How to make a wooden door at home. Covering the corridor with drywall and OSB boards Doors from OSB boards

How to make a house from OSB with your own hands without losing quality and saving money? Indeed, with the same area, the cost of construction, depending on the materials used, can vary greatly. And with some construction technologies, you can’t do without renting powerful equipment. The cheapest, fastest and in a simple way considered frame housing construction from sandwich panels or OSB slabs.

OSB or oriented strand boards are 90% wood chips. The remaining components are binder waterproof resins. Building panels are obtained by pressing large fragments of coniferous wood, aspen and larch. The size of the chips is up to 15 cm. Inside the future product, it fits into three rows. The outer layers are placed parallel to the long side of the slab. The middle layer is perpendicular. The pressure in the press is so strong that the fibers interpenetrate. This guarantees high strength of the final product.

The resulting material is sometimes referred to as improved wood. It is lightweight and easy to handle. Unlike natural solid wood, OSB does not burn or rot; there are no knots or voids in their structure that reduce its stability. In terms of its characteristics, it surpasses sheets of chipboard, MDF or plywood. These panels hold fasteners well: bolts, nails, dowels.

The use of phenol as part of binder mixtures caused the most questions from consumers. But at present, many manufacturers have begun to switch to polymer resins that are completely safe for health. Such a product is labeled "ECO" or "Green" on the packaging.

Construction from OSB panels

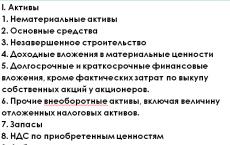

In private housing construction, 4 types of OSB panels are used, differing in water resistance, strength and price.

Moisture resistance depends on the binding adhesive, and strength depends on the relative placement of chips in its structure. Additional resistance to all types of influences is given by lamination and varnishing of the surface. Such plates can be used in the construction of formwork, and repeatedly.

Type 1. OSB-1 has little resistance to stress and is hydrophobic. They are taken for decoration during interior work or furniture manufacture;

Type 2. OSB-2 is also afraid of moisture, but is much stronger and therefore suitable for the construction of partitions, false ceilings, that is, those parts where there are no heavy loads and the possibility of getting wet;

Type 3. OSB-3 are suitable for creating outdoor facades, they are high-strength and moisture resistant;

Type 4. OSB-4 are very durable, they are used to assemble load-bearing elements of walls and roofs, they give rigidity to the structure.

House made of OSB slabs for the most part from products of the 3rd type. Height - up to 3 floors inclusive.

Construction features

- The work takes 2-3 weeks without involving heavy machines.

- The building is not even built, but assembled as a constructor from ready-made parts made at the factory. They are made to order, for a specific project. This means that there will be no unforeseen expenses and urgent purchases of missing building materials, as well as hard-to-sell balances after the completion of all stages.

- OSB boards are much cheaper than bricks or foam blocks.

- The frame building weighs a little, almost 5 times less than a brick house of the same cubic capacity. Therefore, the structure does not require a massive and expensive foundation.

- In the OSB-3 box, layers of thermal insulation can already be laid during production. This is how SIP panels are made. Then additional insulation is not needed. Inside, a comfortable temperature is maintained with external differences from -40 to + 40 ° C.

- The smooth surfaces of the panels do not need to be primed and leveled before finishing. decorative coating on walls or ceilings. Unless you need to putty joints.

- Subject to the technology, OSB houses do not shrink and warp.

OSB boards are a versatile material and can be used at any stage of construction.

Foundation. Laminated or veneered sheets can be used as foundation face shields assembled on a beam frame. They are fastened with ties made of steel wire or thin fittings.

Floor. The plates are laid on the logs with the long side perpendicular to them. A technological (dilation) gap of 3 mm is left along the perimeter of the panels. It is needed to compensate for thermal expansion or other deformations. There is also a gap of 12 mm between the walls and the floor. The sheets themselves are fixed using the “comb-groove” profile and, for reliability, are reinforced with mounting glue.

The connection of the short sides must always take place on supports. An additional layer of waterproofing is pulled under the flooring adjacent to the ground. The step between the lags is determined by the thickness of the material:

Walls. Oriented strand products can be mounted both vertically and horizontally. When assembling the walls, sheets of 12 mm thick are used. They rest on bars with a pitch of 400 and 600 mm. Between the plates, as well as at the junction with door and window openings, gaps of 3 mm are left. For insulation from the outside, the building can be insulated with mineral wool.

