Do-it-yourself potato hillers for a walk-behind tractor - the realization of your locksmith talents and cost savings! The device and use of a hiller for a walk-behind tractor in a summer cottage How to adjust a disk hiller

Distinctive feature motoblock Neva is compatible with almost any type of attachments.

Hillers are designed to form furrows for further planting of crops. Also, with their help, they sometimes loosen the soil and roll the grass from the aisles to the roots of the crops.

The official website of the manufacturer of the Krasny Oktyabr plant offers 4 models. Let's take a look at the differences between each model.

They are all similar in their purpose and end result. But they differ in manufacturers, designs, sizes and functional purposes.

Double-row hillers allow you to simultaneously process two row-spacings with crops. It is a bracket post that connects to the hitch. And two racks with hillers, which are bolted to it. You can adjust the width of the hiller and adjust it to the required conditions.

There are two options on the manufacturer's website.

Double row OND

This hiller is produced by NMZ Energia CJSC.

It is designed to work light and prepared soils. In particular for cultivating land in gardens, greenhouses or small vegetable gardens.

- The maximum depth during hilling is 120 mm, the minimum is 80 mm.

- The depth of penetration of the unit into the ground can be adjusted manually.

- The width of the OND wings can range from 25 to 43 cm.

Okuchnik hinged two-row OND has the following dimensions:

- 72 cm long,

- 54 cm high,

- 35 cm wide.

- With such dimensions, the weight of OND is up to 9.5 kg.

The principle of operation of a two-row hiller is shown in the video:

Double row STV

It is produced by the Volga company ZAO VRMZ.

This company immediately offers two options for the manufacture of hillers for the Neva walk-behind tractor. The main difference in them is the width of the wings and the distance between the hulls. That is, everyone can choose the option that suits him best.

- The mass of models can be 10 or 13 kg.

- The width is from 86 cm to 1 m. The length of the model can be from 39 to 46 cm. And the height is from 46 to 68 cm.

- The distance between the shares is adjustable and can be from 21 to 65 cm.

- The maximum plowing depth can be up to 15 cm.

As we can see, this model presents a wide range of settings. Therefore, each owner will be able to adjust the hilling devices to suit their needs.

If your two-row CTB hiller is slipping, you can use a solution with upgraded lugs as an option:

Single row STV NPD

They are designed to process only one field row. It is more efficient when viewed from the side of ease of management. Because when working with double-row hiller it is necessary to monitor the work of two rows at the same time. But this is not always possible and it is possible to make the wrong movement and damage the sown crops.

Plus, the location of the beds is not always even and there are uneven lines when planting. In this case, the probability of crop damage is high. Single-row hillers for the Neva walk-behind tractor are much easier to manage than double-row ones.

Therefore, CJSC VRMZ offers its customers a wide range of single-row hillers. Various configurations and sizes. In total there are more than 15 various models and configuration.

Here are their average stats:

- Dimensions - 46 cm long, 21 cm wide and 65 cm high. The average weight of the structure is 5 kg.

- The depth of hilling can reach 15 cm.

- And the grip width of the hiller is from 21 to 36 cm.

How to use correctly?

To connect it to the walk-behind tractor, a special hitch is used.

After coupling, special bolts should be used to adjust the working depth and the width of the hiller. To do this, it is necessary to take into account the characteristics of the soil that is planned to be processed.

Hilling depth is adjustable by changing the angle of inclination of the body itself.

If necessary, the angle of inclination can be easily adjusted already during agricultural work.

Here is a video about how a single-row hiller is operated there:

Disk single row

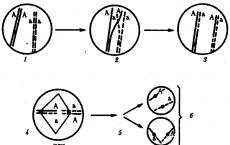

This type is a construction of a rack, disk and shaft. The drain is attached to a special bracket with a bracket. This bracket allows you to adjust the location of the rack in any direction. The shaft is equipped with a sector, it allows you to adjust the angle of the disk. The discs are mounted on a shaft, which is driven by plain bearings.

CJSC VRMZ offers the following characteristics:

- Weight can be from 5 to 10 kg.

- The length of the hiller ranges from 24 to 27 cm.

- The width can be adjusted from 33 to 66 cm.

- The height is set in the range from 54 to 70 cm.

- The maximum height of the comb can reach 20 cm.

- The angle of inclination of the discs is adjustable from 27° to 35°.

