Drawing of the mechanism for turning eggs in an incubator. Homemade incubator with automatic tray tilt. The size of the incubator will also be affected

Electrical diagram of the egg turning system in the incubator.

The constituent elements of the proposed electrical circuit are assembled from the simplest parts and mechanisms.

Automatic egg turning system consists of a mechanical part connected by articulated joints with a trolley on which trays with eggs are located, or directly with the trays themselves, and an electrical part that includes limit switches (fixed position sensors) and an actuating unit.

The switch of the modes of the electric scheme of turning of eggs in an incubator.

We used a small quartz alarm clock made in China. The technological equipment of industrial incubators used a system of mechanical clocks with limit switches that were triggered by pressing adjusting bolts installed on the time scale of a disk rotating instead of arrows.

We used a small quartz alarm clock made in China. The technological equipment of industrial incubators used a system of mechanical clocks with limit switches that were triggered by pressing adjusting bolts installed on the time scale of a disk rotating instead of arrows.

A similar system was taken as a basis.

A similar system was taken as a basis.

On the dial of a quartz watch, every 90 ° (15, 30, 45, 60 minutes) contacts are fixed through which voltage is applied to the control relay windings. And it closes the contacts - the minute hand, on which a small springy electrical contact is fixed on the underside.

The dial can be processed in any way: glue contact rings, melt a wire with a hot soldering iron, place a foil getinaks with contact markings, use photocells, reed switches - everything is at the discretion of the designer and everything - depending on the materials available.

The spring contact on the minute hand is made of tinned copper wire, which is softer than steel.

The spring contact on the minute hand is made of tinned copper wire, which is softer than steel.

The arrow is plastic and it is easy to melt it with a hot soldering iron or glue the finished contact.

The electrical circuit of the rotary system of the incubator is assembled to a minimum and is easy to assemble.

The principle of operation of the electrical system for turning eggs in an incubator.

The control contacts (SAC1) are closed every 15 minutes. Hours work in normal mode.

Electric drive unit of the egg turning system in the incubator.

Any drive mechanism can be used: children's electric toys, an electric drill block, an old mechanical alarm clock, an electric drive mechanism for a car wiper, rotary mechanism from a household fan heater or fan, an electromagnetic traction relay with a vacuum regulator, use a washing machine ready for automatic control or make a screw one yourself with minimal details (by the way, very simple and convenient). Depends on the design and dimensions of the incubator itself.

If you use a gearbox with a crank mechanism, then the main shaft must have a diameter greater than the stroke length of the swivel frame (when the frame is horizontal on the tray). With a screw mechanism, the length of the working threaded part corresponds to the travel distance of the egg turning system.

If you use a gearbox with a crank mechanism, then the main shaft must have a diameter greater than the stroke length of the swivel frame (when the frame is horizontal on the tray). With a screw mechanism, the length of the working threaded part corresponds to the travel distance of the egg turning system.

Electric drive of the egg turning system in the incubator The screw mechanism is controlled by an electric motor with reversible switching, that is, the motor is switched on alternately in the left and right side of rotation.

Description of the operation of the electrical circuit of the rotary system of the incubator.

The battery-powered quartz alarm clock operates normally. At regular intervals, namely: every fifteen minutes of the current time, the minute hand, passing over the contacts fixed on the dial, brings a springy contact to them and closes the electrical circuit through them. Thus, a control signal is generated for the control relay (K2 or K3).

From the reverse side of the relay (K2 or K3), an electrical signal is sent to the limit switch (SQ1 or SQ2).

There is a rod on the movable mechanism of the rotary system, which, moving along with the movable part of the system, presses the limit switch key, being in one of the extreme positions, and thereby breaks the circuit: mode switch - control relay - limit switch.

Simply put, it turns out like this: from the mode switch (modified alarm clock), when its contacts are closed, voltage is supplied to the control relay and then to the limit switch. If the limit switch is in the closed state, the control relay will turn on and close the control circuit of the drive relay with its contacts, which will supply power to the electric drive of the turning system.

The system will start and move the mechanism to one of the two positions carried out when turning the eggs in the incubator. The end position will be fixed by turning off the limit switch by pressing the rod moving with the frame on the switch key.

The circuit with reversible connection of the electric motor is slightly different by the addition of a second drive relay with two controlled (switched) contacts.

The circuit with reversible connection of the electric motor is slightly different by the addition of a second drive relay with two controlled (switched) contacts.

Electronics enthusiasts can use a digital timer with a self-start after a cycle or a time relay, which was once used by amateur photographers. There are many options. You can buy a ready-made electronic unit. Everything comes from possibilities.

List of some details.

- SAC1 - mode switch.

- K3 and K4 - control relay type RES-9 (10.15) or similar.

- K1 and K2 are drive relays with switching current, respectively, according to the load current.

