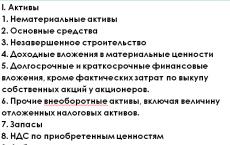

How to make a hanging hammock chair with your own hands for home and garden from different materials. Various models of do-it-yourself hanging chairs Do-it-yourself hanging swing chair

With the advent of summer, many city dwellers tend to get out into nature at least for the weekend, and if there is a summer cottage and circumstances allow, then for the whole summer. There is probably no such person who would not like to take a nap in the fresh air to the singing of birds, swaying in a hammock or chair. To save on the purchase of this simple, but rather expensive furniture element of the interior, a do-it-yourself hanging chair can be made in several ways, which will be discussed later.

For the manufacture of some options, the most simple materials, which even, perhaps, simply litter the barn. For others, you will have to prepare material in nature or purchase it in a store. Making may require the "mobilization" of one's abilities in needlework - weaving or knitting, so that there is work not only for men, but sometimes even to a greater extent - for housewives.

Varieties of hanging chairs

Hanging chairs began to be widely used in the 50s of the last century - then they were at the height of fashion. Many designs have been developed for these peculiar "luxury" elements, made from the most different materials.

- A chair with a rigid frame made of rattan, wicker, metal, plastic or acrylic. In this case, the base can be covered with a durable fabric or braided with wicker rods, rattan or leather strips.

- A chair with a soft frame, made according to the principle of a hammock. The main difference between these seats can be called the size and method of suspension. If the hammock is fixed on two supports located at a certain distance from each other, then one is enough for a chair.

Cocoon chair - for those who like to spend time in solitude

Cocoon chair - for those who like to spend time in solitude - The cocoon chair is made on a rigid frame and has wicker walls. The difference between this type of product and other types of chairs is that its internal space is half hidden from the outside world. Such a place is ideal for people who love privacy.

- The drop chair is mainly designed for children's rooms, as it looks more like a hanging chair. small house in which you can hide or even sleep. In addition, it has enough space to take your favorite toys with you.

Making simple hanging chairs

In this section of the article, several options for making hanging chairs will be considered, which should be quite feasible for most skilled owners.

Hanging hoop chairs

The easiest way to make a hanging chair at home is from a regular hula hoop, which can be found in almost every home or purchased at a sporting goods store. Moreover, there are two options for manufacturing such an item. garden furniture. One of them will require one hoop, the other two, slightly different in size. Both options will be shown - you can choose the one that seems easier to manufacture.

Prices for hanging chairs Kvimol

Kvimol hanging chairs

First option

- To make such a chair, you will need the following materials:

- one hoop from a pipe 20 ÷ 30 mm in cross section, with a diameter of 700 to 1100 mm, depending on how large the chair should be;

- two identical pieces of fabric measuring 1200 × 1200 mm or 1600 × 1600 mm. A strong fabric is selected, you can take the lining material on the padding polyester, which already has a stitching;

- a cut of the same fabric 200 mm wide, 3500 ÷ 4000 mm long (several pieces can be);

- colored dense fabric for sewing pillowcases for two ÷ three pillows;

- synthetic winterizer, also having a width of 200 mm, and a length of about 3500 ÷ 4000 mm (several pieces can be);

- synthetic winterizer for stuffing pillows;

- border for processing cutouts in the case - 800÷1000 mm;

- zipper with a length of 700 ÷ 1100 mm;

- durable nylon cord with a thickness of 6 ÷ 8 mm or a linen rope with a diameter of 10 ÷ 12 mm, a length of 10500 mm (10.5 m);

- two powerful metal carabiners and rings for hanging the chair.

- From the tools you need to prepare:

- threads and needles for hand sewing;

- sewing machine;

- scissors;

- marker;

- tape measure or centimeter.

- The manufacturing process of such a chair is presented step by step in the table:

| Illustration | |

|---|---|

| In the first step, the fabric is spread on the table, and then a hoop is placed on it in the center. |

| Further, with the help of a centimeter around the hoop, a circle is measured and marked with a marker, with a radius of 250 mm more. |

| A circle is cut out of the fabric along the marked line. Such parts need to prepare 2 pieces. |

| The finished elements of the future cover should look like this. |

| The next step is to fold one of the cut out round blanks in half and then cut it. |

| Further, along the line of the central cut of the circle, a lightning is pinned, and then a lightning is attached. 250 mm recedes from the edge of the cut, and from this point the lock is fixed, that is, it must be clearly along the length equal to the diameter of the hoop. |

| After the lock is attached, the two halves of the cover are sewn around the circumference, and then it is turned inside out and laid out on the table. |

| Further, in order to make it convenient to make markings for cutouts, the finished cover should be put on the hoop. The markup shown in the presented drawing is made. The places where cutouts should be made are marked with a marker. |

| According to the marks made, four cutouts are made through which cords or ropes will be attached to the hoop. |

| To make the cut holes look neat, they need to be sheathed with braid. Having finished work on the cover, you can proceed to the preparation of the hoop. |

| The hoop is wrapped with synthetic winterizer. In several places, the metal can be slightly smeared with polymer glue so that the wrapped material does not slip during its stitching. Next, comes the sheathing process itself. It is done by hand, stitches over the edge. |

| The next step is to sheathe the hoop wrapped with synthetic winterizer with a cloth. Well, in order for it not to slip, first its edges are wrapped inward and chipped off with pins. |

| The fabric is also sewn by hand, over the edge. As you sew, the fixing pins are pulled out. |

| The sheathed hoop is inserted into the case through the hole into which the zipper is sewn, which is then fastened. |

| Further, two pieces of 2200 mm each and two of 2800 mm each are cut from the cord. |

| Then, the cords are folded in half and their ends are tied together. After that, they are threaded into the cut holes, under the hoop. |

| The cords are fastened to the hoop by threading the knotted ends into a loop formed on their other side. |

| Lastly, pillows of suitable size are cut and sewn, and the chair is hung in the place chosen for it. How to carry out the process of fixing the chair on the ceiling or in the yard will be discussed below. |

Second option

The second option - two hoops in an openwork weave

The second option - two hoops in an openwork weave In the second version, in the manufacture of a hanging chair, slightly different materials are used, in contrast to the first model. Such chairs are made in the same way as macrame hammocks, but can be made in a different way, accessible to everyone, since not everyone knows the art of weaving.

