Roof for a wooden house from a log. The choice of a roof for a log house and some nuances. Slanted and hanging roofs of wooden houses

A wooden frame made of timber or logs is a traditional building for Russia, which is used both for housing and for utility rooms. The process of assembling such a building takes place according to long-known and constantly improving technologies, so the house turns out to be cozy, warm and comfortable for living. The device of the truss frame deserves special attention, because many qualities of the roof and the features of the functioning of the gable roof depend on its strength and reliability. It is important to know how to install the rafters on the frame so that they can withstand all the necessary loads and serve correctly for many years.

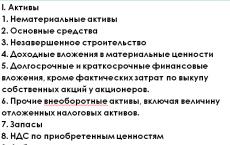

It is customary to call the rafter system the roof frame, a unique set of supporting elements that give it shape, slope and sufficient bearing capacity. Such a roof foundation is made of dry and durable wood that has been treated with antiseptic preparations, or a metal profile. This frame evenly distributes all the loads falling on it between the bearing walls. The following types of rafters are used on log cabins:

- Hanging. Such rafters have only one point of support - Mauerlat, they rest against each other with the free end of the rafter leg, thus forming a kind of triangular arch. This design for a gable roof is used when the log house inside does not have load-bearing walls on which it would be possible to install racks. This truss system experiences a sufficient load on bursting, which is why it includes different kind puffs designed to compensate for such stress. Hanging rafters are distinguished by their massiveness and some complexity of installation.

- Layered. This type of rafter has two points of support - the same Mauerlat and a ridge run that supports vertical racks. This design is used provided that inside the log house there is at least one load-bearing wall or a number of columns on which the ridge can be unloaded. Laminated rafters are only under deflection load, so it is easier to install them.

The log house is made from the well-known natural building material - wood, which has unique properties. At the end of the assembly of the structure, the leveling of the moisture content of the tree begins, so the truss system usually shrinks over about 4 years of operation.

Important! The most significant changes in the size of the object occur in the first year, so it is recommended to fix the rafters only after this time has passed.

Mounting methods

Fastening rafters to a log house made of wood is a technologically rather complicated process, the strength, durability and integrity of the roof directly depends on the correct implementation of it. When working, it should be borne in mind that the wood tends to settle during the drying process, so the geometry of the entire building changes. In addition, this material is subject to thermal expansion, so it is not necessary to fasten the rafters to the frame too rigidly in order to avoid deformation. Rafter legs to the log house can be fastened with two types of fasteners:

- Movable. Such rafter fasteners are called special metal fasteners, which allow the structure to be given a certain degree of freedom in movement and resizing. With the help of them rafter legs do not receive a load on the deflection, and can also respond to the slightest temperature fluctuations, adjusting to the geometry of the log house. These products allow you to fasten the truss frame until the end of the shrinkage of the building without the risk of deformation.

- Stationary. Fixed-type fasteners do not leave a margin of mobility when installing rafters, however, they guarantee the strength and rigidity of the structure to a greater extent. The role of such fasteners are nails, wooden dowels, self-tapping screws, metal staples, lining, and so on.

Important! A log house made of wood has one extremely unique ability - it can, as the people say, “breathe”. This means that the log house itself can regulate the humidity in the room, which is why its dimensions do not have a clear fixation.

Movable fasteners that can adapt to the shrinkage of walls and changes in the size of the material as a result of a reaction to thermal exposure are the best option for fastening rafters to a log house.

Assembly methods

After the shrinkage of the wooden frame has finally passed, they begin to establish truss system and roof construction. This process is complex and painstaking, especially if you work alone. There are 2 ways to properly install the frame on the Mauerlat:

- Installation of finished roof trusses. This process consists in assembling the necessary roof trusses simply "on the ground" with their further lifting to the desired installation site in the assembled form. To lift such massive and heavy structures, special equipment is needed such as a crane, aerial platform, a tractor, and the like. This is usually how layered rafters are installed, weighing less than other structures.

- Assembly of farms "on top". In the presence of heavy weight and dimensions of the structure of the truss system, along with the lack of special equipment, the trusses are assembled right on the spot. The disadvantage of this technology is the complexity and inconvenience of such work.

It is worth considering that experienced craftsmen quite rarely they use the method of installing ready-made truss trusses, because these designs do not allow achieving high accuracy in fitting elements, although they save time significantly.