- HV - light indicators.

- SQ1 and SQ2 are limit switches. You can use microswitches (MK) from old cassette recorders.

Content:

The desire to receive more and give less is human nature. But it sometimes leads to the fact that the miser pays twice. This postulate can be attributed to incubators. The poultry farmer really needs it. Big, good and high quality is expensive. For example, the price of an incubator for 300 eggs is 29,000 rubles. A cheap one can last one season, and even spoil the hatching eggs. So it turns out that the economy does not lead to good.

But now for those who are “friends with technology” and have skillful hands, there is an opportunity to both save money and get a reliable (there will be no one to blame) device that is very important for the poultry farmer. It's about about a homemade incubator. There are complete collection kits on sale, and the automation necessary for their improvement is also sold separately.

Requirements for homemade incubators

Before assembling an incubator, you need to know the technical conditions that it must provide.

- During incubation chicken eggs the number of continuous days of its work is 21 days.

- Eggs in the incubator are laid out at a distance of at least 10 mm from each other

- The temperature in the incubator varies depending on the stage of development of the embryo in the egg.

- In automatic mode, eggs are turned over once every hour.

- Optimum humidity and ventilation are maintained. Air speed 5 m/s.

Ready kits

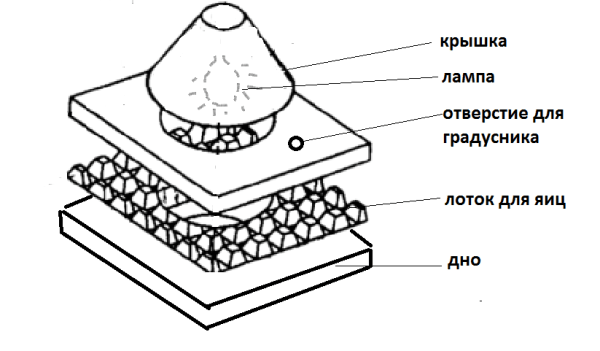

To facilitate work and increase the reliability of the future design, it makes sense to purchase a ready-made automation kit for a home-made incubator. For example, such as in the figure below.

It includes:

- Temperature controller providing automatic visual control of temperature and humidity.

- Sensors that scan the state of temperature and humidity inside the incubator.

- Transformer 220/12V.

- Universal tray with automatic rotation. You can put either quail or chicken eggs in it.

The price of this set is 5000 rubles. But on the other hand, you can be sure that the incubation process is proceeding correctly. The temperature and humidity correspond to the set parameters, and the eggs turn on time.

If you are only interested in automatic egg turning, then you can purchase a simpler kit.

This photo shows dimensions devices. They will tell you how to place it in the future incubator.

This kit consists of the following:

- Reversible motor - 14 W, 2.5 rpm;

- Asterisks - 1 meter;

- Limit switches - 2 pcs;

- Mounting bracket;

- Connecting wires.

The kit is sold already assembled and configured. You just need to connect it to the control thermostat. Price - 3990 rubles.

Connecting this device in a homemade incubator looks like it is shown in the diagram.

But motorized trays have to be in some kind of enclosure. And it matters to the incubator. After all, inside it is carried out thermoregulation of air exchange for the incubation of eggs. Therefore, the thermal insulation qualities of the material from which the incubator will be made are very important.

A great option for the case is an old refrigerator. Its body also has the properties of a thermostat, and the doors close comfortably and securely.

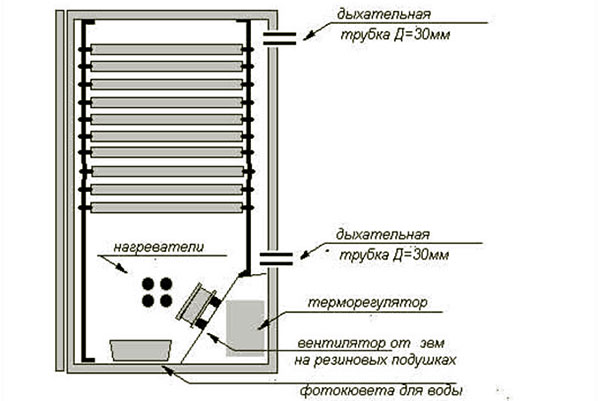

Re-equipment of the refrigerator under the incubator

Before proceeding with the assembly of the incubator from the old refrigerator, it is necessary to get rid of already unnecessary details and remove freezer.

To ensure proper air exchange, it is necessary to establish a ventilation system.

Ventilation and humidity

To ensure ventilation in the refrigerator case, two holes with a diameter of 30 mm are made. One is at the bottom, the other is at the top. Tubes are inserted into these holes. By completely or partially closing these openings, you will regulate the air exchange inside the device.