- So, to make this chair, you need to prepare:

- two metal hoops (ready-made or self-made, for example, from metal-plastic pipe) with a cross section of 30 ÷ 35 mm, with a diameter of 700 mm for the manufacture of the seat frame, and 1100 mm for the bypass of the back;

- in this case a nylon cord for weaving is used, 4 mm thick and it will take 900 m, but instead a linen or jute cord with a diameter of 5 ÷ 6 mm or strips of thick leather can be used;

- nylon cord with a cross section of 6 ÷ 7 mm for hanging a chair - 12 m;

- 2 wooden bars with a section of 20 × 35 mm, or 2 metal tubes with a diameter of 20 ÷ 25 mm. Instead, you can use two pieces of rope with a cross section of 10 ÷ 12 mm.

The manufacturing process of this version of the chair includes the following operations:

| Illustration | Brief description of the operation to be performed |

|---|---|

| The first step is to wrap both hoops with a cord. Every 20 turns, a tightening is done so that the loops do not slip. Sometimes a small amount of polymer glue is used to secure the rope to the metal, which, of course, should not come out. The cord must be laid very tightly, otherwise the finished product will look sloppy. |

| The next step is to braid the hoop, which will serve as a seat. For this, a checkerboard pattern can be used, consisting of various knots. |

| This illustration shows a variant of the checkerboard braid made with diagonal flat knots. |

| In this photo shows the same drawing, but in a direct version. |

| For those home craftswomen who find it difficult to master the art of macrame, or just want to work on the braiding of the hoop quickly, we can recommend using the technique that is used for weaving rugs. But, if, after finishing the rug, it is removed from the hoop, then during the manufacture of the chair, the resulting weaving remains on the round frame. To make the weaving durable, for the base, which is fixed on the hoop, you need to choose high-quality cords. |

| The next step is to connect the two prepared hoops together with a cord, tightly wrapping it in front of the future chair. |

| For the rigidity of the back, two supports are made of bars, tubes or a thick cord, which are tightly braided with a thin cord. These two jumpers (in the illustration above they are shown in green lines) are fixed to the back and seat hoop using weaving. |

| Next, you need to perform weaving on the back of the chair - in the remaining gap between the two hoops. Braiding can also be done using the macrame technique, the above presented technique for creating rugs, or the simplest crochet - whichever is more convenient. |

| It should be noted here that the installation and braiding of the supports of the back of the chair can be done both before and after weaving the back. |

| It is also better to braid the slings for hanging the chair with a cord - so they will be much stronger and more reliable. The slings are fixed on the back hoop in four places, but their length is adjusted to right size already when hanging the chair in the chosen place. |

It should be clarified that for the manufacture of chairs instead of a hula hoop, you can use plastic (polyethylene) pipes for plumbing - they are light in weight and have sufficient strength. The advantage of this material is also that the braid will look much more profitable and more aesthetically pleasing on a larger diameter pipe. In addition, plastic is warmer and softer than metal. Pipes are sold in the construction markets in the form of bays and already have a suitable shape, so you just need to select the desired ring diameter and fasten it correctly.

Suitable for creating frame and pipe hoops. They are somewhat more expensive, but also stronger, since their walls consist of several layers. Metallo plastic pipes, just like plastic is easy to cut off with a hacksaw.

The length of the pipe section required for the hoop is determined by the formula for the circumference:

L = π × D ≈ 3.14 × D

- where D- this is the required diameter of the hoop,

— S is the required pipe length.

For example, if you need to make a hoop with a diameter of 1100 mm, then this will require 3.14 × 1100 = 3454 mm, or when rounding 3.5 meters of the pipe.

No need to buy hard polypropylene pipes, since when bent they can behave quite unexpectedly.

The ends of the pipe are connected to each other using a special insert of a smaller diameter than the pipe, but tightly fitting into it. Such an insert is usually made of wood or dense plastic. It is inserted into the ends of the pipe, then they are tightly shifted and fixed with stainless steel screws 15 ÷ 20 mm long, depending on the diameter of the pipe. This circumstance is important to take into account so that the screws do not pass through.

Wicker hanging chair

Task of increased complexity - wicker chair

Task of increased complexity - wicker chair The traditional option is hanging wicker chairs, which can be made from specially prepared flexible rods of willow, bird cherry, rakita, rattan or bast. In central Russia, the easiest way to find broom or willow, which grows densely along the banks of rivers.

Weaving material - long and flexible wicker

Weaving material - long and flexible wicker In order to make a wicker chair, you need to purchase and prepare the following materials:

- Long willow rods with a diameter of 10 ÷ 15 mm - they will need about 400 ÷ 450 pieces. It is better, of course, to use rattan, especially for those who first try their hand at the art of basket weaving, as it is more flexible and easy to work with.

- For the front of the chair, a metal hoop, metal-plastic pipes can be used as a frame, or the base can be created from several vine rods woven obliquely.

- Strong twine and glue will be needed to tie the frame.

- A secateurs, an awl, a knife and a ruler are necessary for measuring the material and cutting it.

- A cord with a section of 4 mm made of nylon is close in color to the shade of the rods - it will be needed for weaving the back. If there are skills in weaving, then the back is made from a vine.

