What is needed for the production of sausages. How to open a sausage shop

- Room selection

- Recruitment

- stories of real people

- The right assortment

- Sales channels

- Similar business ideas:

How to open a small sausage shop, and what are the features of this business. We read in this article.

How much money do you need to open a sausage shop

Investments are the first and one of the main issues in organizing a mini sausage shop. At first glance, it may seem that a lot of money is not needed here, but when you start counting, you understand that investments will not be limited to one million.

What equipment to choose for a sausage shop

The first thing you need is equipment. To organize a sausage shop, the following kit may be required:

- Sausage cutter - a machine for fine and structural meat grinding (for example, the KILIA 2000S cutter).

- Vacuum filler - designed for filling the casing with minced sausage (for example, TECMAQ vacuum filler).

- Ice maker - used for cooling, transportation and storage.

- Meat grinder - used for making minced meat.

- Thermal chamber - used for smoking meat products.

- Electric frying pan with thermostat.

- Meat mixer - used for mixing minced meat and massaging small meat.

The cost of such a kit starts from 3.0 million rubles. The price ceiling depends only on the performance of the equipment.

Room selection

The following costs are associated with the selection of premises. It's good if you find a room with everyone suitable conditions: water supply, sewerage, electricity of sufficient capacity. And also, it meets all the requirements of the SES and the fire inspection (supervisory authorities pay special attention to food production). Otherwise, you will need to invest several hundred thousand more rubles to bring your workshop “to mind”. There is no need to talk about the construction of a workshop "from scratch", since this is a completely different investment. However, there are alternative options for stationary sausage shops. If there are problems with the selection of suitable premises, then you can purchase a ready-made modular building (mini-workshop), which is already equipped with everything necessary equipment for the production of sausages. Similar constructive solutions are produced by the KOLAKS company.

Recruitment

It is no secret that the success of any food production, whether it is a large enterprise or a small workshop, largely depends on the composition of its personnel. For a small business, this aspect becomes even more important. And a special role in the technological chain of production is assigned to the technologist. Any technological failure in the production of sausages can mean big losses. Therefore, it is worth hiring a person with experience and qualifications for the position of “chief tastemaker”. Even if it costs you the monthly salary of three to four ordinary specialists.

stories of real people

“After 4 months of work, the quality of the produced sausage suddenly dropped sharply,” says Alexander Abramov, director of Tau + Sausage Shop LLC. We changed the meat supplier, replaced the spices, but the sausage still had an unpleasant aftertaste. Only three weeks later we realized what was the matter - the sawdust that was used in the smoking chambers began to rot and spoil the taste of sausages. Consumers had time to what is called to feel this problem. This is how inexperienced technologists sometimes know how to "strange". Another acute problem of modern mini-productions (not only sausages) is material losses. Petty theft in small businesses is, in fact, standard practice. It is difficult to get rid of this problem, since small workshops do not have the means to provide a security guard to each employee. Video cameras, of course, solve the problem, but only partially. And automated accounting systems cost a lot of money, and bring the company to the brink of profitability.

The right assortment

A lot of cones can be filled and when creating an assortment of products. There are so many types of sausages and meat delicacies that you can get confused. “The main thing here is not to intersect with large manufacturers, but to produce something of our own - branded,” advises Alexander Abramov.

The issue of choosing raw materials also cannot be discounted. By the way, this should be taken care of even before purchasing equipment. The purchase price and the composition of the meat have a significant impact on both the cost of the resulting sausage and its taste. “So, Brazilian pork, as a rule, is better than Russian pork, since it has less fat,” says Alexander. But in view of recent events, Brazilian meat has risen sharply in price, so you have to look for suppliers in Europe (in Poland, for example), or sort out local farmers.

Sales channels

Not less than important aspect in the work of a small workshop. Sausage production will not be profitable if you do not take care of the points of sale of finished products in advance. “Now we are working with 67 stores and 30 outlets,” says the director of Tau + Sausage Shop LLC. The majority of small shops order sausages at one or two large meat processing plants and at one small enterprise. Why it happens? The fact is that large enterprises ship 30-50 kg of products at a time, and small ones - no more than 10 kg. Therefore, when a store buys goods from a large enterprise, say on Monday, it makes no sense to re-order on Wednesday, since there are leftovers from the previous order. But to buy a small batch for this day from a small workshop is an ideal option, since it will be more realistic to sell the entire sausage.

