Calculation of heat gains from lighting systems. Installing an outdoor unit inside a glazed balcony

The outdoor unit of the air conditioner emits a large number of heat, so inside it is installed powerful fan, cooling air conditioner condenser by air flow. That's why outdoor unit air conditioner must be installed outdoors. In extreme cases, it can be installed on a glazed balcony, provided that the balcony has several opening windows and one of them is located opposite the outdoor unit fan.

However, this option is highly undesirable because summer period on the balcony, and so there is a “greenhouse” effect, and heat from the outdoor unit will be added to this microclimate. This will not only be uncomfortable for the user, but also unsafe for the air conditioner.

Most "warm" air conditioners can only operate in heating mode down to -5 °C. If the temperature drops below, then you can not turn on the air conditioner - the compressor may fail. Most Mitsubishi Electric models operate down to -10 °C for cooling and up to -15 °C for heating. However, there are special systems in the household series (Zubadan) that work for heating up to -25 °C.

In addition, as a heating device, unlike conventional electric heaters, the air conditioner is very efficient - for every 1 kW of electricity consumed, it produces up to 5 kW of heat. This happens because it does not burn electricity directly, like an electric heater, but uses it to “pump” heat from the street to the apartment. As a result, it becomes even colder outside, which is not very noticeable on a global scale, and it is warmer in your apartment.

First of all, you need to understand what system performance you need (see below for an express method for calculating heat gains). Further, the choice is based on the system functions that you need (Plasma Quad air purification system, 3D I SEE Sensor, able to recognize the location of a person and, depending on this, direct the air, attractive appearance, the presence or absence of a heating mode, with or without an inverter, etc.). Representatives of our authorized dealers will help you to choose the most qualified air conditioner. You can find their contacts at the link: (section "Contacts").

Express method for calculating heat gains

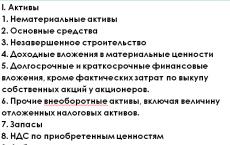

The main heat gains are made up of the following components: Q = Q1+Q2+Q3.

1) heat gains Q1, arising due to the temperature difference between indoors and outdoors, as well as solar radiation, are calculated by the formula:

Q1=V x Qsp, where V=S x h

S is the area of the air-conditioned room;

h is the height of the room;

Qsp is the specific heat of the load, it is taken as:

- 30-35 W / m2 - if there is no sun in the room;

- 35-40 W / m2 - if there is a large glazing on the sunny side;

On average, 300 W is taken per 1 computer (system unit + monitor) or 30% of the equipment power;

3) heat gains Q3 arising from people in the room. It is usually assumed for calculations that 1 person is 100 W at rest (for example, in an office) and 200-300 W at physical activity(restaurants, gyms, etc.).

Q=Q1+Q2+Q3

20% is added to the resulting value for unaccounted for heat inflows, i.e. Qtot = (Q1 + Q2 + Q3)x1.2. In the case of using additional heat-producing equipment in the room (electric stoves, production equipment, etc.), the corresponding heat load must also be

included in this calculation.

This express method is intended for an approximate calculation of heat gains into the room. An exact calculation taking into account the properties of enclosing structures, ceilings, glazing area, heat gain from solar radiation, etc. can be found on the website www.mitsubishi-aircon.ru in the "On-line programs" section.

Mitsubishi Electric has always paid great attention to the management and integration of its air conditioning systems into various systems dispatching. In 2012, Mitsubishi Electric introduced a new MELCloud feature that allows the user to control Mitsubishi Electric air conditioners from anywhere in the world. It allows you to monitor the operation parameters of ME air conditioning systems and control them using any of the currently existing devices: PC, netbook, smartphone, etc.

MELCloud technology is supported by almost all smartphones manufactured by Apple, Samsung, Blackberry, etc., enabling quick access and control of the operation of climate technology, for example, on the road or relaxing on the couch. With it, you can remotely:

- turn on/off the system;

- choose the mode of operation;

- change the fan speed;

- fix the position of the air blinds (horizontal or vertical);

- see the values of the set and actual temperature in the room;

- receive real-time weather information;

- turn on / off the standby heating mode;

- set the function "Weekend mode";

- program the weekly timer.

We recommend cleaning the indoor unit of the air conditioner every three months. This will maintain its performance and energy efficiency. In the FH (Deluxe) series, it is enough to wash the deodorizing and anti-allergic filters in warm water (the manufacturer recommends replacing the filters with new ones once a year). In the Standard series, the antioxidant filter is recommended to be cleaned every two weeks. In addition to filters, it is recommended to clean the indoor unit itself. Unique design Mitsubishi air conditioners Electric allows you to clean even the fan impeller yourself.

A properly selected air conditioner will be able to cool the room in an average of 5-15 minutes with normal conditions. Most important indicator is peak load operation. Let's say you enter a room that has been warmed by the sun for several hours. It is here that the speed of the block exit to the regime will be important. So, for example, the MSZ-FH25VA unit can operate in the performance range of 1.4–3.5 kW, i.e. at peak loads, you get an air conditioner with a capacity of not 2.5 kW, but 3.5 kW (when heating - 5, 5 kW).