At the bottom, install a fan on rubber cushions. You can use a computer fan. Place a container of water nearby. With the help of evaporation of this water, it will be possible to regulate the humidity in the future incubator. Attach heating elements. It can be ordinary incandescent lamps or heating elements.

Air exchange in this case occurs as follows.

- The air below is heated.

- Humidified with water vapor from a cuvette.

- The fan pushes the air up.

- Some of the heat is given off to hatching eggs;

- Part of the air cools and is blown out.

- After cooling, part of the air descends, and the other enters from the outside through the bottom hole.

Heating system

The simplest option heating - these are incandescent lamps with a power of 25 W. Four lamps are taken. Two are installed at the bottom, two at the top. Or you can use more powerful lamps (40 W), but take a smaller number of them (2 pieces). Heating elements can become an alternative to lamps.

Trays and their turning mechanism

You can buy a motorized tray made in China. They are also of high quality, but are cheaper than imported ones. Their kits include:

- a frame on which mini-trays with cells for eggs are installed;

- power unit;

- low-speed engine, excluding sharp jerks at the start of movement.

These are very handy trays. Their rotation is carried out by a built-in motor, which is enough to connect to the included power supply. The full cycle (90 degrees) of turning the trays takes two hours.

If you do not want to use this very convenient solution, you can make trays yourself. For example, from metal, wood and mesh, or any other material at hand. The main thing is to install them without skew in the body of a homemade incubator. Fix the rotary axes for the trays with brass bushings or use special bearing supports.

A chain drive can be used as a mechanism for turning the trays. The diagram of its connection is shown in the figure above, and how it will look in the installed form in the photo below.

Conclusion

It’s worth making an incubator yourself only if you have locksmith skills and are “friends” with electrical engineering. Then you can significantly reduce your costs for the purchase of this product. It won’t be completely free, but you can purchase and install better and more reliable components.

All components of this device can be easily bought. This was written above. To control the entire mechanism, you will need to purchase a thermostat. And then apply your skills in plumbing.

As you can see, this option for equipping the overturning mechanism is more troublesome than purchasing a mechanized tray. And the price advantage is not so obvious.

, topical a question for both amateur poultry farmers and professional farmlands.

Industrial devices often have high price, and their application impractical in conditions small household farms.

For breeding poultry small quantities are fine home. And to construct it with desire will be able everyone.

Important points in the manufacture of the incubator

At independent manufacturing very important moment is the creation of comfortable, maximum close to natural conditions for breeding birds.

Primarily it is worth taking care of the constant maintenance of the necessary temperatures inside the incubator and arrangement in it ventilation.

When mother hen independently incubates eggs, forms natural temperature and humidity for normal development of chicks.

AT artificial conditions, the temperature in the incubator must be constantly maintained at 37.5–38.6 degrees at the humidity level in 50–60% . For even distribution and circulation warm air is used forced ventilation.

Attention: violation of the temperature regime at any stage of the incubation period (overheating, underheating, excessive or insufficient humidity) can lead to a significant slowdown in the development of chicks.

In particular, excessive humidity in the incubator negatively affects embryonic development in the egg and can lead to the death of the chick before it is born.

Insufficient humidity air in the appliance makes the egg shell overdried and very durable unacceptable when hatching.

We make an incubator with our own hands

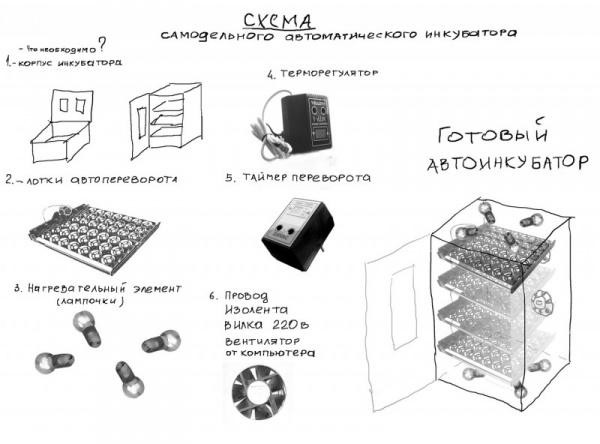

To create an automatic incubator do it yourself You will need to craft or purchase from the store the following equipment:

To create an automatic incubator do it yourself You will need to craft or purchase from the store the following equipment:

- Frame for the incubator itself;

- tray system;

- A heating element;

- Fan;

- Automatic turning mechanism.

Incubator housing

Corps for a homemade incubator can serve, washing machine, knocked down from plywood box and even unclaimed Bee hive.

Corps for a homemade incubator can serve, washing machine, knocked down from plywood box and even unclaimed Bee hive.

To maintain inside the incubator comfortable microclimate(preservation of heat), walls the cases are sealed (most often with foam), and for entry inside fresh air small holes are made.

