Do-it-yourself sofa from boards. How to make a sofa with your own hands? Homemade sofa. Advantages of making your own upholstered furniture

Have you ever thought about whether it is possible to make an ordinary sofa at home, i.e. on your own? At first glance, such a question will seem unusual to us, since in any furniture store you can find the right sofa for every taste and color. But if you think a little about, for example, what you will have to put out of the furniture for sitting in the same rest room in the bathhouse or on the country veranda, then the initial question about a homemade sofa in country house won't seem so strange. In this article we will tell you how to make a sofa with your own hands from auxiliary material.

Sofa from a bar

One of the options self-manufacturing sofa in the country involves the use of timber for its construction, small trimmings of which often remain after the completion of the construction of utility rooms. In addition to these blanks, you may also need the following material for work:

- foam rubber sheets sold today in any specialized store;

- 210 cm long zipper used to make the cover;

- three zippers of 70 cm, going to the manufacture of pillows;

- any material like a tapestry;

- metal corner;

- metal mesh.

The main work on assembling the sofa at home should begin with the construction of the base (bearing frame) of the structure, for the assembly of which we use the beam mentioned above. A bar measuring 70x210 cm can be very convenient for making a frame; while the support legs for our frame can also be made from four small sections of this beam.

The second step towards achieving our goal is the manufacture of a reliable sofa back. Since initially this design option involves avoiding unnecessary complications of the design (do not try to do something like a folding system), we make the backrest according to the same scheme as the frame base of the sofa was made. Such a frame back must be sufficiently rigidly fixed to the base using thick-walled metal corners. You will choose the optimal angle of inclination of the resulting back according to your own taste, but the main thing is that it does not turn out to be very steep (to avoid discomfort).

At the next stage of our work, we will try to mount the support grid on the sofa frame, which would hold the seat cushions. For these purposes, the armored mesh from the metal beds that our grandfathers used was quite suitable (I made sure on own experience in that, if desired, it is quite possible to find such a grid even today). After securely attaching such a grid to a wooden base (using ordinary metal staples), you get exactly what you need. Only one should not forget to insert four transverse bars into the longitudinal bars of the frame before fixing the mesh (the insert is best done using the groove-in-thorn method with landing on special glue).

We now turn to the manufacture of soft upholstery for our design.

After that, we stuff three large pillows with scraps of foam rubber, the covers for which we also make from pieces of tapestry sewn together with zippers.

Sofa from ready-made shields

In the event that you are not skilled enough in handling wood and other materials, you are offered another way to make a sofa on your own. To make it you will need:

- two old door leaves;

- metal staples;

- wood stumps;

- foam rubber;

- the cloth.

As the base and back of the proposed simplified design, two sashes that have served their time are taken wooden doors. All you need to do with them is just clean them of dirt and process them using grinding.

Then you should cover them with several layers of paint, the color and texture of which are chosen arbitrarily (or under the interior of the room where your sofa will be located). It is possible to finish the surface of the doors with wood veneer.

Firmly fix one of the sashes on wooden stumps of a suitable size with nails and attach a back (second sash) to it using metal brackets.

Then you can start making a mattress, for which the foam rubber cut to the size of the seat should be sheathed with some kind of strong and coarse fabric (coarse calico or matting, for example). From above, such a seat can be covered with a high-quality fabric that has an unusual color. Then lay the finished mattress on the base of the structure and place a few small pillows on it.

An impromptu sofa of this type can fit well not only into the interior of your country veranda, but can also decorate any other country corner.

You probably paid attention to the fact that the basis for the independent arrangement of the options for sofa products we have considered is the manufacture of a reliable and strong bearing base (frame). This fact allows us to conclude that any other material that satisfies the specified basic conditions can be chosen as the basis.

A sofa is an absolutely necessary piece of furniture. In small apartments, a sofa can replace a bed, wardrobe, even a living room, in a set with a coffee table. And at the same time, a sofa is a very complex product, one of the most difficult in furniture production, so the prices for sofas are considerable, and amateur furniture makers take them with caution and take inexpensive sofas for samples, relatively little functional and not very strong and durable. This publication is designed to help them better understand the designs of sofas and understand how to make one that will pass on to their grandchildren, unless they have to be pulled over. And designed for rooms with the widest range of conditions of use: from a garden gazebo to a kitchen and a children's room.

It’s not as difficult as it might seem, and making a sofa with your own hands in the luxury category (not to mention simple ones for summer cottages, nurseries, temporary use, until the money is collected for furniture) is quite possible in the garage, shed and even on the balcony. Furniture makers of the old days worked that way. High-tech “bells and whistles” make it possible to reduce weight and dimensions, expand the range of operating conditions, obtain new product qualities and create fundamentally different designs, but the basis of exclusive quality remains unchanged at all times: conscientiousness, accuracy, good knowledge of the properties of materials and a complete understanding of the essence of each production operation. And the design of the furniture is very conservative. Operations that require production conditions, during its manufacture, can almost always be replaced, albeit more labor-intensive and requiring skill with more ingenuity than a well-trained biorobot on a conveyor, but produced with a hand tool.

Corners that sofas

One of the most popular today is a corner sofa. The reason is high functionality, which is especially evident in small-sized housing. For example, a sleeping and living sofa-corner, pos. And in the figure, folded, it has no sleepy look and the most terry orthodox moralist will have nothing to complain about. But at the same time, its right (in the figure) section is already a single bed, and when unfolded, it turns into a double bed. These are also called sofas for bachelors: I’m tired, I’m not up to it - I’ll fall asleep on a single bed. And another (or forever the only) passion came - enough space for two to get settled, as it should be in such circumstances. Structurally, nothing complicated: uniformly designed and put together a single bed and a folding or roll-out sofa like those described below.

The second most popular is the classic soft corner, pos. B. Sitting in the corner is not only Bad sign, but also inconvenient, therefore, in last years the corner seat is increasingly being replaced with a casket-bar, as in pos. In, or, for the kitchen, a casket-table. The scheme of the device of such a kitchen corner is shown in fig. below. You can dine alone on it if in a small kitchen the table is occupied for rolling, cutting, etc. And the casket and wardrobe trunks (the so-called sofa boxes) will serve as bins for vegetables, storage of homemade products, etc.

This kitchen sofa is made according to the so-called. simplified beam scheme (see below). Its peculiarity is that the seats are narrower than those of the sofas on which they sleep, 400-450 mm versus 550-700 mm. The length of the side sections - according to the place in the room; other dimensions are typical, see below. The material of the sidewalls is a hardwood board 40 mm or chipboard 36 mm. The bottom of the sofa - chipboard 12-16 mm on a frame (also see below) or OSB of the same thickness without a frame; the rest is a board 30 mm, bars 50x50 mm and 50x30 mm (shelf supports). Assembly - on self-tapping screws, dowels and a half-tree tie-in, all with PVA gluing or Moment. Materials at current prices require no more than 3,000 rubles.

Device and dimensions

The sofa consists of a supporting (bearing) structure, most often including a drawer, a bed - sofas, in the presence of a lifting drawer, back and armrests. In transformable products (sofa bed), a transformation mechanism is added to them and, possibly, additional pillows stored in a box. Typical dimensions of the sofa:

- Length - 1200-1900 mm.

- Sofa width - 550-700 mm.

- The height of the armrests is from 100 (ottoman) to 400 mm.

- Back height, no add. pillows - 200-700 mm.

- Back tilt - 5-20 degrees.

- The height of the "sitting" surface of the sofa above the floor is 400-450 mm.

The last parameter, in turn, consists of:

- Legs - 50-70 mm.

- Carrier frame - 50-100 mm.

- Box - 150-250 mm.

- The bottom of the sofa (with frame) - 55-75 mm.

Thus, up to 120 mm remains for the soft stuffing with lining. If its thickness exceeds 70 mm, the sofa is considered soft, 40-70 mm - semi-rigid, up to 40 mm - hard.