With a decrease in heat influx into room 138, the performance will be reduced to 1.4 kW, i.e. there will be no hypothermia. As for the temperature - up to the one that will be set on the control panel. In the household series, the minimum temperature is 16 °C.

In the process of assembling air conditioners at all Mitsubishi Electric plants, a unified quality control system has been introduced. It provides for a complex of step-by-step testing of air conditioners during the assembly process, as well as testing of each assembled air conditioner on a test bench before leaving the assembly line. If at some stage of testing a deviation from the standard is noticed, the block is sent to investigate the causes. This optimizes the entire production technology. Therefore, such a thing as marriage is excluded. We also note that each batch of air conditioners is tested for stability in difficult conditions (800 hours, 500 hours, etc.).

Each person perceives noise differently. And it depends on many parameters, including even the material of the wall to which the indoor unit is attached. The market leader in terms of minimum noise level is Mitsubishi Electric. The units of the Standard Inverter MSZ-SF25 series have a noise level of 21 dB(A).

For an objective comparison of the noise level of different manufacturers, it is worth paying attention to the air flow, since the lower the noise, the lower the flow and, accordingly, the performance of the unit. When designing Mitsubishi Electric indoor units, subjective human feelings were also taken into account. For example, the noise spectrum is chosen in such a way as to suppress the most perceptible frequencies. In addition, plastic creaking or the movement of air distribution dampers can cause discomfort. To prevent this from happening, Mitsubishi Electric uses only high-quality plastic, which has the properties of minimal thermal deformation, optimizes the shape of body parts, and uses noise and vibration insulating material in some indoor units.

It is necessary to distinguish between the operation of the air conditioner in winter in heating mode and in cooling mode. In the heating mode at a low outdoor temperature, the heating capacity of the air conditioner decreases, its energy efficiency decreases, and the service life may decrease. No additional installed devices will help a conventional air conditioner work more efficiently in winter.

Mitsubishi Electric air conditioners can operate in winter in heating mode at temperatures up to -15 °C...-20 °C (Standard Inverter, Deluxe Inverter series) and even down to -28 °C (Zubadan series). At the same time, the heat output and energy efficiency remain at a high level, and the service life of the air conditioner does not decrease. In cooling mode, when the outdoor temperature is low, the condensing pressure is greatly reduced, so the air conditioner may turn off or even break down.

In order to expand the operating temperature range of the air conditioner in cooling mode, some installers install the so-called "winter kits" on their own. Air conditioners of the Standard Inverter and Deluxe Inverter series are already equipped with all the necessary devices that allow them to be used in cooling mode at temperatures down to -10 °C.

If it is necessary to ensure the operation of the air conditioning system in cooling mode at a temperature environment down to -30 °C, a low-temperature kit is installed, consisting of a fan speed controller and three self-regulating electric heaters: for the compressor crankcase, for the throttling element and for the drain hose. A complete set of documentation on the results of tests of systems in a climatic chamber can be obtained from distributors.

Distributor companies carry out the installation of low-temperature kits in outdoor units MU-GF VA manufactured by Mitsubishi Electric by prior order.

Such cases are extremely rare. However, user safety has always been a top priority at Mitsubishi Electric. That is why each indoor unit has additional measures preventing the occurrence of emergencies:

1 - Fee indoor unit placed in a metal case to cut off sparks from plastic surfaces devices. This design is an additional protection against ignition of the plastic case and, as a result, emissions of toxic gases.

2 - Side printed circuit board(the plane on which there is soldering) does not have direct contact with the metal case (an insulating element is provided to which the board plate is rigidly attached). This eliminates the possibility of a short circuit, and consequently, fire.

3 - The electrical part (socket for connecting the power cable and control cable, control board) is closed with a metal casing - SafetyBox. This measure is an additional protection against fire.

Yes, during power surges, the air conditioner control boards, as well as the compressor, can fail. Mitsubishi Electric air conditioners are reliably protected and can operate in a wide voltage range. This is possible through the use of a switching power supply and a microcircuit - a voltage monitor on the control board.

If the air conditioner is turned off due to a power failure, all information about the state of the air conditioner is stored and the air conditioner automatically starts working after the power is restored in the same mode and with the same settings that were before the power failure. It should be noted that Mitsubishi Electric air conditioners store all information in non-volatile flash memory, so the information will be stored not for several hours, as is the case with many other air conditioners, but for an unlimited time. This is especially important in cases where the air conditioner is installed in server rooms and similar rooms.

There is! – Option.

European market research has shown that most users never change the special anti-allergic, electrostatic, etc. filters in their air conditioners. After a few months of operation, the effect of replaceable filters is not only completely lost, but they can become a source of mold and odors. That's why Mitsubishi Electric offers either expensive Plasma Quad filters in the Deluxe series or simple antioxidant filters in the standard models. Both filters can be washed periodically, and the Plasma Quad filter will also remind you of this with an indicator on the control panel.