- Cords, chains or ropes for hanging the chair. Their length will depend on the height of the ceiling of the room or other suspension point.

The pattern of weaving can be different, and its complexity depends on the experience in this art.

The simplest option for making a hanging cocoon chair involves the following operations:

- The cut vine is steamed and cleaned of bark, and then beaten off - this is necessary so that it is more pliable in weaving.

- To begin with, the frame of the chair is formed. If a hoop is used for the front part, and an oval shape in the form of a cocoon is planned, then the hoop will have to be slightly flattened. However, it is best to use a metal-plastic pipe for this frame element, which can be easily shaped and connected to its ends with an insert.

- Then, the rest of the frame elements are fixed to the pipe. The rods must have a cross-sectional thickness of at least 6 ÷ 8 mm, and a length greater than the height of the chair by 250 ÷ 400 mm, if they are fixed vertically. If, however, rods of this length were not found, then the frame can be made of horizontally fixed elements.

- Mounting the rods vertically, they are fixed on the upper part of the frame, in its middle, so that they gradually move apart from each other, and in the middle of the chair back, the distance between them should be 20 ÷ 25 mm.

- The rods bend, creating the shape and depth of the chair, and in the lower part they gather again towards the middle. So it turns out a kind of basket-frame, which will be ready to be in a vertical position.

- There is another way to form the base, when horizontal rods are fixed on the sides of the frame. They are also mounted every 20÷25 mm, and the shape of the future chair is also created from them.

- The frame vine is fixed on the base by bending it through the pipe from the inside of the chair to the outside. Then the bent end is intercepted with a twine.

- Further, the frame rods are braided transversely with a thinner vine, starting from the bottom and gradually rising up. If weaving goes along a horizontally arranged frame, then it necessarily starts from the middle of the back to the sides. On the pipe, the end of the rod is bent and twisted around the main vine. Each rod is closely pressed against the previous one.

An example of compacting the laying of a vine when weaving along vertically installed frame elements.

An example of compacting the laying of a vine when weaving along vertically installed frame elements. - The entire basket of the chair is woven in the same order. The end of the last rod is bent, tucked in and secured in weaving.

Since in such an armchair in the seat area there is no reliable support due to the oval shape, a foam rubber pillow of sufficient thickness is inserted into the lower part as it - this can be tried on in place.

Find out how by studying a master class on making chairs for a veranda or terrace in a special article on our portal.

Hanging chair from the board

Another type of hanging chairs can be made from boards, in several versions. Installation of such a design is quite simple, even for those owners who do not have carpentry skills. It is enough to be able to carefully handle the surface of the boards and drill even holes in them.

First option

This option is ideal for a summer cottage - such a chair is easy to hang in the shade of trees, where it will be very pleasant to relax in the fresh air.

- To make such a design, you must have the following materials on hand:

– Boards, size: length 600÷700 mm, width 120÷150 mm, thickness 10÷15 mm. These elements will require 16 pieces. Boards should be well processed, it is desirable to round the ribs on them. Some masters use boards from standard euro pallets.

- Nylon cord-paracord - 10 m.

— Water-based varnish for outdoor work.

- To work, you will need the following tools:

- Hacksaw or jigsaw.

- Drill and drill bits for wood with diameters of 6, 8 and 10 mm.

- Sandpaper.

Work on the manufacture of such a chair is carried out as follows:

| Illustration | Brief description of the operation to be performed |

|---|---|

| If the chair will be made from pallet boards, then it will need to be carefully disassembled, while not allowing cracks to appear or expand. Then, also very carefully, nails are pulled out of the boards. After that, the edges of the boards with holes from the nails are sawn off evenly. All surfaces must be carefully processed to perfect smoothness, otherwise you can easily get a splinter, and in the most inconvenient place. |

| The processed boards are marked out, folded in two or three pieces and through holes are drilled in them at a distance of 50 mm from each other. Here it should be noted that the holes can be drilled along the edge, with an indent from it of 15 ÷ 20 mm, or in the middle of the board in two rows, at a distance of 30 mm from each other. |

| Next, the boards are stacked side by side, and a cord is inserted into the holes, as shown in the illustration. |

| The next step, the cord is pulled through the holes across the previous connections. When assembling, it must be remembered that the cord should not be tightened too much, since the boards must be sufficiently loose in relation to each other. This is necessary so that the resulting design can take the form of a chair. After pulling the cord, it is tied with a double knot on the back of the structure. |

| Further, in the upper board and in the second board from the bottom, with an indent from the edge of 35 ÷ 40 mm, in the middle of the board on its two sides, two holes symmetrical relative to the center are drilled. They will be required to pull the cords of the desired length, for which the chair will be suspended. |

| In order for the cords not to converge pyramidally upward, but to be stretched at the required distance, in the upper part, just below the suspension point of the structure, they must be fixed with a wooden frame. After passing through the frame, all the cords are connected and woven into one rope. |

| The result is a comfortable chair, which can be additionally equipped with a foam mattress or pillow for comfort. |

Second option

Second option wooden chair make it even easier than the first, but it is more suitable for giving as. However, taking the proposed design as a basis and strengthening it, even a hanging sofa can be made according to this principle.

In order to make just such a chair, you will need:

- 14 well-finished boards 500 ÷ 700 mm long, 50 ÷ 60 mm wide, 15 ÷ 20 mm thick.

- Nylon cord with a diameter of 10 mm, length 10 m.

- Self-tapping screws with wide caps (press washers) 10 mm long.

Of the tools, you will need, in principle, only if the lumber is pre-processed and coated with protective compounds.

- In the first step, the boards are evenly laid out parallel to each other, face down, a distance of approximately 10 mm is maintained between them.

- Next, you need to determine how long the cord will be required on each side - for this, a fitting is performed.