The rafter system on a log house, albeit a fairly common option on the territory of Russia, but the issue of installing rafters should always be approached with all responsibility, because the reliability of the gable roof and the entire building as a whole depends on it.

In Russia, the construction of residential buildings made of wood is based on many years of experience and ancient traditions. Our ancestors chose this reliable material for a reason. Wood is still valued for its low weight, ease of processing, low thermal conductivity and a healthy, healing microclimate that forms in the walls. wooden house. Many people rebuilding timber and log country, country and even city houses are wondering which roof is best suited for structures made of this material. In this article, we will talk about the most successful roof designs and roofing materials suitable for timber construction.

Roofing is an integral part of the construction of a wooden house, the quality of which determines the service life of the building, the safety of the people living in it, as well as the temperature regime in the cold and warm seasons. The roof is considered one of the most difficult knots to build, as it consists of many elements and resembles a layer cake in structure. There are two types of roofing for a wooden house:

- Cold. A roof is called cold if its structure does not include thermal insulation material. Russian towers traditionally had such a design. Attic cold roof was not used constantly, therefore, it was not the slopes that were insulated, but the floor coverings with the help of backfill thermal insulation material, most often sawdust.

- Warm. A warm roof is a roof erected over residential attics or simply heated rooms. In this case, the composition of the roofing pie must include insulation and vapor barrier. The construction of a warm roof is more expensive, but it helps to significantly increase the area of \u200b\u200bthe house through the use of under-roof space.

Important! Modern wooden houses can be built with cold and warm roofs, depending on the project and the needs of the builder. Experienced craftsmen believe that for structures with an unheated second floor or used seasonally, it is better to choose a lighter and more inexpensive cold roof that forms a natural air cushion protecting against overheating and hypothermia.

Varieties of forms

The shape of the roof of a wooden house can be varied. The choice of the type and number of roof slopes depends on the design of the structure, climatic factors, the nature of the use of the under-roof space and the taste preferences of the developer. The most suitable forms for the roof of wooden houses are:

Note! When deciding which roof to choose for a wooden house, pay attention to the angle of inclination of the slopes. The choice of this indicator is based on the climatic conditions characteristic of the construction region. For areas with a high amount of precipitation in winter, structures with a slope of 40-45 degrees are suitable, from the slopes of which snow easily rolls. For windy areas, sloping roofs are better suited, the slope angle of which does not exceed 20-25 degrees.

roofing material

The construction market offers a huge selection of roofing materials suitable for covering the roof of a wooden house. They are highly weather resistant, durable, long term service and aesthetic appearance. The roof of wooden structures should not interfere with their "breathing", creating a greenhouse effect, so experienced craftsmen recommend choosing among the following coatings:

Please note that it is better to use light, durable and non-combustible materials that do not weigh down the structure of the house to cover a wooden house. If you choose according to these criteria, then metal tiles and galvanized seam roofs become leaders.

The construction of a roof for houses made of wood is different from the construction of roofs for structures made of other materials. An inexperienced craftsman can make some mistakes that can lead to deformation or even collapse of the structure. To avoid problems in the operation of the house, it is necessary to consider the following factors:

- Time to shrink. Please note that timber and wooden houses shrink during the first time after construction, significantly changing in size. Therefore, the roof for them is erected only after a year of construction.

- Use of movable mounts. When humidity changes, wood changes in volume, so they say about wooden houses that they breathe. In addition, they shrink even five years after erection. Therefore, when erecting a truss system, it is recommended to use movable and sliding fasteners.

- Fire hazard. The tree belongs to flammable materials, therefore it is recommended to treat the elements of the truss frame with fire-blocking substances. It is better if the roofing for such houses is non-combustible, for example, metal tiles.

Important! For roof insulation wooden houses use only vapor permeable eco-friendly materials, n creating inside the "greenhouse effect", which leads to dampness or decay of wood.

They say that the roof of the house is the fifth facade. Any owner of a country cottage knows well that the overall perception of the structure depends on how well the roofing is chosen.

We have already told users of our site about the features of the choice of roofing.

But the roof is only the visible part of a complex system called the roof. The basis of any roof is a reliable and properly designed truss system.

In this material, FORUMHOUSE experts will talk about the main nuances of building a truss system for a wooden and stone house.