CJSC VRMZ does not offer its customers to use what they have. They offer their customers a wide range of mounted hiller settings. So that you can adjust its work for beds of a specific size.

Setup and operation

First, he mates with a walk-behind tractor. Then the distance between the bodies of the hiller and their width are adjusted.

The width can be adjusted by spreading or narrowing the wings.

And the working width is controlled by loosening the bolts and rearranging the body of the hillers. After installation at the required distance, securely fasten them back.

IMPORTANT! After adjustment, the housings must be at a symmetrical distance from the axis. Otherwise, the walk-behind tractor will constantly lead in one direction and work will be impossible.

Before use, it is initially necessary to hitch the hiller with a walk-behind tractor.

Then adjust the angle of inclination and the distance between the discs to obtain a comb of the required height. To do this, use special bolts according to the manufacturer's instructions.

The discs go deep into the ground by pressing the handle of the walk-behind tractor while it is moving.

If necessary, it is possible to adjust the angle of inclination and discs and the distance between them right during the work.

Here is a detailed video review of the disk hiller for the Neva walk-behind tractor and an example of its work:

Homemade options

Motoblock Neva is compatible with any attachments. All that is needed is to make it hitch with the body of the equipment.

The hiller is a relatively simple design that many people can build at home.

The easiest type of hiller to assemble at home is disk. All they need is:

- T frame,

- 2 disks

- 2 racks for them.

For the manufacture of discs, any steel with a thickness of 2 mm or more is suitable. But they will need to be given a convex shape.

Holes are made on the frame, which will be necessary to change the distance between the disc racks. They are attached to the frame with special bolts.

Here is a detailed video instruction that will help you figure out how to make a do-it-yourself hiller for the Neva walk-behind tractor:

When cultivating potatoes, to facilitate the laboriousness of the process, farmers use various hinged structures that cling to a walk-behind tractor or a tractor. One of these devices is disk hiller, which allows you to effectively fight weeds, form high ridges and loosen the soil. As a result of the application of this agrotechnical method, the crop yield is significantly increased. The main thing is to know the features of the device and its application in the processing of culture.

Varieties of hillers

The following models of equipment for a walk-behind tractor are presented on the agricultural machinery market.

Lister Hiller

The fixture is different simple type construction with a constant working width, made of two connected and slightly apart wings. It is the fixed parts of the equipment that make it impossible to adjust the working width. Work with such a canopy is built taking into account the performance of the unit. In the classic version, hillers are produced with a working width of 25-30 cm, but this is not the best way, considering that the crop is grown with a width between rows of 50-60 cm. It is used with a motor cultivator with a power of up to 3.5 hp, with a total weight indicator of 25-30 kg. Thanks to thin racks, overloading the cultivator is excluded when the hiller is buried in the ground.

There are devices with a streamlined shape, they twist the earth less and dry it out. Such equipment is more efficient.

Due to the adjustment mechanism that allows you to change the location of the wings, such products are more in demand and are easy to use. The tool can be adjusted to a specific row spacing. It is used with walk-behind tractors, the power of which is over 4.0 hp, and the weight is from 30 kg. A serious disadvantage of the equipment is considered to be a large energy consumption.

Disc hiller

According to experienced farmers, this the best hiller for a walk-behind tractor, which does not cause difficulties in use. It does not require excessive effort from the farmer, pushing himself, without additional help. If you purchase a hiller for the Neva walk-behind tractor, it is better to give preference to a disk device, with which loosening and the formation of high ridges can be done both after planting root crops and at the stage of their active growth.

Manual potato hiller

The tool is more suitable for processing small areas. It can be of two varieties: disk and in the form of a plow. An indisputable advantage is the possibility of making it yourself from improvised means, in particular, from an old bicycle.

The attachment is synchronized with a walk-behind tractor and a walk-behind cultivator with two forward gears. The second speed, where the power is already 180 rpm, is used for processing and transferring the earth from row spacing to ridges. The equipment, due to the presence of propellers, first crushes the soil and removes grass, and then forms ridges.

The use of hillers

The okuchnik is mounted to the walk-behind tractor on the hitch bracket without a rower by using a locking element, two bolts and washers. For maximum results, the bush processing process is performed in first, low gear. If potatoes are planted using a motor cultivator, the furrows are formed taking into account the width of the single-row hiller. Previously, the site before planting must be cleared of excess vegetation.

To ensure smooth running of the machine before hilling, it is recommended to correctly adjust the attachments for the walk-behind tractor, which will reduce labor costs by constantly monitoring the work process.