The declared noise performance (sound pressure), which can be found in the manufacturer's catalogs, is based on the results of testing a prototype in the laboratory. In reality, the user can hear sounds at certain frequencies that were not taken into account in the tests, but are extremely unpleasant for humans. When testing, the microphone is located in a certain place in front of the air conditioner unit. It may turn out that the noise level at another point will be higher than the measured one.

During operation, cracking of the plastic case may occur due to temperature deformations. In general, many believe that the characteristic crackling of plastic during air conditioning operation cannot be avoided. This is not true. Mitsubishi Electric air conditioners use high-quality plastic with a minimum coefficient of thermal expansion. Moreover, in order to completely eliminate crackling, the plastic from the inside of the blocks is glued with special strips of 134 damping material.

Mitsubishi Electric has its own noise measurement labs in all of its air conditioning plants. Tests are subjected not only to prototypes, but also selective serial products. Therefore, the buyer can be sure that the noise level declared by the manufacturer will not be exceeded in reality.

The size of the indoor unit is determined by the size of the heat exchanger and the space required for uniform air flow around the entire surface of the heat exchanger. If the heat exchanger is made compact, then in order to maintain the performance of the air conditioner, it will be necessary to increase the air flow by increasing the fan speed, but this will increase the noise level.

Mitsubishi Electric prioritizes low noise levels and therefore increases the size of the fan and heat exchanger. To ensure silent operation, the diameter of the fan of the indoor unit is increased to 106 mm, which makes it possible to achieve the required air flow at a lower linear speed of the blades. In addition, the design of the blades has been optimized, the shape of the heat exchanger has been changed.

It should be noted that it is possible to achieve at the same time a low noise level with a compact heat exchanger by lowering the air flow. This is used by some manufacturers of air conditioners. However, in this case, the performance of the air conditioner at a low fan speed becomes lower than the declared one. Mitsubishi Electric guarantees that the air conditioner performance declared by the company is achieved even at low fan speeds with minimal noise levels.

The ideal outdoor unit of the air conditioner should be large and heavy to ensure high energy efficiency and crash resistance. In practice, a trade-off must be found between reliability, performance and cost... Reducing the size of the outdoor unit can be achieved by reducing the size of the heat exchanger, compressor and hydraulic circuit.

Most often, this leads to a decrease in the energy efficiency of the entire system, low compressor power reserves at peak loads and the absence of air conditioner protection mechanisms. Some manufacturers improve the parameters of the compact outdoor unit by using special heat exchanger plates with external fins. However, this inevitably leads to rapid fouling of the heat exchanger, which cannot be dealt with by simple washing. Heat exchangers with flat aluminum fins create very low resistance to passing air and stay clean for a long time. This increases the time interval between preventive maintenance, reduces their cost and increases the energy efficiency of the system in operation. Mitsubishi Electric does not compromise on the reliability and energy efficiency of its air conditioners.

The outdoor units have the weight and dimensions required for optimal performance air conditioner throughout its life.

The inverter allows the compressor to smoothly change the speed, so the performance of the air conditioner and its power consumption also change smoothly. This provides several advantages over conventional air conditioners, in which the compressor cycles on and off.

Firstly, the inverter allows you to reduce the average annual electricity consumption by 20-30%.

Secondly, the inverter does not have inrush currents, which is very important in apartments and offices with poor electrical wiring. For inverterless air conditioners, the starting current can be 2-3 times higher than the rated current. Thirdly, the inverter air conditioner, when turned on, cools or heats the room faster than a conventional one. This is because the inverter compressor can operate in "boost" mode, increasing the speed above the nominal. This "power reserve" is an important indicator for an inverter air conditioner. For example, the deluxe model MSZ-FH25VA has a nominal capacity of 2.5 kW in cooling mode and 3.2 kW in heating mode. And the peak values are respectively 3.5 kW and 5.5 kW. This means that if necessary, this air conditioner can produce 70% more heat per unit of time than stated in its characteristics. It should be noted that operation in this mode does not affect the service life of Mitsubishi Electric air conditioners.

Customers often write to us asking numerous questions. Very often, questions are repeated, and so that many people learn about them, we have created a page on our website where the company's specialists will answer a variety of questions:

Ask a Question

Submit an application

Please wait, shipping in progress...

As well as air conditioning systems is calculated adjusted for the parameters of related engineering systems, which are installed on the serviced objects. In particular, when calculating, it is imperative to take into account the lighting system, which especially affects the air conditioning system.

The included lighting equipment is a source of heat influx. Over the past few years, the Russian government has approved a number of regulations directly or indirectly related to lighting systems.

Eight years ago, the state began to actively develop energy-saving technologies. Yes, throughout long term discussed the massive use of energy efficient lighting systems that were supposed to replace incandescent lamps. Initially, the authorities headed for the rejection of lamps, the performance of which is more than one hundred watts. Further, lamps with a return of 75 watts should have disappeared from the store shelves. Three years ago, the government wanted to ban lamps over 25 watts.

