How to make a threshold in the country from the boards. Making a wooden porch in a private house. Step-by-step instructions for building a chopped log porch

To choose the right porch design for a private house, you need to evaluate your budget and needs, as well as consider photos of various ready-made solutions. Dekorin completed the last task for you: in this article, you will find out what a porch for a private house can be like in terms of its shape, materials and finishes with 40 examples of photos.

Porch in a private house - beautiful options with photos

The dimensions and shape of the porch to the house, as a rule, are dictated by the architectural features and dimensions of the building itself, as well as the personal preferences of its owners. In particular, designers agree that the canopy and porch railing should be made in the same style as the roof and balconies of a private house. For example, if the roof of the house is gable - the canopy over the porch should be the same. And if you ordered forged balconies or grilles for windows, then at the same time take care of the railings - so that they have the same forging patterns. Similarly, you should select the design of columns, arches and other decorative elements.

However, in the photos below you will see that the most interesting facades with a porch to the house were made just with the avoidance of these general rules. But first, let's look at the main design options for the porch:

- Open - the most common type of entrance to the house; it can have a visor and railings, as well as be decorated with decor that is brought into the house in winter;

- Closed - has transparent or translucent walls made of glass, polycarbonate or a simple mosquito net; designed to decorate the entrance to the house, rest at any time of the year or use as a preliminary hallway;

- Mounted - made when private house has a basement or when its necessity is justified by the landscape around the building; its design is often similar to a balcony;

- Porch-terrace - an extended version of the porch, used for outdoor recreation;

- The shape of the protrusion: rounded and rectangular.

Finally, you also have to choose the materials from which the porch for a private house will be made. Today, most porch structures are made from concrete, which can then be painted, tiled, stone, wood, etc. Other common materials are wood, metal, stone, and brick. Let's take a closer look at them!

Wooden porch to the house - ecology and comfort

The most common option today is wooden decking for the porch, which are installed on a concrete, brick or metal base. In 80% of cases, a wooden porch is made from pine, as the most common and cheapest material. With proper sealing, varnishing, and painting, your wood porch will look good for many years to come. In the following photos you will see options on how to make a porch for a private house made of wood.

Concrete porch - strength and variety

Concrete is the cheapest, most versatile and reliable material for building a porch. Firstly, the concrete porch is monolithic and does not loosen over time, as happens with wooden structures. Secondly, it is easy to repair and decorate with any decor. And finally, it can be given absolutely any shape, while it will not particularly affect the cost and duration of the project.

Most often, a concrete porch is finished with clinker or other tiles, less often with stone, paint and other materials. IN modern houses with wood, brick and siding facades, it is often left uncoated to bring out the color and texture of the walls and environment. We look at the photo, what a concrete porch might look like.

Brick porch - reliability and unpretentiousness

A brick porch will be more expensive, but also a very attractive and reliable solution for a private house. Its installation will take quite a lot of time and labor, however, in long term it will fully pay off due to its unpretentiousness in care. Note that quite often a brick porch has a concrete base and / or a step cover.

Chic stone porch - an expressive classic

Natural stone is a very strong, durable and beautiful material for porch decoration. There are many various kinds stone, some of which are used to create the foundation, others - to decorative finishes. Accordingly, the first of them are more expensive and reliable than others. In general, any stone resists well to any weather conditions and does not require Maintenance for a long time.

Wrought iron finish and metal porch

As a rule, under a metal or forged porch, they mean decorative elements of the porch - a roof, steps and railings made of metal. However, sometimes you can see completely metal porch for a private house, as in the following photo.

The main advantages that such a metal porch has are high strength and durability. The only point: you will have to spend extra money on its painting and anti-corrosion treatment. In addition, the metal floor is rather cold, which is why this material is not used for terraces intended for relaxation. In them, a metal base is covered with wood or a concrete base is used.

Finishing the porch of the house with tiles and polycarbonate

Tiles can be installed on a concrete and brick porch when it is necessary to increase its attractiveness or equip it with a recreation area. The modern choice of tiles allows you to find very stylish models in wood, stone and other effects. Particularly popular today are outdoor porch clinker tiles and bright tile designs with patterns in Moroccan and geometric styles.

