Build your own closet. Stages of creating a wardrobe with your own hands. Manufacturing of cabinet elements

Updating your wardrobe every season, you suddenly notice that there is simply nowhere to put new things. throw away clothes good quality, but bought last season, the hand does not rise. You can solve the problem by assembling a wardrobe with your own hands.

Comfortable and roomy designs will collect the things of all family members, while taking up very little space in the room. Basically, this is a place that is little used and not very convenient for placing other pieces of furniture.

Design Options

If you want to install a sliding wardrobe in an apartment or house, you need to make accurate measurements of the intended installation location of the furniture element and place an order with a company that manufactures cabinets. The second option would be to measure the installation site, independently design the structure, order the sawing of parts and install the wardrobe.

You have a choice - built-in structures, corner cabinets and models of separate walk-through structures. Once you've made your choice, you can start building your own.

Types of wardrobes differ in design. If you have never assembled furniture, it is better to start with a walk-through model. This universal model can be installed in almost any room.

In many apartment projects, the entrance hall was made small in size in the shape of a rectangle. If you put an ordinary wardrobe with a swing door, there is absolutely no space left. A wardrobe with a sliding door has become a real salvation. Its height mainly goes up to the ceiling, which gives maximum use of the area. Mirrored door panels visually enlarge the space.

materials

Even the most fastidious buyer will be able to find on the market the color and shade of laminated chipboard he needs, most often used for self-assembly of the wardrobe. Hardboard is used for the back wall. The choice of fittings in stores has practically no boundaries - from the simplest to exquisite bizarre shapes. The door leaf can be made to order from any material.

For cabinets, 16 mm thick laminated chipboard sheets are used. Sheets are sold on the market with a height of 2450 or 2750 mm and a width of 1830 mm. If you want to save money by reducing material waste, consider these dimensions when designing your closet.

Let's take a closer look at the option of assembling a wardrobe with a height of 2450 mm, a width of 2400 and a depth of 650 mm.

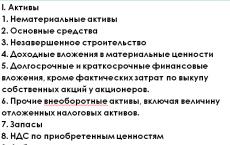

In addition to chipboard sheets, we need a melamine self-adhesive edge. To assemble the cabinet of the design shown in the picture, we need the following details:

- Two sidewalls measuring 2433x650 mm.

- The bottom is 2367x650 mm in size.

- Cover of a case in the size in 2400х650 mm.

- Large shelf - 2367x550 mm.

- Seven small shelves - 778x550 mm.

- Two partitions - 1917x550 mm.

- Rear and front plinths - 2367x100 mm.

- Side parts of the plinth box in the amount of 3 pcs. and 550x100 mm in size.

- Two ribs of the basement box measuring 1159x100 mm.

Hardboard back wall details:

- Wide detail for two compartments - 1940x1595 mm.

- Narrow detail for one compartment - 1940x800 mm.

- Detail for the top of the cabinet - 2395x410 mm.

Sawing parts of the future wardrobe is better to order in the cutting service, which is a must-have at any building supermarket. Show the experts your cabinet design and exact measurements. In our case, there is already detailing and it is better for sawing masters to show it.

It is possible to make a wardrobe door system on your own, but is it necessary? If you are planning to assemble not one, but several cabinets, this can be beneficial. Doors for one cabinet will cost you much more than ordering sliding doors from a company that manufactures, supplies and assembles sliding fronts.

You need to visit the company's office and place an order, indicating the exact dimensions of the clean opening and the number of canvases. For our cabinet, the net front dimension is 2317mm high and 2367mm wide. We need to make two sashes of the same color as the acquired laminated chipboard and one mirrored sash. There must be a seal, stoppers, guides. In general, the whole set necessary for the quality work of the sliding facade system.

Everything related to the facade has already been ordered, but for interior design wardrobe you need to purchase furniture fittings. For our project you need to buy:

- For fixing hardboard screws or nails.

- In the middle compartment of the cabinet for adjusting the shelves in height, you need undershelf supports.

- Confirmations of sizes 70x5 mm.

- Rod holders.

- Self-tapping screws 16x4 mm in size.

- Two bars for hangers measuring 775 mm.

When the finished parts are delivered, you can begin to prepare them for assembly. You will need an iron to work. Carefully attach the acquired edge to the end of the part so that the beautiful side is on top. Carefully walk on it with a heated iron. Make sure your iron is not set to steam.

