Window plate: how to fix the structure without removing the double-glazed window? Installation of plastic windows on anchor plates Bolts for plastic windows

Hello readers! Haven't blogged in a while. The season of installing and adjusting windows before winter has begun. Everyone wants to warm up.

So, many customers are interested in how we fix plastic windows. I will say right away that there is no single fastening.

It all depends on the location of the window. Therefore, we can use anchors or plates. In general, I got tired of answering the same questions and I decided to put them in one article, a link to which will be given to all my new clients.

I hope you find this information useful too. Read, meet.

The choice of fasteners for windows primarily depends on the material of the wall into which you will mount your window:

- Brick;

- Wood;

- Aerated concrete, foam concrete, cinder block;

- Concrete.

Secondly, on the type of construction and installation specifications:

- Loggias;

- Entrance doors;

- Window;

- Stained glass.

How to fix plastic windows. Types of fasteners

1. Anchor or frame dowel. It happens with a diameter of 8 mm, but practice shows that the optimal diameter of the frame dowel is 10 mm. In my opinion, the most reliable and convenient fasteners for windows.

It has different lengths: 72 mm, 92 mm, 112 mm, 132 mm, 152 mm, 182 mm, 202 mm. Used like this:

IN window frame a hole is drilled with a metal drill with a diameter of 10 mm. Then, a hole in the concrete is drilled with a hammer drill, right through the frame.

I consider it optional. Because, as for the dowel cap, there is even a special decorative cap. And the fastening strength in both cases is almost the same.

For every kind window profile, especially popular, produce a certain type of anchor plates. But since, according to the technology, the plates need to be screwed to the window frame, any plates for windows can be used (only for the sake of economy, of course).

By the way, about screwing the plates into the frame. There are so-called crab plates. That is, they cut or snap into the profile.

By the way, about screwing the plates into the frame. There are so-called crab plates. That is, they cut or snap into the profile.

So, if there is a quarter in the opening, many installers do not screw such plates. The window will not fall out, and this is the most important thing. After all, a quarter holds a window.

It must be said that there are cases (at present less often) when window installers, grossly violating the installation technology, do not use fasteners at all. Just fix the window with wedges and fill it with mounting foam.

I hope that such cases will pass you by.

3. Wood screws. Used to fasten windows to wood. The cheapest fasteners, and this is probably the only plus.

4. Concrete screw. Used in my opinion only in Europe. I went to the professional store "Krepezh" in St. Petersburg, where you can buy a lot of things, talked with the sellers. They don't have those screws.

How to fix plastic windows in a brick?

Brick is good material for the construction of buildings. But fixing plastic windows into bricks is sometimes problematic. What is the actual difficulty?

Brick is good material for the construction of buildings. But fixing plastic windows into bricks is sometimes problematic. What is the actual difficulty?

If you use a frame dowel, then it is better to drill holes in the frame for this dowel not in advance, but in place.

This is necessary in order to get the anchor directly into the middle of the brick, and not into the mortar between the bricks. So, of course, no one does (I, by the way, too). It's a waste of time after all.

Frame dowel, it is advisable to choose the longest possible length (minimum brick entry 6 - 10 cm). If the brick is hollow, then use the 202nd anchor.

You can use anchor plates in brick if you are sure that the brick is not hollow. But even a solid brick is Bad quality. And it will be very difficult for a non-professional to fix a plate into it.

How to fix plastic windows in a tree?

An ideal option for fixing windows for wood is anchor plates. And no one can convince me of this. frame houses or timber, only plates.

An ideal option for fixing windows for wood is anchor plates. And no one can convince me of this. frame houses or timber, only plates.

From my bitter experience I will tell you how I fixed the windows with screws into the upper part of the box in a house made of timber. And there was casing, and a gap of about 4 cm. A year later, the beam began to sit down, and these screws, together with the beam, went straight into the double-glazed windows.

As a result, several double-glazed windows were replaced under warranty. Got into money. After this incident, if I use screws, then only in exceptional cases, and only in the side parts of the window frame.

By the way, even when building frame houses, professionals do not recommend using hardened screws. Wood is a living material and when moving, the screws break, and the nail, for example, bends. The same principle applies to the anchor plate.

Anchor plates for wooden houses good for the following reasons:

- Fast installation;

- Compensates for thermal expansion;

- Do not affect window structures during shrinkage.