Working with large retail chains is, of course, a tempting option, but there are several significant disadvantages. First, retail chains work with large quantities of goods that are delivered to dozens of stores. It is not realistic for a small workshop to provide volumes of hundreds of kilograms per day. Secondly, even if a small enterprise manages to get into a large network, problems with the payment of receivables will certainly begin. “Not infrequently we had to wait 30-40 days for payment for goods. And a small business needs money every day,” says Alexander Abramov. Thirdly, the policy of many large networks built on the principle of low attitude towards small producers. Because of this, you have to feel obligated for the fact that they buy products from you. Sorry, this is not pleasant. It is better to work with those stores that take your products, because they are in demand.

Video - sausage production secrets

Step-by-step plan for opening a mini sausage

Having decided to organize a sausage production business, first you need to decide on its scale, develop a concept and find a room, then do the paperwork, which will take more than one week. When all permits are received, you can proceed to the acquisition of equipment and the recruitment of personnel and the purchase of raw materials. The business plan should include work to promote products and control their quality.

What documents are needed to open a business

To organize a sausage business, you need to go through several instances. First, register a business. Then you need to obtain permission from the SES, the veterinary service and the State Fire Supervision, register with pension fund and Fund social insurance. You will also need a certificate of conformity from ROSTEST.

What taxation system to choose for registering a business to open a mini-sausage

You can choose the taxation system UTII or STS. For this, by submitting documents to tax authorities, you must immediately apply for the transition to "simplified". If you don't, you'll stay on OSNO.

Production technology

Each type of sausage has its own manufacturing technology, but it is better to include more semi-smoked sausages in the assortment, which are relatively inexpensive, but are in great demand. There are certain stages that all products go through: separating meat from bones, grinding it, salting, cooking minced meat, filling prepared shells with minced meat, heat treatment and cooling. Not bad if you use a few of your own recipes.

High-quality sausages are produced not only at meat processing plants. Many entrepreneurs make homemade blood, liver, raw smoked and other sausages, which are distinguished by excellent taste. Making sausage at home as a business brings them a good profit. How to open such a mini-enterprise, you will learn from this article.

Activity registration

In order for the regulatory authorities not to close your company, you should officially register your business and fulfill all the requirements of the SES and Veterinary Supervision. In this case, the regulatory authorities will meet you halfway and help you solve all the problems that arise in the process of activity.

First of all follows. The choice of legal form depends on the size of your enterprise. If you want to organize the production of sausages at home, it is enough to register as a private entrepreneur.

In addition, you need to obtain certificates for finished products. This can be done through a declaration-statement, which is a guarantee that your company will produce only high-quality products that fully comply with all established requirements.

To obtain a certificate, you must submit the following documents to Rostest:

- Statement;

- constituent documents;

- Documents for the production premises;

- Certificate issued by SES;

- Product range;

- Documents confirming the quality of raw materials;

- The results of the examinations;

- Product samples;

- Certification agreement.

Before you start paperwork, you need to develop a business plan for a sausage production workshop, describe the technology and compile a list of equipment.

The choice of premises for the enterprise

If you decide to open the production of homemade sausage as a business, you need, first of all, to choose the right premises. The success of your enterprise largely depends on this, therefore this stage should be given special attention. The workshop cannot be opened in a residential area, since the veterinary control will immediately close it. It should be a separate building, located at a certain distance from the house and outbuildings. In order to avoid mistakes, it is advisable to seek help from a specialist. He will help you develop a workshop project and give helpful tips for equipment placement.

The most important condition put forward by sanitary and epidemiological control is the competent distribution of the flows of raw materials and finished products. They shouldn't overlap anywhere. This is very important point, which should be taken into account when equipping the workshop. In addition, the room must be equipped with all communications (water supply, sewerage, ventilation, etc.).

Raw material

Before purchasing raw materials from a supplier, be sure to ask him for all the documents. Meat, casings, threads and other materials must have quality certificates. Verification of the authenticity of veterinary records should be entrusted to a public health officer, who can determine by appearance meat, whether it passed the examination. In addition, the specialist will find out where the products were brought from and where they put the brand.

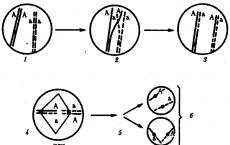

Technological scheme for the production of boiled sausages, frankfurters and sausages, meat loaves

If you buy raw materials for the production of sausages in small batches, you can conduct an examination in your own laboratory organized at the enterprise. Another option is to negotiate with a veterinary laboratory located on the market. Experienced specialists will perform all the necessary analyzes and put stamps.

To purchase raw materials from abroad, it is necessary to issue a permit for its import into the territory of our country. It is issued by the chief state veterinary inspector or his deputies. But if you want to open a mini-shop for the production of sausages, such a document is unlikely to be needed.