In the course of the movement of the equipment, the soil is raked and high ridges are formed from it, which collect the plant “in a pile” and improve the aeration qualities of the earth by crushing it.

Do-it-yourself disk potato hiller

It is quite possible to make a homemade disk hiller from improvised materials. This equipment option is ideally combined with the capabilities of self-propelled vehicles. It is convenient to adjust the hiller depending on the row spacing and the nature of the soil. The disc hiller for a walk-behind tractor makes it possible to process potato plantings at different growth phases, the main thing is to correctly select the size of the discs.

Often home craftsmen do not know what to make them from. Alternatively, you can use old metal cylinders stale in the garage. They cut off the bottom, and the edges of the resulting blanks are processed with a grinder, so it is easier and faster to loosen the ground. To properly make a hiller with your own hands, it is recommended to adhere to all stages of production and have experience working with metal. The video at the end of the article, which reproduces the process, will help in the work.

Preparation and materials

To make a disk hiller for a walk-behind tractor with your own hands, you will need the following tools and materials:

- Two concave discs (40-60 cm in diameter). For their manufacture, lids from pots, parts from a seeder that were in use, or fragments of sheet steel 2 mm thick are suitable. If you use a thinner material, these structural components will soon become unusable and will have to be made anew.

- Two screw tarlepa for connecting the front rod and vertical rack.

- Hollow one-inch pipe 1 m long. It will be used as a vertical stand.

- Metal hollow pipe, the section of which is ¾ inch. This element is necessary for the manufacture of front and rear traction.

- T-shaped leash.

- A special device for bending pipes is a pipe bender. But you can also use a gas burner, where the workpiece is initially heated, and then bent at a specific angle.

- Adjustable disc adapters.

- Welding inverter.

- Bolts.

Below is a drawing of a disk hiller, where you can consider in more detail the design principle and the main connection points.

Manufacturing

Step-by-step instruction for the manufacture of a disk hiller with your own hands:

- In order for attachments to be of universal use, it is recommended that special attention be paid to the adjustment functions. The height is adjusted with a special telescopic device, which is placed in the center. A smaller tube should be placed in a larger diameter tube, which will allow the device to be adjusted to the grower's height.

- To control the angle of attack of the hiller, the tilt of the bed is used. Angle adjustment is made possible by changing the angle difference between the upright and the front link.

- The frame must be set in motion by attaching the front link to the rack in its central part using a hinge. Adjustment is carried out through a screw tarlep.

- Using a welding inverter, they are connected to vertical rack rear struts and two discs.

- The next step is to mount the front link through the use of a hinge and a bolt.

- The end result should be a U-shaped rear link with a width of up to 50 cm. The length of the handle is from 20 cm.

- A vertical tube should be welded in the center of the fork. It is its end that will serve as the element due to which the entire structure will be installed in the vertical thrust.

- To adjust the height of the rack, holes are made in the upper part, such openings are also drilled in the vertical fork. If disks with a flat surface were chosen for the fixture, it is recommended to bend them with a hammer and clean the edges.

- A device for processing potato plantings is ready. Important point: the dimensions of the disk hiller for the walk-behind tractor will depend on the type of self-propelled equipment used.

Installation and use

When installing and setting up a disk hiller, it is important to accurately determine the distance between the lower support points, which coincides with the track width, and the angle of attack. It is necessary to set the wings correctly so that the equipment does not lead to the side. When using a disc device for raking potatoes with a walk-behind tractor, it is better to choose wheels with a diameter of 70 cm and a width of 10-14 cm, which will prevent damage to the bushes. It is also worth taking care of the availability of more suitable wheels for the walk-behind tractor.

A home-made disk hiller for a walk-behind tractor is installed by using a hitch bracket, where a hiller leash is attached to it with two bolts and a stopper. The technique is installed over the row, and at the first speed they pass it.

Based on the material presented, it becomes clear how to set up a do-it-yourself device for hilling potato plantings. The most convenient and effective hiller for potatoes is a model with a variable gripping distance.

Proper cultivation of a personal plot significantly increases the yield of planted crops. In modern conditions of lack of time, summer residents often resort to small-scale mechanization of garden work. The walk-behind tractor has not been in short supply for a long time, and it can be found in almost every household.

Having spent a certain amount to purchase this useful device I want to save as much as possible on the operation. One way to save money is to make attachments with your own hands.