The size incubator and amount in it egg trays are selected based on needs owner.

tray system

As trays for eggs, you can use a strong metal mesh with cells of size 2.5 cm. The trays will be held on special pins, which in turn will automatic flip fixed trays.

As trays for eggs, you can use a strong metal mesh with cells of size 2.5 cm. The trays will be held on special pins, which in turn will automatic flip fixed trays.

L = (H-((N+15)*2))/15

Where L- the number of trays, H- refrigerator height, N– distance of trays from heating elements.

For example: Height incubator 1 meter. For calculation maximum number trays for the incubator, subtract from it distance to heating elements with a margin 6 cm(to avoid overheating), multiply on 2 and divide by height required for ventilation. We get:

L \u003d (100-((6 + 15) * 2)) / 15 \u003d 3.86

Maximum amount trays, which will be required to create an incubator is four.

A heating element

To maintain a constant temperature in a large incubator can be used heating iron spirals by connecting them in series.

To maintain a constant temperature in a large incubator can be used heating iron spirals by connecting them in series.

For small structures, you can get by with several incandescent lamps medium power. You can place them both “above” and “under” the trays at a distance not less than 20 cm.

Note: when installing lamps, a thermometer must be placed in the incubator to accurately control the temperature and a bath of water is installed so that the air inside the device is humid. To control humidity, a psychrometer is used, which can be easily purchased at any pet store.

Fan

AT small a homemade incubator will be enough one fan, For example, from an old computer. Air circulation is very important in the arrangement of the incubator and plays key role in the brood of chicks.

AT small a homemade incubator will be enough one fan, For example, from an old computer. Air circulation is very important in the arrangement of the incubator and plays key role in the brood of chicks.

In addition to uniform distribution of warm air, the fan pumps up inside required for eggs oxygen and removes carbon dioxide. For air to flow into the device in the upper and lower parts of the case, it is necessary to make multiple holes size 15-20 mm.

Automatic turning mechanism

Swivel pins, on which the trays will be fixed, must be perfect aligned to prevent distortion of the entire structure. BUT mechanism parts, connecting the trays and setting them in motion rigidly fixed between themselves.

As drive low-power (up to 20 watt) reduction motors and star chain.

Note: for smooth turning of trays with eggs, it is necessary to use a chain with a minimum pitch (0.525 mm).

For complete automation process, the power circuit of the motor is added relay(switch) which will on one's own turn the motor on and off.

It is important to know: before loading eggs and starting incubation, you need to check and test the created system for 3-4 days. Stabilize the temperature and humidity, experimentally find a place for the fan and start the turning mechanism, stabilize the turning speed and the angle of the trays.

So, manufacture of automatic incubator at home without the cost of modern technologies, the task is quite doable. The main thing- compliance sequences the actions described above and the utmost care for work.

For construction, you can use improvised means: frame old refrigerator, washing machine, plywood or chipboard box, for wall insulation- Styrofoam or an old blanket will do, a computer fan will provide an even distribution warm air throughout the structure.

Following video talks in detail about the incubator for hatching eggs with your own hands:

All experienced poultry farmers are well aware that one of the main conditions for the successful incubation of eggs, in addition to properly selected temperature and humidity, is their periodic turning over.

Moreover, this must be done according to a strictly defined technology. All existing incubators are divided into three groups - automatic, mechanical and manual, and the last two varieties suggest that the process of turning eggs will be carried out not by a machine, but by a person.

A timer will help simplify this task, which, with some time and experience, you can do it yourself. Several methods for manufacturing such a device are described below.

What is it needed for

The egg turning timer in the incubator is a device that opens and closes the electrical circuit after the same period of time, that is, saying plain language, a primitive relay. Our task is to turn off and then turn on the main components of the incubator, thus automating the system as much as possible and minimizing possible errors caused by the human factor.

The timer, in addition to turning the eggs, also provides the following functions:

- temperature control;

- providing forced air exchange;

- start and stop lighting.

The microcircuit on the basis of which such a device is made must meet two main conditions: low switching current with high resistance of the key element itself.

The best option in this case is the construction technology electronic circuits CMOS, which has both n- and p-channel FETs, which provides faster switching speed and is also energy-saving.

The easiest way at home is to use the timing microcircuits K176IE5 or KR512PS10 sold in any electronics store. Based on them, the timer will work for a long time and, most importantly, uninterruptedly.  The principle of operation of the device, made on the basis of the K176IE5 chip, involves the sequential execution of six actions:

The principle of operation of the device, made on the basis of the K176IE5 chip, involves the sequential execution of six actions:

- The system starts up (circuit closing).

- Pause.

- A pulsed voltage is applied to the LED (thirty-two cycles).

- The resistor is turned off.

- The node is charged.

- System shuts down (open circuit).