Technological process

Now let's consider step by step the technology for the production of sausages at home:

- Sorting meat. At the first stage, the raw materials are divided into grades. The best meat for making sausages is lean. They make high quality products from it. Lean meat contains only 30% fat. Semi-fat meat is suitable for homemade sausages of the first and second grade;

- Intestine processing. Small intestines are suitable for sausage production. They are processed immediately after withdrawal. First of all, all contents are removed from the intestine and placed in a basin with cold water. After that, the shells should be washed well, turned inside out and scraped with a knife on a cutting board. After treatment with a solution of potassium permanganate, the cleaned intestines can be used to make boiled sausage. If you want to make raw smoked sausage, the casing should be soaked in salt water for 2-4 weeks;

- Ground meat. For the production of homemade sausages, meat of different types is usually taken. It is cut into large pieces and salted, after which it is left for a day to ripen. Next, the meat must be minced, add various spices, garlic and salt. Also do not forget to add chopped bacon;

- Syringing. One end of the intestine must be tightly tied with a thread, and the other must be fixed on a special syringe or a wide funnel. As the intestine fills, the stuffing itself falls down. The most important thing is to prevent the formation of voids or air cavities. It is not advisable to stuff the intestine too tightly, as it may burst during heat treatment. This does not apply to smoked sausages, the volume of which decreases during the cooking process;

- Draft. Filled and tied sausages should be hung in a cool, dry room for draft;

- Heat treatment. To get air out of the sausage, it needs to be pierced with a needle in different places. Before frying, the product is dried in an oven. The finished sausage is cooled in a separate room suspended.

This is a traditional homemade sausage production scheme. Minor changes can be made depending on the recipe.

Staff

To organize the production of sausages as a business, you need to hire the appropriate staff, since one person will not physically be able to do all the work.

First of all, you will need a professional technologist who will control the quality of products and compliance with the sausage preparation technology. In addition, the technologist develops new recipes for meat products. You also need to hire two butchers for deboning carcasses, an accountant and a shipping agent. This is the minimum staff of workers who can serve a small min-shop for the production of sausages.

Equipment

Before you open, you need to make sure that it brings a good profit. To do this, you must first carry out careful calculations. To quickly return the initial investment, you need to produce at least 200 kg of finished products per day.

What equipment for the production of sausage at home should be purchased?

For work you will need:

- Table for deboning meat;

- Knives;

- Electric meat grinder;

- Machine for kneading minced meat;

- Special syringe designed for filling sausages;

- Bake.

The most important unit in the workshop is the oven. From her functional characteristics largely depends on the quality of the product. At the start, in order to save money, you can purchase used domestic units. Imported sausage making equipment is expensive, but it has many convenient features and high productivity.

Related videos Related videos

Costs and profits

When compiling a business plan for the production of sausages, the following mandatory expenses should be included in it:

- Registration of an enterprise and registration of permits - about $ 700;

- Equipment - from 10 thousand dollars;

- Refrigerators - from 4 thousand dollars;

- Purchase of raw materials - from 1.5-2 thousand dollars;

- Premises rent - 1 thousand dollars.

In total, at the start, you will need about 15 thousand dollars. In addition, you will have to spend money monthly on:

- Room rental;

- Communal payments;

- workers' wages;

- Purchase of raw materials.

To increase turnover, you can learn and engage in animal husbandry. In this case, you can significantly save on the purchase of raw materials. Experts believe that it can bring good profits. If you combine it with sausage production, you can get a decent monthly income. The production of dumplings as a business at home is another effective method to increase the profitability of the enterprise. Such products are always in demand, so you can earn good money in the manufacture of dumplings. You can additionally engage in the production of other semi-finished products: dumplings, cutlets, pancakes.

In this article:

There is an opinion that high-quality sausages can be made only at large meat processing plants, but it is partly wrong. Since for the production of certain types of sausages it is enough to open a small workshop.

Such a sausage production workshop can compete with the largest players in the meat industry. And its owner will receive a constant profit, part of which can be invested in expanding production or creating a small farm. Of course, these prospects are very tempting. Therefore, in this material we will tell novice entrepreneurs how to open their own sausage shop?

Choose a room

From right choice Premises depend a big part of the success of a business. Therefore, at this stage of organizing a sausage shop, you need to be extremely careful and prudent. The thing is that it is forbidden to choose a room for the production of sausages inside a residential building. According to the sanitary rules for meat processing enterprises, the sausage shop should have several rooms:

- cooling chambers for storing raw materials;

- cold rooms for minced meat maturation and storage of finished products;

- shop for processing raw materials;

- workshop for defrosting and subsequent processing of raw materials;

- manufacturing facility;

- a separate room for storage and preparation of spices;

- warehouse for bulk and dry raw materials;

- thermal shop;

- utility rooms for storing tools, materials and additional equipment;

- dishwasher compartment;

- household premises.