Despite attempts to change policy energy efficiency, the initiators of the introduction of fluorescent lamps could not achieve their goal, since such lighting equipment is expensive, has problems with disposal and contains mercury. As a result, four years ago, the Russian authorities approved a document providing for the phase-out of incandescent lamps. The rate of elimination of such devices was influenced by their efficiency and scope. At the same time, the document did not name specific terms for the complete rejection of lamps.

However, the active struggle for energy efficiency continued, which became a prerequisite for the release of a new Code of Practice describing modern requirements for the organization of lighting systems.

Details about the Code of Practice 52.13330.2011

Code of Practice 52.13330 2011 is dedicated to natural and artificial lighting. He came to replace the Code of Rules and Regulations 23-05 1995 edition. Fundamentally, it differs from the previous document in two details.

First of all, in comparison with the old document, the tasks of the draft law No. 384-FZ (issued at the end of December 2009), dedicated to the technical regulations for the safety of construction projects, are taken into account. The concept of normative document No. 184-FZ (developed at the end of 2002), which provides for technical regulation, is also taken into account. In addition, the Code of Practice is in line with the requirements of the draft law No. 261-FZ (created in November 2009), which regulates the conservation of energy and the increase in energy efficiency.

Thus, the energy efficiency norms approved by the legislation have become official specific requirements.

Also Code of Practice 52.13330 partly inherits the prescriptions of the European regulatory framework in order to determine using a common methodology performance characteristics and evaluation methods. At the same time, as it was before, the document specifies the norms for natural, artificial and combined lighting of construction sites. In addition, there are rules for artificial lighting of residential and industrial areas, as well as open work areas.

The course towards the use of energy-saving technologies, initiated by the officials, was also reflected in the regulatory documents on the lighting of buildings. In particular, the artificial lighting part of Code of Practice 52.13330 calls for the use of energy-saving light sources. If several sources have the same power, the one that has the highest light output and service life is selected.

At the same time, the requirements for lighting were extremely carefully connected with the theses of energy efficiency. So, warehouse and production facilities were forbidden to be equipped with incandescent lamps. In addition, the provision of limits on the specific performance of lighting equipment at production-type facilities has been tightened (see Table 1).

With regard to the specific power installed in public buildings lighting equipment, this figure remained unchanged. To do this, you can compare table 10A of Code of Practice 23-05 with table 9 of Code 52.13330.

AT Table 1 You can familiarize yourself with the requirements for the permissible specific power of buildings for public and industrial purposes.

Table 1. Maximum permitted indicators of specific power of lighting equipment used at construction sites of public and industrial type (based on Code of Practice 52.13330)

| Lighting level in the working area, lux | Room index | Maximum permitted specific power, W / m 2 | |

| Industrial premises | public spaces | ||

| 750 | 0,6 | 37 | - |

| 0,8 | 30 | - | |

| 1,25 | 28 | - | |

| 2,0 | 25 | - | |

| 3 or more | 23 | - | |

| 500 | 0,6 | 35 | 42 |

| 0,8 | 22 | 39 | |

| 1,25 | 18 | 35 | |

| 2,0 | 16 | 31 | |

| 3 or more | 14 | 28 | |

| 400 | 0,6 | 15 | 30 |

| 0,8 | 14 | 28 | |

| 1,25 | 13 | 25 | |

| 2,0 | 11 | 22 | |

| 3 or more | 10 | 20 | |

| 300 | 0,6 | 13 | 25 |

| 0,8 | 12 | 23 | |

| 1,25 | 10 | 20 | |

| 2,0 | 9 | 18 | |

| 3 or more | 8 | 16 | |

| 200 | 0,6-1,25 | 11 | 18 |

| 1,25-3,0 | 7 | 14 | |

| over 3 | 6 | 12 | |

| 150 | 0,6-1,25 | 8 | 15 |

| 1,25-3,0 | 6 | 12 | |

| over 3 | 5 | 10 | |

| 100 | 0,6-1,25 | 7 | 12 |

| 1,25-3,0 | 5 | 10 | |

| over 3 | 4 | 8 | |

Note. The room index is understood as a value that is determined taking into account the size of the room and the height of the lighting equipment. Data on the index of the premises are in the supplementary MGSN 2.06 1999 issue of the manual. To do this, it has a table 1.9.1. In general, the document is devoted to the design and calculation of artificial lighting for public premises.

If the index of the room or the level of illumination does not correspond to any of the table values, the maximum specific power of artificial light is determined by interpolation.

Alternatively, the following formula can be used to determine the room index:

ϕ = S / ((h room - h light) * (a + b)).

Based on the formula, S is the area of \u200b\u200bthe room, measured in square meters X; h rooms - the height of the room, measured in meters; h light - the height of the lighting equipment, measured in meters; a and b - the length and width of the room, measured in meters.

Methods for calculating heat inflows from lighting equipment

Specialists involved in ventilation and air conditioning are more interested in the correct calculation of heat inflows coming from the lighting equipment installed in each individual room.

Practical experience indicates the existence of four main ways to calculate heat gains from lighting, which are justified:

- Using the information provided in the terms of reference or project documentation.