About cutting and sewing

The most difficult and responsible part of the work on making a sofa is its stuffing, sheathing and tightness. These are different production operations; each of them individually and all of them together determine the consumer qualities of the product and its durability more than woodwork. True, craftsmen are actively promoting themselves in Runet, promising to reupholster a sofa in an hour or even 20 minutes, but, firstly, they work mainly with non-woven materials (fleece, etc.), which are short-lived in themselves. Secondly, they are fitted according to a simplified system with turning the corners from the inside out, which is unhygienic and guarantees rapid abrasion of the skin. And most importantly, according to this method of work, there is no reliable information about: a) the durability of the product before the need for tightening; b) whether any of the primary clients contacted this specialist again.

To properly sew covers for sofa modules, you need a serious preparatory work. Its essential subtleties will be described later; beginners are advised to fit the sofa in the old amateur way with a saddle fitting. The pros don't work much for them. it takes a lot of time, and who will pay for it? But during the heyday of stagnation (or stagnation of prosperity?), when it was necessary to sign up for furniture upholstery for a year, and even give a bribe, it was also successfully used by “full dummies”. The sofa is stitched step by step as follows:

- The wooden base is covered with technical fabric - canvas, matting, burlap (can be propylene);

- Install soft padding, most often - foam mats;

- They fit soft, in order of preference, spandbond, synthetic winterizer, batting;

- On a piece of decorative fabric, the backstage is swept under the cords, if decorative scars / tightenings are provided, see below;

- A decorative cut, without cutting, is thrown onto the product inside out, pulled off as described below, and the corners are swept with a harsh thread (now reinforced with propylene) with a scar outward;

- After a day, they check if it wrinkles somewhere, if it sags, if the pattern, especially geometric, has led, and if necessary, correct the corners;

- If everything is OK, mark the seam lines, cut and sew;

- Pull cords into the backstage for tightening, if necessary;

- They throw a cover, make the final tightening, starting from the corners;

- After another day, they check according to the drawing, adjust the tension threads ;;

- Everything is OK - fix the lapels;

- Form decorative ties.

The procedure, as you can see, is quite complicated and long. This is explained by the fact that the properties of tissues, incl. upholstery, differ markedly within the piece. Previously, upholsterers were guided by intuition and experience, now the technical parameters of a particular sample are directly entered into professional computer cutting programs. Home-made templates from wallpaper newspapers do not provide this and do not take into account the initial tightening of the fabric. However, it is useful to make them - to determine the consumption of tissue. A rough estimate according to the method: the length of a cut 150 cm wide is equal to 2 sofa widths + 2 its lengths, gives a large waste. Determining the cut length using templates (allowance - from 15 cm) saves up to 1 m in length (!); how much it is in money - see in the store.

Note: for the same reason, if a sofa is being reupholstered, it is undesirable to use the old sheathing as a pattern. Under a microscope or a magnifying glass, it is clearly seen that the structure of its fabric has changed significantly compared to the same, from the same machine, jacquard or tapestry.

Additional explanation is also required. 1-3. If you fill the skin hastily, wood-glue-synthetic winterizer-foam rubber-decor, then after a while it will turn out that the skin is greasy, to the touch, especially in summer, sticky, and the dearest parts of the body are uncomfortable on it. Let “some” be 3 years, but what is this life span for furniture? Therefore, soft padding mats need porous pads from below and from above to wick away fumes/sweat/dirt from them. in furniture with spring blocks, by the way, too, see fig.

What to do?

The basis of the sofa is the supporting frame, pos. 1, with a box attached to it, pos. 2. The backrest is attached to this assembly, then the armrests; most often - already sheathed. The frame and box, if the design of the item does not provide for any visible wood, are also sheathed separately before assembly. Lapels of the fabric at the joints in this case do not reduce the strength of the connection. vertical loads do not tear off the upholstery, and horizontal loads hold extra. fasteners, see below.

Note: the famous tank designer Christie once said that the idea of silent blocks in the tracks came to his mind when he was repairing his sofa. It is not surprising that a rich man himself was busy with furniture, Christie was an engineer of the second kind. The Ι clan shifts papers at the table, and the ΙΙ-th can do with his hands everything he has thought of.

A sofa is installed on the box and its lifting mechanism(in the simplest case - piano / card loops and a cord-limiter). Perhaps the sofa will be stiff with the mattress loose on it. In any case, the sofa is also upholstered in advance separately.

A special case is office sofas, etc., operated in adverse conditions with the possibility of inaccurate use. Their carrier system is made in the form of a three-dimensional beam structure, pos. 3. But it is not recommended for amateurs to use the connections shown there with confirmations obliquely. In the presence of special equipment and tooling, "oblique screws" are economical and technologically advanced and therefore are widely used in industrial production furniture grades to medium. But, firstly, such a connection is not as strong and durable as traditional furniture ones. Secondly, it is problematic, if not impossible, to drill very shallow oblique holes with a hand tool to a given depth, exactly at the right angle and immediately in 2 mating parts. And self-tapping screws that have parted to the sides or along the corner (which is not noticeable from the outside) will significantly reduce the strength and service life of the entire product.

A drawing of a simple sofa of a beam scheme is shown in fig. It fits best in the gazebo. Due to the influence of bad weather, pillows are brought / taken away as they are used, and the parts are individually impregnated with an oil water repellent for wood (it can be worked out) or twice with a water-polymer emulsion before assembly. Finishing - acrylic varnish in 2 layers.

To the dacha, where the rain still does not pour through the roof, it will be easier to make a home-made sofa of a simplified beam system, its device is on the left on the trail. rice. Its basis is strong sidewalls-armrests and a pair of transverse beams. Completes the box-bridge power circuit; in this case, necessarily with 2 bulkheads (partitions). Materials:

- Armrests - plywood 20-24 mm with overlays from the board at the top (so that they are wider) or, if the cottage is heated (does not dampen), chipboard 30-36 mm.

- Drawer - oak / beech board 30 mm; bottom - plywood from 6 mm.

- Leg beams - any industrial wood.

- The back is the same, a shield, (300-400) x40 mm.

Assembly - on wood screws with gluing. Pay attention to how the box is assembled, this method will still come in handy for us. The second feature is that the box is attached with self-tapping screws not only to beams made of timber, but also to the sidewalls from the inside in a zigzag (snake) with a step of 120-150 mm with an indent from the edge of the board by 30 mm. The back is also attached to it.

If the workloads are smaller, but with a greater proportion of dynamic sign-variables, a simplified scheme with 2 longitudinal beams works better. They need to be raised by about half the height of the sidewalls, otherwise the working deflection, in this case already noticeable, will tend to fill up the sides on top of each other and the sofa will soon loosen. According to this scheme, a children's sofa with drawers is assembled, shown on the right in the figure; box assembly diagram down there on the right. The material of all valleys is oak/beech 30 mm; sidewalls and the bottom of the sofa plywood 18-24 and 10-16 mm, respectively. Assembly - on glue.

Note: it is not worth using laminated chipboard - only the E0 phenol class is acceptable for children's furniture, but this material is rather fragile and will not last long in such a loaded product as a sofa.

How to raise a sofa

With the simplest mechanism described above, it will not work to lift the sofa back: the back is in the way. It remains to move forward. But then, taking into account the height of the support, its upper edge, raised, will be 70-100 cm above the floor. If the hostess is not a tall two-meter tall, how can she put / get something? To roll over entirely in a box and squeak, jerking slippers in the air?

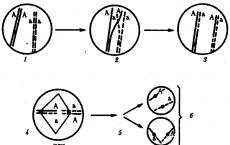

Meanwhile, it is very simple and reliable, and most importantly, not requiring high precision, the lifting mechanism of the sofa can be made by yourself at home, on the principle of a lever-spring system such as an oblique rhombus with 2 dead points. How it is arranged, and at the same time the sofa couch with it, is shown in fig.