Important! If necessary, the response time can be extended up to 48–72 hours, but this will require upgrading the circuit with higher power transistors.

Timer,

made on the KR512PS10 chip, in general, is also quite simple, but there are additional functionality due to the initial presence in the circuit of inputs with a variable division ratio. Thus, to ensure the operation of the timer (the exact delay time), you need to choose the right R1, C1 and set the required number of jumpers.  There are three options here:

There are three options here:

- 0.1 second - 1 minute;

- 1 minute–1 hour;

- 1 hour–24 hours.

If the K176IE5 microcircuit assumes the only possible cycle of actions, then on the KR512PS10 the timer operates in two different modes: variable or constant.

In the first case, the system is turned on and off automatically, at regular intervals (the mode is configured using jumper S1), in the second case, the system turns on with a programmed delay once and then works until it is forced to turn off.

To implement the creative task, in addition to the timing microcircuits themselves, we need the following materials:

- resistors of various capacities;

- several additional LEDs (3-4 pieces);

- tin and rosin.

The set of tools is quite standard:

- a sharp knife with a narrow blade (to short-circuit resistors);

- a good soldering iron for microcircuits (with a thin tip);

- stopwatch or watch with a second hand;

- pliers;

- screwdriver tester with voltage indicator.

Do-it-yourself homemade incubator timer on the K176IE5 chip

Majority electronic devices, such as the incubator timer in question, have been known since Soviet times. An example of the implementation of a two-interval timer for incubation of eggs with detailed instructions was published in the magazine Radio, popular among radio amateurs (No. 1, 1988). But, as you know, everything new is a well-forgotten old.

If you are lucky enough to find a ready-made radio designer based on the K176IE5 chip with an already etched printed circuit board, then the assembly and adjustment of the finished fixture will turn out to be a mere formality (the ability to hold a soldering iron in your hands, of course, is highly desirable).

If you are lucky enough to find a ready-made radio designer based on the K176IE5 chip with an already etched printed circuit board, then the assembly and adjustment of the finished fixture will turn out to be a mere formality (the ability to hold a soldering iron in your hands, of course, is highly desirable).

Let's consider the stage of setting time intervals in more detail. The two-interval timer in question ensures the alternation of the “work” mode (the control relay is on, the incubator tray rotation mechanism is working) with the “pause” mode (the control relay is off, the incubator tray rotation mechanism is stopped).

The "work" mode is short-term and lasts within 30-60 seconds (the time required to turn the tray to a certain angle depends on the type of particular incubator).

Important! At the stage of assembling the device, one should strictly follow the instructions, avoid overheating at the soldering points of electronic semiconductor components (mainly the main microcircuit and transistors).

The "pause" mode is long and can last up to 5, 6 hours (depending on the size of the eggs and the heating capacity of the incubator.)

For ease of setup, the circuit has an LED that will blink at a certain frequency during the time interval setting process. The power of the LED is consistent with the circuit using the resistor R6.

Setting the duration of these modes is carried out by time-setting resistors R3 and R4. It should be noted that the duration of the "pause" mode depends on the value of both resistors, while the duration of the operating mode is set solely by the resistance R3.  For fine tuning, it is recommended to use 3-5 kΩ variable resistors for R3 and 500-1500 kΩ for R4 as R3 and R4, respectively.

For fine tuning, it is recommended to use 3-5 kΩ variable resistors for R3 and 500-1500 kΩ for R4 as R3 and R4, respectively.

Important! The lower the resistance of the time-setting resistors, the more frequently the LED will flash, and the shorter the cycle time.

Adjustment of the "work" mode:- short the resistor R4 (reduce the resistance R4 to zero);

- turn on the device;

- resistor R3 to adjust the blinking frequency of the LED. The duration of the "work" mode will correspond to thirty-two flashes.

Pause mode adjustment:

- use the resistor R4 (increase the resistance R4 to the nominal value);

- turn on the device;

- note the time between adjacent LED flashes using a stopwatch.

The duration of the "pause" mode will be equal to the received time multiplied by 32.

Instructions: how to make an incubator timer on a KR512PS10 chip with your own hands

The KR512PS10 microcircuit, manufactured on the basis of the CMOS process technology, is used in a wide variety of electronic timer devices with a variable division ratio of the time cycle.

These devices can provide both a single switching on (turning on the operating mode after a certain pause and holding it until forced shutdown), and cyclic switching on - switching off according to a given program.

Did you know? The chick in the egg breathes atmospheric air, which penetrates the shell through the smallest pores in it. By letting in oxygen, the shell simultaneously removes carbon dioxide exhaled by the chicken, as well as excess moisture, from the egg.