- Simplified calculations for the size of the room.

- Detailed calculations of heat inflows based on Code of Practice 52.13330.

- Detailed calculations of the performance of fluorescent lighting fixtures.

These methods require detailed consideration.

Using the terms of reference or project of the lighting system

This method is the best, as it provides maximum accuracy for each individual project documentation. During the creation of the terms of reference for the air conditioning system, the exact performance of all lighting devices that create heat inflows.

As an alternative, the performance taken from the terms of reference for the lighting system is used. The obtained values are used in further settlement operations.

The third option is to contact the appropriate specialist in order to obtain the performance values of the lighting equipment. This is done during the implementation of the lighting system project.

The main advantage of all the above solutions can be considered the receipt of information taken from the design documentation that is being developed for a specific construction site. In this regard, the data used in the calculations are extremely accurate.

Simplified calculation of the size of the room

This method involves the use of average values of specific heat inflows. To calculate the heat load created by lighting equipment, the following formula is used:

Q light = q light * S.

In this formula, q lighting is the heat inflows per "square" of the area of the illuminated room; S is the illuminated area of the room, measured in square meters.

If incandescent lamps are used, the value of heat influx is 25 watts per square meter. In the case of using luminescent analogues, this value is 10 watts per "square".

This method is less accurate, since its use does not take into account the geometry of the room and the height of the lighting equipment. At the same time, it can be used to estimate the order of intensity of heat inflows.

Detailed calculation of heat inflows according to Code of Practice 52.13330

Rulebook 52.13330 does not have a specific method for calculating a lighting system, but it is supplemented by tables that indicate the limiting specific performance of artificial lighting. Given the nominal illumination and the index of the room, calculated on the basis of its geometry, it is possible to calculate the maximum specific performance of the lighting system. To obtain the maximum permissible lighting power, it is necessary to take the area of \u200b\u200bthe room and multiply it by the maximum specific performance of the lighting system. This value also reflects the heat input for the air conditioning system.

It should be emphasized that this method is characterized by high accuracy, since its use takes into account the geometric parameters of the room: its area, height, shape, and so on. It is quite obvious that rooms of the same area, but of different heights, will differ in the level of heat inflow. The reason for this is the use of more efficient lighting equipment in high rooms.

Detailed calculation of the performance of fluorescent fixtures

Many designers are extremely interested in learning how to calculate the performance of energy efficient lighting equipment. We offer to master the simplest and most understandable technique that can be used even by people who are not in depth in the study of lighting and power supply systems.

The performance of a lighting system is measured in watts and is determined by the formula:

N lighting \u003d (E * S * K zap * N l) / (U * F l).

In this formula: E is the required horizontal illuminance, measured in lux (to determine it, regulations; if the room is an office, the illumination is three hundred lux); S is the area of the room, measured in square meters; Kzap is a safety factor that allows you to take into account the decrease in the flux of light during operation or contamination of the lamps, as well as in other cases (recommended value - 1.4); U is the utilization factor for the light emitted by the lamp (there is a table 2); N l is the power of the lamp, measured in watts; F l is the luminous flux of the lamp, measured in lumens (if the lighting equipment includes four fluorescent lamps with a capacity of eighteen watts, the value of the luminous flux will be in the range of 2.8-3.0 thousand lumens).

Table 2. Determination of the utilization factor of the light flux, taking into account the index of the room and the reflection coefficients of ceiling and wall, as well as floor ceilings

|

Coefficient reflections floors |

Ceiling | 80 | 80 | 80 | 70 | 50 | 50 | 30 | 0 |

| Wall | 80 | 50 | 30 | 50 | 50 | 30 | 30 | 0 | |

| Outdoor | 30 | 30 | 10 | 20 | 10 | 10 | 10 | 0 | |

| Room index | 0,6 | 53 | 38 | 32 | 37 | 35 | 31 | 31 | 27 |

| 0,8 | 60 | 15 | 38 | and | 41 | 38 | 37 | 34 | |

| 1 | 65 | 51 | 43 | 49 | 46 | 43 | 42 | 38 | |

| 1,25 | 70 | 57 | 49 | 54 | 51 | 48 | 47 | 44 | |

| 1,5 | 72 | 61 | 52 | 57 | 54 | 51 | 51 | 47 | |

| 2 | 76 | 66 | 56 | 61 | 57 | 55 | 54 | 51 | |

| 2,5 | 78 | 70 | 59 | and | 60 | 58 | 57 | 54 | |

| 3 | 80 | 73 | 62 | 67 | 62 | 60 | 59 | 57 | |

| 4 | 81 | 76 | 64 | 69 | 63 | 62 | 61 | 58 | |

| 5 | 82 | 78 | 65 | 70 | 65 | 64 | 62 | 60 |

Note. Table 3 is used to obtain the floor reflectance.

To determine the index of the room, you need to look at the note to Table 1.

The value of the height of the lighting equipment is 0.8 meters. This value is equivalent to the average table height.

