ready-made and sorted raw materials.

The finished material is widely used in:

- landscape design of private households,

- in the improvement of urban areas,

- organization of a comfortable microclimate in the aquarium and terrarium,

- in the arrangement of tombs and cemetery plots.

This material is usually sold in large batches. To reproduce a landscape design project for urban and park areas, tens of tons of colored stone are required, for the improvement of house adjoining and household territories, no less, even for arranging a standard cemetery plot, at least a ton of colored gravel will be required.

Main consumers

- Individuals for the arrangement of adjacent territories and personal plots,

- Utilities and "green farms" to create spectacular flower beds and lawns,

- Landscape design companies

- Organizations offering funeral services - arrangement of the cemetery territory.

- Pet lovers (for aquariums, terrariums, cages),

- Pet shops and pet salons (to recreate a spectacular environment for animals).

Production process for painting gravel

- Acquisition finished, sorted raw materials of medium fraction (10-30mm). Buying crushed stone of a specific faction eliminates the need to sort it. It is placed in the bunker for raw materials, from where it is fed in portions, with the help of shovels, for painting. It is not advisable to store it in the open air, since a dirty stone cannot be painted with high quality. Acrylic paint ideally fits on a dry and clean surface. The source material is purchased in a volume of 10m3 (about 14t) - this is the standard volume of KAMAZ, which usually transports crushed stone.

- Putting it in the paint bin, the role of which is performed by a concrete mixer. When using a concrete mixer with a volume of 0.7 cubic meters, its capacity is not filled to the top, but a little more than half, by about 0.5 cubic meters. Together with crushed stone, acrylic paint is poured into the concrete mixer for facade works desired shade. To produce finished material with a volume of 2 tons per shift, the concrete mixer will have to be run 3 times a day. The use of a smaller volume concrete mixer (say, 0.2 cubic meters) is less cost-effective, since for painting the same volume - 2 tons, it will have to be run 6 times a day (the calculation is made taking into account the weight of 1 cube of crushed stone = 1.41 tons).

- direct coloring. The process of operation of the concrete mixer takes no more than 15 minutes. Immediately after its completion, the painted, raw material must be dried and allowed to drain excess paint.

- Drying the finished material with a vibrating sieve. For drying newly painted crushed stone, a large sieve is needed, on which material weighing about 700 kg (one batch from a concrete mixer) would freely fit. This sieve should be equipped with a drip tray onto which excess paint will drain. A vibrating sieve with a pallet is ideal in this respect. Painted pebbles should have an even color and be perfectly clean. With the cost of a ton of painted gravel at 24,000 rubles (regular, unpainted costs 1000-1100.00 rubles per ton), the buyer will be picky about its quality, so drying should be taken seriously.

- Warehousing finished material. For warehousing and storage of finished material, a bunker is used, similar to the one in which raw materials are stored. It will not work to store such an expensive material in the open air - it must be packed in bags dry and clean.

- Packing in bags. The finished material is packed in bags designed for a weight of 5 to 20 kg. This is done by hand with shovels. The bags are sewn up using a portable bag sewing machine.

What equipment is required for the production of colored gravel

For the production of colored crushed stone from ready-made raw materials, a little equipment and, accordingly, small investments are required.

- Bunker for raw materials,

- concrete mixer for painting,

- Vibrating sieve for drying and draining excess paint,

- Bunker for finished material,

- Bag sewing machine

The table below describes the set of equipment designed for minimum performance and characterized by the lowest cost.

Total: 870 990 rubles.

The set of equipment given in the example allows you to get up to 10m3 (13 tons) of colored crushed stone per shift. Given the working volume of the Prof-BS700 concrete mixer of 0.7 m3, the painting time is no more than 15 minutes per batch and the drying time using a vibrating screen is no more than 5 minutes per batch, it will not be possible to process a larger volume of raw materials.

Accessories and Consumables

shovels. To paint the crushed stone, you will need the paint itself - acrylic, at least 2 shovels to transfer the feedstock from the hopper to the concrete mixer, from it to the vibrating sieve, and from there to the hopper for the finished material. Four shovels for 1360 rubles. (340 rubles each).