Creating a timer for an incubator based on one of these devices will not be difficult. Moreover, you don’t even have to pick up a soldering iron, since the range of industrially produced boards based on KR512PS10 is extremely wide, their functionality is diverse, and the ability to adjust time intervals covers the range from tenths of a second to 24 hours.  Ready-made boards are equipped with the necessary automation, which provides quick and precise adjustment of the "work" and "pause" modes. Thus, the manufacture of a timer for an incubator on a KR512PS10 chip is reduced to right choice boards for specific characteristics of a particular incubator.

Ready-made boards are equipped with the necessary automation, which provides quick and precise adjustment of the "work" and "pause" modes. Thus, the manufacture of a timer for an incubator on a KR512PS10 chip is reduced to right choice boards for specific characteristics of a particular incubator.

If you still need to change the operating mode time, then this can be done by shorting the resistor R1.

For those who love and know how to solder, and also want to assemble such a device with their own hands, we present one of the possible schemes with a list of electronic components and a printed circuit board trace.  The described timers are applicable to control overturning of the tray in operation with domestic incubators with periodic switching on of the heating elements. In fact, they allow you to synchronize the movement of the tray with turning the heater on and off, cycling the entire process.

The described timers are applicable to control overturning of the tray in operation with domestic incubators with periodic switching on of the heating elements. In fact, they allow you to synchronize the movement of the tray with turning the heater on and off, cycling the entire process.

Other options

In addition to the considered options for basic microcircuits, there are many electronic components on which you can build a reliable and durable device - a timer.

Among them are:

- MC14536BCP;

- CD4536B (with modifications CD43***, CD41***);

- NE555 etc.

Some of these microcircuits are currently out of production and replaced by modern analogues (the electronic components manufacturing industry does not stand still).

All of them differ in secondary parameters, an extended range of supply voltages, thermal characteristics, etc., but at the same time they perform the same tasks: switching on and off a controlled electrical circuit according to a given program.

The principle of setting the working intervals of the assembled board is the same:

- find and short-circuit the "pause" mode resistor;

- set the desired blinking frequency of the diode with the “work” mode resistor;

- unlock the "pause" mode resistor and measure the exact operating time;

- set divider parameters;

- place the board in a protective case.

When making a tray flip timer, you need to understand that this is primarily a timer - a universal device, the scope of which is not limited solely to the task of flipping the tray in the incubator.

Subsequently, having gained some experience, you will be able to supply similar devices with heating elements, a lighting and ventilation system, and later, after some modernization, use it as the basis for automatically supplying feed and water to chickens.

Did you know? Many believe that the yolk in an egg represents the embryo of the future chicken, and the protein is the nutrient medium necessary for its development. However, in reality this is not the case. The chick begins to develop from the germinal disc, which in a fertilized egg looks like a small speck light color in the yolk. The chick feeds mainly on the yolk, while the protein is a source of water and useful minerals for the embryo, which are necessary for normal development.

Thank you for your opinion!

Write in the comments what questions you did not receive an answer to, we will definitely respond!

11

times already

helped

Collapse

Guided by the instructions in this article, you can make an incubator with your own hands. It will have the same functionality as a store-bought device, but will cost you much less. In order to assemble an incubator with your own hands at home, you do not need to have special skills and knowledge, follow our advice and everything will work out.

Where to start, what tools do you need?

Before you start assembling, decide on the main material of which the product will consist. If you have an old refrigerator, then you can take it as a basis. Also suitable are large pieces of foam, no less than 40 by 25 centimeters, or a simple cardboard box. The determining factor in the choice of material is its thermal insulation ability.

For heating, you will need to equip the device with a lamp or a heating device, take care of temperature control. In incubators, you can configure auto-rotation by adding additional mechanisms.

Automatic turning of eggs in the incubator is needed to save time. It is usually installed on large devices designed for 200 or more eggs.

All you need to assemble:

- Refrigerator (if you are planning to build an incubator from an old refrigerator), box or foam.

- Standard incandescent lamps with a power of 25 to 40 watts. The number of lamps depends on the size of the incubator, a small device for 100 eggs can be heated with four lamps.

- As an alternative to lamps, you can use electric heaters.

- Incubator tray made from metal mesh or analogues. The mesh should hold the eggs tightly. Wooden trays can be installed in the refrigerator.

- Thermometer, fan.

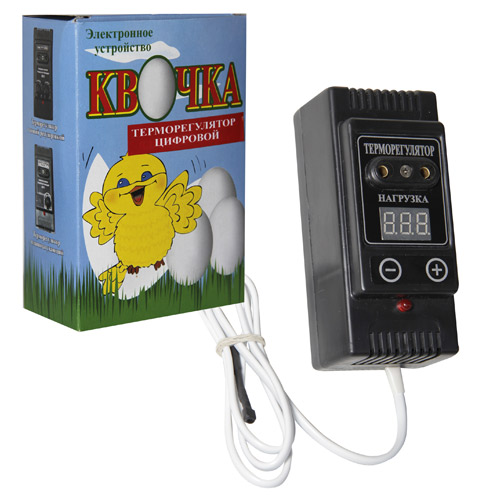

- Temperature controller (if you are designing an automatic incubator). For this you can use bimetal plates, electric contactors or barometric sensors.

