Tuning a PVC inflatable boat for fishing with your own hands - options and practical advice. The main features for tuning pvc boats How to make your own pvc inflatable boat

After buying a PVC boat, there were several tasks for comfortable placement of yourself, gear and other necessary things in the boat.

Started with an echo sounder, where to mount the monitor?

Rummaged through the Internet, read the forums, looked at the pictures. I found this design:

Decided to go further, put the battery in a plastic container, switch on the container.

Saturday: in the morning I went to the household, picked up a container that was suitable in size. In goods for fishing I bought brackets for lyktros, in building corners and self-tapping screws. The remains of 9 mm plywood have long been lying on the balcony.

I pumped up the boat in the garage, measured all the dimensions with a ruler and a square, sketched it, wrote it down. We go home to cut and plan.

I cut it out, checked the dimensions, everything seems to be correct.

I sawed it out, but after I started drilling holes, I found out that I had lost 1 centimeter in length ... well, that's okay.

I processed the edges with a rasp and sandpaper, everything turns out beautifully

Collected, went to the garage to measure the boat. What was my frustration when the holes for the rods were covered with lyktros... Abidna!!! Overlapped by a centimeter, in principle, you can fix it, but it will not be beautiful. Decided to leave everything until Sunday.

On Sunday, I did my homework and decided to create a new version.

I dismantled the first pancake, cut it out and sawed the blanks to the correct size.

A lot of time is spent on processing edges and surfaces with sandpaper.

Assembled the structure

Checked on the boat, everything is fine. Now painting in the color of the boat.

here you can see that the mount is supposed to be 2 lyktros. but after checking on the boat, I realized that the second lyktros is not needed.

assemble the whole structure

in the standard mount of the echo sounder monitor, drilled a hole in the center and placed a sheet of rubber under the mount

Vladimir Kolgin

When the boat has already been selected, then, as a rule, when selling you will be offered to spend boat tuning. What does it include, and how much do you need this whole complex of works?

A boat that leaves the production shop carries only a minimum of everything that is necessary for its operation. It, of course, can be used normally in this form, but will such operation bring maximum positive emotions and will it give a feeling of comfort on the water in terms of the level that you expected?

Based on more than thirty years of experience in using small boats, the answer is obvious to me: no, for the vast majority of ship owners, it will not deliver!

After the first exit on the water, looking at the boats of colleagues, you will want to adapt the boat to your tasks as much as possible. And first of all, as much as possible / * to insure against unforeseen circumstances. Why such confidence? Not always the boat leaves in good weather and returns to the shore in calm. Options are possible. Therefore, it is reasonable to direct the first steps in retrofitting the boat to increasing the level of its safe operation so that it can forgive you mistakes as much as possible.

Boat outboard motor insurance

There are cases on the water when the motor breaks off from its regular place and, in parting, having managed to strike a couple of times on the limit switch of the cylinder with a screw, disappears in the abyss of water. In reality, there are several reasons for such events - from violations of the rules for operating the vessel by the skipper, hitting an underwater obstacle to wear or breakage of the transom linings, breakage of the motor clamps.

Easiest insure the motor with the help of two eye rings (eye bolts) symmetrically installed on the transom of the boat. After installing the motor, they are connected to each other with a strong steel or synthetic cable so as to capture the deadwood of the motor, but also not prevent the motor from freely leaning back in the event of a collision with an underwater obstacle.

