How to process the lining so that it lasts for many years. How to cover the lining inside the house - means and technology for their application How to cover the tree inside the house

Many craftsmen who complete the interior wall cladding with wood, or begin to repair such cladding. You have to choose - what is the best way to cover the lining inside the house?

And while the widest range of protective and decorative materials for wood, choosing the right composition is sometimes very difficult.

Protection and durability of lining

Principles for the selection of protective composition

When choosing how to cover the lining inside the house, we must first answer three questions:

- Does wood paneling need to be coated at all - or can it be left uncoated?

- In what room will we cover the wood paneling - wet or dry?

- Is it necessary to tint the lining, or is it necessary to preserve the natural color of the wood as long as possible?

Namely, based on the answers to these questions, we will choose materials for impregnating and coating the surface of the wall paneling indoors.

Note!

Within the framework of this article, we do not consider how to cover the lining outside the house.

The whole point is that outer skin completely different requirements are put forward, which means that the composition for processing the lining should be fundamentally different.

Clapboard without coating

The very first option that should be considered is lining without coating at all. And in principle, such a decision, despite the seeming impracticality, has its own reasons.

The point here is this: the wooden paneling of the room, left without a protective coating, darkens over time, and this happens quite quickly. And here your own taste already comes into play - if the darkened wood suits you, from an aesthetic point of view, then you should not spend money on additional processing.

Advice!

Not so long ago, a popular way to process lining was its artificial aging with the help of blowtorch. After several passes, the lining not only darkened (as in the photo), but also released resin, which gave it an interesting look. appearance.

Another aspect is purely practical. Finding a high-quality and effective lining for a bath is quite difficult, and it is quite expensive.

That is why many decide not to waste time and money, but simply periodically change the lining - for example, once every five to seven years. If you use inexpensive wood paneling, as well as mount it yourself, then the option has a right to exist.

Cover functions for lining

Well, if we nevertheless decided to choose the most suitable coating for lining inside the house, then it is necessary to understand what functions these coatings can perform.

For the interior cladding of a house from a lining board, you need:

- Ignition protection. It is achieved by treating wooden panels with flame retardants - substances that significantly reduce the combustibility of wood.

- Rotting protection. Antiseptic treatment is very important, especially where the lining is in contact with moisture.

For example, when you choose how to cover the lining on the loggia, be sure to include an antiseptic composition in the purchase list. - Protection against mechanical damage. Let it be first of all necessary to protect the wooden floor from chips and scratches, additional strengthening of the wall cladding will also not hurt.

- UV fading protection. The more effective this protection, the slower the wood changes its original color.

- In addition, the outer coating of the tree should provide it with an attractive appearance.- which means that we can either give the lining the shade we need using tinting, or simply apply a transparent varnish with a matte, semi-matte or glossy surface.

As a rule, several compositions are used simultaneously for processing wood paneling inside the house (see). This is due to the fact that it is almost impossible to combine all the functions in one product.

Compositions for lining processing

Impregnations and stains

When choosing what is better to cover eurolining or ordinary lining, we need to consider different types formulations. And first of all, we will consider substances that penetrate into the wood itself - impregnations and stains for wood.

- Drying oil- an option that is hopelessly outdated, and is used today exclusively for processing utility rooms.

It copes well with the protection of wood, but after a few years after application it darkens, and the impregnated wood is covered with a sticky film. - Protective impregnations- are used to give the lining of antiseptic and fire-fighting agents. As a rule, protective impregnations are applied to a wooden panel from both sides, therefore the application must be carried out before installation.

Note!

As a rule, the instructions for protective impregnation contain information on its compatibility with various finish coatings (varnishes, paints, etc.)

- Antiseptic film coatings are similar in purpose to antiseptic impregnations. They are quite rarely used inside the house, but if you are looking for how to cover the lining outside, then antiseptic coatings are exactly what you need!

- Stains - are used to give wood color, as well as to disinfect it. They are used in the same way as impregnations.

The most popular manufacturers of impregnations and stains for lining are Tikkurila, Senezh, Pinotex, etc. We recommend choosing wood processing compounds from trusted manufacturers - even if their price is slightly higher, but the quality is guaranteed not to disappoint!