- Motor reducer (what the coup mechanism consists of). If necessary, bearings - 4 pieces, clamps for their tie.

- Sealant for sealing gaps for insulation purposes, screws, various fastening materials, metal corners.

- A hygrometer is used to monitor the humidity level.

Attention! Heating lamps must be installed at a distance of more than 25 centimeters from the eggs.

Decide on the size of the incubator, decide what you will collect it from. Then pick up all the necessary components from the list above, and you can start assembling.

How to decide on the size?

The dimensions of the incubator must be planned in advance. This parameter depends on the volume of your production, the number of chickens. The decisive factor in this matter will be the number of eggs that you plan to lay in the device. Also, the size of the incubator is affected by the type of heating system, the location of the lamps and the material from which the device is made.

For more accurate work, you will need drawings with dimensions that will look something like this:

Fig1. Drawing example

Here is a drawing of a small size incubator (for 45 eggs) 25 cm wide and 40 cm long.

Model dimensions for 100 eggs

When forming the dimensions of the incubator, keep in mind that the temperature 2 cm from the egg should be in the range of 37.3-38.6 degrees Celsius. Usually they make a medium-sized device, designed for 100 eggs. The cells make about 45 millimeters in diameter and 60-80 millimeters deep. It is recommended to make a replaceable grille so that you can adjust the dimensions under different types eggs.

By assembling a home incubator with your own hands for 100 eggs, you will receive a device measuring 60 by 60 centimeters. The device weighs about 3 kilograms. It can be converted and used to house duck, goose, turkey or quail eggs.

If you are building an incubator at home from an old refrigerator, it will take up more space and hold more eggs than a Styrofoam or cardboard product.

How to calculate the size?

The dimensions for the incubator with your own hands can be determined using the table below. The table shows the dependence of the length, width and height on the number of eggs to accommodate.

When making a do-it-yourself chicken egg incubator, you should take into account that with the same capacity, the foam construction will be more voluminous than cardboard.

Larger models are usually made in several floors, using other technologies. Therefore, the calculations there are made differently.

How to make an incubator from a refrigerator with automatic egg flipping?

The device of the incubator has many similarities with the device of the refrigerator. Therefore, you can easily make an egg incubator out of the refrigerator. The case of this device retains heat well. It can accommodate more eggs, each incubator tray will lie on a separate rack.

In the role of racks will be the shelves of the refrigerator. Inside there will be optimal humidity due to the liquid exchange system located at the bottom of the household appliance. In this chapter, you will learn how to make your own incubator from the refrigerator by adding a thermostat, heater and rotary mechanism.

Fig 2. Scheme of a homemade incubator from the refrigerator

Consumables and their price

Knowing how to make a homemade incubator, you will save 70% of the store cost of the device. The simplest incubator from the refrigerator can be assembled without investment. But if you want to make it convenient and efficient, you will have to buy a few additional items.

- An old refrigerator - usually purchased for free, you can buy it on an ad for no more than 1,000 rubles.

- Light bulbs for 220 volts - from 25 rubles apiece.

- Thermostat - from 300 rubles.

- Fan - from 200 rubles.

- Chain with sprocket or metal rod.

- Drive for turning eggs - from 500 to 5,000 rubles. You can get it for free. any will do gearmotor, for example, from a car windshield wiper.

Basic camera requirements

A homemade incubator from the refrigerator must meet the minimum requirements that will make it possible to hatch chickens. It takes about twenty days to hatch the cubs. During this period, incubators maintain humidity at 40-60 percent. As soon as the chicks begin to show up, the humidity is raised to 80 percent. At the final stage, before the chicks are selected, the humidity is returned to the original level.

Eggs require temperature control. Therefore, your device must be manufactured with this fact in mind. Temperature requirements vary depending on which eggs you place in the incubator tray. Select the mode according to the table below.

Temperature table

Ventilation system

Making an incubator from a refrigerator involves installing ventilation system. Ventilation affects the temperature and humidity inside the device. Prevents the formation of an unfavorable climate for eggs. The average ventilation speed should be about 5 m/s.

A do-it-yourself home incubator from the refrigerator should be equipped with two ventilation holes that are drilled in the case. One of them is located below, and the other above. Plastic or metal tubes are inserted into the holes so that the air masses do not interact with the glass wool under the casing of the cooling device. Ventilation adjustment is carried out by partial or complete overlapping of openings.