Press the heated edge well and wipe thoroughly. Carefully sand the cut edges with sandpaper. When preparing the details do not need to rush. Try to achieve the highest quality of work so that your closet looks neat and beautiful.

From the details of the plinth, assemble the base of the podium for the bottom of the cabinet. The plinth must be mandatory.

Assembly

To assemble the cabinet you will need:

- Pencil and rectangle.

- Drill and drills 5 and 8 mm.

- Roulette.

Instruction:

- To assemble parts into one whole structure, purchased confirmations are used. First, we look at our project and mark up the attachment points.

- When markings are made on all the details, we proceed to the drilling process. For holes in the plane, we use a drill with a diameter of 8 mm. The hole must be through. The depth of the hole at the ends is not more than 60 mm, and the diameter is 5 mm. We make holes at several levels in the places of installation of the shelf supports. When the cabinet is ready, you can safely move your shelves to the desired level.

- To assemble the structure, you will need the help of one person. The work will go faster and the build quality will be better. We connect all the details of the cabinet and install it in place. We expose the cabinet evenly, using a level.

- Now you can proceed to the installation of the facade. We fasten the upper guides along the edge of the cabinet lid. We retreat from the edge of the bottom of the cabinet a maximum of 10 mm and fix the lower guides. Before tightening the screws, we insert the stoppers into the roller track.

- Now you can put the facade back in place together. One person leads the upper part of the facade into the guide, and the other sets the wheels in the desired track. A hex wrench is used to adjust the front. Adjusting screws are located at the bottom of the front end. By raising or lowering the lower roller, we set the facade to the desired position.

When the closet is loaded with things, the adjustment will need to be repeated. Here is the finished work on the installation of the wardrobe. Now you can proudly consider yourself a master and try to assemble a more complex structure. There is already experience, which means that the assembly will be much faster and better.

Video: wardrobe assembly

We offer you to watch a video on assembling a sliding wardrobe.

Do-it-yourself wardrobes photo

Video version of the article

Where to start assembling a wardrobe

First you need to check whether all the spare parts were brought to you. There should be several boxes with chipboard (at least two), doors and packaging with hardware. The manufacturer can pack hardware and additional elements in a box with chipboard. Be careful when accepting the cabinet, as deliverers can sometimes forget some elements or may damage some of its parts, be sure to check this.

What tools will be needed to assemble the cabinet:

- Phillips screwdriver PH2;

- hex key, edge width 5 mm (L-shaped);

- roulette (ruler);

- level (optional)

The assembly process will be greatly accelerated if you have a screwdriver with bits (hex and cross), but you can do without it.

Preparing to assemble the wardrobe

Assembling a wardrobe with your own hands is a laborious process, so immediately find yourself an assistant who will help you hold or submit the spare part. Before proceeding with the assembly, you need to open all the packages and sort the boards by size. After that, it will be easier to determine which elements are which.

Each panel has characteristic openings for connection, by which it is easy to determine its purpose.

There are 3 circuit diagrams chipboard connections:

- with the help of confirmed screws;

- eccentric couplers (minifixes);

- one of the above methods, but with the addition of wooden dowels (chopics).

Each connection has its own characteristic holes on the plane and at the ends of the boards. Two types of holes are made for confirmations:

- in one part through in a plane with a diameter of 7 mm;

- in the second part, a deaf one with a diameter of 4.5 or 5 mm.

Under eccentric screeds, 2 pairs of holes are also made:

- in one part it is deaf in a plane with a diameter of 5 mm where the minifix stem is screwed;

- in the second part there is an 8 mm end hole connected to a recess in a plane with a diameter of 15 mm for a clamping cylinder.

Holes for dowels are made blind from the end and in the plane with the same diameter from 8 to 10 mm.

Before assembling a wardrobe, look at a set of hardware, by their presence it will become clear what type of connections you have and in what sequence to assemble the elements.

Before deciding on the details, it is worth remembering that for all boards the front side (end) is glued with an edge, and the back (where the fiberboard is nailed) remains bare. So you can correctly position the shelves, lintels and sidewalls.

Many of us are faced with the need to purchase a closet. The closet model has become very popular. Its door design is extremely convenient and saves free space in the room. They are even used as a partition. There are two ways to solve this issue:

- contact a company that assembles furniture;

- order cabinet parts and assemble it yourself.

The second option, of course, will cost less than the first. But this process will require certain skills and abilities. It is very important to correctly measure all design parameters, consider the dimensions of all compartments and shelves, the height and width of the product. If you are ready to take on this job, then you need to figure out how to do it.