How to fix plastic windows in aerated concrete?

The aerated concrete wall is loose. Can be mounted on a frame dowel with a maximum length of 202 mm. This is the easiest and fastest way.

But it is more correct to fix plastic windows on anchor plates through a special dowel for aerated concrete. It's a little longer and more difficult. In addition, you need to buy or have a hex bit in your arsenal.

How to fix plastic windows in concrete?

If you mean concrete good quality, from which, for example, jumpers are made over window openings, then drilling such concrete with a diameter of 10 mm under a frame dowel is difficult, but possible.

In this case, it is better to use anchor plates. But panel and block houses are just more efficient to mount on a frame dowel. It's more reliable and faster.

At the beginning of the article, I said that the choice of fasteners for windows also depends on the type of construction. So I want to talk about such a type as the glazing of loggias and balconies.

As a rule, window fasteners hit the very edge of the upper concrete slab or the edge of the brick bottom and side walls. Therefore, attaching loggias to the edge of the wall on a frame dowel can be quite dangerous.

Anchor plates, this is a great way out of the situation.

And finally, I would like to say about the big plus of anchors, which is at the same time a minus for anchor plates.

When the window frame is attached to the anchor, at the time of drilling, you set only one vertical plane to the level. And adjust the second vertical plane after inserting the anchor.

During fastening with anchor plates, you will have to set two vertical planes at once and only after that make holes with a puncher. This requires a certain skill and skill.

Greetings, dear readers. I have a next door neighbor. We've been friends for a long time. Recently, he bought a plot with a dilapidated house, decided to update it a bit, including replacing the old wooden windows with PVC. After measurements, it turned out that exactly in size you can buy in Leroy and not waste time on window companies. So he bought these ready-made windows, but does not know how to install them. Came to me for advice on which fastener to choose. Well, if you refuse him, we went together, chose, bought.

In fact, there are a lot of different fasteners for double-glazed windows on the market now. For an unprepared person, this can be confusing. On websites and in magazines, this or that fastener is praised. But the durability of the double-glazed window, its reliable installation depends on the choice of the correct fasteners.

Therefore, I decided to write an article about the types of fasteners and how they differ from each other.

Anchor dowel or anchor

The fastener is professional and reliable. The design of the anchor dowel consists of a threaded screw, a metal shell (sleeve) and an inner sleeve.

When screwing the screw, the sleeve expands the sleeve and the fastener is securely fixed. But such fasteners have one main drawback. It is so securely fixed that sometimes it is impossible to remove it back.

When you install a plastic window, you do not think about it. But if in the process the window gets crooked and you need to reinstall it, then the problem will reveal itself. Yes, and from my own experience I know that when drilling, sometimes you can get into the armature and then you have to drill a new hole. And this will lead to the fact that the entire structure can be turned to a terrible state.

If you install a window in a house with multilayer walls, for example, in the P-44 panel series, then there will be difficulties with fasteners. The fact is that the anchor in such walls simply fails and the strut cannot be fixed.

The length of the anchor for installing a plastic window varies between 100-200 mm, thickness 8-10 mm. The length of the anchor must be chosen based on the distance from the frame to the slope. The anchor bolt is attached to the inside of the double-glazed window. If the profile thickness is 4 cm, plus the anchor must enter the wall by 4 cm, then 8 cm is already occupied. If the distance from the frame to the slope of the steam is cm, then you will need an anchor 110 mm long, if 5-7 cm, then the 150th or 160th anchor.

Screws for concrete

Ordinary screws are also suitable for fixing a window. Their advantages over anchors are simple dismantling, if necessary.

The size range of a concrete screw (or nigel) is the same as that of an anchor bolt. From 100 to 200 mm in length and 8-10 mm in diameter. You need to choose the length of the screw in the same way as for the anchor.

Anchor plates

I already wrote about fixing a double-glazed window on anchor plates in. This is one of the most popular types of fastening in window companies.

Anchor plates are:

- rotary;

- fixed.

How to use this fastener for PVC windows, read the article to which I gave the link above. Everything is detailed in it.

It is worth noting the advantages of anchor plates:

- No need to drill through the frame, as is done with an anchor or screw;

- The presence of reinforcement in the wall will not affect the fasteners in any way. The plate can be rotated.