From this article you will learn:

- Where does the design of the truss system begin;

- What nuances must be taken into account when installing the truss system of a stone and wooden structure;

- What kind structural elements truss systems compensate for the shrinkage of a wooden house;

- What features does the truss system of a log house have;

- What is a Mauerlat, and why is it needed in a stone structure;

- What are the requirements for the materials of the wooden truss system;

- What is a truss system built using LSTK technology.

General principles for choosing a truss system for a stone and wooden cottage

Often, novice developers believe that the choice of the design of the truss system can be left "for later", when the walls are already erected. Practice shows that this is fundamentally wrong. Roof even country house is a complex system consisting of many elements. The construction of rafters must begin at the design stage of the house.

Company manager "DDM-Stroy" Vera Vavilova, Moscow:

- The rafter system is the basis (skeleton) of the roof of the house. The quality and durability of the roof directly depends on how competently it will be performed. The manufacture of this structure, especially complex, must begin with its design. This is the only way that will allow you to take into account all the nuances and mount it with high quality.

The service life of the roof largely depends on how competently this structure is selected and mounted. It is also necessary to strike a balance between functionality and design refinements.

Director of company " Smart-Build» Pavel Orlov:

- The design of the truss system begins with the choice of the type of roof - attic or cold attic. For mansard roofs the angle of inclination of the rafters is made from 35 degrees and above. For a cold attic, the base rafter angle is 25 degrees.

The simpler the shape of the roof, the simpler design, the faster it is in production, and the builders are less likely to make a mistake. Therefore, it is cheaper to build and easier to operate a roof that has simple form. A large roof area, the presence of bay windows, the complex polygonal shape of the building significantly complicate and increase the cost of the construction of the truss system - it requires competent design and calculation.

The most cost-effective truss system is for a simple gable roof with a slope of at least 25 - 30 degrees.

The main factors that affect the complexity of manufacturing and the final price of the structure:

- Type of finishing roofing. The choice of one or another coating determines the composition of the roofing cake, the type of lathing and the load on the truss system. The most popular roofs are metal tiles, soft roofs, CPC (cement-sand tiles), ceramic or seam roofs;

- The angle of the roof. It determines the loads, and this is the main factor in the design of the structure;

- Will the structural elements (decor element) be visible or will it be completely hidden behind the ceiling lining;

- Large overhangs at the roof significantly increase the cost of the truss system.

If the construction of the last floor of the house provides for large unsupported spans, then this entails an increase in the cost and complexity of the structure. In this case, depending on the distances, the truss system is performed using trusses.

- The presence in the project of large chimneys, skylights and other passage elements significantly affects both the complexity of manufacturing the structure and its price.

The design of the truss system (especially complex) should be handled by a person with relevant experience. This design is always calculated for a specific building. A common approach - "I will make a rafter, like a neighbor's" leads to disastrous construction results. The rafter does not withstand loads, which ultimately leads to costly alterations.

The design begins with the collection of expected loads on the roof.

The design begins with the collection of expected loads on the roof.

1. Constant values, including the total weight of the roofing, heat-insulating material and fasteners;

2. Temporary values. These are the loads that climatic conditions exert on the roof, especially snow and wind.

Designers lay the calculated step of the rafters in accordance with the expected load. Let's see how true this is.

Pavel Orlov:

- In my opinion, it is better to choose the pitch of the rafters for attic, well-insulated roofs, based on the size of the insulation - so that the distance between the rafters is 1 cm less than the width of the insulation. This will make it easier to install.

The main load on which the calculation of the truss system is made is snow. Usually, all such structures are designed with a margin, but if there is any doubt (it is supposed to mount a heavy roofing - natural tiles, etc.), you can slightly reduce the pitch of the rafters.

Although the snow load is not constant, the rafter must be calculated taking into account the totality of all loads acting on it. The calculation must be carried out not “back to back”, but with some margin in case of heavy precipitation (prolonged snowfall) or increased wind load.

The "work" of the truss system is significantly influenced by the choice of material for the walls of the house.

Features of the truss system in a wooden and stone house

The main difference between the rafters of a stone house and a wooden one is that stone walls have a structure that is not subject to shrinkage and deformation.

Pavel Orlov:

- The rafters of a stone house do not need deformation elements, since a stone house practically does not shrink. main feature the truss system of a stone house is the need for reliable fastening of the Mauerlat. IN wooden houses the role of the Mauerlat is performed by the wall.