Note: the author knows a curious case with an oblique rhombus. A drunk but skilled man, making this ottoman, fenced off the cubbyholes behind the levers (they say, there is also some kind of mechanics) and arranged hiding places for bottles with the necessary swill in them. He even brought the tubes under the lining behind the back. And the better half is more than 10 years old, until he went into a deaf bogged down and did not split himself, and it was not clear why this day is a day drunk, and he does not run to the store for a bubble.

About sofa beds

The sofa bed is, as they say, a classic of the genre. But in the amateur, and in the professional world, innovative works appear all the time. The fact is that the mechanism for unfolding a classic sofa-book is a rather capricious thing. Either he wedges / seizes, then it’s hard for ladies’ hands to assemble / disassemble the sofa, then it turns out to be too expensive and not reliable enough. And an amateur who wants to repeat the chosen sample finds that in a rough-looking piece of iron there are curved surfaces made with a fairly high accuracy, but there are no detailed specifications for them. Therefore, lovers most often make sofa beds roll-out / pull-out.

Here, 2 systems are most common, with a retractable half of the free bed, pos. 1 in Fig., and in the form of a bridge, pos. 2. The first is less labor- and material-intensive, but its Achilles' heel is the legs. It is inconvenient to recline them manually, and gravitational ones (reclining by their own weight) will someday stand askew and break, a sofa that sags when extended will help.

The bridge scheme is more reliable, especially since its movable (on rollers) supports will also be bedside tables. True, they will have to reach out to them, unless users are prone to necrophilia and do not like to sleep with their feet forward.

The device of the sliding sofa bed of the bridge scheme is shown in more detail in pos. 3. The upper paired rollers (guides/stops) run in the troughs of the drawer. Pay attention to children. Q. This is not some kind of additional mat, but just a decorative overlay. The surfaces of the sleeping halves A and B are, of course, flush. Half-bed A is often made leaning forward on the same canopies as for B, hidden by an overlay C. Then small boxes D open. Lovers of "strawberries and cream" (erotomaniacs / nymphomaniacs, a surprisingly monotonous and primitive-minded public) consider them reliable hidden caches and hide intimate accessories in them.

Both of these systems have a common drawback: to transform a sofa into a bed, some extra free space is required behind the back. What does not happen with a small bedroom, and garbage accumulates there. Roll-out sofa beds of the console scheme are deprived of this vice, now for some reason they are completely undeservedly relegated to the background.

How a cantilever sofa bed is arranged is shown in fig. on right. Its width when extended can be increased to 1500-1600 mm due to the proportional broadening of the console and an increase in the height of the back, and its length up to 2000 mm (this is already a normal twin bed). The excess width of the seat in the assembled form in this case is compensated by the pillows, which, when extended, form half of the bed. In the original design (designed for a tiny sleeping compartment in the hozblok), they are stored in a box. Some inclination of the back is obtained due to the piano loop, its hinge. It can be increased by placing a plywood pad under the bottom wing of the hinge.

The main materials are 50x30 bars and 4-6 mm plywood. On the basis of the armrests - cohesive waste construction timber. The frame of the console is the same design as for the drawer. Connections - through spikes or met. corners, anyway. The height of the pillows is 150 mm, but they sag under the rider, therefore, for use in normal conditions, it is desirable to increase the height of the console, and put the box on its legs.

About eurobooks

The concept of the euro is now as soon as not exaggerated. Moldovans, for example (they have experience of communicating with local migrant workers), dig euros in a trench (according to plan, profile and on time), get drunk euros (totally, to death, to a green snake, blue devils and pink elephants), euros go to the toilet for the most part (no constipation or diarrhea). And the usual folding sofa bed is now often on sale for a reason, but as a Eurobook. But this is still all right, but the click-clack-type eurobook sofa (see fig.), This is already something.

It unfolds and assembles really easily, yes, yes. And the mechanism is expensive, but reliable. To get a double bed, the armrests and backrest sides also recline. How to call them is not clear. It doesn't look like headrests. Sidebars, right? When unfolded, triangular gaps are formed in the heads / legs, which are blocked by additional folding wings, which further complicates and increases the cost of the product.

The most important thing is that in order to expand the click-clack into a bed, at least 0.7 m of free space is needed along its contour. Where to get it? Unless in a studio apartment, the inhabitant of which is embarrassed to show that he is also sleeping here. However, such a state of mind is typical for the current, and not only the current, Europeans. You can talk about a double standard of openness, but from the point of view of simple common sense, a click-clack sofa-book is well.

How to do?

But how to make all these sofas? Where to screw, where and how to drill-cut? Well, let's get started. Just do not forget that what is fitted must be fitted before the general assembly. How to fit, we will discuss after the carpentry, after all, the basis is in it, the manufacture of the sofa begins with it.

Frame and box

Professionally handicraft, if I may say so, the supporting frame is assembled on deaf spikes with wedging and gluing. They give a completely hidden connection and furniture lives on such for centuries, but to make them, you need a hand-held wood router, skills in working with it or virtuoso possession of a hammer, chisel and brace.

It will be easier for an amateur to assemble a frame with inset legs, pos. 1 in fig. So it is no less reliable for 30-40 years, and the seam is almost invisible. Cross section of beams from 50-30 mm; legs - from 70x70 mm. In any case, the “stump” of the leg must be at least 40x40 mm. The beams are fastened with pairs of diagonally located self-tapping screws from 4.2x60 with glue.

The box is best assembled on the bosses of a triangular section from 50x50, pos. 2. They are fastened with box boards (oak / beech from 30 mm; pine from 40 mm) with self-tapping screws (4.2-6.0) x45, 2-3 pcs. into each board, i.e. 4-6 pcs. on the boss; connections also with gluing.

Note: the box will be much stronger and more durable if you are not too lazy and assemble the box on the dowels before installing the bosses, a pair per joint.

The bottom can simply be nailed with small nails in increments of 70-100 mm; it will lie on the frame and therefore will not come off. The choice of material is more important here. OSB is the strongest, but the stapler's staples do not fit well into it, many bend and tear the skin; wallpaper nails - too. Chipboard and fiberboard are fragile, delaminate. Suddenly the bottom gets wet, it can simply fail, leaving a nailed strip between the frame and the box.

Note: if you need to pull the sofa, the bottom of the chipboard / fiberboard will show itself in all its glory - when you tear out the old staples, the layered material is picked open so that you can no longer attach a new upholstery.

The best bottom material is plywood 4-8 mm thick impregnated with a water-polymer emulsion. But, if a box is needed without bulkheads, a problem arises: sheets of plywood the width of the length of the sofa are not produced. Pieces need to be connected so that the joint is kept on weight under the weight of the contents. The same question arises if there are trimmings that are enough for the bottom.

In the industrial production of high-quality furniture, plywood sheets are connected with a shaped hardwood plank, at the top at pos. 3. You can make a “cut” yourself if you have a router. Its length is 2 board thicknesses less than the width of the box (equal to its inner width). Fasten the gusset from the inside to the tsargs (boards) with steel corners. If there is no router, the gusset is replaced with a prefabricated T-beam of 50-70 mm planks with a thickness of 15 mm and a 20 mm liner no less than plywood. It will give the beam rigidity, and without it, sheets assembled end-to-end, under workloads, will begin to delaminate each other mutually. Everything is assembled on small nails, fastened in a box like a gusset.

They connect the box to the frame (recall - after sheathing, if provided) with dowels in increments of 200-300 mm, this is enough not to crawl to the side. An option, perhaps in addition to dowels, is flat metal lining from the inside and self-tapping screws, 1 in the middle for short and 2-3 evenly along the length for long sides.

Note: if the box is without bulkheads, the height of the back should not exceed 350 mm, otherwise the back side of the box will not withstand the loads.

Back

The basis of the supporting frame of the backrest (pos. 1 in the figure) is the side member A from a solid board (120-150) x40 mm. Most often, for the sake of simplifying the work, they make it a composite of sections, but it will be stronger in one piece. This is cut flush into vertical racks and placed first on dowels. It is also desirable to assemble the entire frame first on the dowels, and then fasten the corners inside with corners or bosses, like a box. Bosses in this case can simply be timber trimmings, tk. The interior volume of the back is not used.