- Mounting on plates helps out in “difficult” houses. For example, the same P-44 series.

The standard plate size is 100-200 mm. Since the plate is attached to the outer edge of the frame, a length of 130 mm is enough for any home.

I note that each manufacturer of PVC profiles has products with different widths, so the plates need the appropriate size. It is not a problem to find products in large construction hypermarkets. But my advice to you is better to order fasteners along with the window.

How to fix plastic windows in a brick?

Brick is a good building material. But fixing PVC windows into bricks is sometimes problematic. What is the actual difficulty?

If you use a frame dowel, then it is better to drill holes in the frame for this dowel not in advance, but in place. This is necessary in order to get the anchor directly into the middle of the brick, and not into the mortar between the bricks. So, of course, no one does (I, by the way, too). It's a waste of time after all.

It is advisable to choose the frame dowel as long as possible (the minimum entry into the brick is 6 - 10 cm). If the brick is hollow, then use the 202nd anchor.

You can use anchor plates in brick if you are sure that the brick is not hollow. But even a solid brick is of poor quality. And it will be very difficult for a non-professional to fix a plate into it.

Fixing plastic windows in a wooden house

The ideal option for mounting windows for wood is anchor plates. And no one can convince me of this. Frame houses or timber - only plates.

The ideal option for mounting windows for wood is anchor plates. And no one can convince me of this. Frame houses or timber - only plates.

From my bitter experience I will tell you how I fixed the windows with screws into the upper part of the box in a house made of timber. And there was casing, and a gap of about 4 cm. A year later, the beam began to sit down, and these screws, together with the beam, went straight into the double-glazed windows.

As a result, several double-glazed windows were replaced under warranty. Got into money. After this incident, if I use screws, then only in exceptional cases and only in the side parts of the window frame.

By the way, even when building frame houses, professionals do not recommend using hardened screws. Wood is a living material and when moving, the screws break, and the nail, for example, bends. The same principle applies to the anchor plate.

Anchor plates for wooden houses are good for the following reasons:

- Fast window installation;

- Compensates for thermal expansion;

- Do not affect window structures during shrinkage.

How to fix plastic windows in aerated concrete?

The aerated concrete wall is loose. Can be mounted on a frame dowel with a maximum length of 202 mm. This is the easiest and fastest way.

But it is more correct to fix plastic windows on anchor plates through a special dowel for aerated concrete. It's a little longer and more difficult. In addition, you need to buy or have a hex bit in your arsenal.

How to fix plastic windows in concrete?

If we have in mind good quality concrete, from which, for example, jumpers are made over window openings, then drilling such concrete with a diameter of 10 mm under a frame dowel is difficult, but possible.

If we have in mind good quality concrete, from which, for example, jumpers are made over window openings, then drilling such concrete with a diameter of 10 mm under a frame dowel is difficult, but possible.

In this case, it is better to use anchor plates. But panel and block houses are just more efficient to mount on a frame dowel. It's more reliable and faster.

At the beginning of the article, I said that the choice of fasteners for windows also depends on the type of construction. So I want to talk about such a type as the glazing of loggias and balconies.

As a rule, window fasteners hit the very edge of the upper concrete slab or the edge of the brick bottom and side walls. Therefore, attaching loggias to the edge of the wall on a frame dowel can be quite dangerous.

Anchor plates, this is a great way out of the situation.

And finally, I would like to say about the big plus of anchors, which is at the same time a minus for anchor plates.

When the window frame is attached to the anchor, at the time of drilling, you set only one vertical plane to the level. And adjust the second vertical plane after inserting the anchor.

During fastening with anchor plates, you will have to set two vertical planes at once and only after that make holes with a puncher. This requires a certain skill and skill.

Hello. Today we will talk about fasteners for windows. Personally, I prefer a frame dowel with a diameter of 10 mm. Why? Let's learn more about how to fix plastic windows.

The choice of fasteners for windows primarily depends on the material of the wall into which you will mount your window:

- Brick

- Wood

- Aerated concrete, foam concrete, cinder block

- Concrete

Secondly, on the type of construction and installation specifications:

- Loggias

- Entrance doors

- stained glass

How to fix plastic windows. Types of fasteners.

1. Anchor or frame dowel. It happens with a diameter of 8 mm, but practice shows that the optimal diameter of the frame dowel is 10 mm. In my opinion, the most reliable and convenient fasteners for windows.