Mauerlat is a roofing element (paired boards 50x150, timber 100x150 or 150x150 in size), which is laid around the entire perimeter of the upper wall of the house. The lower part of the rafters rests on the Mauerlat. Thus, the Mauerlat redistributes the point load transmitted from the rafters to the entire area of the upper part of the wall.

Also, when designing the rafter system of a stone house, it is necessary to take into account the thickness of the walls.

Pavel Orlov:

- The design requires the calculation of the permissible lateral load of the rafters on the wall with a fixed mauerlat.

A thin and high wall withstands less side load. This requires the use of additional elements for the supporting structure of the rafters - retaining posts and girders.

Wooden houses also have their own nuances that must be taken into account when making a truss system.

Vera Vavilova:

- The main feature is that the walls, which are the basis for the rafters, shrink and change their geometry when the weather, temperature and humidity change outside and inside the house.

The main element that compensates for the shrinkage of the walls relative to the rafters is a sliding support (it is also called a sliding support). A sliding support is necessary in order to compensate for the distortions of the truss structure resulting from the shrinkage of wood of natural moisture.

The sliding support is a composite fastener, which includes a bent plate and a corner with a guide.

The sliding support is a composite fastener, which includes a bent plate and a corner with a guide.

When the house shrinks, the rafter slides along the guide, thus compensating for all distortions of the overall design of the truss system of the house. The sliding part of the support is attached to the rafter beam so that there is a gap between it and the rafter. And the corner with the guide is screwed to the beam.

The slipper must be installed strictly perpendicular to the rafters, with a cut in the timber for the installation of its base. In order to shrink wooden structures to ensure the maximum travel of the slide, when it is installed, it is installed in the most extreme position.

The degree of shrinkage of a wooden house (and hence the amount of movement acting on the rafters) depends on the material used in the construction of the walls. Natural moisture lumber shrinks more, dry profiled lumber shrinks less, and glued lumber gives minimal shrinkage, etc.

The degree of shrinkage of a wooden house (and hence the amount of movement acting on the rafters) depends on the material used in the construction of the walls. Natural moisture lumber shrinks more, dry profiled lumber shrinks less, and glued lumber gives minimal shrinkage, etc.

The walls of a house made of dry timber can shrink by 6% of their total height. If we are talking about the walls of a house built from a bar of natural moisture, then shrinkage can be even greater. Our article details what are the pros and cons .

Building a roof on a log house

In addition to timber, wooden houses are built from the so-called hand-cut logs. Practice shows that the truss system of such a house has its own characteristics.

Dmitry Filippov, company specialist "Traditional Carpentry Technologies":

- IN log houses on the basis of the log house, a male-legged roof system is used plus a “sliding” rafter part.

Roof in the house from a log, the device.

Roof in the house from a log, the device.

The roof for a log house has its own design features. Slegs - horizontal logs cut into a log pediment (the top of them is a ridge) - sit down together with a log house. After that, a lining from a board (aka a ceiling) is laid on the logs (lay down). Next, the rafters are mounted (in gable roofs they are attached to each other on the ridge with sliding fasteners). Then a roofing cake is formed - vapor barrier, insulation, waterproofing, counter-lattice, crate, roofing material is laid on top.

Dmitry Filippov:

- Thus, the rafter part with roofing cake are not tied to the frame, but as if “lying” on it, which allows the roof to retain its shape and integrity when the frame shrinks.

From our article you will learn about the types of structure and roof shapes of log houses.

Materials going to the rafters

In addition to taking into account the features of wooden and stone houses, when designing a truss system, it is necessary to understand the requirements for lumber.

Vera Vavilova:

- Pine and spruce will do. These are inexpensive and meet the basic strength characteristics of wood rafters.

It is important to follow and make sure that the lumber meets grade 0-2 according to GOST 8486. Rafter elements should not contain large falling knots, rot, wane and cracks. These defects weaken the bearing capacity of the truss system.

Pavel Orlov:

Pavel Orlov:

- Edged softwood with a moisture content of up to 20% is used on the rafter system. All lumber used must be treated with certified bio-fire retardant impregnations.

If you put freshly sawn, raw wood on the rafters, then in the process of drying, the already mounted rafters will lead. This will cause deformation of the roof and roofing.