The height H1 is equal to the height of the base frame, without legs, together with the height of the drawer; H2 - the thickness of the sofa, but not less than the height of the spar indicated above. Thickness of bottom slab made of oak, etc. - from 40 mm. Together with the spar and rectangular parts of the uprights, it makes up the lower back belt. This is a very responsible node, because. the normal operating load of reclining people tends to tear it off the lower support.

The normal number of racks for a sofa up to 2 m long is 4 pcs. evenly in length. If the back is wider than the sofa, i.e. captures the armrests, then 2 more are added. The penultimate ones, counting from the middle, fall on the corners of the supporting structure, the most extreme ones - on the outer planes of the armrests, see below.

The upper belt of the back is made of solid timber with a thickness of 50 mm or more. His "responsibility" is necessary when they stand on the back in order to reach something upstairs or when they drag the sofa by the back when moving furniture. Also here, the upholstery is most likely to crawl and wrinkle, so the upper timber is planed into the same plane with the supporting surface of the back and its edges are rounded (shown in the inset). As for the racks, they can be pine.

The backrest is completed by upholstering its supporting surface with plywood, chipboard, fiberboard from 4 mm, as shown in pos. 2. So it is necessary to give the entire module the rigidity necessary for a strong connection with the support, but it is not necessary to sew up the rear yet!

Now compare pos. 2 and 3. The last one is a gross mistake that simplifies the work and allows you to quickly get paid for it, but seriously degrades the quality and durability of the sofa. How to attach this back to the support? Self-tapping screws in the ends of the boards? How long will this sofa last until the back comes off?

Support connection

Assembling the backrest with a support is just the case when metal fasteners in furniture are needed. Together they are connected with corners from 60x60x4, and to the back details with self-tapping screws from 6 mm, and to the box / frame - through bolts from 6 mm (heads in the box / frame), 3 of those and those per corner. Washers from 40 mm under the heads and nuts are required! There are also spring nuts under the nuts, it will not be possible to tighten them later!

Corners, on the other hand, need 2 for each vertical joint in the back (12 with 2 intermediate posts), at the top and bottom, 3 horizontal in each section at the top, in the area of \u200b\u200bheaviest loads (to the spar), evenly along the length, and 1- 2 horizontally below. Better 2, in case the sofa will be dragged behind the back. For attachment to the spar, it is better to use 60x40 unequal corners with holes in a narrow shelf arranged in a row.

And only now the back can be sewn up with the same plywood, chipboard, DSV from the rear, covered with technical fabric, glued foam rubber (40-70 mm), and completely fitted. It is impossible to leave the decor for later, so as not to accidentally damage it during further work: it is unacceptable to put the upholstery folds into the junction of the backrest and the support, and it will not work to fit it after installing the armrests.

armrests

Armrests can be solid wood or frame, like a backrest. They are also fully completed prior to installation. The loads on them are less, therefore they are fixed from the inside with self-tapping screws from 6 mm in an envelope or a snake to the box, and to the support 4-6 pcs. in a row.

Armrests of complex shape are most often made framed. In fact, technologically they are not so complicated, pos. And in fig. The decor on the inside reaches the lower edge of the sofa. The backrest should also match the elegant armrests. Then it needs additional lathing of laths approximately 30x40 and inserts from boards from 30 mm, pos. B. The crate is cut into the back racks, and the inserts are fixed with self-tapping screws into the edge.

Sofa

The bottom of the sofa (plywood or chipboard from 8 mm) is assembled on a frame of 70x50 timber with at least 1 crossbar for every full or incomplete 70 cm of length; distribute them evenly. The frame parts are connected by a half-tree tie-in with reinforcement with self-tapping screws on glue. The bottom plate is attached to the frame with small self-tapping screws or notched nails. The frame bars must be at the bottom, i.e. outside (see fig.), and not inside, as is sometimes advised. True, 50 mm of foam rubber disappears in this case, but there is a significant advantage when tightening: staples / nails do not scratch the top of the box, and thanks to the extra bend, the sofa lining (the most loaded one) lies more evenly and holds on tighter.

Upholstery

Upholstery of different sofas and even different modules of the same sofa is done in different ways, but they all have a common sore spot - corners. Form them with a turn, as in Fig. on the right, the method is common, but therefore no better. According to GOST USSR, tucked-in upholstery corners are generally a manufacturing defect. Only sewn corners are reliable and durable.

Cutting and stitching the corners of furniture fabrics is done in more than 2 ways: without a tongue and with a tongue, see fig. below. The first is preferable for very dense and durable fabrics (jacquard, tapestry); the second is for more prone to abrasion - velor, courtesan, chinchilla - and leather. But note that the numbers in Fig. indicative, fitting with a sketch is required!

Covers are sewn, as usual, from the inside out and put on turned inside out. When putting on the finished cover, the wings (folds) of the scars are straightened with a special tool like a small shoe spoon. It is called a bobbin, although it does not look like a braided bobbin. The tongue is not sewn into the seam, it is bent and left free during the firmware.

Next comes the tightening. If the corners are with tongues, then they level the sheathing with them, and the tongues are fixed. Then the cover is pulled with a harsh thread from the underside along and across, 2-3 ties per 1 m of length and, pulling the threads, they achieve an even, but not tight, tension; it is controlled by drawing. A cover with corners without tongues is leveled immediately with threads. When the upholstery is stretched as it should be, the edges are fixed with an indent from the edge of the fabric of at least 5 cm. If the type of product allows, they are attached with a collar.

Features for different modules

The supporting frame of the sofa and the box are upholstered, as shown in fig. The box is on 3 sides, the back remains open. So it is necessary to ensure the strength of the connection between the backrest and the support, see above.

A pair of small trestles approx. 1 m, see fig. on the left, less than the width of the sofa, so as not to press the fabric. In extreme cases, the sofa blank is placed on a pair of stools. Tightening the back just won’t work, because. it is already attached to the base. Here, first, the fabric is attached along the line of interface with the box, from under the bottom they are pulled on tragus, like a sofa, and for tightening from the sides, small nails will have to be temporarily driven into the support. Well, the armrests can be turned as you like, there are no problems here.

Pillows

Separate cushions for the sofa are sewn in the same way as the blocks of a frameless chair:

- The foam mat is sheathed with technical fabric;

- The decorative cover is sewn inside out, the final (back bottom) seam is left unsewn;

- 2 zippers are sewn into the final seam, fastening towards each other;

- Insert the foam block into the decor, fasten the zippers.

Tight fittings

Sewing several pillows is boring, and dust collects in the joints between them. A smooth sofa does not harmonize with any design. Therefore, sometimes the pillows on it are imitated with ties, see fig. 2 options are also possible here, for less and more dense fabrics. In the first case, loops are sewn on the edges of the cover under the tightenings, and the tightenings themselves are made when the cover is already fixed. According to the 2nd option, front wings (sleeves-tunnels) are stitched on the workpiece under the cords and an even stretch is achieved by pulling alternately the cords, then the tension threads of the cover.

beautiful scars

Another common way to decorate a sofa is decorative scars, see fig. Under them, you also need to sew backstage, but it is better to fill them with a flexible stranded electrical wire in PVC insulation with an outer diameter of 2-4 mm. Wire frames are formed on a template of nails driven into any (vertical) wooden surface of a suitable size, even into the wall of a barn or a dog house.

The ends are stripped of insulation by 25-35 mm, twisted with a British twist (British, British, see the figure on the left), the joint is soldered and, so that the inadvertently emerging vein of the wire does not stick into a sensitive place, they are wrapped with electrical tape. In the pillow, the joint, of course, should be at the back.

About one-piece cases

A one-piece sofa cover is already aerobatics wallpaper business. However, suddenly a shabby but strong sofa of mahogany or Karelian birch is found in the attic of the grandmother? Furniture restorers know their worth, but they love their work and respect intelligent connoisseurs. If you talk to them with knowledge of the matter, then they will take a moderate fee and put your soul into the work.