It has different lengths: 72 mm, 92 mm, 112 mm, 132 mm, 152 mm, 182 mm, 202 mm. Used like this:

- A hole is drilled in the window frame with a metal drill with a diameter of 10 mm.

- Then, a hole in the concrete is drilled with a hammer drill, right through the frame.

- Next, a frame dowel is inserted and hammered into concrete until it rests against the frame. Then the screw is tightened. There is an opinion that the dowel should be recessed inside the profile. I consider it optional. Because, as for the dowel cap, there is even a special decorative cap. And the fastening strength in both cases is almost the same.

2. Anchor plate. For each type of window profile, especially the popular one, a certain type of anchor plates is produced. But since, according to the technology, the plates need to be screwed to the window frame, any plates for windows can be used (only for the sake of economy, of course).

By the way, about screwing the plates into the frame. There are so-called crab plates. That is, they cut or snap into the profile. So, if there is a quarter in the opening, many installers do not screw such plates. The window will not fall out, and this is the most important thing. After all, a quarter holds a window.

It must be said that there are cases (at present less often) when window installers, grossly violating the installation technology, do not use fasteners at all. Just fix the window with wedges and fill it with mounting foam.

I hope that such cases will pass you by.

3. Wood screws. Used to fasten windows to wood. The cheapest fasteners, and this is probably the only plus.

4. Concrete screw. Used in my opinion only in Europe. I went to a professional store "" in St. Petersburg, where you can buy a lot of things, talked with the sellers. They don't have those screws.

How to fix plastic windows in a brick?

Brick is a good building material. But fixing plastic windows into bricks is sometimes problematic. What is the actual difficulty?

If you use a frame dowel, then it is better to drill holes in the frame for this dowel not in advance, but in place. This is necessary in order to get the anchor directly into the middle of the brick, and not into the mortar between the bricks. So, of course, no one does (I, by the way, too). It's a waste of time after all.

Frame dowel, it is advisable to choose the longest possible length (minimum brick entry 6 - 10 cm). If the brick is hollow, then use the 202nd anchor.

Apply anchor plates into a brick, you can, if you are sure that the brick is not hollow. But even a solid brick is of poor quality. And it will be very difficult for a non-professional to fix a plate into it.

How to fix plastic windows in a tree?

An ideal option for fixing windows for wood is anchor plates. And no one can convince me of this. Frame houses or timber, only plates.

From my bitter experience I will tell you how I fixed the windows with screws into the upper part of the box in a house made of timber. And there was casing, and a gap of about 4 cm. A year later, the beam began to sit down, and these screws, together with the beam, went straight into the double-glazed windows.

As a result, several double-glazed windows were replaced under warranty. Got into money. After this incident, if I use screws, then only in exceptional cases, and only in the side parts of the window frame.

By the way, even when building frame houses, professionals do not recommend using hardened screws. Wood is a living material and when moving, the screws break, and the nail, for example, bends. The same principle applies to the anchor plate.

Anchor plates for wooden houses are good for the following reasons:

- Quick installation

- Compensates for thermal expansion

- Do not affect window structures during shrinkage

How to fix plastic windows in aerated concrete?

The aerated concrete wall is loose. Can be mounted on a frame dowel with a maximum length of 202 mm. This is the easiest and fastest way.

But it's more correct fix plastic windows on anchor plates through a special dowel for aerated concrete. It's a little longer and more difficult. In addition, you need to buy or have a hex bit in your arsenal.

How to fix plastic windows in concrete?

If we have in mind good quality concrete, from which, for example, jumpers are made over window openings, then drilling such concrete with a diameter of 10 mm under a frame dowel is difficult, but possible.

In this case, it is better to use anchor plates. But panel and block houses are just more efficient to mount on a frame dowel. It's more reliable and faster.

At the beginning of the article, I said that the choice of fasteners for windows also depends on the type of construction. So I want to talk about such a type as the glazing of loggias and balconies.

As a rule, window fasteners hit the very edge of the upper concrete slab or the edge of the brick bottom and side walls. Therefore, attaching loggias to the edge of the wall on a frame dowel can be quite dangerous.

Anchor plates, this is a great way out of the situation.