Varnishes and paints

As a rule, after processing the lining with penetrating compounds, it looks somewhat unpresentable.

That is why, in addition to stain or impregnation, the lining is opened with a protective varnish with decorative properties or paint.

- Varnishes are used if we want to preserve the natural color of the lining and the texture of natural wood. For interior decoration are best suited - they are non-toxic, fireproof and easy to apply.

The texture of the varnish can be either matte or glossy. - If you are looking for something to cover the lining so that it does not darken, choose a transparent varnish with high UV resistance. But if you want to “age” a light lining a little, give it a darker shade, then it is better to open it with varnish with tinting additives.

- Alkyd varnishes have high strength, therefore they are most often used for processing floorboards or parquet. Lining should be covered with alkyd varnish only in those places where it experiences mechanical stress.

- Lining paint is used less frequently than varnish - but, nevertheless, it is used. The best solution is a translucent paint that partially preserves the texture of the wood. The most common brands of lining paint are Belinka, Texturol, and Senezh.

- Wax paints are the best, but at the same time, the most expensive and difficult to work lining lining inside the house. The basis of such paints is most often natural linseed oil.

Note! What is covered with lining in saunas and baths - a separate question! For these purposes, it is best to use specialized compositions, such as "Supi saunasuoja" or "Evrotex-Sauna".

Clapboard coating technology

Coating preparation

Covering the lining with protective and decorative compounds is carried out in the following sequence:

- We carry out the primary processing of the lining: dry it, clean the surface with a scraper brush, and then sand it, grinding small irregularities. In the same way, sanding must be carried out before updating the previously varnished lining.

- If there are darkened areas on the surface of the wooden sheathing, we carry out a deep cleaning of the lining with wood bleaches (Senezh Neo, Hoarfrost, etc.).

- After bleaching, the lining is thoroughly washed with water and dried again.

- To fill the pores in the wood, we process the panels with a primer. The primer improves the adhesion of lining to the varnish and reduces its consumption.

- After applying the primer, we impregnate the wood with antiseptics and fire retardants. You can also use compositions that provide comprehensive protection for the tree.

After the lining, treated with a primer and impregnation, dries completely, you can start painting or varnishing it.

Applying varnish to lining

Lacquers and paints are applied to wooden panels using brushes or sprayers (depending on the material and surface area to be treated). You can study the application technology in detail by carefully viewing the video instructions attached to the article.

Processing is carried out according to the following scheme:

- To apply varnish, use a brush with natural bristles.

- Thoroughly mix the water-based varnish with tinting - otherwise the tinting of the lining will be uneven.

- On the wall lined with clapboard, we apply the first layer of varnish, moving the brush along the hair of the tree.

- Leave the applied layer to dry completely. After the varnish is completely dry, sand it and proceed to apply the next layer.

- If we plan to cover the eurolining with lacquer with tinting, then each next layer of lacquer should contain less tinting pigment than the previous one. So lacquered surface acquires depth and attractive shine.

- We make the last layer of varnish transparent, and after application we do not sand.

Now you know how to cover the lining in the house, and most importantly - you know how to do it! And therefore, if you face such a task, you will be able to cope with it yourself, saving both time and money!

Both internal and external wall cladding with clapboard is an excellent solution for the owner who cares about the condition of his home. Interior decoration will create a cozy and wellness atmosphere in the room. The outer one will protect the facade of the building from unnecessary damage.

In this article, we will dwell in detail on why the lining should be treated, what kind of protective composition is better to do, what is the technology for applying paints and varnishes, and also what amount should be calculated when painting.

How to effectively protect a tree

How to process lining inside the house? This question is often asked by the owners who used it in wood.

How to process lining inside the house? This question is often asked by the owners who used it in wood.

Today, processing lining inside the house is not a problem. It is only necessary to choose the right protective coating that will fit under a particular room.

Some are more suitable for rooms with high humidity, others perfectly protect the boards from ultraviolet rays, and some generally increase the strength of wood and prevent the risk of premature abrasion.

But also an important factor in processing is that protection should look good on the boards. It should not distort the natural structure of the tree. On the contrary, its task is to emphasize the naturalness of the material used and blend harmoniously with the rest of the interior.