In such a case, as they say in "1001 Nights", know that the basis for tightening the one-piece cover is the lines of the sofa's interface with the armrests and back. They are fixed with cords, as shown in Fig. Cords are brought out along the bisectors of flat corners (outer) and trisectors of triple (internal) along the grooves in the wooden frame and, for triple corners, through the holes in it. The cords are moderately pulled, their ends are fixed and then they straighten and pull the cover.

Backstage for cords can be, depending on the design, facial or purl. The last case is the most difficult, the backstage seam must be double and very even. To carry it out flawlessly, you need a professional 2-needle sewing machine.

Note: in general, the machine is the main problem when sheathing the sofa. Before work, look at your specification and check if it sews jacquard weave fabrics with reinforced thread no thinner than #20. If not, you will have to rent or order upholstery at home. Or sew by hand.

And sooner?

As you can see, making a sofa and covering it is not a field to go over. Couldn't it be somehow quicker and simpler here, to the dacha, in new apartment? To sketch any pillows and collapse?

You can, the solution is called - a sofa made of pallets. From building pallets - a pallet - they generally do a lot of things, including furniture, because pallets are inexpensive seasoned wood of excellent quality.

The main thing here is taste and ingenuity. The simplest, most primitive garden sofa stack made of pallets can be made much more convenient using the same principle as an adirondack garden chair, on the left in fig. A little more difficult of them is to build a rustic-style retractable sofa bed, in the center. And having applied (with a tool, not to a glass) stronger, you can get a sofa, about which you can’t immediately say that it is from a decommissioned container, on the right. For example, see which sofa was made, it seems, by a completely inexperienced, but not at all stupid and not armless guy:

Video: do-it-yourself pallet sofa

It happens the same ... with sofas ...

Since we are talking about containers, then finally - a funny sofa. Comments are not required, what is in Fig. speaks for itself. And it is standing somewhere, sitting on it, lying ...

A beautiful sofa serves as the main design element of any room. This is not just a piece of furniture, but also a visiting card of the whole house, to which the attention of the guests who have come is usually riveted. In specialized stores, such furniture, as a rule, is quite expensive. If you make a sofa with your own hands, it will cost much less. At home, making it is not at all difficult.

Nowadays, furniture items that combine unusual design, style and functionality are becoming increasingly popular.

Using a simple project, even a person who has never worked in production can make a quality product. upholstered furniture. If in modern apartment such a sofa will not look very respectable, then in a country house or in the country it will fit perfectly into the local interior.

One example is a pallet sofa with drawers.

The main components of the product are:

- frame;

- back;

- side parts;

- fabric upholstery.

Such furniture can be made independently from improvised materials, giving it the look that you like.

The frame can be of any shape and size. For its manufacture, wooden slats and bars are used. To give the structure greater rigidity, sheets of plywood or chipboard are used. Assembly is carried out using a screwdriver. All joints are first lubricated with carpentry glue, then the wooden parts are pulled together with self-tapping screws. In addition, it is desirable to fix the joints with corner metal fasteners.

A beautiful sofa serves as the main design element of any room.

The frame for the mattress is made of boards. To give the product greater comfort, the supporting area of the frame can be made of interlaced furniture belts. First, the belts are mounted vertically on the frame, then a horizontal binding is made perpendicularly. Despite the fact that such a sofa does not use traditional steel spirals, it will spring perfectly. Therefore, it will always be pleasant to lie on it.

The corner bed looks more prestigious than the usual folding version.

The back is usually made hollow inside. It can be given a rectangular or sloping shape. To do this, the end width at the base increases, and decreases at the top. The side parts are made in the same way as the back. The top and the front side of the back are pasted over with foam mats. Foam rubber is also glued to the inner sides of the side parts. Glue should be applied with a wide brush in an even layer. Until the adhesive has completely set, the foam sheets must be firmly pressed against the surface to be glued.

Independent production of home goods makes it possible to create an original design that fits perfectly into the interior of a particular room.

Fabric sheathing is performed according to prepared patterns or patterns. If you do not have them, they are easy to make yourself. To do this, the fabric is tried on for each element of the sofa, after which the necessary cuts are made. After covering all the constituent parts with matter, the final assembly is carried out. Simple design such furniture is usually completed in three days.

For the manufacture of a rounded sofa, furniture panels are most often used. They are made from wood or thick plywood. Such material enables the round structure to cope with the required load. To fix the upholstery in dimensions individual parts there must be some margin. It is desirable to make the lower soft parts under the skin multi-layered. Thanks to this, the sitting will be much softer and more comfortable.

The manufacture of a sofa-book should begin with the creation of individual frame elements of the entire structure.

How to make a sofa book

The manufacture of a sofa-book should begin with the creation of individual frame elements of the entire structure. This includes sidewalls, backrest, seat, laundry box. First, a linen compartment is made from the boards. This frame is reinforced at the corners with short pieces of beams, and from below it is supplemented with slats. For the back and seat, bars are also used, which are connected with self-tapping screws or special notched nails.

In the manufacture of the sofa, the following tool is used:

- wood saw;

- screwdriver;

- plane;

- hammer;

- scissors.

For the back and seat, bars are also used, which are connected with self-tapping screws or special notched nails.

Wooden lamellas are screwed to the resulting frames. They should play the role of support for the mattress. After all the frames are ready, assembly is carried out. However, special mechanisms are needed here. You can buy them at the construction market or in the store. When installing the mechanisms between the folded parts, you need to leave a gap of about one centimeter.

The comfort and convenience of sitting on the sofa will depend on the quality of this element.

In this case, the sofa should be laid out. Due to the presence of a gap, it will fold and unfold freely. Before laying foam rubber, on top of the lamellas, you first need to stick interlining. This will enable the sections of foam sheets between the lamellas not to fall through. The surface will always remain flat. So that the sheets do not interfere with the operation of the folding mechanisms, the corners located near these parts are cut off.

However, special mechanisms are needed here.

A soft cushion is usually made on the edge of the seat. To do this, an additional foam strip is glued on top of the continuous layer. The lower edge of the strip is bent under the seat and also glued. The armrests are softened in the same way. A similar procedure is performed with the back. When the glue under the foam rubber is completely dry, the covers sewn to the size of the furniture are put on.

Making a corner sofa

First, the lower part is made, that is, the seat. The boards to be joined are fastened with self-tapping screws and corner plates. Chipboard sheets are screwed to the bottom of the resulting box. A separate frame is made for support. The supporting part is also covered with plywood. Behind you can pull a dense matter. The dimensions of the product are associated with the parameters and shape of the mattress.

When installing the mechanisms between the folded parts, you need to leave a gap of about one centimeter.

The steps for manufacturing an additional structure are similar. To connect the individual parts, an angular structure is made. Usually it is made of the same material as the main elements. During the manufacture of this design, the angle of rotation should be taken into account. The back and supporting parts are pasted over with batting. The back side is covered with a dense cotton fabric.

Family members spend a lot of time on it.

The legs are usually made from square pieces of timber. For fastening to the lower frame, holes are drilled in the bars. After that, they are applied to the bottom of the frame and screwed with long screws. In the manufacture of such furniture, special attention should be paid to the design of the structure. If it is not done correctly, various deflections, deformations, and other similar flaws may appear in the future.

Behind you can pull a dense matter.

For the manufacture of furniture, the following materials are used:

- board;

- timber;

- foam rubber;

- furniture fabric;

- wood glue.

If you decide to buy some unusual bed in a furniture store, then you may not be able to afford it. Original products are very expensive. It will be much better to make a custom sofa bed with your own hands. It requires bars, boards and plywood sheets of appropriate thickness. The back is assembled from planks and pieces of timber. The front part of the assembled frame is best sheathed with chipboard sheets.

The steps for manufacturing an additional structure are similar.