The second option, of course, will cost less than the first. But this process will require certain skills and abilities. It is very important to correctly measure all design parameters, consider the dimensions of all compartments and shelves, the height and width of the product. If you are ready to take on this job, then you need to figure out how to do it.

Preparatory stage

Step-by-step instruction

To do everything correctly, you must follow the instructions. Let's  Let's look at the whole procedure in more detail.

Let's look at the whole procedure in more detail.

Door installation

Be careful when working on doors. The ease of use of the door also depends on the quality of the profile. It is sold unassembled and consists of the following parts:

- guides - rails;

- base - lower frame;

- side frames (C, H) act as door handles, and rollers, the upper frame are attached to them;

- plastic and rubberized rollers;

- stopper for the bottom guide;

- a strip of pile, which is attached to the end of the door, serves to soften the blow from closing the doors;

- silicone sealant for mounting the mirror.

The sealant must be applied along the entire length evenly and accurately. On the mirror, which is in a horizontal position, the profile frames are attached at the top and bottom. Next, the side frames are put on the mirror in a vertical position. The frames are interconnected with self-tapping screws in the prepared holes.

Door installation begins with fastening. We measure the attachment points at the bottom and top of the cabinet. The guides are attached with self-tapping screws with press washers, also into the prepared holes. First install the top part, combining with the side frames, then the bottom. Use a level to avoid warping. Place a stopper to secure the door. We insert the door into the upper and then lower it into the lower guide. The lower rollers adjust the height and angle of the door. Your wardrobe is ready.

At each stage, pay attention to the scheme for assembling this model. To clarify all the difficult points, watch the video instruction. If you doubt your building skills and design abilities, contact the professionals.

To assemble any cabinet (ready-made serial, custom-made or built-in), there are two options: order assembly when buying a cabinet or assemble the cabinet yourself. The built-in closet fits into the size of the room, so it is quite difficult to assemble it. In this case, it is worth contacting a professional assembler so that the cabinet is assembled without defects, which means it lasts a long time. To assemble a free-standing cabinet, your own strength is enough. Cabinet furniture is usually assembled without any problems, besides finished furniture always attached detailed instructions with a description of the number of parts and assembly order.

Before starting assembly, check for necessary tools. The main ones are a screwdriver, a hammer and a hex wrench. You may also need laser level to check the evenness of the floor, a square to check right angles and a tape measure. After unpacking the boxes with cabinet parts, check their conformity with the design and the number of fittings. You should also make sure that there are no chips, scratches or other defects on the panels. Pay attention to the instructions: in order to properly assemble the wardrobe, the diagram must be correct. Compliance with the instructions and the wardrobe model is checked by a short designation based on the number of doors and the type of filling. For example, ShK-2.1 is a 2-door wardrobe with filling option No. 1.

How to assemble a closet mechanism

The finished serial wardrobe is assembled in the following order:

1. A separate plinth is mounted - immediately with the cabinet floor. After assembly, the plinth should be put aside far: it will be needed during further assembly.

2. The frame of the case is assembled, which consists of side towers, a ceiling and a floor (with a plinth). It is best to assemble the frame on the floor if the cabinet is small.

3. The cabinet body is installed in a vertical position. Rods for shelf holders-flippers are attached to the side walls and partitions of the cabinet, and then the shelves are installed.

4. Using a tape measure, the equality of the cabinet diagonals is checked - this way you can determine that there are no distortions.

5. The cabinet is placed on the floor again, after which the back wall is fixed, and the cabinet is installed in place.

6. Rod holders are attached to the side walls and partitions, then the rods are fixed.

7. If the filling of the closet consists not only of rods and shelves, modules with drawers are assembled: first, the base and cover of the module and guides in the cabinet body are installed, then the drawers themselves are assembled and placed in the cabinet.

How to assemble a wardrobe more than 3 meters wide

A 2-door wardrobe is easier to assemble than a 3-door one: a wardrobe that is too wide is difficult to move during assembly and constantly move from a horizontal position to a vertical one. Wide cabinets in most cases are made built-in, which are assembled by a professional assembler. To assemble a wide wardrobe to order, it is also better to call an assembler: in fact, to assemble a wardrobe, the price is not high and mainly depends on the complexity of the design.

But if you ordered a free-standing wide cabinet and want to assemble it yourself, follow a few rules when assembling:

A wide cabinet is assembled in the same order as a regular-width cabinet;

To avoid damage to the panels, it is better to assemble a wide cabinet in an upright position;

It is necessary to check the absence of distortions more often.