To avoid this, it is better to make rafters from calibrated chamber-drying lumber.

Another option for materials used to make rafters can be trusses and glued beams.

The use of these materials is determined by the project, based on the size of the spans and the expected load on the structure.

Vera Vavilova:

In this case, the elements of the truss system are manufactured at the factory and brought to the site in the form of parts ready for assembly.

This eliminates the so-called "human factor". It also saves time, because such a design is assembled faster than the one that is done on the site with the inevitable sawing and fitting of parts on the spot.

Factory truss systems are made strictly according to the project and specifications. Thanks to this, a high quality of the base of the future roof is achieved, because. the wood has already been treated with antiseptic agents, and the entire truss system is assembled according to the principle of the designer.

Another material used in the construction of truss systems of a stone or wooden house can be light steel thin-walled structures (LSTK). Such a rafter does not need to be treated with antiseptic agents, it has a low weight, long service life and high fire resistance. Consider the main features of the truss system built using this technology.

Deputy commercial director of the company "Polymetal-M" Andrey Usachyov:

– The roof truss system, made according to the LSTK technology, includes galvanized rack-mount and guide profiles. If it is necessary to install a warm roof, a thermal profile is used (a profile with perforation along the entire length), which will remove the cold bridge and avoid heat loss.

The thickness and cross section of the profile used in the construction depends on the load that is expected on the truss system.

The thickness and cross section of the profile used in the construction depends on the load that is expected on the truss system.

Each element of the system has strictly specified dimensions according to the project.

This greatly reduces assembly time and also avoids waste at the construction site.

Each profile is marked in accordance with the drawings and assembly instructions.

Andrey Usachyov:

– Thanks to the marking, assembly is simplified. Each profile is marked with a bulge (extrusion). Because the metal frame is fastened together with self-tapping screws, then thanks to the extrusion it is clear where the connection should be. Puklevka increases the rigidity of the assembled node, reducing the force acting on the cut, on the self-tapping screw.

In the FORUMHOUSE topic you can find out what begins. Also here you will find all the information about. Read how to build with your own hands, it is told.

Watch our video about roofing in Russian wooden architecture.

All photos from the article

The ridge run or, as it is also called, the roof ridge log is an important element of the truss system. Moreover, the strength of the roof largely depends on this detail, since the run connects the roof trusses into a single system.

Below we will take a closer look at what this part is and what function it performs.

What is a skate log

So, the ridge run is a log crowning the roof. The very name "run" indicates that the beam is located from wall to wall, or rather from the pediment to the pediment. True, in hip roofs this detail is short, since they do not have gables.

As mentioned above, this detail combines trusses into a single structure. The connection of the beam with the rafters is carried out in the ridge knot. Moreover, in some cases, the span serves as a support for the upper part of the rafter legs.

This frame element is made of beams, however, if a roof is made on a log cabin, then a log with a diameter of 150-200 mm is also used as a ridge element. If the building is large, then the span may consist of two connected parts.

Types of roofs and the function of the ridge span

First of all, it should be said that all elements of the roof are interconnected with each other, respectively, they cannot be considered separately. Moreover, depending on the type of roof structure, the part in question can perform different functions. Therefore, below we will get acquainted with the most common options for roofing systems.

So everything existing species frames can be divided into several most common types:

| Type | Peculiarities |

| With load-bearing gables | In this case, the beam rests on the pediments, which, in fact, represent the upper part of the load-bearing walls. This method of building a roof is the simplest. However, in this case, as a rule, construction costs increase, since more wall materials, the price of which is always quite high. |

| Using racks | The principle of such a system is based on the use of racks installed on load-bearing walls. Thus, the beam is laid on the racks. |

| hanging | In this case, the span does not serve as a support for the rafter legs, but only links them into a single system. Often, hanging systems are made without a run at all. |

| Attic | The basis is broken hanging rafters. Such a frame allows you to expand the attic space, which is most often used as a living space. |

Below we will take a closer look at these designs and the features of their assembly with our own hands.

Frame with load-bearing gables

As mentioned above, this roof is the simplest, since the walls of the house perform the supporting function. As a rule, the beam not only rests on the gables, but also passes through them, which provides an overhang. True, it is also possible to make an overhang by lengthening the crate.

1.

2.

3.