Of course, no one suggests forging a plow in a forge, as was done many decades ago. However, you can not do without elementary plumbing equipment.

For the manufacture of homemade devices to the motoblock you will need:

- Welding machine, preferably for arc welding;

- Gas-burner. Not to replace electric welding, but to warm up the product during hardening;

- corner grinder machine(grinder) of medium power, with a set of cutting and peeling discs;

- Drilling machine or powerful drill. Of course - high-quality drills;

- Electric emery (grindstone);

- High-quality locksmith's workbench, vise, files and fastening tools.

The most popular in use are mechanized hillers for walk-behind tractors. We will talk about the culture for which summer residents are ready to stand in the field for hours, bent over in three deaths. And an indispensable assistant in the struggle for the harvest is attachments.

How to make a potato hiller yourself

First of all, let's decide which tool is right for you. Hilling devices are of several types:

Lister fixed and adjustable angle

Fixed - This is the easiest device to use and manufacture. It is easy to make using the attached drawings:

The base is welded from a steel sheet with a thickness of at least 3 mm. This node is the first to meet the resistance of the soil.

We use a 4 mm steel strip for the bracket, it is advisable to harden the part after molding. The field board can be bent from 5 mm steel, for example from a leaf spring. Only the metal must first be “released”, and then hardened again.

Advice! A crucible is not required for tempering and quenching. With such dimensions of workpieces, a gas burner is quite enough.

Rack - a structural element that carries the entire load. Therefore, for it, select a strip of at least 8 mm thick.

Many owners are thinking about the question of how to make hillers for a walk-behind tractor with their own hands, which general principles device operation. With the help of a walk-behind tractor, it is possible to cultivate a plot for potatoes much more efficiently, to carry out hilling faster.

Motoblock is an indispensable thing when cultivating crops on personal plot. The use of this tool will allow you to cope with the processing of potatoes better than when working manually.

Types of hillers for a walk-behind tractor

This tool is one of the most important for carrying out planting work on a site of both a small and a large area. The use of this tool will allow you to cope with the processing of potatoes better than when working manually.

Hiller models are very different, the most commonly used are the following:

- lister;

- disk;

- propeller type;

- with variable width.

This tool allows you to make furrows, and then fill them with planting material. Potatoes in this case will be planted in neat rows, which will greatly simplify further care for them. In general, even if the tool is used infrequently, the result will be significant savings in your own time and effort.

Characteristics of individual types of hillers

Lister hillers are considered the simplest variety. They are two interconnected metal sheets in the form of wings. The lister hiller will have a strictly defined working width, since both wing elements are stationary, their width cannot be changed depending on the size of the row spacing. When working with a lister hiller, the row spacing must be adjusted to the width of the hiller. This can be very inconvenient, since the width of the rows can reach 60 cm, and the grip of a factory-made lister hiller does not exceed 30 cm.

A characteristic feature of this type of hillers is the presence of racks that do not allow overloading the walk-behind tractor during penetration into the soil.

For work, it is preferable to use streamlined hillers, as they turn the soil to a lesser extent, preventing it from drying out excessively.

Disc hillers are more efficient in operation. With a decrease in the speed of the cultivator, the power of the hiller increases, which leads to an increase in the service life. Hillers of this type are much more convenient to use than lister ones: a motor cultivator with such a hiller will move forward on its own, less effort is needed to work with it.

The third advantage is versatility. You can use the disk tool both before planting potatoes, and during the period when the aerial part becomes quite high.

When choosing, it is worth giving preference to tools made of steel, with a large sheet thickness and with bearings instead of sliding bushings.

Variable width tools are more comfortable to use than lister tools. They are equipped with a mechanism that allows you to adjust the width of the grip by changing the position of the wings. Therefore, the walk-behind tractor in this case can work with row spacings of any width.

Most often, a tool with a variable width is used to work with powerful mechanisms, the weight of which reaches 30 or more kilograms, and the engine power is 4 hp.

Propeller hillers are used on walk-behind tractors with two forward gears. The tool works as follows: when the propeller devices start working, the soil begins to be crushed, the weeds are dug up. Then the beds are spudded with soil.

If the power in second gear exceeds 180 rpm, the tool can be used not only for hilling, but also for transferring loose soil from row spacing to beds.

Methods for making a hiller

Making a hiller for a motor cultivator is not such a difficult matter, especially for a person who has his own plot.