Fig 3. Ventilation system

Reference: the embryos begin to consume oxygen from the outside already on the 6th day of incubation. In the third week, the egg consumes 2 liters of air per day. AT last days before hatching, each chick consumes 8 liters of oxygen.

Ventilation is of two types:

- Constant is a system that involves the creation of a continuous movement of air, with a constant exchange and smooth distribution of heat.

- Periodic - a device that operates once every 24 hours to actively change the air in the chamber.

Please note that even the highest quality ventilation does not allow you to completely abandon the egg flip. Therefore, a mechanism for turning eggs in an incubator is needed in any case. The auto-flip prevents the embryo from sticking to the shell.

Constant

Permanent ventilation for the refrigerator has the following principle of operation:

- A fan installed inside the chamber drives the air flow into the openings. Due to this, the air comes out. When making a home incubator with your own hands, you should pay maximum attention to this moment.

- When exiting, the air flow mixes with fresh air and passes through the heaters.

- Then the air goes down, where it is moistened by a container of water.

- The device of the incubator contributes to the heating of the air, which subsequently gives off heat to the eggs.

- After heat transfer, the air returns to the fan.

The design of an incubator with constant ventilation is more complicated than with a periodic system. But this allows you to simultaneously solve three problems: air humidification, ventilation and heating of eggs.

periodic

Periodic system. If you are making an egg incubator with your own hands, then most likely it will be a manual mechanism. For installation automatic start you will need an electronic controller. The use of a controller is not always justified, especially if you are making a simple homemade incubator with automatic egg flipping. Ventilation in such a system occurs as follows:

- Heating is turned off.

- The fan is started, which replaces the air and cools the eggs.

- After 30 minutes, the fan is turned off and the heating system is started.

The characteristics of the fan are determined depending on how many eggs the chamber is designed for. If you are making an average do-it-yourself incubator with an automatic flip with a capacity of 100-200 eggs, then you need a fan:

- working from a network of 220 Volts;

- diameter from 10 to 45 centimeters;

- with productivity from 35 to 200 m 3 /hour.

In addition, the device of the incubator must assume the presence of a filter for the fan. The filter prevents dust, dirt and fluff from getting into the blades of the device.

Refrigerator incubator case

This is important aspect the topic "how to make an incubator out of the refrigerator with your own hands", since from proper preparation body of the device will depend on the efficiency of its work.

Fig 4. Case from the refrigerator

First you will need to remove the freezer and other built-in equipment. Then make holes for ventilation, as described above in the text about installing this system. Install shelves and trays as you see fit.

Heating system installation

When making an incubator with your own hands with an automatic flip, you will have to organize the heating system yourself. To do this, use 4 incandescent lamps of 25 watts or two bulbs of 40 watts. Lamps are equally distributed between the bottom and top of the refrigerator. The lower lamps must not interfere with the installation of the water container intended for humidification.

Before you make an incubator at home, you need to make necessary calculations and prepare tools. Do not rush in the process of work, as this can lead to disastrous results.

Choosing a thermostat

Many are interested in the question of how to make a home incubator with optimal temperature conditions. To do this, you need a high-quality thermostat. There are three types that poultry farmers use:

- An electric contactor is a mercury thermometer with an electrode responsible for turning off the heating when a certain temperature is reached.

- Bimetallic plate - closes the circuit when the desired heating parameter is reached.

- Barometric sensor - closes the circuit when the pressure is too high.

Fig 5. Finished thermostat

If you are thinking about how to make an incubator with convenient controls, then install an automatic thermostat. This will greatly increase convenience and save time.

Flip mechanism

According to generally accepted technology, the egg turning mechanism in the incubator should work 2 times a day. Some experts recommend turning eggs twice as often.

Turning eggs in an incubator is of two types:

- framework;

- inclined.

The frame rotary device for the incubator functions by pushing the egg with a special frame, which rotates it about the axis.

An inclined rotary device for an incubator involves periodically tilting the tray with eggs at a certain angle. Due to this, the position of the embryos inside the eggs and their location in relation to the lamps change.

Fig 6. Rotation mechanism

The main principle of the automatic turning device is that the motor drives a rod that acts on the egg tray.

How to make a simple turning mechanism for a refrigerator:

- Install the gearbox inside the refrigerator at the bottom.

- Installed inside the refrigerator wooden frame that will hold the trays. The trays must be fixed in such a way that they can tilt 60 degrees in the direction of the door and also in the opposite direction.

- The gearbox must be firmly fixed.

- A rod is attached to the engine, connected to the tray on the other side.

- The motor drives the rod, which in turn tilts the tray.

Video

Making a device out of the box

Consider the question of how to make an incubator out of the box. This option will be the cheapest of the proposed, production will take several hours. Cardboard is a fragile material, but at the same time, it retains heat well and is easy to work with.