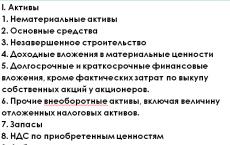

Most often, to protect wood, the following substances are used:

- antiseptic

- bio oil

- Primer

Types of varnishes for working on wood

Speaking specifically, how to process the lining in the house, then the choice of protective mixtures is quite large.

1. Ground

Such a mixture is not only a full-fledged primer, but also an excellent bio-protective agent. Primer - antiseptic suitable for processing both indoors and outdoors.

Moreover, the use of a primer is appropriate even on an affected tree. The primer, along with a textured finish that is meant to protect, will prolong the board's longevity and keep it neat and tidy.

2. Protective and decorative

One of the main qualities of the mixture is that it gives the desired color to the wooden surface. By the way, protective and decorative coatings are an innovation in the market of paints and varnishes.

But it is very important that even when processed with such a composition, the tree structure is still visible.

They are very convenient to use, since they do not first need to use a primer, because they already contain antiseptics. Moreover, they are resistant to fading and temperature changes.

Some types are suitable for use on wet wood. They are great for indoor and outdoor work.

The final coat has a soft semi-matte tone. According to the manufacturers of these funds, the guarantee is 8 years.

3. Scuba diving

Continuing to talk about how to treat the surface inside the house, you should definitely pay attention to water-based products. For work inside the house, professionals recommend scuba diving.

Continuing to talk about how to treat the surface inside the house, you should definitely pay attention to water-based products. For work inside the house, professionals recommend scuba diving.

Advantages of using scuba diving:

- No smell

- Fast intercoat drying

- It does not contain organic solvents

For external work, products with water-repellent additives are suitable, which protect wood from dirt and moisture. Of course, it is not from the budget class, but the owner is provided with durability and ease of maintenance.

4. Oils

Quite often, the surface of the tree is treated with oils or their combined mixtures.

Oil coating provides protection against contamination, moisture and dust, due to the fact that it penetrates deep into the structure of the tree.

An important advantage when using varnish is also that there is no solvent aroma, but you can only feel the smell of the plant on which the oil was created. Moreover, this composition is very easy to tint, with which you can get the desired shade.

Tools for painting operations

We answered the question of how to process the lining, but there was one more thing left: how to process the lining inside the house?

We answered the question of how to process the lining, but there was one more thing left: how to process the lining inside the house?

Its importance lies in the fact that all compositions are different in consistency, so the poet should be especially careful about the selection of tools so that the application of the protective layer is convenient and effective.

An approximate list of necessary when applying paint and varnish mixtures:

- Napkins

- Scotch construction

- Scotch bright

- Sandpaper (#240)

- Tray for paint or varnish

- Roller

- brushes

Whitening

This process is the first step in painting with any composition.

This process is the first step in painting with any composition.

It is the cleaning of the boards from any contamination.

If there are difficulties with the selection of bleach, it is best to use a special stain.

After the bleaching process is completed and the lining becomes a clean canvas, you can proceed to the second stage - priming. The third stage is the application of paint.

Whitening tools needed:

- Roller

- Tassels

- Stain (bleach)

- Solvent

- Gloves

- Eye protection glasses

Video - glazing wooden surfaces:

We paint according to the rules

If the wooden surface has already been repeatedly painted, then before applying a fresh layer of varnish, it is necessary to evaluate the quality.

If the wooden surface has already been repeatedly painted, then before applying a fresh layer of varnish, it is necessary to evaluate the quality.

If it is still good, then you can wipe it with a 2% soda solution.

To prepare such a solution, you need 10 liters of heated water and 300 grams of soda.

After treatment with soda solution, the working surface should be puttied and treated with drying oil. After such a procedure, all the wooden surfaces in the house will change significantly.

If painting the lining inside the house happens for the first time, professionals advise adhering to a certain technology in this matter in order to avoid smudges and bumps.

Paints and varnishes should be applied with the tips of the bristles. It is very important that it be thin. Otherwise a large number of paint may become unusable. So that the pile does not leave a mark on the treated walls and ceiling, before painting, it is better to treat them with soapy water.