Upon agreement with the authorities sanitary and epidemiological supervision Russian Federation, some types of premises can be connected, and some can not be used at all. But for this it is necessary to draw up a technical task in which you need to indicate the following features: give calculations of the consumed raw materials, an approximate range of products, indicate the list of equipment used, production technology. Further, this technical task must be agreed with the veterinary services. And only after the sanitary and epidemiological supervision, the veterinary service and the administration approve the project, you can start organizing a business.

We issue certificates

According to Russian legislation, the production of any product must be certified. Today there are two types of certification:

- GOST certification system - suitable for large factories. Since the list of required documents for this procedure includes: test report, veterinary certificate, quality and production system certificate, hygiene certificate;

- rules for the certification of sausages by means of a declaration statement. This form is more suitable for mini sausage production workshops. It is carried out by submitting an application, which indicates that the workshop will produce high-quality sausage that meets all standards.

Standards governing sausage production

When organizing the production of sausages, it is mandatory to familiarize yourself with the following norms and standards:

- GOST 52196-2003 - "Cooked sausage products";

- GOST 9792-73 - "Sausages and products from beef, pork, lamb and meat of other animals";

- GOST 779-55 - "Beef meat in quarters and half carcasses";

- GOST 1935-55 - "Lamb and goat meat in carcasses";

- GOST 7699-78 - “Potato starch. THAT";

- GOST 4495-87 – Whole cow's milk powder. THAT";

- GOST 7724-77 - “Pork in carcasses and half carcasses. THAT";

- GOST 9793-74 - “Meat products. Moisture determination methods”.

The above list of standards can be continued further, but these norms are fundamental. For aspiring entrepreneurs who plan to open a mini sausage production workshop, the following may be useful OKVED codes:

- 15.13 - Production of meat and poultry products;

- 15.13.1 - Manufacture of prepared and canned products from meat, meat by-products and animal blood;

- 15.13.9 - Provision of services for heat treatment and other methods of processing meat products.

We buy raw materials for the production of sausages

To eliminate difficulties and problems, only certified materials and products should be selected as raw materials. Since the quality of the finished product depends on the properties of raw materials. The main raw materials for the production of sausages are pork and beef. But some manufacturers, depending on the characteristics of the finished product, can use lamb, chicken and other animals.

By fatness, meat of any category can be used. However, beef is usually chosen with a minimum amount of fat. According to the thermal state, chilled, steamed and thawed meat can be used for the manufacture of sausages.

Steam beef is used only for the production of boiled sausages, sausages, sausages. Quality products are obtained from such raw materials. And all because fresh meat absorbs moisture well, compared to thawed or chilled raw materials, which is very important in the manufacture of sausages. The increased moisture capacity of fresh meat makes it possible to obtain finished products of the established moisture content, which improves its palatability.

It also makes it possible to reduce the cost of the production process, since in this case there is no natural loss during cooling.

Animal fats are also used as raw materials. They are added to increase the calorie content of finished products. In the manufacture of dietary sausages, melange and milk are additionally used, and for meat and vegetable products - starch, wheat flour, various cereals and soy concentrate.

In accordance with the technology, in addition to raw materials for the production of sausages, components are needed that give it a specific aroma and taste. These ingredients include spices, spices, salt, nitrite and sugar. Add them in the proportions indicated in the recipes. For spices and spices, there are requirements for chemical, physical properties and the degree of bacterial contamination. To improve the quality of finished products, some manufacturers use components such as glutamate, sodium ascorbate and phosphates.

Cooked sausage production technology

Cooked products are products made from meat and subjected to roasting and boiling. The technological scheme for the production of boiled sausages is displayed below.

So, technological process cooking boiled sausage includes the following steps:

cutting meat

cutting meat- an operation to dismember the carcass into several parts, taking into account the anatomical boundaries, which are indicated in the technological instructions. Half carcasses of pork are divided into 5 parts, and beef - into 8 parts.

Meat deboning

Meat deboning- separating the pulp from the bones. This operation is carried out manually by specialist deboners using sharp knives or on special equipment.

Meat trim

Meat trim- removal of tendons, fascia, small bones, cartilage from the pulp. At this stage of production, the meat is packaged depending on the amount of fat and connective tissue in it.

Grinding on special machines. Depending on the thermal state and type, the meat is ground on tops with different hole diameters or in a special meat grinder.

