How and with what to grout the seams on ceramic tiles - tips from the master. How to grout floor tiles - expert advice

Hello dear readers!

I dedicate today's post, in my opinion, to an absolutely wonderful activity - grouting tiles! And why are you laughing, this monotonous monotonous work has a relaxing, calming and, I would say, relaxing effect on a person. At least for me.

I agree that this is individual for each person, for example, one of my friends loves to peel small potatoes, it calms her down, but it irritates me terribly! But my husband always entrusted me with such jewelry repair work as grouting tiles.

Women, as a rule, are more pedantic, more corrosive or something, and are able to produce an equally good result of the work done for a long time. And this is just what you need for high-quality grouting. In addition, women have an almost innate vision of beauty. This quality also plays into the hands in this matter. Why? Then you will understand it.

Any work, and this one is no exception, should be started with positive thoughts in your head and a mindset only for a positive result. But at the same time, do not forget that difficulties can arise at any moment and you need to be ready to cope with them.

So, all work will consist of several stages:

1. Materials and tools for grouting.

1. Brush with soft bristles.

2. Screwdriver or any other object with a sharp and hard end, so that they can clean out the remnants of hardened glue or mortar.

3. Soft sponge or cloth.

4. Rubber spatula.

5. Whisk for stirring or nozzle (for mixing large volumes).

6. Dry mix (grout).

7. Water 5-20 ˚С.

8. Capacity for kneading.

As for the question of which grout to choose, I, for example, use Ceresit grout in my work, because. it is today considered one of the most environmentally friendly building mixtures.

IN required amount water at a temperature of 5-20 ° C, add the required amount of the dry mixture, and stir properly. It is in the water that you add the dry mix, and not vice versa.

When stirring, it is convenient for me to use an ordinary whisk for whipping, it has a shape like that of a mixing nozzle for a blender. Of course, this method is suitable if you knead a small amount of the mixture for working alone.

If the batch is half a bucket, for several people, a room of twenty square meters will have to be overwritten. meters, you won’t get off with a whisk. In this case, it is better to use a special nozzle, we used it to knead the mixture when working on.

After mixing well, breaking all the lumps, leave for 5 minutes. After this time, stir again and proceed. The consistency of the grout should be like that of thick sour cream, it should not flow out of the seams, but it should not roll and crumble from the density.

If this happens, do not waste your nerves and do not spoil your mood, it is better to immediately correct the mixture, add a little water or vice versa dry powder.

It is better to use a round or oval form for diluting the grout, such as a plastic paint bucket. Everything is well mixed in it and dry powder does not clog in the corners, as it could happen in a square container.

If you are doing this for the first time, do not mix all the grout at once. Start with 0.5 kg or even less. At this volume, you will have 30 minutes to practice before the mixture starts to dry.

Right to left or left to right?

From which side you start horizontally, right to left or left to right, it does not matter. But vertically it is better to start from the top. It's just more convenient, tested on own experience, if something drips from the spatula onto the wall, it will not spoil the already finished seam.

In order not to get lost in the entire volume of empty seams that need to be overwritten: visually define blocks for yourself, for example, 4 by 4 tiles and work with them one after another.

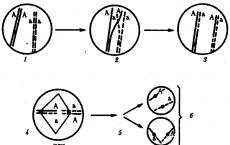

4. How to grout the seams on the tiles.

We take a little grout on a rubber spatula and carefully begin to apply it to the seams between the tiles with pressing movements.

Periodically remove the excess mixture that has fallen on the tile around the seam, while placing the spatula perpendicular to the seam. Thus, not only the excess is removed, but also the top layer of grout is leveled flush with the surface of the tile.

In principle, the story of how to grout the seams on the tiles could not be continued. When the mixture dries (after 30 minutes), wipe the tile with a wet cloth to remove the dried grout from the tile itself and that's it.

But, in my opinion, everything will look much prettier if the seams between the tiles are designed in the form of a groove. This will give the wall relief, and highlight each tile. This is very simple to do, after you have applied the grout flush with the tile, take a rubber spatula and walk along the seam with its corner, cleaning out the excess mixture.