Video - how to properly process the walls inside the house:

Particular care should be taken when applying the final layer. To make the coating even, it is best to start applying the protective composition from the top. Hard-to-reach places, for example, frames, baseboards, the space near the batteries, are best painted over with a brush that has a diameter of no more than 5 cm.

It is best to start painting the door from the paneled side.

A dry brush will help prevent smudges of paints and varnishes. Brush movements upward will save the surface from unnecessary flaws.

Video - painting the house inside:

Cost of work

The price of painting the lining for one square meter is approximately 280 rubles.

The price of painting the lining for one square meter is approximately 280 rubles.

One square meter of the lining itself will cost the buyer about 320 rubles. But the cost of boards is significantly influenced by the wood from which they are made and its grade.

Varnish to process wood can be bought for about 260 rubles per liter.

We hope that this article will help each owner to paint the lining with high quality, as well as to choose the right materials. Good luck with your work.

It's pretty practical stuff. However, the cladding, left without a protective coating, begins to darken and soon completely changes the interior of the entire room. If changing the color of the wood is part of the planned style of the room (for example, a room decorated with "old wood"), then you can leave the surface without finishing until the desired shade is obtained. But anyway, after changing the color, it will be necessary to apply a protective coating, because unprotected wood loses not only its color much faster, but also the original characteristics of hardness and moisture resistance.

You don’t have to wait for the darkening of the bars, because you can “age” the wooden lining with a blowtorch or a special burner. However, even in this case, the question of how to process the lining inside the house remains paramount both at the beginning and after the installation work is completed.

The choice of means for processing

What is the best way to process the lining? It is necessary to select a lining for lining long before installation, because it may happen that wood protection work may require the processing of bars from all sides. First of all, you need to decide on the functions that the tool should perform. Despite the fact that lining is a fairly durable material, it can lose color for several reasons at once. In this regard, compositions can be used to treat the premises, with the help of which it is ensured:

- ignition protection. Such processing is recommended almost everywhere, especially in places where wiring can be hidden behind the cladding, as well as in kitchens using gas stoves. The substances used in this case are called flame retardants. Such impregnation for lining significantly reduces the level of flammability wood flooring. In some situations, fire retardants can also save the color of the cladding, helping the wood withstand the effects of significant temperatures for some time, for example, significantly increase the protection of the lining from darkening indoors due to careless handling of electrical appliances, including electric heaters, soldering irons, irons and other devices and factors.

- decay protection. This will help antiseptic treatment. Special means for impregnating wood are quite affordable. Antiseptics will retain the color and structure of the cladding. Mandatory processing should be subjected to lining on the loggia and kitchen. In the first case, premises without central heating are considered, among which summer houses can also be included. In the spring and autumn, they will be subject to a sharp change in temperature, due to which a significant amount of condensate can collect on the back wall and front side of the skin. Initially, moisture will contribute to a change in the color of the lining, and later the structure of the bars. Kitchen cladding, on the other hand, will be exposed to internal processes;

- protection against mechanical damage. It may not seem very important, but minor scratches on the walls can quickly darken later and, as a result, greatly spoil the appearance of the entire cladding.

- UV protection. It is one of the most important for those owners of wood paneling who are concerned about maintaining the original color. It is fading under the action of sunlight - this is the most significant cause of darkening of wooden cladding. In this regard, the cladding of a room with large windows and direct exposure to the rays of the daytime sun should be treated with special means that prevent exposure to ultraviolet radiation.

- change in appearance. Agents that change the appearance of the cladding usually affect its color with the help of colors added to the composition. The most popular among them are, with and without additives, as well as a more radical solution - paint.

The protection of the lining with the help deserves special attention. Back in the USSR, it was widely used to process a variety of wooden structures, including facings.

It should be noted that at first she really copes well with complex protection. However, already 2-3 years, the active stage of darkening begins, as a result of which the drying oil coating not only loses its original color, but also acquires a sticky oily film. Now the chemical industry has stepped far forward, and more convenient products can be found in stores. Processing the lining with the cheapest of them will be much more effective than covering the lining with drying oil. How affordable way protection of wood, it is best used only for the utility room.