They are quite durable, and in stores building materials are inexpensive. It is desirable to treat the assembled base with a stain or varnish it. As a result, it will last much longer. Foam rubber sheets are used for the soft parts of the product. Fabric materials are attached to the frame with special wide-head nails.

Fancy sofas

Often they are made from improvised material. Especially if the product is intended for giving. The base and back of this furniture can be made from used door leaves. Details are cleaned of old coating and dirt, and then processed grinder. Then they need to be painted or glued with veneer. One door leaf is mounted on wooden supports. The second sash is used as a back. It should be attached to the base at an angle convenient for you.

In a cozy home there is always beautiful upholstered furniture.

The mattress is cut out of foam rubber. The piece of material must match the size of the seat. The resulting blank is first covered with a dense fabric, then a beautiful fabric is put on top, having good quality. In the manufacture of such furniture, special attention should be paid to the reliability of the frame base. It should easily withstand the load that will arise from sitting on the sofa of several people.

Often they are made from improvised material.

Beautiful and cozy furniture for relaxation can be made with drawers in which it is convenient to store bedding and clothes. Due to the high functionality of the design, there is no need to additionally install a chest of drawers or a wardrobe in the bedroom. This will save living space, make the room more spacious.

The product includes the following components:

- back;

- seat;

- a pair of armrests;

- drawers.

It should easily withstand the load that will arise from sitting on the sofa of several people.

Each part of the product is knocked down separately. The back is assembled from long slats. To ensure the necessary rigidity, the planks are reinforced with short transverse bars. To get a sloping back, the back slats must be longer and the front slats shorter. Chipboard sheets are installed on top of the resulting frame, which are then pasted over with foam rubber and sheathed with fabric.

A similar frame is mounted for the seat. Its only difference is that it does not have a beveled part. Armrests are attached to the sides. They should be screwed with long screws in several places. Drawers are frameless. Chipboards are also used as a material here. To make both drawers slide out easily, special mechanisms are installed on the racks of the frame.

Beautiful and cozy furniture for relaxation can be made with drawers in which it is convenient to store bedding and clothes.

After all the details are pasted over with foam rubber, a synthetic winterizer is laid on top of it. Further, to protect the soft material, the entire sofa is sheathed with a strong fabric. Depends on the quality of the final skin appearance furniture. If you want your product to look fashionable and respectable, you can use leather or a good leather substitute. Now in the construction markets of such materials is represented a large number of.

Use of improvised materials

From simple elements, you can make furniture that will easily fit into any interior. If the design consists of natural wood, the product will serve properly for more than one year. Worn-out covers or cloth lining, if necessary, is easy to replace. Today, those pieces of furniture that have an unusual design and style are popular. By making a product from improvised materials, it can be given the most unexpected exclusive look.

Each part of the product is knocked down separately.

Independent production of home goods makes it possible to create an original design that fits perfectly into the interior of a particular room. If your own product turned out to be fashionable, reliable and beautiful, you can be proud of it, brag to your friends. Creating your own furniture sets is within the power of anyone who knows how to use carpentry tools at least a little and has patience. To create an original furniture masterpiece, it is enough to turn on your imagination, show a little perseverance and diligence.

Chipboard sheets are installed on top of the resulting frame, which are then pasted over with foam rubber and sheathed with fabric.

In a cozy home there is always beautiful upholstered furniture. The dominant place, as a rule, is occupied by a luxurious sofa. Family members spend a lot of time on it. Here they play with children, sleep, arrange gatherings with close friends. Before producing your own sofa, you need to understand well which type of sofa will best meet the needs of all family members.

The most popular products are:

- corner;

- book;

- Dolphin;

- with folding mechanisms.

A similar frame is mounted for the seat

This can also be attributed to the ottoman. This product is extremely simple. It does not have any folding mechanisms. Therefore, making an ottoman with your own hands is not difficult. It is advisable to choose a future bed, taking into account the place where it will be installed. Before starting work, you should take the necessary measurements, make preliminary drawings.

Carpentry rules

The corner bed looks more prestigious than the usual folding version. If you are doing this work for the first time, it is better to do the most simple craft, which does not have any additional shelves and drawers. When assembling the frame, do not try to make tenon joints at the ends of the boards. Such work is carried out only by professional carpenters. It is not advisable to fasten individual elements with nails. Since the assembly is constantly loosened, over time the nails begin to loosen the fastening. It is better to use self-tapping screws or screws.

Now there are a large number of such materials on the construction markets.

From natural wood, coniferous species should be preferred. Their fibrous structure is saturated with resin, which protects the tree from decay processes. Thanks to this, pine products have a fairly long service life. Before starting the assembly, the finished elements must be carefully sanded. This will provide the necessary security for further work. It is desirable to cut materials outdoors, since a large amount of wood dust is released.

From simple elements, you can make furniture that will easily fit into any interior.

The frame is the main part. All other details are attached to it. When assembling the seat, you need to check the box for matching diagonal sizes. The correct shape of the box ensures the stability of the entire frame. All connections should be checked before sticking upholstery. If any joint staggers, it should be reinforced with additional screws or metal corners.

By making a product from improvised materials, it can be given the most unexpected exclusive look.

There are several unusual ways to make a sofa out of readily available materials. Thus, you will receive a piece of furniture at the lowest cost.

Parameters

The first method involves the use of beams left after the construction of large buildings as a material. In addition to the beam, the following materials will be required:

- foam rubber, which can be bought in a special store;

- zipper 21 cm long, which will be required when sewing the cover;

- three 7 cm zippers used on pillows;

- upholstery material, such as tapestry;

- corner and metal mesh.

frame

Most of the work on the construction of the sofa is the construction of the supporting structure from the timber. To make the process more convenient, you should make a choice in favor of a bar with a size of 7 × 21 cm, from which you will also make furniture legs.

Back

Equally important in this matter is the collection of a strong back for the sofa. Since this version of the sofa is quite simple and does not provide for a folding system, the backrest is made in the same way with a frame base. The backrest is fixed to the base with thick metal corners as tightly as possible. How much the back will be tilted is up to you to choose, based on your feelings.

In the third step of the work, you will make a lattice for support on the sofa frame, necessary to hold the seat cushions. This is done using a metal armored mesh from an old bed. By fixing the mesh on a wooden base with metal brackets, you will get the desired result. For greater reliability, glue several transverse ones on the longitudinal frame bars.

Upholstery

Proceed to soft upholstery in the following sequence:

- cut two pieces of foam rubber that match the size of the sofa back and at least 15 cm thick;

- sheathe the cut out elements with material, for example, tapestry, connecting them with a zipper;

- using decorative tape, attach the mattresses to the supporting structure. You will receive a tape from upholstery material and Velcro. Fasten one end of the tape to the frame with small carnations, and the other to the tapestry cover;

- after sewing three covers from the same upholstery material and equipping them with zippers, stuff them with the remnants of foam rubber. You should get three pillows.

Shield

This method is suitable for people who do not have skills in working with wood. This option is a little easier and for its implementation you need to stock up:

- two used door leaves;

- metal staples;

- wood hemp;

- foam rubber;

- upholstery material.

The base and back of this sofa model will be two used wooden doors. You will need to pre-clean them from old coatings and dirt, and then process them with a grinder.

The base and back of this sofa model will be two used wooden doors. You will need to pre-clean them from old coatings and dirt, and then process them with a grinder.

Next, the doors are painted in the color of your choice, while trying to match the overall interior of the room in which the sofa will be installed in the future. You can choose finishes wooden surface veneer.

Using nails, fix one sash on a wooden stump of the appropriate size, and then fix the second part (back) on it with metal staples and glue.

After that, start making a mattress: cut the foam rubber of the same size with the seat and cover it with a dense fabric (matting is ideal for this). Already on top of this material, a bright fabric of good quality will be stretched.

The main requirement is the construction of the most durable and reliable frame base. It is on him that all the main load falls, and if you neglect this requirement, you can get injured during operation, and it will not last long. Based on this, you can choose another base material that meets the requirements.