- Between the laid boards, at a distance of 40 ÷ 50 mm from the edge, a cord is laid with a snake, and then it is laid in the opposite direction in the same way. Thus, each of their parts on both sides should be “dressed” with cords. The cords are twisted among themselves in the gaps between the boards, pulling them up so that the distance between the crossbars is approximately 8 ÷ 10 mm.

- When the cord is completely intertwined on one side of the chair, on the bottom board, on the wrong side of the chair, both ends of the cord are aligned and securely pressed with a wide-headed self-tapping screw.

Prices for hanging swing chair

hanging swing chair

After that, the same thing is done on the other side of the chair.

- Now, on each crossbar, on its two sides, on the back of the chair, the installed cords are fixed by screwing in self-tapping screws.

- Everything, the chair is ready, and it remains only to fix the slings and hang it in the chosen place.

How to hang a chair

The suspension chairs discussed above can be fixed indoors or outdoors. If the decision is made to hang the finished chair to the ceiling, then it is necessary to carefully prepare the place for this. The ceiling must be strong enough to securely hold a mount with a load of at least 120 kg.

- If the ceiling is concrete, which does not have voids, then, as a rule, there are no problems with mounting the mount. It is enough to drill a hole for a powerful anchor with a hook, and then fix the hanger.

In the assortment of hardware stores, you can even find a special kit designed for this application - an anchor, a hook, a metal chain.

- If the ceiling plates have voids, then a hole is made in the place necessary for hanging the chair, through which the cavity is filled with a special solution. These mixtures are called differently and they are made on the basis of high strength polymers. Such compounds are usually sold in special packages (tubes) for building syringes.

Special composite polymer composition - "chemical anchor"

Special composite polymer composition - "chemical anchor" When the hole in the ceiling is filled, the metal anchor itself with a hook or ring is already mounted into it, and then left for at least two days until the solution is completely polymerized and hardened. Only after that it will be possible to hang the chair on the mount.

- If the ceiling has guaranteed reliable, durable ceiling beams, then fasteners specially designed for hanging the chair are mounted on them with bolts.

- If the main ceiling is closed by a suspended structure, then another mounting option is used to hang the chair, having a connecting section of the required length, ending with a threaded coupling. Such a bracket is fixed in the concrete ceiling and exits through the surface of the false ceiling, and then a ring or hook is screwed into it, usually having a decorative cuff. Further, a chair can already be hung from the ring.

- You should not come up with your own mounting structure, as it may simply not withstand a large load. It is recommended to purchase a special ceiling mount made of high-strength metal alloys and designed for the appropriate load.

- Slings for hanging a chair can be chains, cords, ropes, ready-made or woven independently from durable fabrics. It is desirable that the ropes correspond to the chosen style solution, harmonize both with the chair itself and with the general interior of the room.

Other interesting hanging chair options

There are other options for hanging chairs that can be made at home. Perhaps someone will find one of these designs easier or more interesting.

- Such a model of a swing chair can be made not only by those who own the macrame weaving technique. Those who have the simplest sewing skills can also do it, as the back and seat are weaved, knitted or sewn.

For manufacturing, you will need slings and four wooden or plastic parts. From wooden elements a kind of frame is fastened, which will become a frame for the seat and back, and slings are also tied to it for hanging the chair from the ceiling.

Find out how to do it by reviewing the several options available in the article on our portal.

Such a chair is quite comfortable for adults, but most likely not suitable for small children, as it is not safe enough.

- This version of the chair can be made independently by those who own the welding craft, since the frame for such a design is made of steel reinforcement and a metal sheet. The seat of the chair is made of plywood, on which foam rubber is laid and fixed, and then sheathed with leatherette or leather.

Frameless chair - only fabric, foam rubber and strong cords

Frameless chair - only fabric, foam rubber and strong cords - For this swing chair, you will need a dense fabric, foam rubber, which will give the seat and back a shape, a nylon cord and a wooden spacer for the slings. To make such a chair, you only need a sewing machine, a centimeter, scissors and the ability to work with these tools.

- One more interesting option this unusual piece of furniture. The most difficult element in this design is the frame part of the back. In this case, it is made of bent wood, but it can be replaced, for example, with two metal-plastic pipes. They are fastened together with construction tape, and then, they are decorated with a nylon cord harness, or they are first sheathed with padding polyester, and then with dense fabric or leatherette. Slings are also made of rope or cord, and the seat and back are cut out of durable fabric and attached to the frame back in four places, in the same place where the slings will be fixed.

From the examples considered in the article, it can be seen that making a hanging chair on your own is not such an impossible task, it is feasible for any diligent person. Therefore, you can choose the option that is most harmonious for a particular interior and is most suitable for the complexity of the work and the level of your own skill, and then feel free to get to work.

At the end of the article - a detailed demonstration of the manufacture of a country hanging chair-hammock.

Video: Making a hammock chair yourself

In an effort to comfortably equip living space, many people prefer non-standard design solutions. They are able to bring originality to the familiar interior, provide additional comfort. These items include hanging chairs that you can make yourself.

What hanging chairs can be made with your own hands

Among the variety of hanging chairs, there are models that you can make yourself. Such options will be the highlight of your interior. Besides, independent production allows you to realize an individual plan, which is based on proven and reliable designs.

Hanging swing

Unusual swing chairs are made from various materials. A feature of such structures is their elegance, simplicity and the ability to use both rigid and soft frames. These chairs can become a stylish decoration country house, an unusual addition to the interior of a bedroom, living room, children's room or veranda.

wicker cocoon

No less popular is the cocoon chair or the egg chair. A feature of the model is the presence of walls that hide the internal space by about 2/3. Such chairs allow you to enjoy privacy, they are most popular among children because of the external resemblance to a hanging house suitable for games. Cocoons are usually made from natural materials intended for weaving.