Skills acquired during construction and repair work on the site, it is quite enough to make this tool yourself, without going to a specialized store.

Lister type spud tool is enough simple design, therefore, it is not particularly difficult to make it with your own hands.

From a metal sheet 0.2 cm thick, cut out halves - “wings”, which must be bent so that a radius is obtained. Then carry out welding in several approaches.

The seam is treated with a grinder, cleaned. If necessary, selectively weld and clean again. As a result, the layer should become perfectly even.

Stages of manufacturing a disk hiller

Before making a simple disk hiller, you need to select all the materials and tools necessary for this:

- steel sheet 0.2 cm thick;

- welding machine;

- Bulgarian.

As in the previous case, the parts are connected to the union of the radii, welded by welding. Then the seams are welded, the seam is processed and cleaned until the surface is completely leveled.

Before making a hiller, the master should study the drawings well, where the dimensions of each element of the part are indicated. For high-quality work, you must select the type of disk. In steel blades for discs, the lower edges are bent, which must be bent. When manufacturing, it is important to take into account that the disks must be located symmetrically, otherwise the walk-behind tractor will periodically “go away” to the side, which will greatly complicate the hilling process.

During the assembly of the disk hiller, plowshares will be needed. They can be taken from old structures. These parts are always mounted at an angle. A step is maintained between the lower points. Its length can be determined by the track width for the wheels.

The parts are connected using bolts, although in some cases it is more convenient to use welding. With the help of an adapter, the disks are connected to each other. In addition to the main elements, you need to install a T-shaped leash, racks and turnbuckles. The latter are necessary in order to correct the rotary axis of the disks. Lanyards are mounted to the walk-behind tractor using a beam.

A disk hiller can be made using two different technologies. The first involves the creation of a fixed working width, the second - adjustable. In the case of a clearly defined working width, in order to correct the distance between the working disks, it will be necessary to change the location of the racks.

To facilitate the further operation of the tool, it is necessary to install plain bearings - units of mechanisms designed to support and guide the axes. This measure will increase the efficiency and durability of the walk-behind tractor. Sliding bushings are not recommended.

To connect the hiller to the mechanism itself, a clutch bracket is used. The wire of the hiller is connected to it with the help of bolts. A stopper is installed in the inner space of the pipe, then the part is pressed tightly against the surface.

The bracket will change position with the help of bolts. The wiring of the walk-behind tractor is placed along the axis of the mechanism.

After fixing all the elements, the assembly of the disk hiller is considered completed. The walk-behind tractor with a new hiller is ready for the first inclusion and further work.

Hiller from improvised materials

Buying a sheet of steel requires money, while a do-it-yourself hiller is most often made out of a desire to save money on buying parts for a walk-behind tractor. Instead of a template, you can even use unnecessary materials that are literally at hand. For example, old pot lids.

However, they must be chosen very carefully, in accordance with such a parameter as the required disk diameter. To make a simple disk hiller with your own hands, a cover with a diameter of 40 cm is suitable, but it is better to take more, 50-60 cm in size.

These figures are obtained taking into account such parameters as the length of the potato root system, planting depth plus ground clearance. The planting depth is usually no more than 8 cm, the length of the root system is up to 20 cm.

The selected cover is sharpened on all sides. Then it is slightly bent with a hammer and attached to the walk-behind tractor.

As you can see, at home it is quite possible to make both a simple lister and a more complex disk hiller. Such a simple operation will allow you to make a spare part for any domestic walk-behind tractor (MTZ, Neva, Salyut, etc.), saving money, while speeding up the process and increasing the hilling efficiency.

The walk-behind tractor with the help of trailed and mounted implements can easily perform year-round work related to rural life. An okuchnik for a walk-behind tractor is necessary, with it you can create furrows for planting, cut beds and plant plants. The efficiency of tillage depends on the design of the tool.

The use of okuchnik when cultivating the soil

The hiller must, overcoming the resistance of the soil, lift it up from a flat area, creating a ridge. The pointed end must be below the surface to the specified depth. It lifts and loosens the soil, and in order to direct the soil to the base of the plant, there are guide planes that create collapse on both sides. The design of the hiller for a walk-behind tractor looks like an arrow from above, on the side the blades look like butterfly wings.