After this operation, the seams between the tiles look a little sloppy and somewhere even rough. To fix this, I took an ordinary foam rubber sponge, moistened it a little in water and, with a slightly pressing motion, ran it along the seam. This can be seen in the photo. After that, the seam becomes even and smooth.

When the seams are dry, you can take a not very wet sponge or cloth and gently wash the tile itself.

By the way, in the photographs in the article "" the results of my work on grouting joints between tiles.

Now on the market there is a grout of various manufacturers, and most importantly different colors. Therefore, it will not be difficult to choose it to match the tone of the tile.

And you can also experiment and make a contrasting option where the tile is white and the grout, for example, is burgundy. Of course, such a solution should be in harmony with the overall design of the room and furniture. This is to the issue of the vision of beauty mentioned above.

In any case, I wish you success in your work and an excellent result, which you will be satisfied with!

I hope that the article on how to grout the seams on the tiles was useful to you.

In conclusion, I propose to watch a short video clip “How do-it-yourself tile grouting is done”:

Most often, tiles are used to finish floors in bathrooms and kitchens. The choice of color of ceramic tiles and images on it is very wide, so everyone can choose the most suitable option for myself. Installation rules require leaving a gap between the tiles, the so-called seams. This is required in order to hide irregularities when laying with your own hands. Then the seams are processed with a special grout, which makes the lining more attractive. It is not difficult to do this work yourself, the main thing is to choose the right mixture.

Choosing the right grout for floor tiles help avoid problems in the surface finishing process. The main criteria are the color of the mixture, its purpose, composition and properties.

- Color. For many people, this item is of paramount importance, because from color solution depends appearance the entire room. In order for the tiles on the floor to look like a monolith, the grout for the joints is selected to match the tone of the coating. Today, you don’t need to run around the shops and look for the paint of the right color, just add color to the white mixture. The most daring designers choose contrast.

- Appointment. For grouting joints on the floor, the standard mixture is not suitable. Since the load on the surface is intense, a more tenacious grout is required.

- Composition and properties. The composition of mixtures for processing joints may include Portland cement, alabaster, epoxy resins, gypsum, etc. The properties of the mixture depend on the composition. If it is necessary to grout the seams on the floor in the bathroom, in which the level of humidity is high, then epoxy compounds should be used, since they are moisture resistant and more durable.

Grouts for tiles: dry and ready

Grouts for tiles: dry and ready Among the varieties of grout mixtures, there are also:

- Cement-sand. Suitable for rooms with gentle conditions (moderate temperature and humidity), and the base is made of concrete or brick. Used for decorative stitching.

- Polymer. Made from silicone. Resistant to temperature changes. Suitable for rooms with a "warm floor" system, and are also used for seamless laying of porcelain stoneware or stone, followed by polishing.

- Polymer cement. Designed for rooms of the same type as cement-sand. However, their composition contains polymer components that make the composition more durable and moisture resistant.

- Epoxy-cement. Just like epoxy, they are used in the process of internal and external works. Thanks to chemical properties suitable for use in harsh environments.

When choosing a grout for floor tiles, you need to consider, among other things, whether the mixture is compatible with the adhesive on which the flooring is mounted, and the width of the joints. As a rule, manufacturers of ceramic tiles and mixtures themselves give appropriate recommendations.

How to properly seal the seams?

Grout mixtures are available in dry and ready-made form. The convenience of the powder is that you can use it as needed, and it is stored for a long time. However, when breeding, it is quite difficult to calculate the required amount of dry mix.

Finished grout - the most convenient option. It is an elastic mass packed in jars or buckets. However, an open container has a short shelf life. Therefore, if you decide to rub the seams with your own hands, it will be financially profitable to purchase dry mixes.

As a rule, it is possible to rub the seams a day after laying the tiles. Before you begin to process the gaps between the floor tiles, you will need the following tools:

- Water;

- Brush;

- Container for mixing the solution;

- Paint mixer or drill with a special nozzle;

- Trowel or small rubber spatula;

- Foam sponge or clean rag.