Hoop nest chair

The role of the most popular home-made model is a nest chair, made on the basis of a hoop frame. Such a model can be equipped with many decorative elements, and its shape harmoniously fits into the living space. modern apartments. In the manufacture of a nest chair, a variety of weaving techniques are used.

Materials and techniques for making home chairs

When choosing the materials necessary for the manufacture of hanging chairs, first of all, consider the features of the model of interest.

- Dense textiles, synthetic ropes are suitable for a swing chair various kinds and wooden blocks.

- The chair-cocoon is made of rattan, willow, bast, willow or bird cherry twigs, which have the necessary flexibility.

- For the manufacture of a nest chair, plastic or steel hoops are required to ensure structural rigidity. And also you can not do without wear-resistant textiles, synthetic fillers, decorative cords for weaving and wooden blocks of different sizes.

To create the seats of hanging chairs, craftsmen use various techniques:

- macrame. The artistic interweaving of rope and rope knots gives the chairs airiness, providing an impeccable appearance;

- patchwork. To ensure the strength of the seat, a patchwork fabric is sewn over a dense wear-resistant material;

- knitting. The combination of durable cords of various colors allows you to implement unusual design solutions;

- tatting. Due to their openwork, these designs look weightless, instantly attracting attention.

Remember that the selected materials must meet certain weight loads. Too thin fabric or openwork weaving can tear under the weight of a large person. Fastening elements also deserve special attention and strength testing: chains, ropes, braid, on which the structure is suspended.

DIY hanging chairs - gallery

Suspended fabric swing chair - a convenient addition to a country house  Cocoon chair made of dense fabric will appeal to children

Cocoon chair made of dense fabric will appeal to children  Rattan cocoon hanging chair is strong and durable

Rattan cocoon hanging chair is strong and durable  Hanging nest chair made of dense fabric is suitable for relaxing on suburban area

Hanging nest chair made of dense fabric is suitable for relaxing on suburban area  A simple model of a swing chair is easy to do with your own hands

A simple model of a swing chair is easy to do with your own hands  The original hanging chair, made by hand, will be the pride of the owners

The original hanging chair, made by hand, will be the pride of the owners  Hanging swing chair woven using macrame technique adds coziness and comfort

Hanging swing chair woven using macrame technique adds coziness and comfort  An openwork seat for a hanging chair can be woven from a thick cord

An openwork seat for a hanging chair can be woven from a thick cord  Hanging chairs can be used as a cradle for an infant

Hanging chairs can be used as a cradle for an infant

Step-by-step instructions for making a hanging swing chair

The swing chair can rightfully be called one of the simplest models that you can do with your own hands. To create it you will need:

- 2 meters of dense fabric (canvas, satin, trouser fabric);

- a wooden stick about 1 m long and 5–6 cm in diameter;

- drill and twist drill (15–20 mm);

- carabiners (11 cm) with a load capacity of 160 kg;

- rope for static insurance with a thickness of 10–11.5 mm with a breaking load of 2600 to 3200 kgf;

- sewing machine, scissors, ruler.

- paint, brushes, iron and strong threads made of synthetic fibers.

Having prepared everything you need, you can start making an unusual interior detail.

- Fold the chosen fabric in half, then count 18 cm from the top corner.

- Carefully cut off the resulting triangle (photo 1).

- Hem all sides of the fabric cut, while bending the edges by 1.5 cm (photo 2).

- Form pockets for the ropes (Pic 3). On the long side of the workpiece, fold the edges 4 cm and sew them with a sewing machine (photos 4 and 5).

- On both sides of the wooden stick, make two holes at a distance of 5 cm from each other, while the distance between the pairs of these holes should be about 80 cm (photo 6).

- Pass the rope through the holes located closer to the center of the stick and fix it with knots. At the same time, in the center of the cable, also tie a knot necessary for attaching the carabiner.

- Pass the lengths of the cable hanging under the stick through the fabric blank, and insert its ends into the free holes located closer to the edges of the stick. Fix them with a reliable knot (photo 8).

- Attach two carabiners connected to each other to a hook previously fixed on the ceiling. This will ensure that you can safely swing in the chair. Pass the cable through the bottom carabiner.

The resulting hanging swing chair can be additionally equipped with soft cushions that provide comfort.

How to make a hanging hammock from a hoop and fabric yourself - video

Drawings and diagrams for the construction in the form of a cocoon

To make an original model of a hanging chair, you will need:

- rods of rattan or willow with a diameter of 10 or 15 mm, approximately 450 pieces;

- finished metal hoop, metal pipes or several thick vine branches woven together in the form of a circle;

- strong rope and glue, which will be needed for tying the frame;

- knife, ruler, pruner and awl;

- nylon cord with a cross section of 4 mm, used for weaving the back (it can also be made from a vine);

- ropes, chains or cords for hanging the finished structure from the ceiling.

For beginners, a ready-made cocoon scheme is useful, which allows you to correctly calculate the dimensions of the future chair.

When making, follow the instructions.

- Cut the vine, remove the bark and steam, then carefully beat off. These manipulations will provide her with the flexibility necessary for weaving.

- Then proceed to the formation of the frame of the future chair. It can be made from metal pipes or a slightly flattened hoop if the final shape of the product should be oval. In case of using a pipe, connect its ends with inserts.

- Attach all the remaining elements one by one to the pipe acting as a frame base. If the chair is mounted vertically, use rods 6-8 mm thick, the length of which should exceed the height of the chair by 250-400 mm.

- Attach each of the rods to the upper parts of the frame so that a gradual separation is maintained between them. In the middle of the backrest, the distance should be 20 - 25 mm.

- By bending the rods, give the future chair depth and shape. Make sure that they reassemble at the bottom of the structure.