Such fixation, in my opinion, should be provided in any boat, despite various options payola or inflatable bottom. Having fixed the gas tank in place, you can not worry about its safety and location even in stormy weather. It is more convenient to carry out any fastenings in the boat with the help of half rings and slings. Depending on the type of bottom, the half-rings can be installed using screws, self-tapping screws, or glued using special pads. Exactly the same mounts can be placed in any part of the boat cylinder to fix any equipment and inventory. In this way, you can unfasten small bags, and hermetic packaging, tubes with spinning rods, and, most importantly, the anchor, securing it with the help of rings from spontaneous falling overboard.

pvc boat hull

The boat is moored to the shore. During fishing, there may be several such moorings. If the shore is a sandy or rocky shoal, then any, even the most gentle contact of the hull with it during mooring, will leave traces on the boat. The accelerator, if you like, the catalyst for wear, will undoubtedly be waves. Regular dragging across sandy and rocky spits or shallow water can also quickly wipe off the PVC layer on the bottom. All this gives reason to think about the maximum reduction in the likelihood of damage that is caused to the bottom by such abrasive abrasion.

To reduce the consequences of this phenomenon, a bottom reinforcement system has been worked out. It comes down to gluing an additional layer of PVC along the entire bottom or in places that most often encounter obstacles when moving. It can be either an additional layer of fabric or a profile cast from PVC.

It is clear that any such reinforcement will inevitably lead to some increase in the weight of the entire structure, which can be very critical for large or maximum ship loads. The width and thickness of the profile for reinforcement are different. The general selection criterion may be the weight of one running meter; it usually ranges from 70 to 350 g.

One should be noted design feature boats with an inflatable bottom. Since there are no rigid elements on the bottom, there is no need for this type of protection. And on catamaran-type boats, a kind of shell protection was already initially laid down by the manufacturer. Boats of this type, when moored, come into contact with the shore surface exclusively with skegs / additional cylinders located inside protective covers.

If the boat is prepared mainly for trips on rapids as a rafting vessel, then the reinforcement for safety purposes should be maximum.

If you have to operate in ordinary flat water areas, then you can, as they say, get off with “little blood”.

And one more argument in favor of the installation of protection. When the bottom of the boat is worn out, it is much easier and cheaper to replace the PVC profile when wiping than to patch or even change the entire bottom sheet.

And now a little more about which routes should be reinforced on boats with a hard payol.

Usually, the manufacturer lays only one tape along the keel of the so-called "halt" (the manufacturer's term for a profile cast from PVC).

If you glue one more tape on both sides of this profile to the very transom, then such protection will reliably protect not only the bottom panel, but also the keelson.

The next element, which is also noticeably worn out, is the balloon. Therefore, the protection of its lower surface with a halt is the second stage of amplification. It can take from ¼ to ¾ of the length of the cylinder, counting from the stern, that is, only the part that is subject to wear. It is also recommended to amplify the stringers.

And why is it actually needed? Unlike rigid hulls, a PVC boat noticeably deforms during movement and the shape of its inflatable elements changes somewhat. Only the rigid elements of its design - the payol and the transom - are subject to minimal deformation. Tight contact of the transom with the cylinder and the bottom is ensured by the strength of gluing on profiles or tapes. Unlike it, the payol is only inserted into the cockpit and installed in the gap between the cylinders.

The places of contact of a hard payol or stringer with the fabric of a cylinder or bottom are the most vulnerable when the boat is moving. Especially if some kind of abrasive, such as sand, gets here. Without proper protection, the consequences of such an "abrasive attack" can be felt very quickly. Therefore, the installation of protection in these places is also justified, both inside the boat with appropriate tapes or linings, and outside the boat, in the form of a PVC profile.

And another necessary type of protection is protection against the joints of the floorboard. PVC tapes are installed under the joints of the floorboard sections.

We strengthen the transom of the pvc boat

And we are completing a set of works to strengthen the transom. Structurally, in this place only a layer of the bottom sheet is glued to the plywood.

Reinforcement along the transom is made with a low-profile cast halt or a special corner profile so as not to create additional resistance.

You can do the strengthening work yourself if you have experience with PVC and you are far from service centers. Moreover, all the elements for this and for many other work with the boat, including glue, can be purchased at stores from a number of manufacturers. Such kits for independent creativity are quite widespread under the name "tuning kits".

If the service is nearby, then you should entrust the work with the boat to professionals.