Table 3. Determination of the reflection coefficient corrected for the color of the coating

Calculation of heat inflows from lighting equipment on a specific example

An example is a real office-type premises with workplaces.

The room has a length of 9.6 meters and a width of 6 meters. Thus, the area is 57.6 square meters with a height of 3.3 meters for the fixtures. The ceiling surface is painted white, the walls are light colors and the floor is gray. At the same time, the tables located in the room have a height of 0.8 meters.

The room is equipped with eighteen lamps with four fluorescent lamps in each. The performance of each lamp is eighteen watts. The level of illumination is at the most comfortable level, as the illumination falls on all tables without exception.

If you follow the first method, you need to calculate the number of lighting equipment, followed by determining the power consumption. Heat inflows are:

N 1 \u003d N * n * N l \u003d 18 * 4 * 18 \u003d 1.3 kilowatts.

According to the third method, the performance of lighting equipment is defined as:

N 2 \u003d q lighting * S \u003d 10 * 57.6 \u003d 0.6 kilowatts.

The second method is related to the data prescribed in the Code of Practice 52.13330. First of all, you need to determine the index of the room:

φ \u003d S / ((h room - h light) * (a + b)) \u003d 57.6 / ((3.3 - 0.8) * (9.6 + 6)) \u003d 1.48.

If the illumination is equal to three hundred lux in public buildings (the value is taken from Tables 1), interpolation of room indices j of 1.25 and 2 gives a maximum possible specific performance of 19 watts per square meter.

N 3 \u003d N 2 specific * S \u003d 19 * 57.6 \u003d 1.1 kilowatts.

The fourth technique involves the use of data on the color of wall, ceiling and floor coverings. The determination of the reflection coefficients of the ceiling, floor and wall surfaces is carried out according to Table 3. Thus, they will be 75, 50 and 30. As for the luminous flux utilization factor, it is 0.61. For its calculation, data are taken from Tables 2(reflection coefficients are 80, 30 and 50, and the room index is 1.5).

Taking the illumination as three hundred lux, we calculate the performance of lighting equipment:

N 4 \u003d (E * S * K zap * N l) / (U * F l) \u003d (300 * 57.6 * 1.4 * 72) / (0.61 * 2850) \u003d 1 kilowatt.

The use of four methods brought rather conflicting data in the range of 0.6-1.3 kilowatts.

As mentioned above, the most accurate way is considered to be obtaining data from real project documentation on lighting systems. The third and fourth methods showed similar results. At the same time, their difference from the first method was more than twenty percent. It should be emphasized that when calculating according to the third and fourth methods, the illumination was three hundred lux. However, in the initial data, almost the maximum level of illumination was indicated. Without carrying out measuring procedures, it is clear that the illumination level is more than three hundred lux. This was the reason for the prevalence of actual lighting costs over calculated ones. If we take the lighting level of four hundred lux, the results of the first, third and fourth methods will be very similar.

Speaking of the third method for calculating the performance of the lighting system, the largest deviation should be indicated. The difference in values is due to the outdated power density factor and the general surface approach, which does not take into account the height of the room and the level of shading of wall, floor and ceiling surfaces. It should be borne in mind that in our time, indoor lighting systems are being developed with excessive power of lighting equipment. In addition, ideas about comfortable lighting have seriously changed. Taken as a previously comfortable level of illumination in this moment considered low. Therefore, new office premises are equipped with powerful lighting equipment, which gives more intense heat inflows.

As a supplement, it must be said that the first calculation method is ideal for modern construction projects, where the premises are equipped with complex lighting systems, providing for the presence of main light, local lighting and decorative lighting. Thus, each of these lightings differs in power, the type of light sources used and the variability of use: some of the equipment emits light rays constantly, while the rest of the devices are turned on only for a certain time. From this we can draw the following conclusion: in order to get a general idea of the lighting of the premises, it is necessary to interact with the engineers of the design department of specialized firms, thereby obtaining data on the performance of the system.

Disputes during calculations of heat inflows from the lighting system

Despite the long existence (for six years) of the Code of Practice 52.13330, as practice has shown, this document is not the main one for related areas. Project developers are already accustomed to tracking changes in regulatory documents related to certain subsystems. Therefore, updated standards describing adjacent engineering systems are taken into account very rarely.

So, during the approval of one of the project documentation for air conditioning, the customer did not like the overestimated value of the refrigeration capacity, due to increased heat inflows, in the creation of which lighting also took part. Despite the small number of heat inflows from the lighting system, the result was tens of kilowatts.

At the same time, there was no approved project for the lighting system, and the customer accused the engineers of using outdated methods for calculating heat inflows. The new design team was faced with the task of using up-to-date regulatory documents to correctly calculate the refrigeration capacity of system air conditioners. As a result, Code of Practice 52.13330 helped to solve the problem.

As an example, we can take another construction project, which was also associated with the problem of excessive performance of the air conditioning system. Only in this case the reason lay in the loss of thermal energy, part of which was retained in the ceiling space, not getting into the working area of the room. If a device for extracting hot air is installed in the ceiling area, this solution contributes to significant savings in the cooling capacity of air conditioners.