- When using horizontal rods in the process of creating a frame, fasten them to the sides of the workpiece. Mount them at a distance of 20-25 mm from each other, then give them the desired shape.

- To secure the vine, gently bend it through the pipe from the inside of the chair to the outside. Secure the ends with a rope.

- Weave the finished structure with thinner rods, moving from bottom to top.

- If it is necessary to braid the frame from horizontally fixed rods, start work from the middle of the backrest in both directions. Bend the end of the rod that is on the pipe and twist it around the base.

- Press each new layer of thin twigs as tightly as possible to the previous one.

- Braid the entire basket. Bend the end of the last rod, tuck it in and securely fasten it in the main weave.

To give additional comfort to the seat of such a chair, you can use a thick pillow.

You can braid the frame in different ways. Suitable for beginners simple techniques providing a solid base for seating.

Simple weaving techniques from rods - gallery

Even beginners can cope with such weaving

Even beginners can cope with such weaving  Various weaving patterns can be used to make hanging rocking chairs

Various weaving patterns can be used to make hanging rocking chairs  With the help of weaving rods, you can create a dense base for a chair.

With the help of weaving rods, you can create a dense base for a chair.

How to make a nest chair with a knitted bottom

To create a nest chair, which will become an exquisite decoration of an apartment or garden, you need to prepare the following materials:

- a metal hoop with a diameter of 90 to 110 cm, a cross section of at least 35 mm;

- 700–800 m of polyester cord with a diameter of 4.5–5 mm;

- crochet hook No. 8–9;

- slings - 12 meters;

- roulette;

- scissors.

Wrap the hoop taken as a basis with strong twine, fixing every tenth turn with a knot, this will not allow the cord to unravel.

To create the bottom, you can use a variety of crochet techniques. To make such a seat, you will need from 120 to 160 m of cord. The exact amount depends on the selected knitting pattern.

- Start from the center. Work the circle as tight as possible using single crochets and air loops.

- Start forming the seat from the 6th-7th circle, and then move on to the back in the form of a knitted mesh.

- Pull the finished napkin over the hoop, evenly distributing it over the entire base. The resulting design should not sag. Fasten to the hoop from the side of tight knitting, without cutting the cord.

- Attach slings to the finished product.

Making a seat using macrame technique

For this version of the hanging chair you will need:

- 7 threads of 6 m;

- 4 threads of 5 m;

- 4 threads of 4.5 m;

- 2 threads of 4 m;

- 2 metal hoops with a diameter of 90 and 110 cm.

Having prepared the cords of the required length, proceed to attach them to the hoop.

- Starting from the center, fasten 7 long threads in pairs at a distance of 6 cm from each other.

- Continue fastening the threads along the sides of the warp. As a result, on one side there should be 2 threads of 5 m each, 2 threads of 4.5 m each and 1 thread, the length of which is 4 m.

- Then start weaving the pattern from the center of the workpiece.

- As a result of the work, you should get an openwork circle.

- To prevent the cable from moving in a circle, fix each thread with a flat knot.

- When knitting, constantly maintain tension, placing knots at 6 cm intervals.

If it is necessary to create a fringe, the length of the threads should be increased by about a meter and, at the end of work, do not cut the remaining cord.

Equip the resulting structure with reliable slings and a soft pillow.

Hanging hammock chair using macrame technique - video

Suspension mounting options

Hanging chairs can be attached in a variety of ways. One option is a ceiling mount on a hook. The finished product, suspended in this way, can swing in different directions, but moving it to another part of the room is very problematic.

This method can only be used if there is a high-quality concrete floor or with coffered ceilings that allow fastening directly to the beams.

No less popular is the rack mount, which can be purchased at specialized stores. This design is equipped with circular platforms that provide stability. The armchair on the rack can be easily moved around the apartment and even taken out into the street.

Another option is axial fastening, which allows you to fix the structure between the ceiling and the floor. This method is suitable for decorating children's rooms.

If the ceiling in your house is not sufficiently reliable and hollow, you can install a hanging chair using a chemical anchor. This method involves the introduction of polymer paste into the ceiling cavity from a syringe, after which the product is installed.

Simple options for making a hanging chair at home are available even to novice craftsmen. Unusual designs decorate the interior, give the room originality and comfort. Good luck with your work and create with pleasure!

People have come up with many interesting devices for rest and relaxation. Today we offer you to make one of them - a hanging chair with your own hands. It is also called a flying chair. Swinging in this cozy nest, you can take a nap, meditate and forget about your problems. You will be convinced that the chair will immediately become the center of attraction both in the apartment and in the country. Therefore, without delay, let's get down to business.

1. Making a hanging chair with a cover

Tools and materials necessary for work

No time-consuming operations will be carried out, so we stock up on a lightweight arsenal of tools. We will need:

- Steel hoop ∅90 cm.

- Durable fabric 150 cm wide - at least 3 m.

- Doublerin, interlining or trouser tape.

- Sling - 8 m.

- Iron ring for attaching the chair to the ceiling.

- Four metal buckles.

- Tailor's tape measure, scissors, sewing supplies.

Let us dwell in more detail on the hoop, which plays the role of a supporting frame in the structure. Home craftsmen went through several options for this important element, comparing their physical characteristics.

- Gymnastic hoops. Even steel, they are unlikely to withstand the weight of an adult for a long time. We do not consider plastic and aluminum at all. The limited choice of diameters (from 65 to 90 mm) is also an annoying minus. In addition, the section of the sports hoop is only 16 mm. For a high-quality and beautiful product, the cross section of the ring should be approximately 32 mm, and if the chair is wicker, then all 40 mm. However, a gymnastic hoop can be successfully used for a children's hanging chair. A small cross section in this case is compensated by several layers of filler screwed onto the ring.