This is the initial complex, which will significantly extend the life of your vessel.

The next group of useful little things can be described as increasing the level of comfort on board.

Now let's see what else is in the stash of manufacturers. What other devices are there that make life easier for a fisherman, hunter or just a vacationer.

Soft pads for boat cans

They can be either homemade from improvised means, or industrial production. They can also be used as independent devices, and together with a waterproof bag. In this case, the bag with zippers is fastened to the lining and installed under the jar. The volume of such bags, depending on the model of the boat, is determined by the width of the cockpit and the width of the can used. Very useful device for storing small items, as well as those that moisture can ruin.

To get a little more comfort, it is proposed to use inflatable seats. These are inflatable puffs. various forms and sizes that can be designed to fit anywhere in the boat. They can be fastened both in the thrust between the cylinders, and with the help of all the same half rings.

Even greater comfort in the boat can be obtained by installing inflatable backrests for ottomans.

It turns out a luxurious inflatable chair, which, however, rather relaxes than allows you to focus on fishing.

PVC boat covers

A canopy for small rowing boats is similar in function to an umbrella, providing more protection from the sun than from the rain.

For motor boats, there are several types of awnings that, in my opinion, deserve special attention, because they are very functional products. And they can be partly categorized as a means of increasing safety in a boat.

Let's start with the awning, which acts as a nose cone. With some skill in dealing with sewing machine it is easy to make it yourself.

For most manufacturers, it is found in two forms: entirely made of thin PVC fabric and with a transparent window in the front. The awning is quickly installed on a U-shaped arc and stretched along the side halt on hooks. It protects the crew very well from splashes, and the boat from flooding through the bow with a steep wave.

If the side number is covered by the tent material, then a transparent pocket for the double number must be sewn on the side of the awning.

The cockpit of a motorboat can be completely closed with an awning. It is made from Cordura or Avisent, less often from 350-550

PVC Structural features of these tents:

The base of the awning is U-shaped aluminum arcs, which are attached to special eyelets cast from PVC and mounted on the boat cylinder with the help of bolts or screws. The design is quick release.

When raised, it allows the crew to take shelter from the weather. The main purpose is to protect against dust and precipitation in the parking lot of the vessel.

Due to the presence of transparent windows under the awning, it is possible to move under the motor in a displacement mode. Due to the large windage, movement under it is possible if there is no strong wind.

The fixation of the sides in the lowered position is carried out with zippers, and in the raised position - on special slings. The sides can be lifted in any number and in any sequence. The most comfortable is under an awning with ventilation windows.

Somewhat less common is a kind of parking tent, which is created on the basis of collapsible arches (the design is similar to modern tents).

Such a concept as "tuning" means the improvement, refinement or modernization of a product. IN this case, finalization of PVC boats. Large-scale "tuning" of such boats costs a lot of money, especially since it involves improving the design or individual elements. PVC structures boats.

The reason for the modernization of a floating facility may be various factors. The first factor includes her imperfect appearance associated with the purchase back in the "ancient" time, when few people thought about the perfection of the product. The second factor is very serious and is related to the financial side of the matter. People buy inexpensive things with the hope that they will improve them without spending a lot of money. In addition, modernization can be carried out gradually, which will not lead to instant costs. At the same time, it should be remembered that in the process of refinement it is better to install only the necessary and useful elements that improve the characteristics of the product. Although, everyone has the right to decide which innovations are suitable for a floating vehicle.

Many elements can be purchased and installed on the boat. It is not necessary to make them yourself, especially since this process can be delayed in time.

PVC fabric, which serves as the bottom of the boat, is quite durable, but it is inconvenient to move around on it. Since the bottom is not hard, every angler experiences a number of inconveniences. Therefore, strengthening the bottom is the first task. In the future, the reinforcement will have to be repaired, but not the bottom of the boat. It will cost less, and it will be easier to replace the gain with a new one or repair it. It is possible to produce both full and partial strengthening of the bottom of the boat.