4.

5.

Building a roof is a long and laborious task, but it is necessary to protect the house from bad weather and heat loss. At self erection Do-it-yourself installation of roof rafters is feasible if you follow all the requirements for creating a roof base. The main thing is to have the necessary knowledge and at least a little experience in construction. Do not forget: the condition of the house depends on the reliability of the roof. In order to do everything correctly, you need to know the features of creating a truss system, and perform all the work in sequence.

Roof and rafter systems

The roofs of houses are usually inclined planes - they are called slopes. Roofing slopes are based on a truss system, on which a crate is laid for laying roofing materials.

The lower ends of the rafters are usually supported by a Mauerlat. At the intersection of the slopes, ribs are obtained - inclined and horizontal. Horizontal elements are called a ridge. At the intersections of the slopes formed by the incoming corners, valleys and grooves are equipped. The edges of the roof protruding above the walls of the buildings are called gable or cornice overhangs. They are located horizontally, and a ledge extends beyond the outer walls. After laying the battens, then the rafters above them, the roofing material is collected. Before installing the roof, heat, steam and waterproofing must be laid.

From what bias they have roof slopes, roofs are flat and pitched. The first have a slope of 2.5-10%, and the second - more than 10%. Slopes are roof planes that allow water to drain off it.

Roofs are divided into the following types:

- shed - based on two outer walls of different heights;

- gable - they are supported by two external walls of the same height (in more detail: "");

- tented - they have four slopes, which have the shape of identical triangles converging at a single point;

- four-pitched (hip) - roofs with triangular slopes at the ends; when it does not reach the eaves, the roof is called half-hipped;

- attic (broken) gable - two planes of such roofs are rectangles connected at obtuse angles.

The type of pitched roof mainly depends on which rafter installation scheme was used. Rafters are the main load-bearing elements of the roof, and they must not only support the weight of the roof, but also be resistant to the pressure of snow and wind. To perform calculations of the rafter system, it is necessary to be guided by the type roofing material, characteristic for the region, the strength of the winds and the size of the snow cover.

Rafter legs are interconnected in order to increase the rigidity of the frame. To prevent the roof from blowing away in strong winds, the frame must be connected to the "box" of the house even before. When building private houses, timber truss systems are usually used - they are easily processed and installed.

Types and features of rafters

Before proceeding to how to install the rafters, you need to understand their device and types.

Rafters are layered and hanging. Methods for installing rafters and their type are selected based on roofing materials, loads in the form of wind and snow, and roof slope. Hanging rafters rest only on the extreme two points, for example, on the walls of the house. Intermediate supports in this case are not needed. Hanging rafters are designed to bend and compress. Also, such a system creates a significant bursting load horizontally, transmitted to the walls. It can be reduced with metal or wooden puffs connecting the rafters.

Puffs are placed at the base of the rafters, while the screed is also a floor beam. This method is usually used to create a mansard roof (read: ""). Puffs can also be located above the rafters. The higher the puffs are located, the more reliable and powerful they should be. Such truss systems are used in cases where the spans are 7-12 meters, and additional supports are not provided. Thus, the main elements of the hanging system are rafter legs with puffs of the lower belt.

Rafters of the layered type are built differently. They are installed in houses in which there is an additional load-bearing wall or supports located in the center relative to the outer ones. bearing walls. The ends of such rafters rest on the side walls, and for the middle part there is support from load-bearing pillars or an internal wall. The elements of such rafters work like beams - only in bending.

The installation of one roofing system over several spans involves the alternating installation of hanging and inclined roof trusses. In those places where there are no intermediate supports, hanging rafters are installed, and where they are, inclined ones. If the roof span (gap between supports) exceeds 6.5 meters (with an additional support element of 10-12 meters), layered rafters are used.

This design is created in the same way as in houses with a frame system. The crate is made from solid double beams or planks of sparse flooring, and it is attached to the rafters with nails.

Lathing under the flooring from soft roof, for example, they are made of roofing material in the form of a continuous flooring. It should consist of two layers of boards - the result is a double flooring. The top layer of the crate is protective, the bottom is considered working. A single solid or sparse (having a gap of 20-30 millimeters) flooring is used as a base for a coating of asbestos-cement slabs. A crate of bars with a base of 50x50 millimeters is used as the basis for classic slate, wavy and tiles.