- Metal pipe. Some craftsmen advise bending the frame from a thin-walled 32 mm pipe. At first glance, the option seems acceptable. But, having calculated the parameters of such a metal product, you begin to doubt: 3.2 m of pipe will go to a ring with a diameter of 1 m, and this is about 7 kg of net weight.

- Bent wood. Wooden hoops are light and environmentally friendly, but unsuitable for country conditions. Changes in humidity and air temperature (somewhere in the gazebo) will lead to drying and warping of the tree. To dry and process the ring, you will have to remove the case.

- metal-plastic water pipe. This is the most successful and inexpensive option for our goal of how to make a hanging chair. You should choose among pipes rolled into bays. Straight polypropylene pipes can behave unpredictably when bent. The manufacturing technology of the hoop is simple: we cut off the desired length of the pipe with a hacksaw and turn it into a ring. The connection will serve as inserts made of plastic or wood. You can additionally strengthen the joint with short screws.

Choose the best option for yourself, in accordance with the size and location of the chair. Perhaps you will have your own ideas for making a frame. We will assume that we have a strong hoop, we can start cutting the cover.

Cutting and sewing a cover for a hanging chair

Cutting fabric does not tolerate haste and inattention. If in doubt about the size, leave more allowances - they can then be cut off. The order of work is as follows:

Step 1. We take a three-meter piece of dense fabric and cut out of it two equal squares one and a half meters long and wide. Fold each part four times. From the central corner we mark the fourth part of the circle with a radius of 65 cm. We draw a line along the marks. We cut out two identical circles from the squares. We retreat from the edge of the resulting circles four centimeters inward, and draw a dashed line.

Step 2. We mark the holes for the lines on the first circle. To do this, fold the material in four and iron it. The folds are considered guidelines. Two slings will have an angle of inclination with respect to the bend of 45 °, the other two - 30 °. Having marked the corners, unfold the circle and iron it again. Now we have axes pointing to the slots for the lines.

Step 3. We designate cuts on all four axes obtained - rectangles 15 cm high, 10 cm wide. Inside the rectangles, markings are made in the form of the letter Y. We will cut along it. We add the circles together, making sure that the shared thread of one part does not coincide with the other. So the cover will better hold the normal shape. Put the marked circle on top. We chop them off and make cuts on two circles at once.

Step 4. We bend the petals of the cut holes to the inside. We glue the rectangle around the perimeter with interlining, doubler or sew on ordinary trouser tape so that the fabric does not crumble. After that, we make a full cut and stitch it along the edge, stepping back 3 mm.

Step 5 Stepping back from the edge of the previously marked 4 cm, we grind both circles together, leaving a hole for inserting the hoop. We cut a four-centimeter allowance, making it jagged around the entire perimeter. Turn cover right side out and iron.

Step 6. We cut the filler strips and sheathe the hoop with them, it is possible in two layers. We insert the sheathed frame into the case. Moving the ring to the edges, we sew both circular parts into a basting at a distance of seven centimeters from the edge.

Step 7. We turn inside out the edges of the unstitched hole left under the insert of the hoop. We notch and cut off the allowances from the front side so as not to deform the geometry of the circle. We sew the edges and sew them on a typewriter, stepping back 2-3 mm. We move the hoop to the stitched edge, sweep the cover at a distance of the same 7 cm.

Step 8. We cut the synthetic winterizer in the slots and slide it inside the cover, fixing it with threads. We sweep the cuts along the edges with a hidden seam. Now we strengthen the cover on the frame, stitching it along the 7-centimeter mark made. After making 4-5 stitches, tighten the knot. We make the next row of stitches at a distance of 7-8 cm from the previous one, so that the dense fabric can freely gather in soft folds.

Step 9. We cut the sling into four parts of two meters each. Its ends can be melted over an open fire. We pass the end of the sling into the hoop at the slot. We fold, forming a loop, we cut off with needles and sew. We repeat the operation with each line.

Step 10. We thread the free end of each sling into the buckles, then into the ceiling ring and again into the buckles. Thus, we will adjust the height of the hanging chair and its angle of inclination. The ring, in turn, will collect all the lines into one suspension.

The flying chair covered with fabric is ready. This was the simplest option, based on one hoop.

2. Making a wicker hanging chair

1. Now we will look at the original design of two hoops braided with macrame cord. It will require the following materials:

- Two hoops from a metal-plastic pipe with a section of 35 mm. Hoop for the back with a diameter of 110 cm, hoop for the seat - 70 cm.

- 900 m polyamide cord 4 mm thick. Ask for a cord with a polypropylene core that creates tight knots when knitted.

- Slings - 12 m.

- 2 thick cords for fastening both rings.

As for the dimensions of the hoops, they can be made smaller, since these parameters are actually the limit for a hanging chair. It is better to purchase the entire volume of the cord at once so that there is no discrepancy in color and texture. Now that everything you need is prepared, you can get to work.

2. First we braid the hoops. For each meter of pipe, an average of 40 m of cord is required. The coils should be laid tightly, evenly and with good tension. Every 20 turns, fasten the winding by pulling and twisting the last loops until it stops. The surface of the braid must be even and strong, because the mesh for the back and seat will be attached to it. Work better with gloves.

3. Now we weave the net right on the hoop with a double cord, attaching it to the braid with a double loop. The weaving pattern is the so-called checkerboard pattern, with flat knots. The ends of the knots do not need to be trimmed, they will form a fringe. The elasticity of the mesh depends on the tension of the cord during operation. The possible deformation of the ring during tight weaving is further compensated by the equal tension of the knots, and the shape of the hoop will be restored.

4. The next step is to fasten the braided rings into a chair. From one edge we interlock the hoops by firmly winding them with a cord. Insert two identical wooden rods from the opposite edge. Cuts are made at all four ends of the rods so that the hoops do not slip off. This will ensure the correct tilt of the back and allow you to weave an even rigid mesh for it. We set the length of the rods depending on the selected backrest height.