The bottom is reinforced by gluing a special PVC tape, which is called a "fender". The fender can have a thickness of 1.2-3 mm with a width of 60-235 mm. It is attached with 2-component adhesive. This will make the bottom more rigid and more protected from various underwater surprises.

Keel reinforcement

The operation boils down to the fact that a PVC tape (fender bar) is glued over the factory tape. A similar strengthening applies to kilsons.

Reinforcement of cylinders

Reinforcement is done as needed. Cylinders are also subject to constant wear and tear.

Transom reinforcement

For this element of the boat, reinforcement is simply necessary, since the transom is protected by only one layer of PVC fabric.

In order not to suffer with individual elements, the bottom of the boat can be sealed completely using a fender. If you are careful and accurate, as well as choose the right glue, then the operation can be done independently. This approach will solve many problems associated with the deterioration of the performance of the boat.

Installing stringers

If a hard floor is installed on the boat, then you will have to install duralumin profiles. Since the boat is deformed during movement, the rigid floorboards touch the inflatable parts of the boat and a friction process occurs. This can lead to abrasion of the fabric, which is undesirable and can lead to a violation of the strength of the boat. In the bow, where the profile of the boat has a curvilinear shape, stringers are not installed.

Independent fastening of the fender

Self-reinforcing PVC boat consists of the following operations:

- The boat is washed, after which all contaminants are removed. After that, the boat is dried as thoroughly as possible. It should be remembered that the slightest amount of moisture will not allow the elements of the boat to be glued together with high quality.

- The surfaces to be glued are degreased with gasoline or acetone. Degreasing is carried out carefully so as not to disturb the fabric.

- Using a brush, a layer of glue is applied to the surface. Usually glue is applied to the boat and the fender. After 15 minutes, a second layer of glue is applied. The layers dry up until the glue stops sticking to the hands.

- The beam is superimposed on the surface and pressed.

- In order for the surfaces to adhere securely, it is better to heat them with a hair dryer. Heating is carried out very carefully so that the plastic does not begin to melt.

- After that, the surfaces to be glued are again pressed with maximum effort.

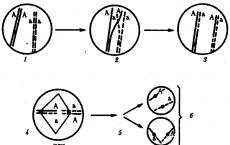

Redans to the boat

Such elements make the boat more stable. Redans are PVC elements that have a different shape.

Anchor

An anchor for a PVC boat is an indispensable element that allows installation at any point in the water area. It is especially effective in the presence of a current, when the boat can leave the intended place.

Spinning holders

A very useful accessory. Special mounts can be purchased at the store. The best option for one - 2 mounts, for two - 3 mounts. Extra fasteners can be a hindrance. Being ready a large number spinning is not desirable. If necessary, they can be pulled out of the tube at any time.

Alternatively, you can make your own rod holders from PVC tubes. They can be easily purchased at hardware stores.

Transom

A transom is required under the motor. When buying a boat, a transom may or may not be included. It is desirable to install an echo sounder on the transom.

Anchor eye

It is installed at the stern of the boat and facilitates the process of lowering and raising the anchor. The roller is placed slightly lower so that there is no abrasion of the fender.

Transom wheels

Install them or not, depends on the nature of the reservoir. Most reservoirs, especially wild ones, do not have the conditions for a normal boat launch. In such conditions, you have to lower the boat on your hands. So, there can be no talk of any transom wheels.

inflatable keel

As a rule, simple boats are not equipped with a keel, which does not allow her to stay on course. If you install an inflatable keel on it, this will help solve the problem of boat stability, especially in the presence of waves.

The size of the keel depends on the length of the boat. If you install a keel on a boat that is less than 3 meters long, this will cause the bow of the boat to rise. This element is attached using special ribbons, which are included in the package.

seats

Almost all models of such boats are equipped with hard seats, which is not very convenient, since you have to sit in one place a lot. To make fishing fun better seat replace with soft ones or modify old ones. Most boat owners make ice fishing-style seats with a storage box under the seat.