Visor over the porch made of polycarbonate

Polycarbonate is inexpensive, highly flexible and light material, which trim the walls and canopies above the porch. Usually it is mounted on a metal base and pasted over with a sun-protection film. The most economical and easiest way to create a canopy over the porch of a private house from all available for 2016! And it looks good:

You have viewed 40 photos on the topic of what a porch for a private house can be. We hope you enjoyed it. Leave your comment below so that we can improve our articles and delight you with even more interesting materials!

Beautiful porch for a private house - 40 photos updated: May 31, 2018 by: Margarita Glushko

We will send the material to you by e-mail

TO The stigma is a functional element of any household and is its hallmark. Such a structure should be located at the entrance to the building and fit into the created exterior of the building. By choosing the right material, you can build a luxurious porch to the house with your own hands. Projects, photos and design drawings can easily be found in our review. In addition to practical functions, this structure performs a decorative function. At the same time, the canopy and railings are decorated with beautiful carvings and other decorative elements.

In many buildings, the porch is part of the project and fits perfectly into the overall exterior.

The porch in a private house, photos of which can be viewed on the site, is an open area with a staircase in front of the entrance to the house. It can be of any shape, and also made of various materials.

Such a structure can be made in the following variations:

- the structure of the attached type is more mobile.

Useful information! To avoid skewed steps and cracks, a foundation must be installed.

Foundation: construction features for all types of porch

A strong foundation is needed to make a porch to the house with your own hands. Designs, photos and descriptions will help create a quality foundation.

The depth of the foundation for the porch and the house must be the same, otherwise the smaller structure may be displaced. The type of foundation depends on the material of the main structure. If brick or concrete is used, then the base must be reinforced. Foundation installation begins with markings. Piles are driven into the corners of the resulting rectangle, and then a trench is made along the contour. For a large visor, you will need to install additional supports. Formwork is recommended. For it, boards, or chipboard, are used. It is also important to make waterproofing. In this case, the bottom of the pit is covered with roofing material. For reinforcement, bricks and a special mesh or are used. Then the concrete mixture is poured. Each layer of the solution must be rammed with a shovel.

Useful information! After pouring, the foundation surface must be leveled and covered with roofing material. To the surface concrete pavement moisture must not get in in case of rain.

Related article:

Do-it-yourself porch to the house: projects, photos of various types of porch

They will help you choose the best design of the porch of a private house with photos that can be found on the site. In this case, it is worth deciding on the material for the future design. Traditional options include wood, concrete, stone and brick, or metal.

Metal structures: the nuances of the device

Metal products are mounted using electric welding. The design is assembled from standard parts. If desired, you can use forging elements for a metal porch in a private house. The photo will allow you to choose interesting solutions.

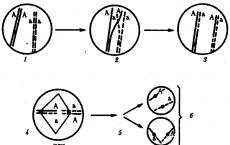

Such a design is mounted in several stages:

- two channels are laid in parallel at a distance of future steps. Then a corner is cut to the size of the steps;

- a part equal to the height between the steps is cut off from the corner. Both elements are welded in the form of the letter G;

- L-shaped parts are attached to the channel;

- then the channel is connected using corners.

Ready. Steps made of any material are mounted on it. If more than three steps are provided, then railings are mounted. The visor completes the design.

Concrete options: design features

The concrete structure involves the continuation of the foundation in the steps. In this case, reinforcement is used, which will prevent the appearance of cracks. Such a structure requires additional cladding with stone or tiles.

Formwork is made for each step. The finished structure is covered with decorative material.

Useful information! The space between the foundations of the main building and the extension is sealed with mineral wool, which ensures better stability of the structure.

Do-it-yourself wooden porch for a private house: installation features

Do-it-yourself wooden porch to the house is popular. Projects and photos of such structures are diverse. best material larch and other conifers are considered. For such raw materials, special protective impregnations are required.

Installation of a wooden structure consists of the following steps:

- the manufacture of stairs includes the formation of a bowstring. These elements are connected to the base;

- installation of the site consists of mounting the shelf boards to the finished base;

- steps are being installed. At the same time, steps and risers are attached with the help of self-tapping screws;

- the design is carried out with the help of railings and a canopy.

Useful information! The durability of the structure depends on the correct preparation and processing of wood. The material must be well dried.