You can beat the finished design as you like, it all depends on your preferences and imagination.

corner sofa

For the manufacture of a corner sofa, it is not necessary to use complex connections, for example, spike products, as well as expensive materials. For work, we suggest using the following material, the volume and amount of which depends on the size:

- beam 30 × 50 mm;

- plywood, 5 and 15 mm thick;

- self-tapping screws and wood screws;

- nails;

- synthetic winterizer, with a density of 140-170 g / day;

- batting;

- foam rubber, 20 and 40 mm thick with a density of at least 30 kg / m 3;

- glue for foam rubber and wood glue;

- foam crumb;

- furniture fabric;

- lifting mechanism;

- furniture legs 5 cm high.

As for the tool, for work you will need:

- wood saw;

- miter box;

- screwdriver;

- stapler;

- sewing machine;

Each structural block is made of a frame, which is based on timber, chipboard and plywood. The internal space in blocks 1 and 2 can be used rationally by making removable covers. For their supports, a beam of 20 × 30 mm is fixed along the perimeter of the frame. It is installed below the upper cut by the thickness of the cover plate. To make the lid easy to lift, you can drill holes for your fingers in it.

Blocks 1 and 2 are identical in design. Their only difference is in size. The first block is 100x60 cm, and the second is 60x60. It is the second block that will be located in the corner of the structure and connect the first and third blocks together. As for the third block, you can make a drawer-seat in it. Due to this, the useful area of \u200b\u200bthe sofa will increase. To do this, you can install a retractable or rotary mechanism.

The drawer will also be equipped with a chipboard lid. If it is not difficult to assemble it, then difficulties may arise in the manufacture of legs. Why? When pushing the drawer into the sofa body, they will interfere. Therefore, instead of legs, it is necessary to increase the height of the front side of the drawer. When unfolding a corner sofa, it will serve as a support platform. And to make the drawer easy to pull out, furniture wheels can be fixed to the bottom.

The cover for the third block (indicated in the diagram) can also be made removable. Inside, for example, it will be possible to fold bed linen.

The size of the seat cushion must be equal to the size of the drawer. Therefore, when the box is pulled out, a pillow is removed from the back and placed on it instead of a mattress.

Now it's time to do the back to corner sofa. The manufacturing process looks like this:

- Place 3 beams horizontally and connect them as in the illustration uprights. The height of the back in our case will be 105 cm.

- The lower second beam will be located at a height of 25 cm. They will serve to fix the back to the sofa.

- The upper beam will be used for the base of the skin fastening and provide the necessary structural rigidity.

- The frame is sheathed on both sides with plywood 5 mm thick.

- To avoid the appearance of hooks and bumps when laying the upholstery, sand all corners with sandpaper.

- Glue thin foam rubber on the side and front surface, due to this, the upholstery will be soft.

In conclusion, it remains to sheathe the entire sofa, including the backs, with the selected material.

Before that, you take all the measurements, and then cut out the fabric with an allowance for the hem. You can fasten the material with a stapler. The place of fastening should be on the invisible part of the end of the panel. Make sure that the fabric does not wrinkle at the corners. As for the manufacture of pillows for the back and seat, they can be made of foam rubber with a density of 140-170 g / day and a thickness of at least 10 cm. You will also need to sew a cover with a zipper. This will allow you to remove the cover and wash it if necessary.

The sofa can perform several functions. So, it can be used for a short rest during the day and for a good rest at night. Consider the sequence of work. The description will be accompanied by diagrams, so that you can visually see the manufacturing process.

sidewalls

From boards with a thickness of 19 mm, cut off two blanks with a length of 775 mm and 381 mm. From them you assemble the frame A / B. Panel D is cut out of plywood of the same size. First, the frame is glued together, and after the glue dries, it is twisted with self-tapping screws. After that, cut out the bosses C. Thanks to them, the bed ties will be securely fastened. The thickness of the boss is equal to the thickness of the frame. These parts are glued to the frame and set aside to dry.

Now it's time to cut out blank D (381x775mm). Fix the cutter in the collet of the router. She will perform a selection of 3 × 6 mm folds around the entire perimeter of the workpiece, but only from the front side. After that, take the 2 panels that will be located on the inside of the sidewalls and connect them with double-sided tape face to face. On one of the panels, mark the places for making holes Ø19 mm, which will indicate the end and the beginning of the slot. Further, through both panels, drill holes in the intended place.

Next, draw lines between the holes. After separating the panels, cut the slots with a jigsaw. To make sure that the slots are even, run a dowel Ø19 mm inside them. If necessary, sandpaper can be used to refine places where the size does not correspond to 19 mm. Finally, chamfer the edges of the slots, 3 mm wide on the front side of the part. Paint the bottom of the folds with a stain, so you emphasize the shadow gap that forms between the edging of the sidewall and the edge of the panel.

Now you can try on the made panels to the previously made frames. At the edges, both parts must completely match. After these manipulations, cut out the side and bottom / top edging parts E and F. They must be cut with an allowance of up to 25 mm in length. For their joining, the edges are cut off at an angle of 45 °. The edging is connected to the frame with glue and self-tapping screws. If necessary, the assembled parts are polished with sandpaper.

To make the legs, cut off block parts G, leg ties I, spacers J and front panels H. Connect blanks G and H together so that the sides and bottom of the parts converge. Then, using a clamp, fasten the blanks to the couplers I and make countersunk holes.

A countersink hole is made for the head of a countersunk screw. To do this, it is best to insert a screw with a head of the desired diameter into the drill chuck. Chips can occur when using a drill, especially when drilling holes in plywood.

The resulting hole is used to connect the ties and legs. Mill a 3 mm chamfer around the bottom end of the legs. After that, grind the resulting element with sandpaper. If you want to give the blanks a special tone or color, you can process them with stain.

Spacers J must be connected to the undersides of the sidewall. Make sure there are no protrusions on the sides. Next, the leg is attached and it must also be aligned with the edges of the workpiece F. Make a hole through the ties I, countersink it and connect the parts with self-tapping screws. On the opposite side, you need to make an armrest of the appropriate size. The armrest should protrude beyond the edges at the front and back, and should be flush with the interior panels.

Back and seat

To make the back and seat, several blanks should be cut: the M post, the N top bar, the O bottom bar, the Q side bars, the R pads, the back S and the front seat bar T. A 50 mm board can be used for manufacturing. As for the seat panel U and backrest P, they can be done later.

Now drill holes and counterbores in the Q side bars and the M post, and fasten the R pads to the Q side bars.

Countersinking is a countersinking process, which involves cleaning the end surface. As a rule, counterboring is performed in the form of mounted heads that have end teeth. This process is carried out under the washer, nuts or thrust rings.

In the racks, make grooves 38 mm wide. Also make folds at the end of the front T-bar 76 mm wide, and at the end of the top N-bar and back S-38 mm.

A tongue and groove means a longitudinal protrusion on the edge of a board or beam. It fits into a matching groove on another board with a similar shape. This connection method is known as tongue and groove.

After that, take the workpiece N and T and mill a rounding with a radius of 12 mm on them. Also do 15° bevels. At the ends of the part N, T and S, make counterbores 8 mm deep, with a Forstner drill Ø10 mm, and make mounting holes in the center of the counterbore.

At the next stage, it's time to make the back and seat P and U. Having cut them to the specified dimensions around the perimeter of the part, you should mill a 10 mm wide fold around the entire perimeter. In this process, ridges should be formed. They must fit into the sheet piles T, S, Q, O, N and M. Next, grease the sheet piles T, S, R/Q, O, M and N and, fixing with a clamp, glue them to the panels U and P. After earlier made holes on parts T, S, N and M, drill a hole in the panel and fix the parts with self-tapping screws. After that, wooden plugs / plugs must be glued into the counterbores. Finally, these plugs should be ground flush with the workpiece.