Dye. Given the productivity of 2 tons per day (44 tons per month), about 310 kg of paint will be required at an average cost of 110 rubles. per kg. Total for 34,100 rubles of paint per month.

Colored crushed stone is packed in 20 kg bags. Accordingly, 2200 bags of 4.5 rubles are needed per month. a piece. Total - 9,900 rubles. per month.

Total additional costs:

- The total cost of the instrument is 1360 rubles.

- The cost of consumables for 1 month of work is 44,000 rubles.

Feasibility study of the project

The total cost of opening and launching the production of multi-colored crushed stone will include the cost of the necessary equipment, tools, basic raw materials and consumables (paint and bags).

How much money will you need to start a business?

- Purchase of equipment and tools - 872,350.00 rubles.

- Purchase of raw materials (crushed stone, paint, bags): 100,000 rubles.

- Registration in the INFS and other expenses for starting a business - 50,000 rubles.

Total: 1,002,350 rubles.

How much can you earn on this?

The calculation of revenue is made taking into account performance 2 tons per shift and 22 shifts per month.

How much crushed stone should be sold per month to reach the break-even point?

Under the condition of a gross margin of activity in the amount of 480% and the presence of general fixed costs in the amount of 200 thousand rubles, in order for the activity to reach the level of self-sufficiency, it is necessary to sell 250 thousand rubles a month, i.e. about 20 tons of products.

Landscaping is distinguished by the widest range of possibilities and techniques used. This creates unique compositions that often require the use of original materials. In this regard, colored gravel has gained immense popularity, through which you can create real masterpieces of landscape design. The production of colored gravel, as an idea for a business, is a very promising and profitable niche that can pay off very quickly with little investment.

Colored gravel production technology

Crushed stone is one of the main materials used in construction. It is a part of cement-concrete mixtures and asphalt concrete, it is indispensable during the manufacture of reinforced concrete structures, and during the construction of roads. More recently, a couple of decades ago, crushed stone began to be used as a decorative material.

Crushed stone, usually granite, is specially painted using a fine fraction of stone for this. After staining, it becomes smooth. The paint used for this purpose is resistant to temperature changes, high humidity bright sun and other influences.

Painted crushed stone is called colored pebbles, gravel, decorative colored stone. Packed this construction material in bags weighing 20-25 kg. It is bought to decorate garden plots, burial places, interior decoration, in aquariums, etc.

How to start the production of painted gravel?

To launch the production of colored gravel, it is necessary to understand the commercial benefits of this type of activity. One ton of raw materials (crushed stone) costs 2,000 rubles, one bag of colored crushed stone costs 600-700 rubles. Accordingly, packing such a product in bags, you can make good money. Since the price of painted stone is much higher, its production will give a good profit.

Crushed stone from granite (marble) goes through the process of painting with a special dye. The next stage of production is its drying, then packing and sending to consumers. The best coloring agent for this material is acrylic dye.

Accordingly, to start production, you need to purchase equipment and tools, as well as choose a place for production.

What equipment will be needed?

In order to open the production of colored gravel you need to find a suitable room or platform with a canopy with dimensions of about 300 sq.m.

To get started, you will need to purchase:

- installation or room in which the painted crushed stone will dry, a well-ventilated room;

- vibrating screen VG-1, or similar equipment, 1 pc. - 90,000 rubles;

- concrete mixer (painting hopper, 1 pc. - 8,000 rubles;

- paint - 200 kg;

- crushed stone - 3 tons.

Documents required for organizing the production of colored gravel

In order for your business for the production of colored gravel to comply with the requirements of the legislation of the Russian Federation, you must register with the tax office, funds (social insurance, pension, medical insurance) and Rosstat.

But, before proceeding with the paperwork, you must choose the legal form for your business. If there are no other founders besides you, and you do not plan to create a huge enterprise, then it is enough to register as an individual entrepreneur. For this you need:

- Write an application to the FTS.