And finally, I would like to say about the big plus of anchors, which is at the same time a minus for anchor plates.

When the window frame is attached to the anchor, at the time of drilling, you set only one vertical plane to the level. And adjust the second vertical plane after inserting the anchor.

During fastening with anchor plates, you will have to set two vertical planes at once and only after that make holes with a puncher. This requires a certain skill and skill.

May 8, 2017Specialization: professional in the field of construction and repair (full cycle of finishing works, both internal and external, from sewerage to electrics and finishing works), installation of window structures. Hobbies: see column "SPECIALIZATION AND SKILLS"

PVC window anchor plates are used as an alternative to standard anchors. This type of fastener is quite practical and easy to use, but at the same time it has its own characteristics that must be taken into account.

Below I will explain what a typical plate is and also give an example correct installation using these elements.

Mounting plate features

Design and varieties

Window structures made of wood, aluminum or metal-plastic profiles can be installed in two ways - with or without unpacking (that is, with the removal of a double-glazed window).

For an inexperienced specialist, removing a double-glazed window without damaging it, and then installing it back correctly is not a trivial task, therefore, when doing the installation yourself, it is best to do without unpacking.

Yes, it's harder, but it's easier to find a physically strong assistant than a specialist in dismantling glazing beads.

In order not to damage the frame and not waste time on curing the double-glazed window, not anchors, but special plates should be used to install the structure. Such a plate has a fairly simple design:

- Material- galvanized steel. High-quality products are covered with a multi-layer anti-corrosion coating, due to which they practically do not rust.

- Dimensions- approximately 150 mm long (there are also longer ones, for installation in deep openings) and 25 mm wide.

- metal thickness- from 1 to 2.5 mm. Standard products are made of 1.5 mm steel, and this is quite enough to securely fix typical windows in the opening. Mounting plates from 2 mm are used when fixing heavy structures from a multi-chamber profile, large-sized frames and for high-altitude installation.

Thickened modifications have two drawbacks - the high price and the complexity of bending. If 1.5 mm bends perfectly with your fingers, then 2.5 mm will have to be bent with a hammer on a template, which will also damage the galvanization.

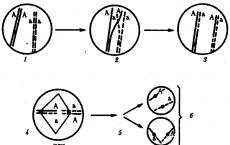

Plates for fastening window structures are of two types:

- Universal. They are just perforated strips of metal. Also applicable for wooden windows, and for PVC products, and for other purposes.

- Specialized. They are usually equipped with latches, the configuration of which corresponds to the configuration of the protrusions on the PVC profile. At the same time, they are fixed not only through the use of fasteners, but also due to the hook on the profile.

The second variety is more reliable, so if possible, try to use it.

Terms of use

The fixing plate for PVC window blocks provides less fixation rigidity compared to the anchor. On deaf structures, this is not so noticeable, but in windows with large and heavy sashes, the difference will be quite obvious. To compensate for it, you must strictly follow the rules for using plate fasteners:

- Fixation of plates on the profile. The part must not only be snapped onto the frame, but also additionally secured with a self-tapping screw with a diameter of at least 4 mm and a length of 25 mm or more (with a drill). The self-tapping screw is twisted so that the drill enters the reinforcing profile.

When installed on a wooden frame, each element is attached to the array with at least two self-tapping screws.

- Correct placement. On the sides, the plates are installed from above and below, at a distance of about 200 mm from the corners. In the upper part, fasteners should be placed either strictly in the center or opposite the impost. The optimal step for installing the plates is 500–700 mm.

- Bending angle. To ensure contact with the opening, the plate is not bent at a straight line, but at an acute angle. Due to this, the transverse displacement of the frame is minimized, and the rigidity of the fixation is increased.

- Fastening to the opening. Fixation of each plate in the opening is carried out using one or two plastic dowels with a diameter of 6–8 mm. The dowel is driven into a pre-drilled hole, and its wide neck should press the metal part against the plane of the opening. Final fastening is done with a locking screw with a conical point.

For installation according to all the rules for each attachment point, it is necessary to choose a bed with a depth of about 2 mm with a chisel so that the plate is flush with the opening plane. So, of course, no one does: all the same, the fasteners will be hidden by plaster or slope sheathing.

Plate mounting technology

The instruction for the installation of window structures involves working according to the following scheme:

| Illustration | Stage of work |

|

Design preparation.