The grout mixture is kneaded in small portions, so in order to achieve its uniformity, you can get by with a spatula or trowel. If you need large volumes, you will need a mixer.

Before applying the grout, the tile must be cleaned of glue, dust and dirt. The seams are cleaned with a damp cloth, and right before processing they are moistened with a foam sponge to reduce the absorption of liquid from the grout. Also, experts advise treating the seams with an antifungal agent.

The next step is to dilute the powder (if a dry mix is \u200b\u200bused) according to the instructions on the package. It is important to remember that the grout must be plastic. If it turns out to be too liquid, the strength will decrease significantly. After mixing, the solution should stand for about 10 minutes, then it can be applied.

Work is being carried out from the far corner of the room to the door.

Grouting on ceramic tiles carried out using a flexible spatula. For a more accurate application of the solution, you can use a pastry bag. The seam must be completely filled with the mixture so that there are no voids inside, the excess is removed. The borders of the grout must necessarily coincide with the surface of the tile. When the solution dries, it must be slightly moistened with water to prevent cracking. It should be borne in mind that the solution may “sag” when it dries, so it is necessary to rub the seams twice or thrice.

The places where the tiles adjoin the wall are sealed silicone sealant. This is an additional protection against water leakage and the appearance of fungus.

To process 3 sq. m floor with your own hands, it will take about 20 minutes.

Finishing tiles

After the grout dries, you can start finishing the seams. But how do you know if the mixture has seized? This can be checked with a foam rubber sponge. It must be moistened with clean water and drawn along the seam line. If the solution is not frozen, it will follow the sponge. If the grout has set, it will stay in place.

Regardless of the nature of the room, the gaps must be re-treated with an antiseptic. Thus, the appearance of mold or fungus will be minimized. If we are talking about the bathroom, there is a high probability that water will accumulate on the floor. To prevent liquid from penetrating into the seams, it is better to coat them with epoxy. This will be the last stage of do-it-yourself grouting work.

Next comes the turn of the tile. Using a foam sponge, wet cleaning is performed, which gives the work a finished look. This is done carefully, the sponge is driven in a circular motion. For better cleaning, before this, you can walk on the floor with a dry brush to sweep out the dust.

If glossy tiles are laid on the floor, then at the very end it is necessary to treat it with glass cleaner and polish it.

It is very important to monitor the condition of the seams. As they say, cleanliness is the key to health. The cleaner the gaps are, the less likely it is for pathogens, fungus, and mold to thrive. It is necessary to carry out general cleaning at least once or twice a month. To do this, you can use citric acid, vinegar, soapy water or detergents with a disinfectant effect. The good old disinfectant is chlorine. If the grout has lost its original color, it can be bleached with soda and peroxide. You can wash the seams, for example, with an old toothbrush, but it is more convenient and faster to do this with a steam cleaner.

The beauty of floor tiles depends not only on the quality of the facing material itself, but also on the right choice of grout for the joints. Take care of your floors and they will last you long years. Leave comments on the article in the form below!

The modern market of building and finishing materials pleases with a variety of choices, however, the undoubted leaders in this area have been determined for a long time. Ceramic tiles are one of the best time-tested facing materials. The tiled surface is practical and lasts a long time, and the presence of a material with an unlimited color palette allows you to realize the most sophisticated design projects. In addition, the popularity of tiles is also explained by the fact that, in principle, you can tile the walls yourself, and the necessary recommendations can be easily found on the global network. For example, we want to offer you the maximum useful information about how to grout the seams on the tiles.

Grout for tile joints - the offer of the modern market

After laying ceramic tiles, the final touch is grouting; without this procedure, finishing the walls and floors with tiles cannot be considered complete. In addition to practical significance, the seam also has a decorative feature - it complements the overall pattern on the wall or floor. Moreover, manufacturers produce many color additives.

Two types of grouts: based on cement or epoxy resin

Cement based grout Supplied as a dry mix, which is brought to working condition by dilution with water or liquid latex. Although in retail network you can also find ready-made grouts, but their price is an order of magnitude higher. Cement grout for tile joints in the vast majority of cases is made on the basis of Portland cement, and the special additives that make up the composition are the distinguishing components. All grouts of this type are divided into three groups:

- based on industrial Portland cement;

- based on dry hardener;

- based on a mixture of latex with Portland cement.