Ambassador and maturation of meat. After grinding, all raw materials are laid out in special containers and subjected to salting. The meat is seasoned with spices and spices and placed in special chambers in which the temperature is maintained at 2-4 ° C. In the process of maturation, minced meat acquires a specific aroma, stickiness and its moisture capacity increases.

Secondary grinding

Secondary grinding process.

Upon completion of maturation, minced meat is re-crushed on cutters and tops. cutter - equipment that resembles a bowl with wide and thin blades mounted inside.

Ground meat

Stage of minced meat preparation.

During this operation, food additives are added to the minced meat: spices, spices, bacon. Then everything is thoroughly mixed and water and ice are added to the mixture in the right amount. The purpose of this technological stage:

- obtaining a mixture homogeneous in composition;

- mixing meat particles with water;

- uniform distribution of bacon pieces in minced meat.

syringe

syringe- this is the filling of artificial and natural shells with minced meat. At the end of this operation, sausages acquire their inherent shape. The diameter of the casings depends on the type of sausage being made. Filling the shell with minced meat is carried out on special equipment using a syringe.

knitting

Knitting sausages: if the sausage is large in diameter, then it is tied transversely every 4 cm. This ligation improves the strength of the casing. At this production stage, workers also carry out scalding, piercing the shell of the loaf where air has accumulated. Sausages placed in an artificial casing are not mated.

Draft

At this stage, the sausage loaves are hung on the slats of the frames in 5-12 pieces so that they do not touch. Then the frames are placed in a special compartment for sedimentation, where the sausages are kept at a temperature of 5-7 ° C for 2-4 hours.

Roasting

After the draft, the sausages are sent to the roasting chambers, where they are processed with smoke from the sawdust of a certain type of wood. (This operation lasts about 4-6 hours at a temperature of 75-80°C.

Cooking

Cooking- the final heat treatment operation, which is carried out in steam chambers, at a temperature of about 80 ° C. Sausage loaves with a large diameter are cooked for about 2 hours, and sausages for 10 minutes. The readiness of the sausage product is determined by measuring the temperature in the thickness of the loaf, which should be about 70 ° C.

Cooling and storage

Cooling. At this stage, sausage sticks are cooled under the shower or in special rooms. After cooling, the sausages are dried in a special compartment and sent to cold stores for storage.

Storage. Most cooked sausages do not keep for a long time. The duration of the sale and storage of sausages depends on the characteristics of the casing used.

We draw up a business plan for opening a workshop for the production of boiled sausage "Molochnaya"

1. We buy equipment for the production of boiled sausage:

Defroster DRx14 - equipment designed for defrosting raw materials. average price defroster is 63,000,000 rubles;

spinning top- a meat grinder of large sizes, which is used for grinding meat in large quantities. Price - 455,000 rubles;

twister– equipment that allows you to dose and twist sausages

Conveyor for trimming and deboning meat. The design of such equipment provides for the creation of several conveyors with different capacities by sorting sections. The average cost is 660,000 rubles;

Trolley - 2000 rubles;

Ice maker with a capacity of 100-6000 kg. per day costs 100,000 rubles;

cutter used for re-grinding minced meat. The bowl capacity of this equipment can be 80-420 liters. Price - 800,000 rubles;

block cutter– frozen meat grinders. They are used for grinding frozen blocks of meat for their subsequent processing in meat grinders and cutters. Cost - 120,000 rubles;

Syringe vacuum rotary type. Used for stuffing various kinds pates and sausages. Price - 520,000 rubles;

Slicer- for grinding various food products and cutting them according to the specified size and shape parameters. Cost - 90,000 rubles;

The clipper is designed for packaging food products in bags. Price - 700,000 rubles;

Thermal chamber- equipment used for heat treatment of sausages. Main processes: roasting, drying, boiling, cooling, smoking. Cost - 2,710,000 rubles;

Total: 69,257,500

The cost of delivery and installation of equipment - 1,000,000 rubles

Total capital costs: 70,257,500 rubles.

2. We hire workers

For the production and sale of products, 18 workers are needed, which include:

- director with a monthly salary of 50,000 rubles;

- accountant - 20,000 rubles;

- 2 masters - 20,000 rubles;

- driver - 8000 rubles;

- technologist - 16,000 rubles;

- 10 workers - 100,000 rubles;

- loader - 8000 rubles

- seller - 8000 rubles;

The total monthly wage fund for the designed workshop will be: 230,000 rubles.

Annual payroll fund: 2,760,000 rubles.

3. We plan sales volume

The planned workshop will be able to produce 70 tons of finished sausage products per month. The average cost of 1 kg of milk sausage is 280 rubles per 1 kg.

Monthly revenue for the month will be: 280 * 70,000 = 19,600,000 rubles.