Related article:

Porch made of brick or stone

It is very difficult to make brickwork for the porch, since the brick must be laid out perfectly evenly. It is even more difficult to lay a stone porch without certain skills. The chipped edges don't fit together.

TO simple options includes the construction of a staircase made of concrete and facing it with stone or brick.

Visor options

An important addition to the extension is the canopy over the porch. The photo on the site allows you to see interesting options this element.

The visor is created from timber, metal, plexiglass or metal pipes. Wooden structures must be treated with special solutions every 2-3 years so that the wood does not deteriorate.

The visor should at least protrude half a meter beyond the area of \u200b\u200bthe main structure. Piles for the canopy supports are mounted at the stage of creating the foundation. Polycarbonate, plexiglass or tiles can be used as a coating. This element must have a pitched shape.

Useful information! A wooden structure or metal sheets can be coated with paint in several layers.

Which porch is better: glazed or open?

A closed porch is often used for a private house. Photos of projects can be found on the Internet. Most often, these are transparent structures made of metal and glass. The frame and piles are made of metal. The walls are made of glass. A roof of this design can be combined with a balcony on the second floor.

The glazed version is made with a concrete foundation, a canopy and a staircase. The frame is made with the help of corners. In this case, the corners are attached to the installed piles.

Save Time: Featured Articles Every Week by Mail

Porch country house most often erected from metal, wood or concrete. The choice of a particular material depends mainly on the architectural features of the building itself. For each of the varieties of street stairs, there are construction technologies.

They will be discussed in this article. You will learn not only how to properly make a porch to a house from one material or another, but also how to tie it to the foundation of the house and what its own foundation should be.

The choice of material for the porch

The choice of material for the porch to the house mainly depends on what its walls are built from. So, at the facade of a wooden building, it is best to build a structure of boards and timber. to concrete or brick house can be attached concrete or metal structure. Tiles, bricks, wood or even plastic are often used for decoration:

Porches made of wood for a country house

Porches made of wood have a number of undeniable advantages. They are beautiful and practically do not require additional finishing. Such designs are somewhat cheaper than other varieties.

Construction of a porch to the house. Photo of an aesthetic and not difficult to manufacture design

Wooden street stairs are usually attached only to a chopped or cobbled building or to a bathhouse. But there are exceptions to every rule. The simplicity of the design of such stairs makes them extremely popular and often a carved or ordinary wooden porch can also be seen near concrete or brick houses.

A wooden staircase can be attached, including to a concrete house

Is it worth making a porch out of concrete?

Concrete porch options can be filled. They are also built from blocks. Such a design can be made at the entrance to a concrete or brick building. The main advantage of a concrete staircase is durability. How to fill the porch with your own hands and how to make it from blocks will be discussed below.

Concrete marches look very beautiful and at the same time solid and solid

Metal constructions

Do-it-yourself metal porch at the dacha It is best to make it from a corner or a profiled pipe.

On a note: Very beautiful designs are obtained from galvanized material. However, making them at home is hardly possible. In order to make such a ladder, considerable experience in working with a welding machine is needed. Therefore, at the entrances to private houses, you can often see painted metal structures made of ordinary steel.It is better to make the steps of street stairs made of metal wooden. In some cases, they are made of metal.

Using wooden steps, you can build a very beautiful metal porch.

You can build a porch in a country house or in a country house using different technologies. The choice of a specific one depends on what material will be used for its manufacture:

Assembling a wooden outdoor staircase

First, consider how to make a porch with your own hands to wooden house. To build even the simplest wooden porch so that it turns out to be reliable can only be done by drafting a project. In this case, the calculation of the stairs should be performed taking into account the following factors:

- The angle of inclination of a comfortable march varies from 27 to 45 degrees;

- The width of the step should be approximately 30cm, height 17cm;

- The height of the railing should not be less than 90cm.

How to build a porch with your own hands. Drawings of comfortable street stairs

To make a simple wooden ladder, you will need to prepare the following materials:

- Edged board for steps and stringers;

- Beam at least 80*80mm. From it it will be possible to make porch supports;

- Board 3cm for a bowstring or stringer;

- Beam 50 * 50mm in order to make a railing and a canopy frame;

- Board 2cm for sheathing the visor.