Alternatively, you can design a movable seat that is installed at any point.

Installing the bag

The bag can be equipped under the seat or in the bow of the boat.

boat motor insurance

Fishing is an interesting but also dangerous activity. Sometimes it is difficult to predict what can happen on a fishing trip. Quite often, when emergency situations intervene in the process of fishing, a motor stall occurs. As a result, the motor simply goes under water. To prevent this from happening, the motor is insured with a steel or artificial cable. It is attached to the transom through 2 eye rings. In other words, the motor is simply tied.

Gas tank mount

Elements such as an additional canister for gasoline require mandatory fastening. This is necessary so that when moving or making sharp turns, the canister cannot change its location. Fastening is carried out by means of a rope and half rings attached to the boat. They are attached to the boat as follows:

- half rings are glued to the bottom if it is made of PVC fabric;

- screwed to the floorboards with screws if the floor is hard.

fasteners

All additional elements are attached to the PVC boat with a two-component adhesive. There are several models of universal fastening systems. If you install it, then you can adapt any elements to it.

The dream to assemble and make a boat was a long time ago… Since childhood…

But then there was no experience and funds ... Now I have accumulated and decided ...

In the end, it turned out...

And so…

I inherited the frame of aluminum arcs from an experienced fisherman and lay in my garage for about twenty years ...

And this year it's time to create a new skin, upgrade and launch...

The tarpaulin lining rotted away before the "skeleton" came to me...

It was necessary to make a new one. At first I wanted to make it from stainless steel according to ED's schemes, but this design is not separable ...

Therefore, I decided to still make the lining of a soft material ...

I settled on banner fabric ... Soft and inexpensive (sometimes some firms give away marriage for free) ...

I didn’t want to go to the city (there, in a large advertising company, they were ready to give away the fabric for free)

therefore, I bought a banner fabric 3x4 meters in size near the house for 700 rubles, it was not in operation (marriage only in painting), with a density of 600.

And also two bottles of super-NN glue ... Plus three brushes and a roller ...

I purchased consumables for sheathing, but ...

How to accurately make a pattern on the existing boat frame ???

I thought for a long time, measured - it's easy to make a mistake ...

Somehow I came across a site of kayak designers, where one of the comrades published photos and recommendations ...

I wrapped the assembled case with adhesive tape: sticky side up, and the second layer sticky down ...

The solution is simple and inexpensive ... I bought scotch tape in the store, so 200 meters ... And wrapped it ...

For gluing, the fabric (PVC) was degreased with acetone (it took 3 bottles). After the seams missed with a brush, rolled with a roller,

then (the next day) I glued the seam on top with an additional strip for strength, again rolled it with a roller ...

The result is a boat...

The plating of the boat came out well ... But I did not take into account that it would need to be disassembled, only after I glued the hull on the hull, I began to think about how to make it collapsible ...

Again, I turned to the site of kayakers, I spied on the “castles” there ... By the way, simple design!

But it was too late... The skin was stretched. Strongly, accurately holds the contours of the body ...

This is not something to separate, or rather to unclench the metal tied with PVC ...

Three hours of torment - and yet I stretched the skin, fortunately it was a sunny day ...

In the middle of the frame of the boat I made “locks” ...

My compact watercraft began to fold up and fit in a bag ...

Then there was a test drive...

"Departure" (attached the wheel to the boat) to the nearest body of water ...

Fees…

The child liked my creation ...

But how will it be on the water, and how to get to it ...

Yes, it’s very simple: a boat-wheelbarrow ...

I thought so: not inflatable, but with a solid hull, so that every time you launch it, you don’t “inflate” it and collect it.

Three hundred meters passed normally, even on coarse gravel ...

And on soft ground it’s generally good ...

A slight upheaval in place...