Usually, it is necessary to process wooden cladding inside the house several times, because it is impossible to combine all the necessary properties in one tool.

It should be noted that flame retardants and antiseptics are recommended to be applied to the lining even before installation begins.

The lining is best processed after finishing the sheathing. Especially if varnish or paint is used. To create a truly durable coating, it is important to consider the possibilities of combination. You can find out the compatibility of protective equipment by reading the instructions for using the impregnation.

Finishing layer

Protective impregnations for lining are often just the start of processing. The final layer is mainly varnish or paint. To date, manufacturers have greatly expanded the range of products produced. Any varnish or paint must be chosen depending on the conditions in which the wood cladding will be located.

In order to select the required coverage, you should know the following information:

- Clear nail polish. It is applied to leave to wood its natural color. Water-based varnish is best in this sense. It does not emit toxic fumes. Covering the lining with such a varnish will be much safer than treating the lining inside the house with alkyd counterparts. This is also due to the fact that water-based products are more resistant to fire.

- Lacquer with additional properties. Highly targeted products are classic lacquer bases, to which either color can be added for the effect of artificial aging, or special products that provide additional protection from ultraviolet radiation.

- Alkyd varnish. It can be both transparent and with various additives. More difficult to work with and more expensive than water-based counterparts, but much stronger. In a room where the possibility of a significant mechanical effect on the walls is foreseen, the sheathing should be treated with alkyd varnish. It will be much more effective in terms of protection against damage than water-based.

- Dye. This topcoat is used less frequently than lacquer treatment. The best variety is translucent paints. They not only give uniformity to the entire lining, but also partially preserve the texture of the lining. Among the translucent products, the most expensive and, accordingly, the most effective and spectacular will be paint containing wax. The basis for it is oil from flax. After drying, the surface covered with such paint acquires water-repellent properties and provides surface protection better than any analogues.

To create a truly durable coating, it is important to consider the possibilities of combination. You can find out the compatibility of protective equipment by reading the instructions for using the impregnation.

A huge number of the most different materials and household items. Wood is always valuable and never ceases to be fashionable. This is one of the few materials that always remains in trend. Today there is a very popular style - eco.

Natural materials are not only safe, but also popular. Despite such a positive start, it is worth noting that wood is not only a beautiful and stylish material, it is also very capricious. Care is needed constantly if you want it to serve you for a long time and retain its original appearance. The question immediately arises - what is the best way to process the lining inside the house?

Methods for protecting wood products

There is no shortage of such materials on the market. The variety of different mixtures, consistencies and compositions for the treatment of wooden surfaces and materials is sometimes misleading, and you don’t even know what is best to choose.

When deciding on a protective mixture, you must consider the purpose of protection:

- some compounds protect the tree from fading;

- others repel moisture;

- the third - protect against damage of various types.

How to process the lining inside wooden house not only to protect it from external factors, but also to make it exquisite - this question has been asked more than once by lovers of practical and beautiful at the same time. There are such mixtures and they are available to everyone, the main thing is to know which ones to choose.

To process wood with your own hands, you need to know a few rules and the name of the compositions that will be needed for the process in question.

So:

- mandatory use of antiseptics;

- a primer will also be needed to protect the material;

- fire-resistant impregnations;

- varnishes of various types;

- biologically oils (preferably);

- do not forget about the means to remove the previous coating you do not need.

Now you know how to process the lining indoors, you already have a list of compositions, so there should be no problems with the search. In any hardware store and in the market in the department of goods for home and construction, you can buy everything you need. The photo shows the compositions that you will need to protect the coating you have chosen.

Paints and varnishes for woodworking

Primer

One of the main compositions needed to protect the coating is a primer. This mixture is also a biological defense. It can be used for both outdoor and indoor work.

- Even if the tree is slightly damaged, such a composition can be used, and even necessary.

- The primer coating extends the life of any wood material.

- Among other things, the primer gives the product a well-groomed appearance.

Decorative and protective coatings

Relatively recently, new paint mixtures have appeared on the market that not only protect wood, but also paint its surface in any color. Now, thanks to such mixtures, you can protect and create a unique design in your home.

A positive point in the characteristics of such compositions is that when stained with them, the texture of the tree is visible and remains the same. As part of such a mixture, an antiseptic is already present, you do not have to buy it separately.