- Pay the state fee.

- Prepare a copy of the passport and TIN.

- Choose a taxation system.

In addition, you must indicate the code for your activity, according to the all-Russian classifier. IN this case fit:

- OKVED 26.70– processing of decorative stone;

- OKVED 26.82– production of other non-metallic, mineral products.

To register an LLC, you need to additionally prepare papers on the establishment of a company, resolve the issue with a legal address and form an authorized capital.

In addition to documents confirming the registration of an LLC or individual entrepreneur and the fact that you are a tax payer, you need to obtain permits from Rospotrebnadzor and the fire inspectorate.

And good news for start-up entrepreneurs who decide to start producing colored gravel. For this type of activity, in addition to the above list of documents, no additional permits or licenses are required.

Optimal tax regime

For enterprises specializing in the production of colored gravel, experienced businessmen recommend choosing a simplified taxation system. The amount of tax liabilities can be calculated in two ways:

- 6% of total revenue (gross income);

- 15% of the difference between gross income and enterprise costs.

Note! When calculating the amount of taxes, consider only those expenses that are supported by documents. If you decide to work for the simplified tax system, you need to write a relevant application to the tax office and submit it along with the documents for registering a company.

One more important point. If you plan to create a large enterprise that will employ more than 100 people, then you will have to work under the general taxation regime.

How much money do you need to start a business?

If there are not enough funds to purchase equipment, you can work without a screen for the first time. Screening of crushed stone can be carried out manually through meshes of a certain outer size. You can also not buy a drying chamber at first, dry the crushed stone in the open air. In this case, only a concrete mixer will be needed for uniform and high-quality staining of crushed stone.

A small set of equipment suggests that colored gravel production project is low cost. It will be enough to invest about 100,000 rubles in this business idea to start your own production.

Even if this amount is not available, you can purchase a minimum of equipment, and do some of the work manually. When the funds appear after the sale of finished products, it will be possible to gradually understaff.

Another positive point is that two unskilled workers can be hired to perform the work, even if they do not have work experience.

D To purchase equipment, you need about 90,000 rubles.

Raw materials and materials per 1 ton of finished painted crushed stone will cost:

- crushed granite (or marble), 1 ton - 2,000 rubles;

- acrylic paint (200 rubles / kg), consumption of 20 kg per 1 ton of crushed stone - 4,000 rubles;

- buckets - 2 pcs (for raw materials and finished product - 600 rubles;

- shovels - 2 pieces for 2 workers - 800 rubles;

- bags (10 rubles/piece) for packing the finished product 50 pcs. - 500 rubles.

In total, funds are needed for the purchase of raw materials and materials - 7,900 rubles.

How much can you earn in the production of crushed stone?

One ton of colored gravel sold at retail costs about 30,000 rubles. Without taking into account the cost of fixed assets (90,000 rubles), the profit per ton of finished products will be 30,000 - 7,900 = 22,100 rubles.

It does not take into account taxes, salaries, advertising campaign costs, transportation costs, rent of premises, sites. All these costs will amount to about 50% of the investment. For a business with a small investment, these are pretty good numbers. It can pay off in one season of work - 8-9 months.

Features of the production of colored gravel

Any production that wants to be successful must have customers for the continuous sale of its products. no exception and business idea for the production of colored gravel. Before starting this project, you need to research the market and the demand for such a product in a particular region in order to be sure of the possibility of marketing. It is necessary to establish contacts with landscape design companies in order to market their products to them. Some of it can be sold through hardware stores or via the Internet.

Making colored gravel is not difficult. It is necessary to purchase ordinary crushed stone with a diameter of 10-30 mm and paint it in the desired color with acrylic paint. How to establish such production and get a good income, we read further.

What is this product for?

Despite such ease of manufacture, colored gravel is in demand in a number of areas that cover the improvement of territories. These primarily include:

- organization of design and microclimate in a terrarium or aquarium;

- improvement of urban areas;

- landscape design in various territories;

- arrangement of cemeteries, tombs.