And a boat on the water...

Fully equipped for carp fishing... (landing net and fishing rod are attached to the "skeleton" of the boat).

Further test: the boat went like a “feather” on a smooth lake, does not go deep, the course is good, rowing is just a pleasure ...

I checked the buoyancy, decent ... I put a child in the boat ...

Ride…

The boat was light. Then a child was already rolling me around the lake ..

Ride my son, we are returning ...

I'm going fishing again...

As a result, large crucian carp - there were never such ones from the shore ...

Now I take it on almost every trip to the OVH, it is simply not replaceable on still water, the fees are minimal, the comfort for one fisherman is maximum ...

P.S. experience in PVC gluing and patterning has been obtained, the next stage I think will be the construction of a catamaran ...

A PVC boat is probably the most favorite vehicle among fishermen for moving on water. The only drawback of such a boat purchased in a store is its minimal convenience and low functionality. Manufacturers have taken care of the quality of materials, but it seems to be completely forgot about the consumer.

How to make a new boat more comfortable and better? The fishermen have their own secrets for improving this vehicle, which they are happy to share with everyone.

Here are five examples PVC boat tuning. All this can be done with my own hands with a little patience and ingenuity.

bottom reinforcement

Many begin with the strengthening of the bottom. Although it is made of durable material, there is no escape from wear and tear.  With active use or careless contact with a rocky shore, the bottom may be damaged.

With active use or careless contact with a rocky shore, the bottom may be damaged.

Dealing with this trouble by gluing profiles made from PVC. They certainly add to the overall weight. The decision to upgrade a watercraft must be made wisely. If the boat is operated on a fast river with rocky rapids, there is no escape from the maximum strengthening. For still water, the amplification can be kept to a minimum.

Reinforcement is made by PVC membrane or profile. Adhesive used pvc"Poligrip", "Vinicol", "SAR-306" or "Uranium".

Membrane reinforcement without glue

- The surface of the boat must be cleaned from grains of sand and degreased.

- Then the valve is removed and the transom wheels are detached.

- Previously, paper is applied to the boat in the inflated state and two patterns are cut out according to the size of the bottom (the area between the keel and the cylinders). According to these patterns, details of PVC fabric (membrane) are cut out. The thickness is about 1.5-2 cm, the weight of one part is 1.5 kilograms.

- The material must lie in the sun or in a warm room to take the desired shape.

- Then the parts are heated with a hairdryer and at the same time smoothed with a roller to extrude air. Edges are carefully worked out. Gluing occurs from heating the membrane under the influence of high temperature (without glue!).

We invite you to watch all this in practice in this video clip.

Reinforcement "halt"

PVC profile or "halt" is glued to the keel on both sides, which also protects the keelson. The boat is also strengthened along the cylinders by about a quarter of their length. And also along the transom, because only a layer of the bottom fabric lies on it.

PVC profile or "halt" is glued to the keel on both sides, which also protects the keelson. The boat is also strengthened along the cylinders by about a quarter of their length. And also along the transom, because only a layer of the bottom fabric lies on it. soft seat

As is known, being uncomfortable on a boat. You will have to take care of a comfortable seat for many hours of fishing. The stores offer inflatable seats, which not everyone likes to use. Getting out is pretty easy.

For this type of tuning you will need two pine boards, for example, 45 centimeters long (you first need to clarify the distance between the cylinders!) And 15 centimeters wide, window fittings (2 pcs.) - so that the seat folds if necessary, and wide enough car seat belts.

- The boards are connected to each other with fittings for window vents.

- The seat belts are attached to both sides of the seat with screws.

- The seat is adjusted directly on the boat. Belts go through the bottom!

- The foam rubber of the desired thickness is superimposed on the seat. The cover is sewn from raincoat fabric or tarpaulin. For a fastener, an ordinary zipper (or Velcro) is suitable.