Interesting! Portland cement is a special type of cement that got its name because it was very similar in color to building stone, which was mined on the English island of Portland.

Epoxy grout includes epoxy resin and hardener, and gives the seams increased impact resistance and resistance to various chemical influences. Such a grout is characterized by a high cost and, as a rule, is used in the arrangement of premises for industrial or commercial purposes.

In addition, epoxy grout is characterized by excessive viscosity, so only a specialist can successfully work with it. Moreover, there are certain restrictions on its use: the thickness of the tile is from 12 mm, and the minimum joint width is 6 mm. Otherwise, such grout will simply not be able to properly penetrate into narrower seams.

Attention! To avoid serious problems with independent production work carefully read the manufacturer's instructions. This is the only way you can determine which tile grout is best for your particular situation.

Is it necessary to use sealant?

Grouting tile joints - a video instruction of the process, by the way, is located at the end of this article, it also involves processing joints using a sealant. It will protect the surface of the tile from excessive absorption of moisture, as well as protect it and the seams from stains. If the surface is finished with unglazed tiles, then it is completely covered with liquid sealant. Such a specific substance has acrylic, varnish or silicone in its composition. Therefore, it is necessary to choose it based on the type of tile and grout.

Between tiles distance

By and large, the width of the grout joint depends solely on personal preferences. Many people prefer narrow seams, which visually seem to suppress the tile. If the surface is made of elements with a size of 10-30 cm, then the most optimal will be a seam of the order of 3 mm. Sometimes, according to this scheme, a 60 cm tile is also laid. If the tile is in operation irregular shape, it is advisable to make a wider seam, but it should not be more than 12 mm.

Attention! The wider the seam, the more likely it is to crack. To seal it, it is necessary to apply a grout with the addition of sand, but this may not always ensure a seam from deformation.

On the other hand, you should not make the grout too narrow, as this will greatly complicate the grouting process, and as a result, they may turn out to be leaky, that is, water will seep under the tile. According to professional tilers, the joints should be wide enough so that they can be filled without problems with any of the selected grouts.

Only in this case, they will become waterproof and will act as a kind of shock absorbers in the process of compression or expansion of the tile. If the seam has a negligibly small width, then it will not have such parameters.

Tools and auxiliary materials

- Respirator (working with cement-based grout).

- Protective glasses.

- Rubber gloves.

- Roller, rubber spatula or scraper with a rubber nozzle.

- Bucket.

- Sponge.

- Plywood.

- Jointing, a wooden stick sharpened at one end or a toothbrush.

- A piece of clean cloth.

- A small paint brush or paint roller.

Brief plan

- The grout is mixed.

- The solution is aged to the required level of water absorption.

- The grout is mixed very thoroughly again.

- The solution is distributed.

- Excess is cleared.

Solution preparation

As a rule, dry grout is mixed with either water or latex liquid additives that replace water.

Note! Dry polymer grouts can only be mixed with water.

When using any type of liquid, it is necessary to add only such an amount that will be sufficient to prepare a plastic and easily spread mixture. This aspect is extremely important, since excess moisture can provoke a weakening of the grout. To do everything right, the solution must be mixed strictly according to the proportions indicated on the grout packaging. The container in which the solution will be mixed must be dry and clean.

When mixing the grout, the dry ingredient is added to the liquid. Moreover, initially about ¾ of the norm of the liquid indicated in the recipe is used. After all dry components are introduced into the solution in small portions, the remaining liquid is added, while not forgetting to control the consistency of the mixture.

Important! The grout preparation process can be influenced by such external factors, as the temperature regime in the room, relative humidity, and in addition the component composition, for example, the presence of a dye.

It is recommended to use a trowel or an electric stirrer to mix the solution. If preference is given to the "automation" of this process, then the agitator must be completely immersed in the solution during operation, so that air will not enter it. After all, air bubbles can also weaken the grout solution. It is for this reason that the speed of the blade revolutions should not exceed 300 rpm. At the end of the mixing procedure, the solution must be left alone for 8-10 minutes, and then it can already be safely used for its intended purpose.