Everything shows that the goods will be sold in bulk. For example, landscape design will require tens of tons of such material. Even for a tomb, it also needs about a ton.

The target audience

Your business plan should not only detail the production of colored stone, but also its distribution channels. To do this, you need to determine the target audience. The main buyers of such goods are:

- pet salons and pet stores that purchase it for retail sale for terrariums, aquariums and furnishings for other animals;

- pet owners for the same needs;

- organizations providing funeral services;

- landscape design companies;

- utilities and landscaping services for creating lawns and flower beds;

- individuals for the arrangement of their own sites.

Company registration

For your business to work legally, you need to register it. Which organizational and legal form to choose depends on what volumes of production your company expects to produce. For small volumes, it is enough to register an individual entrepreneur. This procedure takes about five days and will require the payment of a state duty in the amount of 800 rubles. In addition, in future activities it will be easier for you to keep records of the enterprise.

If you are planning volume production and are planning to receive large orders, it is worth registering a legal entity. As a rule, they stop at such a form of organization as an LLC. True, in this case, you must have an authorized capital of at least 10 thousand rubles.

When choosing a taxation system, it is recommended, if possible, to stay on a simplified system, which involves the payment of 15% of profits. When registering, you must indicate the desire to work on this system or switch to it within three days after receiving the registration documents.

Production technology

For the manufacture of crushed stone of the middle fraction is required. Moreover, in order to facilitate production, it is necessary to purchase raw materials of a specific fraction - then there is no need to sort it. As a rule, one purchase batch is about 14 tons and is delivered by standard KAMAZ.

If heterogeneous raw materials were purchased, it must be sieved and crushed stone of the desired fraction should be selected. To do this, use special equipment - a vibrating screen. Production begins with washing and drying of raw materials, since the paint does not adhere well to a dirty and damp surface.

The raw materials ready for painting are loaded into a special bunker, from where they are fed with a shovel into a concrete mixer. It is filled with raw materials a little more than half. Then the paint of the desired pigmentation is poured into it and the concrete mixer will turn on for no more than 15 minutes. After that, the painted stone is unloaded to dry.

This stage takes place on a special vibrating screen with a capacity of approximately 700 kg. A tray must be installed in the sieve, provided for draining excess paint from crushed stone. Using a vibrating screen will help color the stone evenly and keep it clean. After drying, the crushed stone is loaded into a special bunker, where it is stored until the next stage. The production ends with the packaging of the material in bags with a capacity of 5, 10, 15 or 20 kg. As a rule, this is done manually, as well as sewing bags with a manual machine.

Equipment for the production of

The start of production involves a small amount of equipment. The business plan includes the purchase of such basic equipment:

- bag sewing machine;

- bunker for painted gravel;

- vibrating sieve for drying;

- concrete mixer for painting,

- bunker for raw materials.

Usually, a concrete mixer with a volume of 0.7 cubic meters is taken for painting and filled with crushed stone up to 0.5 cubic meters. For a shift, two tons of rubble can be painted on it, but it will have to be loaded three times. As a rule, smaller volume concrete mixers are not used, as it is not cost-effective. Then, for a shift, it must be launched twice as much, which increases the consumption of electricity and labor costs.

In total, about 960 thousand rubles will be spent on equipment that produces up to 13 tons per shift.

Additional tool

In addition to the main equipment, the business plan should provide for the purchase of additional equipment. You will need four shovels. One is for loading raw materials into the hopper, the other is for transferring from the hopper to the concrete mixer, the third is from the concrete mixer to the vibrating sieve, and the fourth is for unloading from the sieve into the bin for storing finished products. Each shovel costs an average of 340 rubles.

For a concrete mixer of the specified volume, the business plan will require the purchase of about 310 kg of paint per day. On average, a kilogram of such paint costs 110 rubles. That is, a little more than 34 thousand rubles will be required for paint per month.

The finished product is packed in bags. Such a container for 20 kg costs about 4.5 rubles. unit. At least 2.2 thousand pieces will be needed per month, that is, almost 10 thousand rubles must be allocated for their purchase.