Rafter legs can be fixed in several ways, depending on the materials from which the structure was built:

- by connecting to the upper strapping of wooden frame buildings;

- connection with the upper crowns (relevant for houses of wooden chopped and cobbled);

- by connecting with support bars (used for stone houses). In this case, the thickness of the Mauerlat should be 150-160 millimeters. It can be solid (the beam is laid along the entire length of the building) or partial (the beams are laid only at the junction with the rafter legs).

Rafter legs of a small section must be protected from sagging - for this, a lattice of struts, crossbars and racks is used. At the same time, racks and struts are made of logs with a diameter of 130-140 millimeters. Correct installation rafters on the roof means connecting them with puffs. So that the rafter legs do not slip along the puff and do not chip, they are cut with a tooth 1/3 of the puff size high, and a spike is created. Sometimes both are used at the same time. Cutting the rafter leg to the end of the puff, the tooth is pushed as far as possible. The puff can remain unharmed if the rafters are installed 30-40 centimeters from its edge.

Rafter installation

To create a truss structure, you can only take lumber of 1-2 grades without rot and wormholes. Boards and beams are cut to the desired length with a circular saw using the transverse cutting method, then the products are trimmed according to a given pattern on the same machine. In width, the elements are sawn on a circular saw along a longitudinal cutting.

The technology for installing rafters is as follows .

Elements of the system are assembled on the striker in templates. The parts to be connected are placed at the striker in a convenient order so that they can be used without unnecessary movements and efforts. Before starting the assembly, a full-size rafter scheme is applied to the striker with charcoal or chalk for connection. On the striker, you can fill the strips that will fix the assembled rafter legs.

After the cutting is completed and the control assembly is carried out, the rafters are marked and completed. The control assembly of the rafter legs is needed in order to be able to install without fitting. In the truss elements, places are provided for installing bolts and dowels. Rafters with a small span are sometimes assembled directly at the enterprises, and delivered to the construction site already in finished form.

Rafter log structures

In the manufacture of log rafters, round debarked wood with a diameter of 18 centimeters is used. Logs should be straight and even, without rot, wormholes, curvature. Small irregularities are processed with an ax along the cord.

Installation of rafters on a log house is the creation of a support for the rafter legs on the upper crowns of the building. The reliability of the design depends on how correctly this is done. The puffs with which the rafter legs will be connected must be made of wood. High Quality. The log selected for tightening is trimmed to the required length. Since most often a round beam is supplied with a length of 6.5 meters, puffs for large spans are usually made from two or three logs interconnected along the length. Then they select the material for the rafter legs.

Struts and racks, having a shorter length, are made from scraps or from short logs. For selected products, the ends are trimmed and markings are made according to a template of plywood or thin sheet metal. The points of the cuts at the end of the marking are cut out and cleaned with a sharply sharpened ax.

Composite-type beams on lamellar dowels are used in the arrangement of ceilings and upper chords of the truss - they are assembled from beams on wooden dowels. The most common precast section design is the beam. It is a construction of two or three coniferous timber beams connected to each other by lamellar dowels and made using hardwood (most often oak, sometimes birch), it is used during installation. The pins in the beams are installed along the entire length, with the exception of the middle part, in which the shear forces are insignificant.

Beams are produced from first grade beams, previously dried to a moisture level of not more than 20%. This indicator for lamellar dowels for beams should be no more than 10%.

Before installing the rafters on the log house, the beams are assembled. This can be done using a special device consisting of two stands (supports), they have a shaft that performs rotation in two bushings. Bars are located on the trestles on each side of the shaft. With the help of clamps-strands, the ends of the beams are shifted. In order to achieve the desired mounting lift in the beams, two spacers with a thickness suitable for the lift are attached to the shaft.

After the ends of the beams are coupled, their middle becomes bent under the influence of spacers, and the beams are bent based on the magnitude of the rise. During the bending of the beams, care must be taken to ensure that the planes of the beams in contact with each other are fitted to each other.

In general, the installation of rafters during the construction of the roof of the bath is identical to the assembly of the structure on the house. Before installing the Mauerlat, they assemble roof truss and make a crate.

After the installation of the truss system and the batten is completed, you can proceed to the flooring of the roofing material. When creating a roof, do not forget about heat, hydro and vapor barrier, especially if you plan to use an attic.