How to assemble sliding doors for a wardrobe

After assembling the cabinet body, it remains only to install the system sliding doors: guides and the doors themselves. First, the guides are attached: upper and lower, and it must be ensured that there is no discrepancy between them and distortions, otherwise the doors will get stuck or at least creak.

The number of doors does not affect the assembly method. Instructions on how to assemble a 2-door and 3-door wardrobe are the same for the door system:

1. For the far door, the top edge of the door is inserted into the far upper track, and the rollers are installed into the far lower track.

2. To install the near door, the same process is repeated.

3. Using a hex wrench, the doors are adjusted so that they do not warp.

4. It is checked whether the doors move smoothly.

After that, you can put things in a new closet. Assembling the cabinet with your own hands or calling an assembler - this issue should be resolved when buying a cabinet in order to agree in advance with the assembler at a convenient time for you.

Popular wardrobes

Call to a member function getField() on null (0) /var/www/site.test/www/bitrix/templates/.default/components/bitrix/catalog.section/shelves_in_section/template..test/www/bitrix/ modules/main/classes/general/component_template..test/www/bitrix/modules/main/classes/general/component_template..test/www/bitrix/modules/main/classes/general/component..test/www/bitrix /modules/main/classes/general/component..test/www/bitrix/modules/iblock/lib/component/base..test/www/bitrix/modules/iblock/lib/component/elementlist..test/www/ bitrix/modules/iblock/lib/component/base..test/www/bitrix/components/bitrix/catalog.section/class..test/www/bitrix/modules/iblock/lib/component/base..test/www /bitrix/modules/iblock/lib/component/base..test/www/bitrix/modules/main/classes/general/component..test/www/bitrix/modules/main/classes/general/main..test/ www/bitrix/templates/.default/components/bitrix/news.detail/advices/catalog..test/www/bitrix/templates/.default/components/bitrix/news.detail/advices/template..test/w ww/bitrix/modules/main/classes/general/component_template..test/www/bitrix/modules/main/classes/general/component_template..test/www/bitrix/modules/main/classes/general/component..test /www/bitrix/modules/main/classes/general/component..test/www/bitrix/components/bitrix/news.detail/component..test/www/bitrix/modules/main/classes/general/component.. test/www/bitrix/modules/main/classes/general/component..test/www/bitrix/modules/main/classes/general/main..test/www/bitrix/templates/.default/components/bitrix/news /advices/detail..test/www/bitrix/modules/main/classes/general/component_template..test/www/bitrix/modules/main/classes/general/component_template..test/www/bitrix/modules/main/ classes/general/component..test/www/bitrix/modules/main/classes/general/component..test/www/bitrix/components/bitrix/news/component..test/www/bitrix/modules/main/classes /general/component..test/www/bitrix/modules/main/classes/general/component..test/www/bitrix/modules/main/classes/general/main..test/www/advice s/index..test/www/bitrix/modules/main/include/urlrewrite..test/www/bitrix/urlrewrite.php:2The closet plays an important role in any interior. It is not surprising that stringent requirements are imposed on it: not to take up too much space, to be roomy, to have a sufficient number of shelves and drawers. Models on the market do not always fully satisfy individual wishes.

It can be even more difficult for owners of non-standard layout apartments to choose an option that fits into the room. In this case, you can order a cabinet from specialists who will take into account all the wishes for the design and internal content.

Unfortunately, this option is not for everyone. Then the best solution to the problem will be to use your own hands and ingenuity, because it’s not difficult to assemble a cabinet on your own!

Preparatory stage

Each room has its own type of construction, so you should familiarize yourself with the main ones.

Cabinet with a closed facade - a direct model with hinged doors. To open them, you need to provide additional space, do not forget about this if you are making a closet for the hallway.

The cabinet with an open facade has no doors, and its contents are in plain sight. It imposes certain requirements on the order.

The wardrobe doors are mounted on a rail mechanism and open, moving apart. There are designs with an upper and lower rail, which one to choose is a matter of taste.

Ideal design for a built-in wardrobe

The corner cabinet fills the corner. Suitable for a room of any size, if it is square or close to it.

Having chosen a suitable design, you can begin to create a project for the future cabinet. Since this piece of furniture has been serving for more than one year, it is worth considering what functionality may be required of it. It is better to build a drawing on whatman paper, entering all measurements there.

Decide on the location and dimensions of the cabinet. If a niche is provided in the room, it is ideal, but if it is not possible to build it in, choose a place where neither he nor he will interfere with anything.