Here's what should happen:

Here's what should happen: The main advantage of such a seat is its cheapness compared to store models and the ability to freely move it in a boat.

inflatable keel

Not all boats are equipped with an inflatable keel. And this detail is important for large boats with a length of more than three meters, which are used complete with a motor.

At maximum speed, the bow of such a vessel begins to break away from the surface of the water, which leads to capsizing. An inflatable keel gives stability and ensures accurate following of a given course.

You can make it yourself. For manufacturing, you will need a dense PVC boat fabric and Moment glue.

- The keel is a flattened tube with a valve made of waterproof fabric, glued along the seam.

- To seal the main and end seams, before use, you need to pour an aqueous mustard solution inside, shake it well, and then drain it.

The peculiarity of such a keel is its placement not outside, but inside the boat. In shallow water, the air from the keel can be lowered for ease of movement. Not a single real keel boat can boast of this “skill”!

Making a collapsible anchor

- You will need a stainless steel tube with a diameter of 25 mm and a length of 270 mm. A sleeve with an M12 thread is welded to the end of the tube, the thread length is 25 mm.

- The legs of the anchor are made of stainless steel strips 260 mm long and 40 mm wide, the strip thickness is 4 mm.

- The edges are sanded to remove burrs.

- Two strips are welded on one of the paws. This is done to prevent the paws from turning relative to each other in the assembled position.

- The paws are put on the anchor rod and tightened with a nut standard size M12. Additionally, a ring is welded onto the nut to facilitate assembly of the anchor by hand, without tools.

- On the opposite side of the anchor, a hole was made into which a ring with a diameter of 40 mm and a wire thickness of 5 mm was inserted.

- The weight of such an anchor is 1 kg 600 g. To ensure the stability of the boat in windy weather, it is recommended to pour an additional 2 kg of lead into the anchor rod.

In the video below, in addition to detailed instructions on the manufacture of a collapsible anchor, it is told about the method of tying a rope to it.

The anchor is attached to the seat with a cord with a carabiner.

A ring welded to the nut (fastening the legs of the anchor) is used to secure the line in case of a rocky bottom or the presence of snags. That is, the anchor clings not to the upper part, but to the lower ring. This makes it easier to pull it out of the water in case of a hook on the bottom.

Transom wheels

Not a single self-respecting boat owner can do without this attribute now! Given that the store prices for the chassis " bite”, craftsmen make them on their own. Indeed, often you cannot drive up to the water by car, but somehow you need to transport a heavy boat to the reservoir. In such cases wheels come to the rescue.

Not a single self-respecting boat owner can do without this attribute now! Given that the store prices for the chassis " bite”, craftsmen make them on their own. Indeed, often you cannot drive up to the water by car, but somehow you need to transport a heavy boat to the reservoir. In such cases wheels come to the rescue.

For small boats, a one-wheeled model is suitable. Large ones require twin wheels to ensure the most comfortable movement of the craft.

You can literally make a chassis from everything that comes to hand in the garage. And buy wheels on the market.

Below is a video tutorial on making wheels that do not require traditional fasteners. This is a quick and economical way to put a small boat on wheels that has handles on the back of the cylinders.

You will need an old plastic barrel, two parts 20 cm wide are cut out of it. A kind of “tie” is cut out at the edges - a narrow part on which fasteners are installed. And the wheels are fastened in the middle of each part with four stainless steel bolts. The holes are sealed with silicone.

The only downside such small wheels - the impossibility of using them in a set with a large boat and on viscous soil (clay, deep sand).

Each fisherman has his own ways and methods to improve the boat bought in the store. Some do not skimp on any funds and purchase additional details of industrial production. Others, on the contrary, save and master everything is handmade.

The main thing in this case is to show reactive thinking. Then your favorite boat will never let you down, and fishing will bring you pure pleasure. If you have something to add, and I'm sure you have - write your "Must have" in the comments at the bottom of the article.

No tail for everyone, no scales!