Roof. The sheets form a continuous crate, on which the roofing is subsequently laid. Installation begins along the ridge, wood panels are laid similar to the floor. Each sheet is attached so that two supports are located under it. The joints of the plates should also fall on the rafters.

In order for the roof to withstand the snow load, choose the gaps between them depending on the thickness of the slab:

When working at any stage, consider the main rule of building a house from OSB: the joints of the support beam and panels must be sealed. Joints and corner parts are fastened with self-tapping screws in increments of 15 cm.

Due to the properties of oriented strand sheets, the structure does not rot and is not undermined by insects. He is also not afraid of fires. According to experts, the service life of a house made of OSB-3 panels is the same as that of a brick house.

Video

We offer you to watch a video about building a house from OSB panels.

Source: KakPravilnoSdelat.ru

For the manufacture of doors, manufacturers are increasingly using composite materials, plastic, steel. However, the tree has not lost its popularity. Durable and warm material is ideal for front doors to the house. From the boards they independently assemble a canvas for outbuildings and baths. Making a wooden door with your own hands is easy. You just need to have a good board and a set of tools.

Being engaged in the production of wooden doors, you need to know the advantages and disadvantages of the material. The final result depends on this. The main difference between wood is its hardness. Soft woods are easy to process, but less resistant to moisture. Such material is suitable for interior doors. It is difficult to process hardwoods with hand tools, but the material is more resistant to moisture. Such wood is suitable for the manufacture of entrance doors.

Speaking of wood species, it is worth considering the resin content of the material. Larch occupies the first place in this regard. The product from it will stand in dampness for a long time. The resin protects against decay.

The following requirements are imposed on the choice of the board:

- the minimum number of knots;

- moisture content of wood is not more than 15%;

- perfect evenness.

For outbuildings, used material taken from the dismantling of old buildings is suitable. Beautiful doors to the house are best made from a new board.

hardwood

- Birch quite hard and difficult to process, but has an attractive texture.

- Beech characterized by increased strength, but deforms with a change in humidity.

- Alder soft and rots quickly in high humidity.

- Oak hard, tends to split, but resistant to moisture and beautiful.

- Nut has an interesting texture, is easy to process, is not afraid of moisture and mechanical stress.

- Maple moderately hard, well processed, moderately resistant to moisture.

For the manufacture of wooden entrance doors, oak or beech is more often used.

conifers

- Of the conifers, the most popular is considered pine. Soft wood is easy to process, but does not resist moisture well. The material is best used in the manufacture of wooden interior doors.

- Larch characterized by a beautiful texture and great resinity. Solid wood resists moisture perfectly, which makes it possible to use the board for assembling entrance doors.

- Spruce knotty, lighter and softer than pine, slightly inferior in strength.

Instruments

In production, special machines are used for the manufacture of wooden doors.

- Reismus required for board processing. The most productive are bilateral planers, cleaning the workpiece in one pass.

- Without milling machine tool production of wooden doors is impossible. With its help, lock joints are made on the boards, chamfers are selected, curly blanks are processed.

- When pasted on wooden frame overlays apply press.

- Circular saw spread the board to the desired size.

To do it yourself at home wooden interior doors, no one will buy expensive machines. Electric board is suitable for spreading the board disk saw.

You can choose grooves, and you can process the surface of the workpieces manual router.

Additionally, you should have on hand:

- drill;

- screwdriver;

- wood saw;

- grinder;

- chisels, mallet, corner, level, tape measure.

For painting the door leaf, it is advisable to use a compressor with a pneumatic gun.

Necessary materials

For the manufacture of wooden door with your own hands you will need the following materials:

- dry grooved board;

- self-tapping screws;

At the time of purchase, the thickness of the boards is selected taking into account the installation location of the door leaf. For an interior sash, wood 25 mm thick is sufficient. For front door use a board 50 mm thick. After purchasing, it is advisable to dry the wooden blanks by laying them on a flat surface using linings.

Additionally, a mortise lock, hinges, handles, and a peephole are bought for the entrance wooden door. For an interior sash, it is enough to take hinges and a handle with a latch.

How to make a wooden door

When assembling a simple wooden door with your own hands, a drawing, a complex diagram is not needed. It is enough to measure the height and width of the door leaf. The dimensions of the sash are calculated so that it fits into the grooves door frame, and there was a gap of about 5 mm around the perimeter. In the manufacture of a wooden door, the main elements are prepared: a tongue-and-groove board with a tongue-and-groove lock for the canvas and a cross member made of edged blanks.