Annual revenue from the sale of sausage products: 235,200,000 rubles

4. Calculate the cost of production

We calculate the material costs for 1 ton of finished products ...

Costs for the purchase of basic raw materials and materials:

- trimmed beef - 41250 rubles;

- trimmed pork - 73,200 rubles;

- melange or chicken eggs - 4000 rubles;

- cow's milk powder (whole) - 3000 rubles;

- edible salt - 300 rubles;

- sodium nitrite - 10 rubles;

- granulated sugar - 30 rubles;

- ground white or black pepper - 400 rubles;

- ground allspice - 320 rubles;

- nutmeg - 400 rubles;

Total cost of raw materials: 122,910 rubles.

Auxiliary materials:

- shell - 3 rubles;

- twine - 2 rubles.

Total cost of auxiliary materials: 5 rubles.

Energy costs of all types and water:

- water - 250 rubles;

- steam - 3 rubles;

- cold - 160 rubles;

- compressed air - 450 rubles;

- gas - 330 rubles;

- electricity - 200 rubles.

Total costs for energy and water: 1393 rubles.

Total costs for the production of 1 ton of products: 124,308 rubles.

Calculation of the cost of 1 kg of boiled sausage "Milk":

- Cost of materials, including returnable waste - 220.3

- General business expenses - 3 rubles;

Commercial expenses - 1.2 rubles;

Full cost of 1 kg. finished products - 224.5 rubles.

We calculate the fixed annual costs:

- Equipment depreciation - 1257.5 thousand rubles * 0.12 = 150.9 thousand rubles;

- Rent and repair of premises - 80,000 rubles;

- Salary - 2,760,000 rubles;

- Administrative expenses - 60,000 rubles;

- Utilities - 70,000 rubles;

- Advertising - 450,000 rubles.

Total fixed costs: 35,709,000 thousand rubles.

Variable costs (per year): 224.5 * 70,000 * 12 \u003d 188,580,000 rubles.

Gross costs: 35,709,000 + 188,580,000 = 224,289,000 rubles.

Coverage amount: 235,200,000 - 188,580,000 = 46,620,000 rubles. Coverage ratio: 46620000/235,200,000=0.19

Threshold revenue: 35,709,000/0.19=187,942,105 rubles

Sales revenue is above the threshold.

Calculation of profit and profitability:

Profit is calculated as the difference between the sales proceeds and the total cost of production. 235,200,000 - 188,580,000 = 46,620,000 rubles. Profitability of products (profit from the sale of sausage products / cost): 46,620,000 / 188,580,000 = 24.7%.

The meat business industry is represented different types products. Sausage in any form does not lose its popularity among consumers with different material incomes. But quality and prices do not always suit the population, which causes interest in new manufacturers that may meet their expectations. Therefore, the meat products segment opens the door to young entrepreneurs who are interested in how to open a sausage shop from scratch. The business is profitable, but requires serious financial and physical investments. How to start a sausage business? Is the meat direction profitable in the face of serious competition for a novice entrepreneur? Step-by-step instruction The article will provide answers to exciting questions.

Summary

Opening a sausage enterprise implies two investment options, which depend on the financial situation of the entrepreneur:

- A small workshop equipped with automated equipment, with a capacity of up to 200 kg per shift. Does not require large areas for placement (up to 50-70 sq. m). To launch a sausage shop, investments from 500 thousand to 1 million rubles are needed. The range is minimal, no need to spend money on developing a recipe until the shop starts to make a profit. Relevant for farmers who decide to expand the scope of animal husbandry and independently process poultry, pork, and beef.

- Automated sausage line, designed for productivity from 500 kg of products per shift. Requires powerful equipment, which requires a room of 100 sq. m. A small business can grow into a large sausage supplier if it organizes activities correctly. Investments from 5 to 10 million rubles or more will be required.

Regardless of what business idea a novice entrepreneur has, you need to go through the steps that are the same for both a small sausage shop and a production complex:

- Writing a business plan with detailed calculations and analysis of the selected segment.

- The choice of the form of activity, registration with the Federal Tax Service.

- Collection of documents for opening a sausage production.

- Search for premises that meet the requirements of inspection services and project conditions. Repair, equipment of the shop for the production of sausages.

- Selection of raw material suppliers (if necessary).

- Promotion of products on the market.

- Making a profit, analysis of the work performed.

Let's dwell on each stage in more detail.

Project preparation

Business begins with a project that reflects the idea and how to bring it to life. The analysis of competition is carried out. In sausage production important indicator. Depends on the region in which it is planned to open a workshop and further sell products. If there are only a few local producers and they do not interfere with attracting the required number of target audience, then it makes sense to enter the local market. In a different situation, you will have to look for customers in other regions or make products more attractive to buyers than those of competitors.