We unpack the frame, remove the sashes from the hinges, install the connecting and expansion profiles. We glue mounting tapes on the frame: vapor barrier on the inside, vapor-permeable on the outside. |

|

Plate installation.

In the selected places, we install the plates, snapping their fasteners into the grooves of the profile. We bend the plates at an angle so that when the frame is installed in the opening, they are pressed against the slopes. |

|

Plate fixation.

We fix each plate with a self-tapping screw with a drill. Spinning it through plastic profile into a metal armour. |

| Drilling for fasteners.

We install the frame in the opening and align it in three planes using mounting wedges. We correct the position of the mounting plates, pressing them tightly to the edges of the opening. We drill sockets for fasteners through the holes with a drill. The depth of the nest must be at least 10 mm greater than the length of the dowel used. |

|

|

Structure fixation.

We hammer plastic dowels into the holes, pressing the plate to the base. We fix each dowel with a locking screw. |

Working according to this scheme, we get the opportunity to quickly fix the frame without violating its integrity and without removing the double-glazed window. The fastener itself will subsequently be masked by the finishing of window slopes.

Conclusion

Anchor plate for plastic windows It's a pretty versatile mount. But in order for the installation to ensure reliable fixation of the structure in the opening, it must be carried out in accordance with all the rules. The tips and videos in this article will help you learn these rules, as well as advice that you can get by asking a question in the comments.

May 8, 2017If you want to express gratitude, add a clarification or objection, ask the author something - add a comment or say thanks!

9125 0 0

How to fix a window: an overview of fasteners and a photo report on the installation

Hello. In this article, I will talk about how to fix plastic windows in a residential building with your own hands using an available tool. I hope that this topic will be of interest to you, as installation skills can save money.

Despite the fact that for many manufacturers the price of windows includes the cost of installation, there are many companies where they will sell you a double-glazed window cheaper due to self-assembly. Saving money is obvious!

Basic information about window installation

Installation of glazing in the opening differs depending on the type of profile used and depending on the type of walls. For example, installation in a stone, concrete or brick wall is carried out directly without any structures that compensate for the mechanical loads on the window.

At the same time, installation wooden house is carried out with a mandatory casing box device, which compensates for loads due to shrinkage processes.

For installation plastic double-glazed windows there are two main requirements:

- Strength and reliability of the installed glazing;

- Correct location in terms of level relative to the vertical and horizontal plane;

- Properly executed sealing of gaps along the perimeter of the opening to ensure optimal energy efficiency of the glazing.

Fasteners for installation of double-glazed windows in PVC profile

Commonly used fasteners for plastic windows: a - frame dowel with a metal seal; b - frame dowel with plastic seal; c - universal plastic dowel; g - screw (self-tapping screw); e - anchor plate

Before proceeding to the description of the installation, I propose to find out what fasteners for PVC windows can be purchased at hardware stores. There are many fasteners and such a variety is not accidental, since each variety is intended for one or another type of wall.

Window fasteners, according to the type of walls, are divided into the following categories:

- for concrete walls;

- for the installation of brick walls;

- for installation in aerated concrete walls;

- for fastening to wood.

By the way, with the use of the listed fasteners, a protective grille can be installed.

Fasteners for installation in concrete openings

Plastic double-glazed windows are installed in concrete openings by means of anchors or, as they are also called, frame dowels.

For reliable fixation of a heavy window in a concrete opening, it is customary to use anchors with a diameter of 8 or 10 mm and a length of 72 to 202 mm. The length and diameter of the hardware are selected taking into account the density of the wall - the more porous the concrete, the longer and thicker the anchor.

No matter how long and thick the anchors are, the strength of the finished result will depend on how carefully the hole is drilled. If the walls of the hole are broken as a result of unprofessional drilling, even the most reliable fasteners will not provide the necessary mounting strength.

Installation with anchors is carried out in two ways:

- A hole is drilled in the profile and the anchor enters the concrete directly through the profile;

- An anchor plate is attached to the profile and through the plate the window structure is fastened to the opening.

The first method is relevant if the technological gap between the profile and the gap is small. If the distance between the profile and the opening is more than 1 cm, an anchor plate can be used, since the fasteners can be covered during finishing if plastic slopes are used.