Composed step-by-step instruction do-it-yourself wooden door assembly from the following steps:

- boards are sawn according to the height of the future canvas and laid out on a flat surface in compliance with one direction of the pattern of annual rings;

- spikes with grooves are lubricated with carpentry glue, connect all the boards, tightly squeezing the canvas with a clamp;

- after the glue has dried on the extreme bar, a spike is cut off from the end of the product, and the entire surface of the shield is subjected to milling and grinding.

- To prevent the sash from falling apart, the structure is fastened with crossbars. edged board they give the shape of a trapezoid, make grooves on the canvas to a depth of 1/3 of the thickness of the wooden blank and lubricate them with carpentry glue. The crossbars are inserted into the recesses, tapping with a mallet. For reliability, you can fix it with self-tapping screws.

- In order for the sash to last longer, it is treated with antiseptic impregnations. If it is necessary to install a double-glazed window on a wooden door, a window is cut out in the shield with a jigsaw. A plank is nailed in the center of the end of the entire perimeter of the opening - an emphasis for two glasses. After installing the double-glazed window, the edges are framed with a glazing bead or a decorative strip.

If you need a thick canvas, the sash is made of two layers. In the two-layer manufacturing technology of a wooden door, the perpendicularity of the boards of both shields is observed. Glue them together with wood glue.

Keyway

You can assemble warm wooden doors for a private house without much effort from boards with dowels. Manufacturing technology consists of the following steps:

Usually for the entrance to the house massive doors are made of oak, beech or cedar. The canvas can be decorated antique or give it modern style. A simple wooden door, assembled with your own hands from a pine board, is suitable for a bathhouse or a barn.

Shield

Shield door - a budget option. The frame is a rectangular frame made of board. Fiberboard sheets are glued on both sides. In industrial conditions, an additional lining of veneer or laminate is used. Another feature of the door design is filling the voids of the frame with insulation from woodworking waste: sawdust, shavings, small chips, corrugated cardboard.

Consider how to make a do-it-yourself wooden panel door from boards step by step:

- according to the size of the sash, a sheet of fiberboard is cut out, as well as blanks from boards for the frame;

- all elements are laid out on a flat surface, interconnected with wood glue and self-tapping screws;

- the lower shield made of fiberboard with a wooden frame formed voids that are covered with sawdust;

- the upper part of the frame is lubricated with glue, a second shield made of fiberboard is laid and the entire sash is pressed with a press.

On the finished door leaf, as a finish, veneer can be glued on top, and sharp corners can be rounded off with a milling cutter.

Paneled

The design of paneled doors is a frame made of timber, inside which a set of horizontal crossbars, vertical lintels, and mullions are inserted. As a result, cells are formed for inserting a panel. The technology allows you to make a wooden door with glass, plastic, and other materials. The strength of the canvas depends on the number of crossbars.

The panel is cut out in such a size that it enters the cell with a gap of 2 mm. Glass inserts or fiberboard are immediately fixed with glazing beads. The edges of a thick plywood or chipboard panel are milled until they become thinner by 2 mm of the grooves cut on the frame. The framing beads are attached last.

Decor

Decorating a homemade wooden door begins with grinding. Further processing goes with an antiseptic that protects the wood from dampness and pests. After drying, the surface of the door is covered with two layers of primer or putty. The final layer is paint or varnish.

If there is a professional tool, as well as certain skills, the canvas is decorated with carvings, stencils are cut out and even mosaics are made.

OSB (Oriented Flat Strand Board) is now widely used in construction. I first encountered him in the late nineties of the last century. A company that sells perfumes threw boxes of this material in the trash. And I, after dismantling the boxes, formed a whole bunch of plates 600x800x6mm. I liked the texture of the material so much that I immediately decided to use it for decorative purposes. as a finishing material. Well, he made a lot of things out of it. Here are speakers with OSB finish, for example.

I made a couple of bedside tables, I already mentioned them here. Door with OSB inserts. Here is the decoration of the hallway and corridor.

We cut out panels and three types of rails for embedding panels. Reiki sawed out on a simple machine "Skillful Hands" - greetings from the USSR for 32 rubles.