Total additional tool will require about 1360 rubles, and for consumables - 44 thousand rubles. for a month of work.

Staff

The business also has the advantage that it is quite easy to find staff to work with. You can hire two workers per shift. At the same time, their qualifications do not matter - the work is simple and does not require special knowledge. Therefore, it is possible to recruit employees for production in the shortest possible time.

Financial side of the project

Summing up all the above, we can say that a business at the start will require a little more than a million rubles, namely:

- 873 thousand rubles for tools, equipment;

- 100 thousand rubles for the purchase of raw materials;

- 50 thousand rubles for opening and registration.

As for the revenue, it can be calculated based on the production of 2 tons per shift with 22 shifts per month. Accordingly, up to 44 tons of products can be manufactured per month. Sold colored gravel for 12 thousand rubles. per ton, subject to wholesale purchase, that is, the proceeds will be 528 thousand rubles.

The cost of 44 tons of crushed stone will be 110 thousand rubles. In this case, it is necessary to subtract 200 thousand rubles. for workers' wages and other expenses. Total remains 218 thousand rubles. net profit. That is, the business will pay off in about six months, if at least 20 tons of finished products are sold per month.

Colored gravel production technology quite simple, the main thing here is to purchase high-quality raw materials, the average fractions of which will be at least ten and not more than thirty millimeters, and paint over them acrylic paints. This is how colored (painted) crushed stone is obtained, which allows landscape designers to create real works of art in areas adjoining territory or summer playgrounds cafes and restaurants. Customers are very interested in the new design proposal, so this one has every chance of success.

An entrepreneur does not have to manufacture, produce and develop anything, it is enough to carry out work on painting ready-made particles, and an original and sought-after building decorative material is obtained. Raw materials that a businessman acquires for painting, already prepared and sorted in advance. Colored decorative gravel can be used in a variety of ways: as an element of landscape design of the local area, as a decoration for city squares, parks and streets, as fillers for aquariums or terrariums, and even for arranging the territory of a cemetery plot.

Most often, such material is purchased in large quantities, since it will take more than a dozen tons of rubble to process one park or house territory, the only case when a ton is enough is the improvement of a tomb or a place in a cemetery. When compiling a business plan for production, it is necessary to allocate in advance the target audience to which the activity will be oriented. Design material will surely interest you:

- Individuals who decide to equip the adjoining or household territory;

- Representatives of public utilities or green economy, for the purpose of original decoration of flower beds, lawns, paths made of colored gravel;

- Firms that are engaged in landscape design;

- Funeral services agencies;

- Citizens who breed animals have aquariums, cages or terrariums;

- Shops and salons for animals, in order to create non-standard design in the environment in which pets are kept.

Colored gravel production technology

The production of colored gravel is a simple process, but at the same time it consists of several stages, each of which has its own characteristics.

- Initially, the entrepreneur must purchase the source material, namely sorted crushed stone ranging in size from ten to thirty millimeters. If a certain size of granules is purchased, then in principle there is no need to sort such material. The production of colored crushed stone begins with the unloading of the source material into special containers, and then it is sent in certain portions on shovels for coloring. It is undesirable to keep the crushed stone in the air, without a canopy, as the material will become dirty, and it will be much more difficult to paint it. In order for acrylic paints to adhere well, the surfaces must be not only dry, but also clean. A standard KAMAZ will deliver fourteen tons of raw materials, and it is in such portions that most often they supply material for the production of colored crushed stone.

- Next, the fractions should be placed in paint containers, which are concrete mixers. If the volume of the unit is 0.7 cubic meters, then it will not be completely filled, but by half a cube, that is, almost half of the concrete mixer will remain empty. The technology for the production of colored gravel involves filling the container with acrylic paints, namely the shade that was originally chosen by the entrepreneur or customer. In order to produce two tons of finished material during one shift, you will need to load the machine three times during one day. You should not buy smaller concrete mixers, since such production of colored gravel will not be profitable, because more launches will have to be made.