Grouting ceramic tiles - direct execution

Grouting ceramic tiles begins with laying the mortar on the surface of the tiles. For proper distribution, it is best to use a special trowel. It is held at an angle of 30 0 relative to the surface of the tile and is applied diagonally. It is necessary to go over the treated area with a grater 2-3 times, and not just covering the distance between the tiles, but trying to rub the solution into the seam with an effort to completely fill it. Naturally, the greater the resistance, the greater the filling density of the seam, and, accordingly, the stronger it will be. main idea This work consists in the fact that all voids and corners around the tile, remaining after its laying, should be filled as much as possible. When applying the grout, the liquid will leave it, and the seam will be filled with particles of cement and sand. Thus, after hardening in the seam, a solid body will be obtained.

It is not necessary to grout the entire surface at the same time. The best option would be to distribute the solution in a small area, about 1-2 m. In the process, it will be found out how quickly the grout sets and whether there is a need for frequent stops associated with cleaning the surface. In some cases, it is possible to wipe 9-10 square meters. m, and then deal with the cleaning of the working area. If the solution sets quickly, then only a small area is overwritten.

What is a grout bag?

If the tiled surface has such a structure that its cleaning process requires considerable effort, for example, imitation of an old brickwork, it is recommended to use a special grout bag. This "tool" visually resembles a pastry bag, with which housewives decorate cakes. A tip is attached to the end of the bag, the diameter of which corresponds to the width of the grout. Then the bag is filled with a solution, which is squeezed out with force directly into the seam.

When using a trowel bag, the tip is placed at the top of the joint and then advanced along as it fills. As a rule, all horizontal seams are filled first, and then vertical ones. In the process of applying the grout, it needs to be squeezed out a little more than it seems at first glance. After some hardening of the solution, it is compacted using jointing or a small piece of a metal smooth tube, the cross-sectional diameter of which is larger than the size of the seam. Then, within 30 minutes, you need to let the grout pressed in the seam seize and then the excess is removed using a stiff brush.

Wet grout removal

When it is visually determined that the grout has hardened sufficiently, the lined surface is wet cleaned. To do this, take an ordinary sponge dipped in ordinary clean water. In a circular motion, excess grout is removed from the tile, while do not forget about the frequent washing of the sponge in water, which must be changed as it gets dirty.

Dry grout removal

The seams need to be aligned and smoothed with a joint, that is, a wooden stick with a sharpened end or the end of a toothbrush handle. Then the edges are trimmed with a sponge. The resulting seam should be even and non-convex, in the vast majority of cases it turns out to be slightly concave. All seams must be the same shape and depth.

We hope our detailed instructions will help you to properly perform self-grouting on a ceramic tiled surface. If some points require clarification, then we suggest that you familiarize yourself with the training video clip.

The final stage of laying tiles is the processing of joints between tiles. If you do it yourself, you need to know how and how to grout the seams on the tiles, these skills are necessary not only to make the final work look beautiful and complete. The duration of the service life of the coating, as well as the issue of hygiene, depends on the correctness of its implementation.

Grouting tiles is the final stage of any facing work.

Why is it needed

At the very beginning, the question is brewing: when and why do you need to grout the seams on the tile? You need to understand this in order. Seams - this is the space between the fragments of the cladding at the junction. The laying technology predetermines the standards and norms that you need to focus on during the installation of tiles. It is recommended to leave a space between the elements on average from 2 to 5 mm. How more tiles- the wider the seam can be.

This is done for several reasons:

- In the process of wall shrinkage, the tile may shift slightly, so it needs to leave room for movement;

- The wall "breathes" through these cracks in the cladding;

- Grout protects the walls in the bathroom from the penetration of excessive moisture, if this is not done, sooner or later fungus and mold will form in the seams, and the situation will be aggravated by dirt clogged in the joints;

- Grouting improves adhesion between fragments;

- It plays a certain decorative role. Neat and even seams look quite aesthetically pleasing and mask the remains of the mortar and small defects along the edges of the tile, such as chips and notches.