The hiller must, overcoming the resistance of the soil, lift it up from a flat area, creating a ridge. The pointed end must be below the surface to the specified depth. It lifts and loosens the soil, and in order to direct the soil to the base of the plant, there are guide planes that create collapse on both sides. The design of the hiller for a walk-behind tractor looks like an arrow from above, on the side the blades look like butterfly wings.

Design improvements relate to contours that reduce drag, make the crest higher or wider. The principle of operation of such a hiller does not change - it loosens, takes out a layer of soil and throws plants planted in a row to the base. In the same way, grooves are cut under.

Another type of hillers for walk-behind tractors is a pair of discs. Due to the thin rim, the structure enters the soil at a given depth with low resistance. They are not stretched in a stationary state, they are spinning, and thus overcome resistance with less effort. But in order for the discs to create a stroke, they must have an adjusted vertical angle of inclination and a take-off angle. The distance between the discs on the frame is set according to the width of the processed row. Look at the video of how they spud potatoes with a walk-behind tractor on the stony soil of Simferopol:

Another type of hillers for walk-behind tractors is a pair of discs. Due to the thin rim, the structure enters the soil at a given depth with low resistance. They are not stretched in a stationary state, they are spinning, and thus overcome resistance with less effort. But in order for the discs to create a stroke, they must have an adjusted vertical angle of inclination and a take-off angle. The distance between the discs on the frame is set according to the width of the processed row. Look at the video of how they spud potatoes with a walk-behind tractor on the stony soil of Simferopol:

Conventionally, all hillers in form and principle of work are called:

- lister;

- disk.

At the same time, lister arrows have various forms of plane bending; an arrow that goes deep into the ground can have a massive tip. Flaps or shares have a bend, slope, can have an adjustable and customizable profile.

Pairs for a walk-behind tractor must match in size, contour and weight. Otherwise, the comb will not work out even. The system for adjusting the angles of descent and inclination allows you to set the desired profile of the stroke.

For powerful heavy walk-behind tractors, hillers are paired, light weeders for the MTZ walk-behind tractor are mounted in threes.

The device facilitated and accelerated the hilling of potatoes with a walk-behind tractor - video

How to make a hiller for a walk-behind tractor yourself

Mounted implements are not included with the walk-behind tractor. They are made and sold separately. On the agricultural machinery market, for any type of cultivators, you can find a hiller, designed for the draft power of your horse. But the problem is that the finished tool costs more than 10 thousand, and this is a significant amount for a rural resident in modern conditions. But in a landfill or outside the outskirts, you can find everything you need to build a hiller for a walk-behind tractor.

Mounted implements are not included with the walk-behind tractor. They are made and sold separately. On the agricultural machinery market, for any type of cultivators, you can find a hiller, designed for the draft power of your horse. But the problem is that the finished tool costs more than 10 thousand, and this is a significant amount for a rural resident in modern conditions. But in a landfill or outside the outskirts, you can find everything you need to build a hiller for a walk-behind tractor.

In order to install a propeller hiller, you need to make sure that your walk-behind tractor has a two-shaft engine with reverse, 2 forward speeds. There must be a selective shaft.

First you need to decide whether we will make a disk or lister hiller. A single or double row tool will pull the cultivator. Whether it is necessary to provide sliding wings, adjustable distance between two tools. That is, before building a do-it-yourself hiller for a walk-behind tractor, you need drawings and videos, for example, this:

Of course, you need to have metalworking skills. Not every villager in an abandoned barrel of a heater will make out valuable knots for the economy. Therefore, they go to craftsmen for advice, asking for help.

But not only disks, the device for attaching them must be thought out, and do-it-yourself drawings of a disk hiller for a walk-behind tractor are offered to help the master.

Here, in addition to the disks, the dimensions and section of the most important nodes homemade hiller.

Here, in addition to the disks, the dimensions and section of the most important nodes homemade hiller.

The design will change significantly if you manage to find discs from decommissioned cultivators or other agricultural equipment. In any case, in the manufacture of the frame, you will need to consider a disk adjustment system.

The wisdom of masters with golden hands is boundless. So if there are no disks, they can be replaced by a round blade from a circular saw. The steel is of high quality, the teeth additionally loosen the soil. You still have to create a bearing assembly, otherwise saw blade will not rotate. But tool steel and in the hands of a craftsman, a do-it-yourself disk hiller for a walk-behind tractor will work efficiently.