We can agree with this factor, but we must remember that the only source of thermal energy is the lamp, and not any other part of the lighting equipment. When designing luminaires, the maximum penetration of the light beam into the room is taken into account. To this end, the upper part of the lamp is equipped with a light reflector, which reflects not only light energy, but also heat. It follows from this that the air heated in the ceiling space does not play such a significant role as it seems in reality.

Reflection of the light flux in an office lamp

findings

Specialists involved in the design of engineering systems should take into account the actualization normative documentation in related areas, one of which is the lighting system. Code of Practice 52.13330 dedicated to natural and artificial lighting can be gleaned useful information on the ultimate specific performance of lighting systems installed in public and industrial buildings. The document helps to justify the heat inflows generated by the lighting system.

Useful for specialists in the design of lighting systems will be information on how to calculate thermal emissions from lighting equipment. It should be noted once again that in complex conceptual solutions of lighting systems, when calculating heat inflows, it is rational to take data on energy parameters from the finished design documentation of lighting systems. This will allow you to get the most accurate calculations.

Based on materials from the magazine "Climate World"

- Forward

Power (more precisely, cooling power) is the most important characteristic of any air conditioner. The area for which it is designed, as well as the cost of the air conditioner, depends on this value. The calculation of power consists of several stages.

Determination of the approximate power of the air conditioner

Define estimated power household air conditioner is very easy - for every 10 sq.m. the refrigerated space requires 1 kW of power. with a ceiling height of 2.8 - 3.0 m. That is, to calculate the power of the air conditioner, it is enough to divide the area of \u200b\u200bthe room by ten: 2.0 kW is required for 20 sq.m, 4.5 kW for 45 sq.m, etc. d. This simplified technique determines the required power to compensate for heat gains from walls, floors, ceilings and windows.

Accounting for the side facing the windows

If the room has a large glazing area or windows face the sunny side, then the heat gain will be greater and the power must be increased by 15 - 20%.

Q = S*h*q, where

Q- heat gains (W);

S- area of the premises (sq.m);

h- room height (m);

q- a coefficient equal to 30 - 40 W / kb.m (for the south side - 40, for the north - 30, the average value is 35 W / kb.m).

Note that these calculations are applicable only for capital buildings, since it is almost impossible to air-condition an iron stall or a store with a transparent roof - on a sunny day, heat gains from walls and ceilings will be too large.

Accounting for heat generated by people and electrical appliances

It is believed that in a calm state, a person emits 0.1 kW of heat; computer or copier - 0.3 kW; for other devices, we can assume that they emit 1/3 of the nameplate power in the form of heat. Summing up all the heat releases and heat gains, we get the required cooling capacity.

Example: we will calculate the air conditioner for a typical living room with an area of 26.0 sq.m (ceiling height 3.0 m) in which there are two people and a computer.

To compensate for heat inflows from walls, windows, floors and ceilings, you must:

26.0 sq.m * 3.0 m * 35 W / kb.m = 2.73 kW.

To compensate for the heat generated by people and the computer, you must:

0.1 kW * 2 = 0.2 kW (from people) and 0.3 kW (from computer)

In total, we summarize all heat releases and heat gains:

2.73 kW + 0.2 kW + 0.3 kW = 3.23 kW.

Now it remains only to choose an air conditioner model close in power from the standard range - by 3.5 kW (most manufacturers produce air conditioners with capacities close to the standard range: 2.0; 2.5; 3.5; 5.0; 7.0 kW). By the way, models from this series are usually called "seven", "nine" ... "twenty-four". These numbers are present in the names of air conditioners of most manufacturers and indicate their power not in the usual kilowatts, but in thousands of BTU (British Thermal Unit).

1 BTU is equal to 0.3 W (0.2931 W to be exact). Accordingly, an air conditioner with a capacity of about 7000 BTU or 7000 * 0.3 = 2.1 kW will have the number 7 in the name, etc. At the same time, some manufacturers, such as Daikin, link the name of the models to the typical power in watts (the Daikin FTY35 air conditioner has a power of 3.5 kW).

Power calculation

Power calculation

Online calculator for calculating the power of the air conditioner

Calculation of the cooling capacity of a domestic air conditioner (simplified calculator):

Approximate selection table by area and power:

After choosing the type of air conditioner, it is necessary to determine the required cooling capacity. This parameter is the main characteristic of any air conditioner.

Cooling (heating) power is the main characteristic of the air conditioner. When choosing an air conditioner, first of all, it is the required cooling capacity that is calculated. It depends on the power whether this or that air conditioner will reach the required temperature in your room and how long it will serve you. Solar radiation, walls, ceiling, floor, electrical appliances, people - they all generate heat that must be compensated to achieve a comfortable temperature.

The simplified formula for calculating the required power looks like this - the area of \u200b\u200bthe room is divided by 10 and the result is the required value (in kW) for cooling this room (it is used to calculate the cooling power of small living rooms with a ceiling height of up to 3m). A person emits from 100 to 300 W of heat (depending on his activity), a computer emits 300 W, the heat dissipation of the rest of the equipment can be taken as half of the nameplate power.