How you seal the seams between the tiles determines how long the coating will be in a usable condition.

Grout affects the quality and performance characteristics all coverage

How to choose a mixture

In order to properly grout the seams on the tiles, and in the process there were no unnecessary problems, it is important to choose the right mixture. This nuance is given no less importance than the process itself.

You need to select material based on the following criteria:

- Color. Perhaps this point is fundamental for most people. The appearance of the finished coating largely depends on the color of the grout. White is considered universal. If you want the surface to look like a single monolith, you need to choose the right shade for the tile. Today, this is quite simple to do, you can simply add color to the standard white mixture. You can play on the contrast, but this approach is used much less often.

- Composition and properties. Mixtures for grouting joints on tiles may contain materials such as gypsum, alabaster, Portland cement, epoxy resins, etc. Depending on the composition, the properties of the mixture change. For rooms with high humidity, such as a bathroom, you need to choose water-repellent components, and for surfaces with high load and wear, stronger and rougher compounds. The best option is an epoxy mixture.

- Purpose. Standard grout is designed for processing wall joints between tiles. However, it still wears out over time and needs to be updated. On the floor, it is better to use a more tenacious mixture, since the tile is constantly subjected to stress and contact with shoes and other objects. That is, a loose structure in this case is categorically not suitable.

Tile joints can be filled with grout of any color

How to prepare grout

Most often today, grout options from manufacturers are used. It is convenient, besides, you can choose the perfect composition for a particular case. Grout is available in two types. The first is dry powder. Not everyone is able to correctly calculate the required amount of material. The powder can be used as needed, it can be stored for quite a long time, subject to necessary conditions. You adjust the density of the mass yourself, the proportions are indicated on the package, so there will be no difficulties with preparing the grout.

The second option is the finished mass. This is an elastic mass, most often produced in jars or buckets. The advantage is that you do not need to breed anything, the material is already completely ready for use. The obvious disadvantage is the short shelf life of an opened can. Therefore, the remains, most likely, will have to be thrown away. Since it is more profitable to make grout for tile joints with your own hands, purchase dry mixes.

You can make your own grout. The easiest option is a mixture of water and alabaster. It turns out an elastic white mass, however, when it dries, it can crumble, so this putty will not last long. Gypsum additives can strengthen the mixture, but they will not fundamentally change the situation.

Since it is very difficult to prepare high-quality grout for tiles with your own hands, it is better to give preference to the purchased option.

Application

To perform the work, you will need a rather modest list of tools and auxiliary materials:

- solution container;

- small rubber spatula;

- foam sponge;

- water;

- brush;

- construction mixer.

Since you need to dilute the grout for tiles in small portions, you will need a small container. The mixer is used only when harvesting a large number mass, in other cases, uniformity can be achieved by kneading it with a trowel or spatula.

Facilitate grouting between tiles called "pastry" bag

How to apply grout to tile:

- Clean the seams of dirt and dust, degrease and treat with an antifungal agent.

- Using a brush, wet the seams with water for better adhesion to the material.

- Dilute a small amount of mastic.

- Apply the elastic mixture with a rubber spatula directly to the seam itself, tamping it inward so that no voids remain.

- Remove excess with a spatula.

- When the mass dries, lightly moisten it with water so that it does not crack.

- The joints of the tile with the bathroom or countertop where the plinth will lie should be sealed with silicone sealant. It will provide one hundred percent protection against water leakage and the formation of fungus along the wall.

The grouting between tiles on the walls and on the floor has some differences. The direction of work in the vertical plane is from top to bottom. The sealant is applied last. It is convenient to work with it, as the tube has a special narrow nozzle. If you are working on the floor, you need to move from the far corner to the exit, just like when laying the tile itself.

Final processing

The next day, after the grout dries, in rooms with high humidity, such as a bathroom, it is necessary to re-surface the worn seams with an antiseptic, this will reduce the likelihood of mold and mildew in the most vulnerable places of the wall and floor covering. On horizontal surfaces, no matter how hard you try to prevent this, water will accumulate, it can leak along the seams, therefore, in addition, to prevent the penetration of moisture, they can be opened with epoxy. On this, do-it-yourself tile grouting can be considered complete. Next, you need to take care of the tile itself.