Starting a business without analyzing the market and consumer demand is risky. You can invest money and not get the desired income. The conclusions are entered into the business plan in order to understand whether the idea is profitable or whether it is better to choose a different direction.

The second point at this stage is the choice of the legal form of entrepreneurship. Two forms are suitable for a sausage shop:

- An individual entrepreneur, if there is only one owner and plans only the wholesale sale of his products, without opening personal outlets for the sale of sausages, sausages, meat. Registration requires a smaller package of documents and finances.

- A limited liability company, if the sausage shop is opened by two or more founders. It is relevant for large-scale production, where large investments are needed in equipment, premises, promotion, but this is beyond the power of one person.

- Peasant (farm) economy, if a sausage shop has decided to open an entrepreneur living in a rural area, having a plot or premises for accommodating sausage equipment. Beneficial for individuals engaged in breeding animals or poultry and decided to independently process meat into sausages and sell to the consumer.

Which form of activity registration to choose depends on the specific case, but you always need to weigh the pros and cons and find the most favorable conditions. At this stage, it is worth studying the requirements for preferential taxation so that taxes are feasible at the stage of promotion.

Paperwork

The meat direction in business is associated with walking around the controlling departments. They issue documents for the premises, communications. Confirm availability specific equipment. Check for compliance of meat with the requirements of the veterinary service, product quality.

The list of documents for opening a sausage shop and further delivery of goods to store shelves contains the following items:

- Documents for the premises (rent or ownership, technical conditions, sanitary condition). We get them at the BTI, SES, the fire department. The room must be spacious to accommodate a workshop, a warehouse for storing raw materials and the final product.

- Sanitary book for each employee of the shop.

- The conclusion of the veterinarian on the quality of meat, compliance with the conditions for cutting meat.

- License for sausage products, recipe of each type, laboratory tests.

- Trademark registration.

If the documents are not collected completely, no retailer will want to enter into a contract for the supply of sausage. The opportunity to earn is shifted indefinitely.

Advantages and disadvantages

The cost of starting a business depends on the condition of the building chosen for production, the distance from the electricity, water supply, and sewerage lines. Sausage production has both positive and negative sides for a budding businessman. The profitability of a sausage shop depends on many conditions, but with the right approach it is 25-30%.

Pros and cons must be considered at the stage of preparing a business plan. The advantages include the following points:

- Constant demand for products.

- Large networks are interested in purchasing products from local manufacturers.

- You can start a sausage shop as an extension of your own livestock farm.

There are also disadvantages:

- There is a lot of competition, it is difficult to reach the consumer and win his trust.

- Paperwork can drag on and push the launch of the sausage shop to work.

- Constant monitoring by the veterinary service, SES, Rospotrebnadzor, the need for laboratory confirmation of product quality. Without this, there is no way to sell products to retail chains.

- The dependence of reputation on the quality of raw materials, it is not so easy to find good suppliers if you do not have your own livestock farm.

Eventually

There is always a demand for sausage products, but the competition in the industry is quite tough. If there is an opportunity (a special recipe, meat at a bargain price or a private farm) for the production of sausages that will attract the target audience with price, taste, quality, then there are no barriers to the implementation of the plan. We recommend that you familiarize yourself with the sausage shop business plan with calculations on our portal in order to get more information for reflection.

At first glance, the business of selling sausages is simple and can be done by any entrepreneur. But in fact, it has many pitfalls. Therefore, it is necessary to study the topic in advance, when a business plan is still being formed. This is the only way to ensure the success of the sausage business.

Niche analysis

First of all, it consists in studying competitors. Walk through the nearest points of sale in the area where you plan to open your sausage shop. Study the range of competitors, their pricing policy, which suppliers they work with, what offers they rely on. This will give you an understanding of how to form your own assortment of sausages.

It is advisable to study the opinion of the residents of the area in order to understand how the existing proposal covers their needs. And also to understand what specific types of sausages they prefer, which manufacturers they like best. All these studies should provide for a business plan.

Types of sausages

And, of course, how to open a sausage shop if you don’t know what types of sausages exist on the market in principle. There are such types:

- boiled;

- boiled-smoked;

- semi-smoked;

- raw smoked;

- dry-cured;

- liver.

The most popular is boiled sausage, which is made from minced meat and often contains a considerable amount of soy. Due to the fact that the product is boiled (at a temperature of about 80 ° C), it contains a lot of water and has a short shelf life. When boiled sausage is smoked, it turns out boiled-smoked sausage. The composition of such products often contains pieces of meat and a lot of spices.