Some of these mixtures can even be used on wet wood. They can be used for both interior and exterior decoration.

The resulting tones are very soft and slightly matte. Temperature fluctuations and ultraviolet rays do not affect the quality of the mixture for a long time. For this reason, you definitely won’t need the next processing of lining inside the house for ten years.

Use of scuba diving

Some argue that it is easier to choose a different material than to process the wall paneling indoors, but in fact this is not the case, you need to know. How to process and how to carry out this process without unnecessary costs and problems.

Great for woodworking. By the name it was already possible to understand that they include water, and to a greater extent than all other components.

A number of advantages of such material for coating wood:

- The absence of any smell;

- It dries very quickly;

- There are no organic solvents in the composition.

There is another type of scuba diving - water-repellent. Due to their composition, they protect wood from moisture and repel water, which means they have a ubiquitous field of application.

The price of such funds is an order of magnitude higher than typical analogues, but at the same time you get one hundred percent protection for many years. In rain, snow and hail, your wooden surface and structure will look perfect.

Oils

Treat wooden surfaces with oils - a good idea, it is even better to use their combined formulations. The oil has such a structure that, when applied to the surface, it impregnates them well from the inside, getting into every pore.

Protects the tree and delays:

- dust;

- dirt;

- moisture;

- Sun.

It is a pleasure to work with such tools, there are no unpleasant odors, only the smell of the plant on which this oil is made is felt.

The hue of the wooden surface becomes golden. If you want a bright wood color, you can paint it any color you like.

Treatment with protective compounds

The quality of your work will depend on attentiveness and accuracy, as well as on the correctness and consistency of following all the rules and recommendations. Full instructions are presented in the video:

Output

Now you know how and with what to process the lining inside the house, what compositions are better to apply and how to extend the life of any wooden surfaces. Whatever you do, whatever work you do in your home, remember that diligence and patience will lead you to success and achieve a positive, expected result.

You should not save on protective equipment, because they justify their cost and prolong the life of wooden materials.

Lining is a finishing material that looks good in the interior of a wooden house. It is used for both residential and commercial premises. The wood from which it is made needs to be treated with protective agents. And to give an attractive appearance to the lining is applied decorative coating. Naturally, to create a beautiful coating, you need to choose the right processing tools and decor materials.

Why process lining and how to choose the right funds

Before processing the lining, you should find out:

- Do I need to apply a protective coating, or can I do without it;

- in what rooms the processing will be carried out - in dry or with high humidity;

- whether to apply a decorative coating, tint or leave it natural.

Having decided, you can proceed to the choice of impregnation and material for decorative lining of the lining in the interior. You can leave the lining uncoated, but this option is suitable for people who are satisfied with the fact that the tree darkens over time. Some owners specifically do artificial aging with a blowtorch. After this, it not only darkens, but also releases resin, which gives the surface an individuality. It happens that the owners of the baths do not process the walls due to the fact that they use cheap lining. It will be more practical for them to change it completely in a few years than to spend time and money on processing it.

In order to properly process the walls, you should know what functions the impregnation for lining inside the house should perform. So, the impregnation should:

- give good protection from ignition, such qualities give wooden products flame retardants that reduce its flammability;

- protect from moisture, especially in damp areas. To do this, antiseptic agents are applied to the wooden surface;

- protect from mechanical damage (chips and scratches);

- protect from exposure to ultraviolet rays. Wood treated with UV-resistance products changes color more slowly;

- provide bactericidal protection against insects;

- give the walls a beautiful look. You can give the lining the desired shade using toning. Using varnish, you can make the surface glossy, matte or semi-gloss.

To give the tree the necessary properties, usually several compounds are used that have the necessary qualities.

Types of compositions - fire retardants, stains, varnishes and paints

All compositions for processing lining can be divided into two groups: protective and decorative. The first are designed to extend the service life. They protect against moisture, insects, the formation of fungus, mold. The latter give the lining an attractive appearance. Processing must be updated regularly, as funds lose their properties over time. Processing of lining in the premises is carried out by the compositions listed below.