How to clean the surface

In order for the tiled flooring to take on a complete look, you need to take care of its cleanliness and remove all traces of putty. It is usually necessary to rub the tile in two or three approaches, if the mastic sags when it dries, the surface is cleaned at the very end.

It is better to apply grout and remove its excess with special tools

To do this, wet the foam sponge with water and rinse the tile so that the grout on its surface is slightly soaked. Next, use a spatula or scraper to remove any excess, holding the tool perpendicular to the surface. Divorces and residues are removed with a sponge or a damp cloth, with its help you can correct the seams. Note that they should not be convex or go on the tile itself. To clean the corrugated tiles, you can use an old toothbrush and water.

Please note: you need to work with putty that has not yet completely dried, otherwise it will be very difficult to soften it, which will greatly complicate and slow down the cleaning process.

By scraping off the hardened mass, you risk damaging the tile, especially if its surface is glossy. It will be almost impossible to remove such material from relief tiles. At the end, treat the shiny tile with glass cleaner and polish it.

It is not enough to know only the features of the grouting work. In addition, you need to familiarize yourself with the basic rules for caring for such a surface.

They love tiles for that, because they are very practical and easy to clean.

First of all, remember that the cleanliness of the seams prevents the reproduction of pathogenic microbes and fungus. It is necessary to carry out a general cleaning once every one to two months. To do this, you can use a soap solution, lemon, vinegar or special detergents with disinfectant effect. You can disinfect the surface with bleach, and bleach it with peroxide and soda. It is convenient to wash the seams with an old toothbrush. The steam cleaner does an excellent job of removing stubborn dirt and germs.

Do not throw away the leftover mixture, if any, as you will need to grout the seams on the tiles more than once, especially in the bathroom and in the kitchen. Re-treatment should be carried out regularly as needed. If the seams have darkened, crumbled, or a fungus has appeared on them, you need to clean out the old layer. After that, the joints are coated with an antiseptic, then a new grout is applied. The sealant is removed with a blade and then a new layer is applied.

The correct choice of mixture, adherence to the basics of grouting, regular maintenance and timely renewal not only guarantee the aesthetics of the coating, but also significantly improve the performance of the surface.

It does not matter whether you decide to lay the tiles yourself or call the master - this knowledge will be useful in any case! Knowing the process in theory, you will be able to apply the information obtained with ease in practice, as well as control employees. After all, it is you who will then have to face possible problems.

Choosing materials - classic cement or modern epoxy?

It used to be that tilers used the same mortar for all operations, but today mixes are available to craftsmen for each individual stage of laying. The grout for tile joints must not only be durable, but also have high decorative qualities, resist moisture, household chemicals and dirt. In order not to get lost in the names, consider the very essence of the grouts. To begin with, we divide them into two groups: cement and epoxy.

Cement grouts consist of especially finely ground cement, fine sand, color, plasticizers and other additives that improve the physico-chemical characteristics of the hardened mixture. Like any cement mixture, these grouts are kneaded with water or latex, resulting in a very plastic, somewhat putty-like mixture. It should be noted that cement grouts are very easy to work with, which cannot be said about their main competitor - epoxy grouts, which require remarkable skill and diligence.

Cement grouts begin to harden 20-30 minutes after application, as evidenced by a decrease in color brightness. At this time, the remains of the grout should be removed from the surface of the tile - a damp foam rubber sponge is best suited for this, you can get by with ordinary rags. After a few more hours, they pass over the surface of the tiles with a damp cloth or mop.

Cement grouts have one significant advantage - low price and availability. However, there are a number of disadvantages - the rough surface of the grout is quickly clogged with dust, due to which the seams become dirty gray, due to exposure to moisture and household chemicals, the solidified mixture begins to crack and crumble, in wide seams even at the stage of grouting appear cracks.

Partially, the problem is solved by water repellents or polyurethane water-repellent varnishes, which should be applied with a thin brush to each seam.