The technology for the preparation of semi-smoked sausages involves frying, boiling, and only then smoking. Raw smoked sausages do not undergo heat treatment at high temperatures, but are cold smoked at a temperature of 20-25 ° C. It takes about 40 days to make them. To speed up the ripening process, a special acid is added to them.

Dry-cured sausages are made from marinated minced meat. They are smoked for 3-4 days, after which they are dried at 15-18 ° C. The cheapest are liver sausages, which are prepared from minced meat based on meat by-products.

Your assortment

In order for your business to get a chance of success at the start, you need to correctly form your own assortment. Based on market analysis data, it is necessary to purchase about 30 different types of sausages in small quantities. Then, based on the results of a certain period, conduct an analysis of demand. The next stage of the purchase should start with popular sausages, and refuse unpopular ones.

Features of drawing up a business plan

Of course, a business plan cannot take into account all the factors that affect the success of a business. They can be foreseen, but it is difficult to predict how decisive they will be. But it is necessary to focus on the monthly amount of investments in turnover of about 30 thousand rubles. At the same time, the monthly profit of your sausage store should be 6-120 thousand rubles.

As practice shows, all the estimated costs that the business plan provides for must be multiplied by two. This is the only way to get a picture as close to reality as possible. If the amount that is obtained clearly exceeds your budget, you can take out a loan, or try to get state assistance for entrepreneurs.

Sausage shop

When choosing a room for a sausage shop, one should be guided by the rules for selecting any other grocery store. So, the premises must be sought in a busy place, preferably away from competitors. Please note that it must comply with the sanitary standards that are put forward by food stores. Therefore, it is advisable to look for a place where a similar object used to be located, then it certainly meets all the requirements. Otherwise, the business plan will have to include the costs of issuing the relevant certificates. Then it is advisable to hire a competent lawyer, because in each region the list of required documentation may change.

By the way, your store can work in the following formats:

- stationary institution;

- stall;

- car shop.

Equipment and other organizational issues

There is no point in getting too sophisticated with the design of the room. Enough for a shop simple solution with a minimum of decorations. The main place in the room should be occupied by equipment with a wide range of sausages. Refrigerators and refrigerated display cases should be included in the procurement plan from equipment.

Often suppliers offer branded equipment for free, but with conditions for the sale of their products. Sometimes it pays to take a closer look at these options.

It does not hurt to buy a slicer for a store - a device for cutting sausages and meat. But if you trade from a car shop or a stall, this equipment will be superfluous.

Supplier selection

It is not difficult to find suppliers, it is more difficult to find conscientious and reliable ones. It is advisable to personally drive up to the production and warehouses to see how the product is made, which you will offer to the final buyer. It is necessary to evaluate suppliers not only by the quality of sausages and pricing policy, but also by the remoteness of production from your store. The final price will also be affected by the cost of logistics. When visiting enterprises, immediately clarify the schedules and terms of delivery, especially regarding the holidays, when you will have an increased demand for products.

Store staff

It is extremely important to pay attention to the selection of the seller in the store. This is the person who is in direct contact with the client. And the success of your business largely depends on how well he knows how to establish this contact. The rest of the details, knowledge of the range, the features of a particular product is a business that will come with experience. But it is better, of course, to take a seller who is versed in these matters.

Store advertisement

- Catchy store name. It should be short, memorable and clearly convey the essence of the trade.

- Signboard. It is advisable to design it in an original, bright and catchy way if you are in a busy part of the city. If not, better pay attention good design windows and showcases.

- Discounts and promotions. Only they can bring excitement to your store by attracting new visitors. Offer tastings, attract promoters, buyers will at least remember you.

- Order packages with your logo and pack products purchased from you in them for free. Thus, your customers will become free advertising for your store. As a rule, packages are ordered with a circulation of 5-10 thousand rubles. They last an average of six months.

- Distribution of flyers The best way tell about your promotions and the store in general. But you need to hire conscientious promoters who will actually distribute leaflets, and not throw them away.

Settlement part

In addition to the costs of registering an enterprise, renting premises and issuing all permits, it is necessary to allocate funds for:

- scales - 5 thousand rubles;

- refrigerated showcase (bonnet) - 80 thousand rubles;

- slicer - 20 thousand rubles;

- refrigerating chamber - 25 thousand rubles.

- stickers, knives, packing bags (per month) - 2 thousand rubles.

In total, it will take about 30-40 thousand dollars to open a store in the district center. At least a thousand dollars will be spent on utilities and other expenses per month. At the same time, monthly income can be 2-4 thousand dollars. If you plan your business correctly, it can pay off in a year and a half.