You can choose any patterns for weaving the back. Those who are engaged in macrame can choose any pattern. The cord is attached to the top of the back. The mesh is weaved down to the seat. Cords are tightened on the lower ring. The bottom residues are collected in brushes. The design is reinforced with two thick cords connecting the seat and backrest. Slings are tied to the chair, and it takes its place in the garden, on the balcony or in the apartment.

Make such a chair for yourself, and you will forget the way to psychotherapists, find peace and a philosophical attitude to all troubles.

2.

3.

4.

5.

6.

7.

8.

9.

I quote:

Difficulty level: not for beginners.

1. At the first stage, of course, we will get acquainted with the object closer.

The highest quality image of the finished chair, which was found on the Internet, gives an acceptable level of product detail when the image is enlarged:

2 hoops, pre-braided with cord,

weaving pattern - "checkerboard",

knots when weaving - flat,

the cord is used paired (double),

fastening the cord to the base - double loop.

In addition to four slings that are attached to both hoops, there are 2 additional tight cords in the back of the chair, which give the structure additional rigidity. All ends of the cords and braided lines form decorative tassels under the lower hoop.

2.

Metal - plastic pipes with a metal braid inside are the most durable (they cost more, but they can even withstand an elephant!), So they are ideal for us to create a chair.

Cut off the required length of the pipe with a hacksaw, determining it by the formula S = 3.14xD, where S is the length of the pipe, D is the required diameter (width) of the hoop.

For example, for a hoop with a diameter of 1.2 m, you need to measure 1.2x3.14 = 3.77 m of pipe. You should not take straight pipes (not twisted into coils), especially polypropylene ones, because they behave inadequately when strongly bent.

To connect the ends of the pipe to each other, use an internal insert of a suitable diameter made of wood or plastic. To strengthen, you can use stainless steel screws of small length.

The specifications of the finished product say that the diameter of the larger hoop is 72 cm, however, I made hoops with diameters of 110 and 70 cm to make the chair wider and more comfortable. The proportion of diameters turned out to be, perhaps, the maximum. When choosing sizes, I recommend sticking to the Large Diameter / Small Diameter ratios from 1.2 to 1.6.

3.

As a material for weaving, a white polyamide cord 4 mm thick with a polypropylene core was used. In total, over 900 meters of such a cord were used for the product. The cord can be found in the construction market. Do not buy polypropylene cord, the fibers of which are similar in structure to the fibers of a sugar bag! Polyamide cord has a soft surface, almost indistinguishable from cotton fibers. The polypropylene core gives increased rigidity to the knots.

If possible, buy all the necessary amount of material at once. Due to my own optimism, I bought the cord three times (each time it seemed that it was enough), and then I was surprised to find that the texture and shade of the cords turned out to be different.

4.

The primary braid of the hoops "ate" as much as 230 meters of cord, i.е. approximately 40 meters per meter of hoop circumference. You need to wrap carefully. To make the winding strong and even, carefully place the coil to the coil of the cord, and tighten the winding every 20-30 turns - grab the last turns with your palm and twist with force in the direction of the winding until it stops, at the same time sealing them. The surface of the braided hoop must be rigid and durable, because macrame cords will subsequently be attached to it. It is better to carry out the whole procedure with gloves, otherwise you will definitely fill the calluses on your hands.

5.

The weaving of the net was carried out immediately on the hoop. The first to braid was a small hoop (seat). As you can see in the figure (Scheme 1), the weaving pattern is quite simple. The fastening of the cords to the base with a double loop is shown by blue dots, the flat knots of the mesh are orange. It is better not to cut the ends of the cords (shown as “tails”) yet, then decorative brushes are formed from them. Schemes for weaving flat knots and fastening the thread with a double loop can be viewed in detail on the Internet.

The strong tension of the cords during weaving made the mesh very elastic. When about half of the base was woven, the hoop was slightly deformed (it was squeezed from the sides), but when the lower knots were fixed (also with a stretch of the cord), the pressure was compensated, and the hoop again took the correct shape.

Original hammock chair from a hoop for a summer residence. How to make a hammock chair with your own hands: diagram, photo, video.

very interesting and original solution folk craftsmen found an ordinary, metal gymnastic hoop by making a hammock chair out of it.

You can easily make such a hammock chair with your own hands, all photos and diagrams are provided in this article.

The larger the circle of fabric, the deeper the hammock chair will be, but it will not be very comfortable to sit in a deep hammock. Cut out two such identical circles from the fabric.

To make the hammock cover removable, you can sew a zipper into one circle, the length of the zipper should be equal to the diameter of the hoop, in our case, the length of the zipper will be 95 cm. Fold one circle in half, cut and sew the zipper.

Fold the two circles together with the right side inward and sew in a circle sewing machine. Turn the stitched circles right side out.

Along the edges of the cover, we cut out four holes for fastenings for the hoop and sheathe them with braid.

The layout of the holes for mounting the hammock.

To make it comfortable to sit in a hammock, the metal hoop must be sheathed with a soft cloth, such as padding polyester.

We put our cover on the hoop. Now the hammock chair needs to be hung, for this we need four ropes, two of 2, 2 m and two of 2.8 m.

Each rope must be folded in half, tie the edge into a knot and tighten on the hoop. We fix all four ropes on a metal ring or carabiner.

Now it remains to hang the hammock, we tie a rope on the veranda or to a tree branch in the garden and fasten it to the metal ring of our hammock chair.

To make it more comfortable to sit in a hammock, you can also make a couple of small pillows.

The hammock chair can be placed on the veranda or in the garden.

Making a hammock chair from a hoop does not take much time, and you will have a great place to relax in the fresh air in the country.

I suggest to look interesting video about making a hammock chair.