The wisdom of masters with golden hands is boundless. So if there are no disks, they can be replaced by a round blade from a circular saw. The steel is of high quality, the teeth additionally loosen the soil. You still have to create a bearing assembly, otherwise saw blade will not rotate. But tool steel and in the hands of a craftsman, a do-it-yourself disk hiller for a walk-behind tractor will work efficiently.

When creating a new fixture in your backyard, do not forget about safety measures. When carrying out welding work, you work with a mask. But at this time, "bunnies" can be caught by relatives, watching the craftsman. When working with a dangerous tool, take care of the safety of others.

Varieties of lister homemade and factory hillers

The simplest unregulated hiller is a solid construction of two divergent figured plates, arranged in a mirror and having a common stiffener.

The simplest unregulated hiller is a solid construction of two divergent figured plates, arranged in a mirror and having a common stiffener.

This is the base, but if you add flaps in the form of adjustable plates to it, you get an adjustable hiller own production. Without plates, this is an excellent cultivator of potato rows, in which the soil is compacted and air does not enter the roots.

The fixed-grip hiller can be used on flat fields, with the same row spacing when using a seeder. Such a tool is used with low-power traction, since adjustable plates create additional resistance to the earth layer.

The fixed-grip hiller can be used on flat fields, with the same row spacing when using a seeder. Such a tool is used with low-power traction, since adjustable plates create additional resistance to the earth layer.

Motoblocks of medium power are equipped with a device with an adjustable grip. Such designs are used in narrow row-spacings with a width of about 35 cm. Corn rowing is performed by just such a hiller.

But creating a breakup mechanism and making it work are two different stories. To regulate the depth of lowering into the soil, for an even creation of a stroke, a frame structure with a hitch must be made. Only a well-centered unit will spend a minimum of effort for quality soil cultivation. Immersion of the hiller into the ground occurs due to the vertically exposed rack. If the hiller for potatoes to the walk-behind tractor with your own hands goes low when setting up or adjust the angle of the rack on the surface. For a two-row lister tool, when mounted on a frame, it is necessary to accurately set the distance between the booms.

Devices resembling a home fan use translational and rotational motion in tillage. But you can install the tool on a unit with a two-shaft engine with a reverse and 2 gears. There must be a power take-off. The propeller-type hiller is more efficient than other models, but due to the complexity of execution, it is expensive. Craftsmen took the idea, but the tool is not very similar to a propeller.

Devices resembling a home fan use translational and rotational motion in tillage. But you can install the tool on a unit with a two-shaft engine with a reverse and 2 gears. There must be a power take-off. The propeller-type hiller is more efficient than other models, but due to the complexity of execution, it is expensive. Craftsmen took the idea, but the tool is not very similar to a propeller.

For manufacturing, you will need high-quality steel, a welding machine and a grinder. Details of the “propeller” are welded onto the axles fitted to the frame. In one pass, there is a deep loosening of the earth and its transfer to the ridge. The hiller for the walk-behind tractor is made unregulated, so the corners must be set empirically.

Why do I need a hitch assembly for walk-behind tractor tools

In order for the hiller to be fixed on the walk-behind tractor, in addition to the frame made, there must be a hitch assembly that is adjustable and reliable. By aligning the holes on the rack and on the hitch body and fixing, the implement will form a single unit with the unit.

In order for the hiller to be fixed on the walk-behind tractor, in addition to the frame made, there must be a hitch assembly that is adjustable and reliable. By aligning the holes on the rack and on the hitch body and fixing, the implement will form a single unit with the unit.

The handmade universal hitch makes it easy to adjust the tool to the working position. It is in this node that adjustments are made to the position of the rack relative to the ground, radial angles. After adjustment, the nuts are tightened and the device is adjusted to the type of soil, soil moisture, plant height.

How to set up a hiller of any design for work

Any mounted or trailed tillage equipment must be adapted. Before you start working in the field, you need to make sure that everything is set up correctly, secured and adjusted. A test site is selected and a test run is made. At this point, you should listen to the technique, check the stroke profile, the distance between the grips. On the disks it is necessary to set the angles of attack, on the listers - the depth.

Any mounted or trailed tillage equipment must be adapted. Before you start working in the field, you need to make sure that everything is set up correctly, secured and adjusted. A test site is selected and a test run is made. At this point, you should listen to the technique, check the stroke profile, the distance between the grips. On the disks it is necessary to set the angles of attack, on the listers - the depth.

It is important to choose the processing speed that would correspond to the power of the mechanism and the quality of the field processing.

Video about disk hillers for walk-behind tractors