I attached the panels to the walls with glue and small nails. All this is processed with sandpaper, then stained and varnished. Well, here's a brief overview. Maybe someone will like it and it will be useful. By the way, recently I finished the kitchen as well as the corridor, but not with OSB, but with laminate. And I didn’t saw the slats, but bought them ready-made in the construction arsenal. Two packs of extra laminate were formed, so I decided to use it in this way. One laminate board has a length of 1200mm. We make the height of the curb 800mm., That is, we saw off 400mm from each board. We assemble the wall, alternating boards of 800mm and 400 + 400. Thus, we obtain a waste-free, one-piece construction of the curb with inconspicuous seams. Glue to the wall with liquid nails. Close up the top plastic profile. Pour PVA glue into the gap between the wall and the laminate and carefully hammer the profile. In the photo you can see how it turned out.

My house has two floors, and most of the rooms have been relatively or completely renovated. But the corridor, where the boiler is located and the exits to the bathroom and toilet, is still unfinished. Finally got around to it:

1. The condition of the room can be seen in the photo. I insulated the wall near the boiler with foam blocks, but it wasn’t enough for one strip, so it stands. The second wall used to have a window leading to summer kitchen, I laid it, but the transition with the wall was very large. There was not enough time to plaster normally, so former window the remains of concrete mortar from other works were taken out.

2. I cleaned the walls with a broom, and proceeded to install the profile on the wall. I measured the desired piece, cut it off with scissors for metal. The wall is not long, so I decided to put the profile on 3 anchor bolts.

3. With a drill for metal, I drilled holes for the bolts in the profile. The drill took a slightly smaller size than the thickness of the bolt.

4. With a concrete drill, I made holes in the wall.

5. Installed the anchor bolts on the profile as shown in the photo.

6. I attached the profile with bolts to the holes and, using a hammer, drove them into the wall approximately at the middle of the length of the anchor.

7. Then, with the help of a screwdriver, I tightened the bolts tightly, pushing them a little into the profile.

8. This is what a fully installed profile looks like.

9. Installed the remaining two profiles in the same way.

10. Under the boiler, I have a rather tangible threshold, on which there is a cat litter box and a voltage transformer for the boiler. In addition, there are a lot of taps near it, both water and gas, so you can’t close them with shelves. Access to them should always be complete, so I decided to make a closing wall with a door, immediately from the toilet door, there is just a beam on which the wall is fixed. I cut off a piece of the profile, and installed it with the help of self-tapping screws. On both sides, he made cuts in the profile on the sides, bent them and fastened them with steel self-tapping screws with a press washer (flea).

11. From above, I installed a similar crossbar in the same way.

12. After that, it was necessary to install the crossbeams to which the door would be fixed. Yes, and to strengthen the structure, it will be just right. I measured the length of the desired piece of profile from floor to ceiling. For a tight installation to an existing profile, I made cuts on the sides of the profile at the points of its joining with the installed profile.

13. Bent and smoothed the edges with a hammer, as in the photo.

14. I fixed it with “fleas”, the result is in the photo. It turned out solid, there is no backlash anywhere. On the floor, I also fixed it for the cut sides of the profile. But for this I used anchor bolts.

15. Installed another transverse profile in the same way.

16. After the installation of drywall began directly to the profile on the wall where the window used to be.

17. First, I planted it on a few screws from above and below, and then walked over the entire sheet. The wife was brought in to fix the sheet.

18. It took 2 sheets, but there are good pieces left that will find a place in the house.

19. From below I have sewer and heating pipes, so they need to be closed. To do this, I installed another piece of the profile. On the one hand, from the wall, putting him on anchor bolt, and with the other "fleas" to the profile.

20. Cut out from OSB right size piece and attached it with metal screws to the installed profile.

21. Cut out the side wall that will close the pipes. They should have access, for example, to clean the sewer, so I made it so that it stood and not attached, but leaving it like that in a house where there are children is not safe, so I made it with self-tapping screws in several places.

Download video and cut mp3 - we make it easy!

Our site is a great tool for entertainment and recreation! You can always view and download online videos, funny videos, hidden camera videos, feature films, documentaries, amateur and home videos, music videos, videos about football, sports, accidents and disasters, humor, music, cartoons, anime, series and many other videos completely free and without registration. Convert this video to mp3 and other formats: mp3, aac, m4a, ogg, wma, mp4, 3gp, avi, flv, mpg and wmv. Online Radio is radio stations to choose from by country, style and quality. Online Jokes are popular jokes to choose from by style. Cutting mp3 to ringtones online. Converter video to mp3 and other formats. Online TV - these are popular TV channels to choose from. Broadcasting of TV channels is absolutely free in real time - broadcast online.