Now you need to make stops V at one end with a bevel. It must be pressed with a clamp to the seat at the designated place. After drilling the holes, countersink them and fasten them with a self-tapping screw. Sand a 3mm chamfer around the butt and cut off a 57mm length. As a result, you will need to make 4 such parts and fix them in the holes of the backrest racks. At this stage, you still need to make four wooden washers, 6 mm thick and Ø127 mm. Sand these spacers smooth.

To connect the backs, it is necessary to cut out the drawers L. Immediately before assembling the sofa bed, make sure that there are no sharp corners and chips. If necessary, they should be sanded with sandpaper. In conclusion, it remains to perform the skin, as well as the final assembly. Closely adhering to the schemes and outlined step by step instructions, you will be able to do all the work yourself.

Making upholstered furniture is not an easy process. It requires accuracy, care and diligence. We invite you to familiarize yourself with the instructions for making a sofa-book, which, when unfolded, will have dimensions of 1400 × 2200 mm, and when folded, 1000 × 2200 mm. To do this, you need to prepare the following material:

- board 25 mm thick: 1000 × 50 (12 pcs.); 800 × 50 (2 pcs.); 800 × 200 (2 pcs.); 1900×200 (2 pieces);

- timber: 50×50×200 (4 pcs); 40×50×330 (4 pcs); 40×60×530 (6 pcs); 40×60×1790 (2 pcs); 40×60× 1890 (2 pieces);

- glue intended for foam rubber;

- staples for stapler 16 and 10 mm;

- self-tapping screws 89D and 51 D;

- nails 70 and 100 mm;

- nuts 8 and 8 mm;

- furniture bolts: 6×70 (8 pcs.); 6×40 (4 pcs.); 8×120 (4 pcs.);

- interlining - 4 m;

- foam rubber;

- fabric 6 m / p and 1.4 m wide;

- Fiberboard 1.7 × 2.75 3.2 mm thick (1 sheet);

- holders (64 pcs.) and wooden lamellas (32 pcs.);

- legs 4 pcs.

- 1 set of book sofa mechanism.

Prepare also the following set of tools:

- stapler;

- open-end wrenches;

- set of drills;

- drill;

- screwdriver;

- hammer;

- roulette;

- pencil;

- square;

- hacksaw.

With all of the above, you can get to work.

The first step is to make frames for the armrest, drawer for linen, backrest and seat. First, let's assemble a box for linen. For this you need to use:

- 4 beams 40 × 50 (50 × 50) 200 mm long;

- 2 boards 25 mm, 50 mm wide and 800 mm long;

- 2 boards 800 mm long and 200 mm wide;

- 2 boards 25 mm thick (40 mm thick or 20 mm plywood), 1900 mm long and 200 mm wide.

From boards 800 and 1900 mm long, assemble the frame, reinforcing the structure with transverse rails. Fiberboard of the appropriate size is nailed to the bottom of the structure. Next, you need to assemble the back and seat of the sofa. Size bed should be spacious enough, so take this into account when calculating. So, assemble 2 equal frames, size 1890 × 650 mm from a bar 40 × 60 mm. The timber frame is best fastened with self-tapping screws. To do this, pre-drill holes Ø8 mm to a depth of 10 mm. After making the frame, it is necessary to fix the lamellas to hold the mattress.

The next step is to make the armrests. For this purpose, you can use chipboard 25 mm thick. Cut out the left and right armrest, according to the dimensions indicated in the photo:

Next, you should make a wooden frame. At the same time, it should be 20 mm shorter than the chipboard size. After that, make holes Ø8.5 mm in the frame and insert 8 × 120 mm bolts into them and after that the frame is sewn up. Also drill holes on the laundry box, only Ø10 mm.

Now the individual parts of the sofa are assembled into one. A special transformation mechanism is also used. When assembling two frames, take into account the fact that in the unfolded state there is at least 10 mm between them, and in the folded state the seat does not protrude beyond the armrest.

After that, the frame must be sheathed. It uses foam rubber and prepared fabric. Do not forget to also sheathe the armrests with fabric and foam rubber.

Sofa-transformer - its types

There are several types of transforming sofas:

- Book. This model is one of the simplest. Folding out the sofa creates an extra bed. And for convenience, springs are installed in the back.

- Eurobook. With a slight pull of the seat, the sofa is conveniently unfolded, and pillows are placed on the resulting free space.

- Withdrawable. The lower part is movable. As a result, a full-fledged sleeping place is pulled out. This model has the main drawback - the rapid wear of mechanisms.

- Dolphin sofa. This type of construction is most often made angular. When it is extended, two sleeping places are obtained. And the extra bed rises from under the fixed part.

- Sofa accordion. This model is quite compact, consisting of 3 parts that unfold and fold.

Video: assembling a eurobook on a plywood block

Video: making a Chester sofa

If you still decide to buy a sofa or make it to order, then contact the online furniture store. On the Internet you can find inexpensive options for various shapes: both straight and angular.

A photo

Schemes

The diagrams show various options making a sofa

Modern designers come up with more and more unusual sofa designs, and manufacturers are no less actively embodying them. The market is overflowing with models of all shapes, colors and sizes. But the trouble is - among all the variety it is not so easy to find a simple and comfortable sofa satisfying one's own sense of beauty.

Why not take a different approach and try to make your dream sofa with your own hands? After all, it is not as difficult as it seems at first glance.

How to understand which sofa you need?

If you decide to make a sofa with your own hands, then the store ones do not suit you with something. When designing a new interior, do not forget about other important points.

How and where will you use it? Do you need a sofa that will comfortably accommodate a large company, a sofa for sleeping, or both? For example, as much as you like the idea of upholstering it in leather, it's not the best choice for a sleeping place. Some types of upholstery will quickly become unusable if you have pets.

What size sofa do you need? Take measurements carefully to be sure that these parameters are optimal. Check if it will interfere and whether it will fit into the space provided.

Where exactly are you going to put it? The sofa on the balcony, kitchen and hall has its own requirements for size and design.

Finally, decide on the mechanisms. If you intend to use a new thing instead of a double bed, you should make a folding sofa. Despite the existence of more advanced mechanisms, the "book" does not lose popularity. The principle of its operation is simple: we lift the seat, the back reclines - the sofa has decomposed.

When deciding on the design and upholstery material, it will be useful to take into account the overall interior of the room. Assembling the sofa yourself, you are free to choose absolutely any fabric, but how will a green flock in a blue flower look in a minimalist room in black and white?

They will help you decide on the nuances of a photo of sofas made by yourself. They will also give an idea of what a homemade sofa might look like.

Before starting work, you should get a general idea of \u200b\u200bthe designs of sofas and their features. Let's consider the main ones.

If you need a sofa for sleeping, choose a straight model. This is the most common form available on the market in many variations.

A corner sofa will fill the corner and become a spectacular addition to the interior. This sofa is suitable, for example, in the kitchen.

A modular sofa is a good solution for a studio apartment. It is a set of modules that can be combined in any order or used separately.

Material selection

The body material is usually wood. To work with it does not require special skills, it is durable and environmentally friendly. You can use linden, walnut, birch, but pine is not the best choice, as it needs factory processing.

Plywood is a durable and reliable material, cheap and environmentally friendly. Perfect for creating any furniture with your own hands.

MDF and chipboard are very fond of furniture manufacturers. Keep in mind that they are cheap, but short-lived.

Do not limit your imagination: the most unusual objects can act as material: pallets (pallets) left over from construction, or cardboard boxes.

Upholstery fabric must be purchased with a margin, taking into account the thickness of the parts. A few points to pay attention to:

- velor, being soft and pleasant to the touch, quickly gets dirty and is not suitable for pet owners;

- chenille is an excellent choice for a nursery due to its practicality;

- a flock with a fine pile is pleasant to the touch, but quickly gets dirty and will be erased after a few years;

- jacquard is practical, but not very pleasant to the touch;

- gunny is a rough and durable fabric. Not suitable for cat owners

- leather looks solid, but expensive.

The choice of color and pattern is a matter of your tastes, but try to choose colors that are in harmony with the interior.