An approximate calculation of the cooling power Q (in kilowatts) is carried out according to the generally accepted method:

Q = Q1 + Q2 + Q3,

Q1 - heat gains from the window, walls, floor and ceiling.

Q1= S * h * q / 1000, where

S - room area (sq. m);

h is the height of the room (m);

q - coefficient equal to 30 - 40 W / m³ - coefficient of the degree of illumination by sunlight, equal to:

q \u003d 30 - for a shaded room - weak (30 W / m³) - if the sun's rays do not enter the room (north side of the building);

q \u003d 35 - with average illumination - average (35 W / m³) - under normal conditions;

q \u003d 40 - for rooms that get a lot sunlight. If direct sunlight enters the room, then the windows should have light curtains or blinds - strong (40 W / m³)

Calculation by this method is applicable for small offices and apartments, in other cases, calculation errors can be significant.

Heat gains from an adult:

Q2- the sum of heat gains from people.

- Rest in a sitting position - 0.120 kW

- slow dancing- 0.260 W

- Moderately active work in the office - 0.140 kW

- Light work in a sitting position - 0.130 kW

- Light work in production - 0.240 kW

- Light standing work - 0.160 kW

- Work of medium severity in production - 0.290 W

- Heavy work - 0.440 kW

Heat gains from household appliances:

Q3- the sum of heat gains from household appliances

Heat gains from office equipment typically account for 30% of the power input.

For example:

- Computer - 0.3 - 0.4 kW

- Copier - 0.5 - 0.6 kW

- Laser printer - 0.4 kW

- TV - 0.2 kW

Heat inflows from kitchen appliances:

- Coffee machine and electric kettle - 0.9 - 1.5 kW

- Coffee maker with heating surface - 0.3 kW

- Waffle iron - 0.85 kW

- Electric stove - 0.9 - 1.5 kW per 1 m 2 of the upper surface.

- Gas stove- 1.8-3.0 kW 1 m 2 of the upper surface.

- Toaster - 1.1 - 1.25 kW

- Fryer - 2.75 - 4.05 kW

- Grill - 13.5 kW per 1 m 2 of the upper surface

When calculating heat gains from kitchen appliances, it should be taken into account that all appliances at the same time, as a rule, are not turned on. Therefore, the maximum power combination for a given kitchen is taken into account. For example, three of the four burners on the kitchen electric stove and a coffee machine.

For other appliances, it can be considered that they emit as heat 30% of the maximum power input (i.e. it is assumed that the average power input is 30% of the maximum). The power of the selected air conditioner should be in the range from -5% to +15% of the calculated power Q. Note that the calculation of the air conditioner using this method is not very accurate and is applicable only for small rooms in capital buildings: apartments, separate rooms of cottages, office premises up to 50 - 70 sq. m.

For administrative, trade and industrial objects, other methods are used that take into account a larger number of parameters.

Accounting for the influx of fresh air from an open window.

The method by which we calculated the power of the air conditioner assumes that the air conditioner operates with the windows closed and fresh air does not enter the room. The instructions for the air conditioner usually also say that it must be operated with the windows closed, otherwise outside air, getting into the room, will create an additional thermal load. Following the instructions, the user has to periodically turn off the air conditioner, ventilate the room and turn it on again. This creates some inconvenience, so buyers are often interested in whether it is possible to make both the air conditioner work and the air be fresh.

To answer this question, we need to understand why the air conditioner can work effectively together with supply ventilation, but cannot - with the window open. The fact is that the ventilation system has a certain capacity and delivers a given volume of air into the room, so when calculating the power of the air conditioner, this heat load can be easily taken into account. With an open window, the situation is different, because the volume of air entering the room through it is not normalized in any way, and the additional heat load is unknown.

You can try to solve this problem by setting the window to the winter ventilation mode (opening the window slightly) and closing the door in the room. Then there will be no drafts in the room, but a small amount of fresh air will constantly flow inside. Let us immediately state that air conditioner operation with open window is not provided by the manual, so we cannot guarantee the normal operation of the air conditioner in this mode. However, in many cases this technical solution will keep indoors comfortable conditions without occasional ventilation.

If you plan to use the air conditioner in this mode, then you need to consider the following:

- The power Q1 must be increased by 20 - 25% to compensate for the heat load from supply air. This value is based on a single additional air exchange at an outdoor temperature/humidity of 33°C/50% and an indoor air temperature of 22°C.

- Electricity consumption will increase by 10 - 15%. Note that this is one of the main reasons for the prohibition of the operation of air conditioners with open windows in offices, hotels and other public places.

- In some cases, the heat gain may be too large (for example, in very hot weather) and the air conditioner will not be able to maintain the set temperature. In this case, the window will have to be closed.

- It is advisable to choose an inverter air conditioner as it has a variable cooling capacity and will operate efficiently over a wide range of heat loads. A conventional (non-inverter) air conditioner with increased power, due to the specifics of its work, can create uncomfortable conditions, especially in a small room.