- The stage of direct staining of the fractions begins, which lasts about fifteen minutes. Paint for the production of colored gravel covers the surface of the granules, after which it is necessary to dry the finished material, leaving time for excess paint to drain.

- To dry colored decorative gravel, it is proposed to use a rather large vibrating sieve. It should have a capacity sufficient to freely accommodate seven hundred kilograms of finished material, since that is how much one portion weighs, processed by one start of the unit. The vibrating sieve must certainly have a pallet, it is here that paint will flow for the production of colored gravel. This design is the most convenient and reliable, and the resulting designer gravel is painted evenly, and itself remains neat and clean. Feedstock can be purchased at a price of a thousand rubles per ton, but colored (painted) crushed stone is already sold for twenty-four thousand. Almost all customers carefully inspect the offered goods, therefore, in order for the production of colored gravel to bring a good income, it is necessary to control the quality of the material, avoiding even the slightest defect.

- When the material dries out, and the excess paint goes into the pallet, it must be relocated to a warehouse, which is basically identical to those bins where raw gravel is stored. You can immediately exclude the possibility of storage in the air - the technology for the production of colored gravel provides for the placement of the finished product only in covered areas. Otherwise, the product may lose value and external characteristics.

- The last stage is the process of packing the finished material into bags, weighing from five to twenty kilograms. Most often, this is done by production workers, wielding shovels. But such bags will be sewn up by a portable machine, which is specially focused on sewing up bags.

Equipment: production of colored gravel

Even for implementation business ideas with minimum investment , you will need specialized equipment, which costs a certain amount of money. Next, consider what an entrepreneur needs equipment: production of colored gravel involves the purchase of:

- Bunkers for starting material;

- Concrete mixers for coloring granules;

- Vibrating sieve, necessary for drying the finished gravel and dripping paints;

- Containers for finished products;

- Bag sewing machine.

If we combine the most cost-effective and high-quality models of the necessary equipment, then eight hundred seventy-one thousand rubles must be paid into the business plan, which will be spent on the purchase of equipment. With such equipment, the entrepreneur will have the opportunity to organize the production of colored crushed stone in the amount of ten cubic meters during one work shift.

In addition to the basic technical equipment, production of colored gravel also requires additional consumables and equipment. It's about about shovels and paints. An entrepreneur will need at least two shovels in order to paint gravel, a scoop type. With their help, the loading of raw materials for painting works is carried out, as well as the unloading of colored particles to the platform of the vibrating screen and, after drying, into containers for finished goods. It is optimal to buy 4 shovels at once, which will take no more than one and a half thousand rubles.

As for paints, naturally they are needed in sufficient quantity and assortment, because the production of colored gravel is based precisely on painting work. To produce two tons of material per day, you will need more than three hundred kilograms of paints, which are sold at one hundred and ten rubles per kilogram. Monthly, you will have to spend no more than thirty-five thousand rubles on paint. In addition, packing material is needed - two thousand two hundred bags, a capacity of twenty kilograms for thirty days. That will cost ten thousand rubles.

From this it follows that in production of colored gravel, in addition to the cost of equipment, you will also need to invest forty-four thousand on account of the material base, and one and a half thousand on tools.

Technical and economic side of the issue

Sale of colored gravel- a rather profitable line of business, if only due to the growth in demand for such a product among the citizens of the country. In order to organize such an enterprise, you will need to spend a little more than a million rubles, and this is taking into account business registration and related costs.

How profitable is the production of colored gravel? No more than two tons of material will be produced per shift, and twenty-two shifts per month, that is, the monthly volume of production will be forty-four tons. Prices for colored crushed stone on the wholesale market are twelve thousand per ton, while the amount of proceeds will be five hundred and thirty thousand rubles, and the cost of production will be one hundred and ten thousand.

For related expenses, such as rent, wages, taxes, and so on, about two hundred thousand are deducted monthly, while the profitability of the business is two hundred and eighteen thousand. As far as payback is concerned, production of colored gravel will pay off no later than in five months.