Anchor plates are metal strips of a simple or complex configuration. Plain plates are ordinary perforated strips. Along with such devices, there are “crabs” - plates that cut into the profile, which simplifies the finishing of slopes.

Fasteners for installation in brick walls

Fixing plastic windows brick opening performed in much the same way as in . But there is one problem: if for installation in concrete, holes for the anchor in the profile can be drilled in advance, then in the case of brick walls holes are drilled in place, as you need to get into the center of the brick, and not into the seam of the masonry.

For installation in brick, the same frame dowel is used as for concrete walls, but with a length of at least 10 cm. A length of 10 cm is the minimum entry into the brick at which you can be sure that the fastening will not loosen or weaken when operation.

If you are sure that the brick is not hollow, and today this is rarely used, you can use dowels 6-8 cm long.

Fasteners for installation in wooden openings

The best option for installing windows in a wooden opening without a casing is self-tapping screws in combination with anchor plates. This type of fastening is equally good for log, lumber and frame buildings.

If a casing box is installed in the opening, installation can be done with screws directly through the profile. To install glazing in a wooden opening, I recommend using self-tapping screws with a length of at least 10 cm and a diameter of 8 mm. We screw in the screws in increments of 30 cm.

Fasteners for installation in aerated concrete openings

Aerated concrete blocks are characterized by low density, and therefore we choose special dowels for installation and perform installation with a small pitch between the screws.

The installation of glazing in aerated concrete walls requires detailed consideration, as more and more houses are being built using such blocks. That is why, in order to get acquainted with the installation technology, I offer a small photo report on the work done installation work Oh.

Installation of a plastic window in the walls of aerated concrete blocks

To perform installation work you will need:

- Perforated anchor plates (160×40 mm and 2 mm thick);

- Plastic dowels (50×10 mm) for mounting in aerated concrete;

- Universal metal self-tapping screws (60×6 mm);

- Electric drill and drills in accordance with the diameter of the dowel;

- Screwdriver with a set of bits;

- water level;

- Roulette and pencil.

Installation instructions are as follows:

- If the perforation in the anchor plates does not match the diameter of the dowels, we drill holes, if the diameter initially matches, skip this step and proceed to the next one;

- Along the perimeter of the profile, we fasten the anchor plates to the self-tapping screws so that the holes drilled for the dowels are located outside;

In order for the frame to be securely fixed in the opening, we mount the anchor plates on 2 self-tapping screws, which will prevent them from turning. In addition, the installation step should not exceed 30-40 cm.

- We install the frame in the opening on plastic inserts and position it according to the level in the horizontal and vertical plane;

- After the structure is aligned in the opening, we drill holes in the aerated concrete blocks in accordance with the perforation in the anchor plates;

For drilling aerated concrete blocks, it is not necessary to use a drill with a winning surfacing. Since aerated concrete is soft, it is quite possible to use the same drill that was previously used to drill out anchor plates. By the way, when drilling, we try not to pull the drill from side to side, since breaking a hole in aerated concrete is easier than ever, and as a result, the dowel will not stick to the wall.

- We screw dowels into the drilled holes;

- We screw self-tapping screws into the screwed dowels;

At the end of the installation work, we do not remove the liners from under the window, as they will provide additional stability to the structure.

- From the spray gun, we abundantly moisten the technological gap between the opening and the profile;

- We fill the technological gap around the entire perimeter with mounting foam, so that the excess applied foam comes out from the outside and the gap is completely filled;

- After the foam has dried, the excess is cut off with a mounting knife on both sides of the profile.

By the way, how to attach a thermometer on the window and at the same time not make holes in the profile in vain?

It turns out that there is nothing complicated, just buy a special thermometer with Velcro on the glass. Thermometers with lugs and mounting holes should not be mounted on plastic, but on wooden frames. But, if there is a thermometer with holes for screws, fix this device on the profile with short self-tapping screws - this will not harm the profile.

In conclusion, I note that if you don’t know how to fix the handle on the profile, you can also use small self-tapping screws that will go through the PVC and will be held in the metal.

Output

Now you know how to install a PVC window block in an opening of walls of different composition. I hope that the suggested instructions were useful to you. If you have any questions, as usual, ask them in the comments to the text. Also, don't forget to watch the video in this article.

September 24, 2016If you want to express gratitude, add a clarification or objection, ask the author something - add a comment or say thanks!