Think over the internal content: the location and number of shelves and drawers, their sizes, additional elements like mezzanines or interior lighting.

Don't Forget Your Choice exterior finish, decorations. The colors "oak", "alder", "beech" are the most popular today. And you can choose wood with an interesting pattern and leave your native pattern. Get creative, decorate the doors with a carved pattern.

materials

The material can be natural wood, plywood, MDF or chipboard - all of which are used by furniture manufacturers.

The tree is environmentally friendly, does not require additional decorations, it is convenient to use. A wooden cabinet will last more than one year and will look solid and impressive. The perfect choice for a classic style interior.

Plywood is glued sheets of veneer (birch or coniferous trees are used). This cheap, practical material is suitable for the manufacture of almost any furniture. It is best to choose laminated plywood (FOF brand).

Chipboard (chipboard) is the cheapest and most common option. When assembling your own closet, they usually use it. Short-lived.

A self-adhesive melamine film is also useful for processing the side faces.

The rod diameter must be at least 22 mm. The easiest way is to buy it in a specialized store. You can also buy pens there.

Instruments

- Ruler, tape measure, pencil and others for taking measurements and building a drawing.

- Level.

- Electric jigsaw or hacksaw for cutting.

- Screwdriver or drill and screwdriver.

- Glue.

- Ratchet key.

- Iron for gluing edging film.

- Accessories. Each door opening mechanism has its own set.

- It is better to buy confirmations for a chipboard cabinet with a length of 7 cm and a diameter of 0.5 cm.

Working process

First of all, measurements are taken and a drawing of the future cabinet is built. The final result depends on a correctly drawn up drawing, so approach it with all seriousness.

Making cabinet doors with your own hands is not difficult, the main thing is to correctly calculate the dimensions. If its vertical height is less than the height of the opening, the door will not completely close it, and if more, it will not fit. Finding the horizontal dimension, we must not forget about the fastening elements: they will add a few millimeters to it. The width of the doors should be ~3 mm less than the opening.

Now you need to mark the placement of the mounting bolts on the sawn parts and drill all the holes.

The assembly begins with the installation of the bottom and attaching the walls to it. Make sure that assembled cabinet fits into the allotted space and other furniture will not interfere with the opening of the doors. If you are making a wardrobe, guides are installed at this stage.

The location of drawers and shelves is outlined, shelf holders and guides are installed. They must be strictly parallel so that they do not skew.

It is time to install the upper shelves and roof. A gap of ~ 7 cm is left between the ceiling and the roof for the installation of confirmations. Fasteners are made by hand, finally tightened with a ratchet.

The side shelves are attached to 4 confirmations (two on each side), in some cases dowels (small wooden cylinders) are used. One end of the dowel is inserted into the wall of the cabinet, a shelf is put on the other.

The last step is to install the doors. Before installation, attach the handles with an outward bend. For sliding doors is especially important correct installation mechanism. Don't rush, be careful.

It's time for the finishing touches. Treat the cuts with a decorative film, decorate the facade. Put mirrors, interior lighting and other elements.

Tricks and nuances

Build on existing cabinet layouts when designing your own.

A corner cabinet requires more care in design and assembly than a straight one, so it may be too complicated for an inexperienced person.

If you do not have enough experience, it is better to entrust the cutting of parts to the master. His hand will not tremble, and the cuts will be even and neat.

In order not to get a piece smaller than necessary, consider the thickness of the saw. The wall thickness must be at least 18 mm. Otherwise, the strength of the structure will be insufficient.

When working on the drawing, pay attention to the curvature of the floor. If the floor is not level, gaps may appear between the doors. To avoid this, adjust the mounting canopies for the swing mechanism, and change the height of the wheels for the sliding mechanism.

Guides for sliding doors should be parallel. Be very careful when marking and installing guides for drawers and shelves.

Drill holes for confirmations symmetrically. Use a drill of the correct size. The exact number of confirmations depends on the number of parts. Confirmates are covered with plugs to match the color of the structure.

Installation of the mirror begins with the installation of a seal around the perimeter. The film is glued to the slices of chipboard with an iron. Smooth it with a cloth, pressing it as tightly as possible. The edges can be trimmed with a regular knife.

Study photos of handmade cabinets: you will get a boost of inspiration and mark interesting ideas for yourself.

We hope our tips have helped answer the question of how to make a wardrobe with your own hands.

DIY cabinet photo