Flame retardants reduce the combustibility of wood. This is especially important for living rooms. In the event of a fire, flame retardants prevent the spread of fire, help to extinguish it. They are odorless and therefore harmless to health.

Antiseptics protect against the formation of mold and fungus. Stop the spread of existing mold. Over time, the product is washed out and evaporates, so re-treatment is required. There are bio moisture protective agents that not only protect against fungus, mold, pests, but also give the tree water-repellent qualities and an attractive appearance. They are expensive, but they make it possible to refuse treatment with stain, antiseptic and varnish.

The stain performs antiseptic functions, but at the same time gives the wooden surface a shade. The most popular are stains that give dark shades. This tool does not create a film on the surface, but penetrates into the pores of the material to a small depth. Stained wood should be varnished, otherwise the surface looks dirty. Drying oil was previously very popular, but in Lately it is being used less and less. The tree quickly darkens, and after 2-3 years the surface becomes sticky. It is used for business premises.

Bleaches are designed to be removed from wood surfaces. dark spots, areas with a blue tint, stripes. There are several types of such funds, differing in application and effectiveness. Usually the product is applied to the surface and washed off after a certain time.

Varnishes are used if you want to preserve the naturalness and texture of wood. Indoors, acrylic varnishes are used that are harmless to human health. The first layer is applied transparent, without dyes, and coloring pigments are added to the second. Alkyd varnishes are more used for floors, as they have high strength properties. They are applied to walls in places where high mechanical loads are possible. Wax mixtures can serve as an alternative, which protect the wood and give the surface a semi-gloss shine.

Oil paint penetrates deeply into wood, provides good protection against moisture, and is resistant to mechanical damage. Used for decorative finishing. Disadvantages: low vapor permeability, dries for a long time, loses color over time. Acrylate paint is in many ways superior to its oil counterpart: it dries quickly, does not fade over time, penetrates well into pores, gives a rich color, and has high vapor barrier qualities. Does not crack if the panels led from temperature changes. This paint has one drawback - the high cost.

Technology for applying protection and decorative coatings

A novice builder at the finishing stage has to master new technologies. You need to properly nail the lining, know how and with what to process it, perform decorative trim. The coating of the material with the selected means is carried out in stages. Before processing, prepare the lining.

- 1. First, it should be cleaned of contaminants with a solution. To do this, dilute soda in warm water. Wash the lining with this solution. If there is an old layer of paint, for better adhesion, it is advisable to completely remove the previous layer in order to remove cracks and peeling.

- 2. Inspect the cleaned lining: remove mold, fungus, treat darkened spots with bleach. Finally, the panels should be wiped with a clean rag to completely remove dirt and paint residue. If there are damaged panels, they must be replaced.

- 3. At the next stage, we perform surface grinding. The operation is performed with a pumice stone or fine-grained sandpaper. So that there are no unpolished places left, divide the entire wall into small sections and process them sequentially. Grinding perform evenly, trying not to rub in one place and not to apply great effort.

- 4. The final step in preparing the lining for applying funds is priming. We apply a layer of primer to the wall with a brush or spray gun. Particular care must be taken to process the seams between the panels. One layer is enough. Sometimes a paint composition is used as a primer.

By itself or with a brush. For painting, prepare two brushes: narrow and medium - with the help of a narrow one, hard-to-reach places are stained. In order for the coating to serve for a long time and be durable, you need to apply 2-3 thin layers. The coloring procedure is as follows:

- mix the paint and pour it into a small container;

- dip the brush in the paint to half the bristles;

- before applying, press the brush to the surface and smoothly guide along the panel;

- then the paint is similarly applied in one direction over the entire surface, without affecting the painted areas;

- paint corners and openings with a narrow brush.

Start applying the paint from the top so that there are no streaks. To eliminate color differences, apply a layer at a time. If necessary, interrupt work should be left in a place that is not visible. The next layer is applied after the previous one has completely dried. We make the final layer of the minimum thickness, apply with light uniform movements from top to bottom.

Lacquer is applied in the same way. If the product is tinted, then before applying it should be thoroughly mixed and periodically stirred during operation. We add less coloring pigment to each subsequent layer, in this case the surface after staining will acquire a deeper and more attractive sheen.