Epoxy mixtures are devoid of all these disadvantages, but still they cannot be called ideal - their price is not at all ideal, and as mentioned above, it will take a lot of experience to work with them. The fact is that the mixture obtained after mixing the components is quite solid, and it requires great effort to apply it, moreover, the grout quickly hardens, creating problems when cleaning the mixture from the tile. Therefore, even experienced craftsmen make very small portions by mixing the hardener with epoxy.

But then you will forget about tile seams forever. After hardening, epoxy compounds acquire a flat, smooth surface, which perfectly repels dust and dirt, is absolutely indifferent to the effects of acids and alkalis, and easily tolerates cleaning with a metal brush. decorative properties such compositions are enhanced with the help of all kinds of sparkles, and even glow-in-the-dark components. Please note that you can only remove such grout from the seams with the tile itself.

Grouting - do it yourself

Step 2: Making your own grout

Cement grout mixture is prepared by adding a dry composition to water. The density of a properly prepared grout is similar to the consistency of sour cream. Mix the composition in small volumes, since even cement grout hardens within 20 minutes. In no case do not try to dilute the hardened solution with water - even if you manage to get a homogeneous mixture, it will crack very quickly after hardening.

Epoxy grout is prepared by mixing two components - the epoxy itself with dyes and fillers and a hardener. At first, epoxy resin may seem very hard and unyielding - don't worry, everything is right, a little diligence, and you will be able to mix the components until a homogeneous mass is obtained. To be sure, watch the video on how to handle such a composition.

Step 3: Apply grout to the seams

Do not be afraid to use a wide spatula - take more grout on the spatula and apply it with a wide strip on the seams, counting on capturing 1 square meter. Do not be afraid to use force, as if pressing the grout into the seams - the harder and denser you press, the better the mixture will be distributed inside the seams, the smoother they will look. The spatula should be held at an angle of 30° and guided diagonally across the tile. Remove the rest of the mixture with a spatula and use for the remaining areas. It should take you no more than 15 minutes to use one batch for cement grouts and even less time for epoxy grouts.

Step 4: Remove Contaminants

Immediately after applying the solution, you can proceed with your own hands. To do this, use a soft foam sponge, which should be washed frequently and squeezed out well. The sponge should be barely damp so as not to wash out the solution from the seams. The sponge should be guided along the seam, this way you will form the final shape of the line. However, the most the best option is the smoothing of the line with the index or thumb. Please note that the grout should be below the level of the tile, as if in a recess. After all, the tile should be wiped dry with a clean cloth. After polishing will help to achieve perfect cleanliness. Grout from the tile is well removed by means such as table vinegar, lemon juice, ammonia, or toothpaste.

Grout update - we carry out restoration work

Cement grouts quickly lose their presentable appearance, but there are no difficulties in updating the seams. The easiest way is to cover the grout with special paint, which is sold in every hardware store. In addition to the paint itself, you will need a thin brush, sandpaper and a vacuum cleaner. Before applying the composition, the seams should be treated with sandpaper, and the resulting dust should be removed with a vacuum cleaner. This method allows you to update the color in a matter of hours, however, the effect will be short-lived.

If the seams are deep, and there is at least 2 millimeters to the plane of the tile, a new one is applied over the old layer. To improve the quality of the connection of the layers, the previous one should be thoroughly cleaned of dirt and dust, as well as increase the roughness with coarse sandpaper. Before applying fresh grout, the joints should be moistened.

The most cardinal option for updating tile joints is to completely replace the grout with your own hands. The previous layer should be removed completely. To do this, it is moistened with a special acid cleaner, which is impregnated with the surface of the joints - after some time, the grout will tighten softer, and it can be removed with a joint expander. You will find this tool in every hardware store - it is a curved, durable handle, at the end of which there is a kind of nail file.

When the old compound is removed, vacuum the seams thoroughly and go over with sandpaper again on the remnants that could not be removed after the first time. Then wash the seams with soapy water to neutralize any remaining acid cleaner. After a day, when the seams are completely dry, you can start sealing them - the instructions above will help you with this.