They continue to build a wooden porch with their own hands by installing supports. To make them durable, it is worth treating their ends with automotive oil. Under them, in the ground at a distance from the wall equal to the width of the upper platform, they dig holes about half a meter deep.

A durable porch can only be built with reliable supports.

At the next stage, the upper platform is knocked together. Next, you will need to make strings or bowstrings. At one end of the kosour, they are attached to the upper platform, and at the other they rest on a concrete pad. Then proceed to stuffing the treads and risers.

Wooden porch with their own hands. Photo of the process of installing steps on stringers

Advice: Steps during construction wooden stairs it is better to fix a private house not on self-tapping screws, but on bolts with nuts. Weak fasteners from a constant load in the future simply simply loosen up.So, we have examined how to build a wooden porch with our own hands in stages. However, without a railing and a canopy, the design will be unfinished. Balusters are mounted on metal studs. Next, the handrail is attached to the bolts. After that, you need to make a visor by sheathing a wooden frame with boards.

Making reliable railings with your own hands when building a porch is not so difficult.

How to build a welded metal porch

Now let's figure out how to build a porch to a metal house. The technology of erecting such structures is slightly different from the method of assembling wooden ones. Install supports from a pipe, angle or from a profile of at least 50 * 50mm. Next, you need to make the frame of the upper platform. The bowstring should be made from a channel or corner.

A porch to a metal house can be made using welding machine

During the construction of the porch, the steps are welded from the corner in the form of frames, to which the racks are welded along the height of the riser. Further, the resulting elements are welded to the bowstrings, to their upper edge. Then the edged board is screwed to the corner.

Since metal is a material that does not tolerate moisture, a canopy must be made. You can equip a porch with your own hands made of metal, for example, with a visor made of profiled sheet. In this case, the frame should be made of a steel corner.

The construction of a metal porch involves the mandatory installation of a visor

If you like arched, domed or curved canopies, polycarbonate can be used instead of a metal profile. You can make a curved frame yourself using a pipe bender. Polycarbonate sheets are attached to it with self-tapping screws with thermal washers.

From polycarbonate you can make a visor of a very interesting shape

Important: Holes for fasteners should be slightly larger in diameter than their rods. The self-tapping screws themselves do not tighten too much when installing the sheet, since polycarbonate sheets expand with increasing temperature.How to build a concrete march

A concrete porch should be attached to the stone building. With your own hands, you can make it filler or block.

Monolithic porch. How to build

When building a porch from monolithic concrete, formwork is used. Its form depends on the chosen form of the march itself. It is easiest to make it from the board, and it is a multi-tiered structure (by the number of steps). All steps must be reinforced. The concrete mixture is made from cement, sand and crushed stone in a ratio of 1 * 4 * 4.

To build a concrete porch, you need to make a multi-tiered formwork

On a note: A semicircular, round or oval concrete porch looks very nice. In this case, during construction, the formwork can be made of tin or plastic.See below how you can build a porch with your own hands (video):

How to build a block porch

In order to make a neat porch of a country house from blocks or from foam blocks, marking should be done. Next is the foundation. The ladder is laid out with dressing of the seams. After construction, a block structure, just like a monolithic one, must be tiled or boarded. In this case, you will get not only a solid, but also a beautiful porch.

The porch can also be built from concrete blocks.

Approximately according to the same technology, a do-it-yourself porch is made of brick or stone.

How to tie a ladder to a house

In the event that the porch of a village house is arranged during its construction, it is poured simultaneously with the foundation of the building.

Important: At the same time, the foundation of the street staircase is laid to the same depth as the foundation of the house itself.

It is best to build a porch at the same time as the building itself

However, more often the march is tied to the building after it has been erected. In this case, you should follow the rules for attaching the porch to the basement, which will be discussed below.

Concrete stairs. How to build a reliable

When attaching the porch of a private house with your own hands, it is worth remembering that heavy structures are not recommended to be fixed rigidly to the foundation and plinth. In this case, roofing material or polyethylene is laid between the march and the house. It can also be plywood or boards impregnated with bitumen. The fact is that an extension is usually made to a house that has already shrunk. A heavy concrete or brick staircase will definitely sit down.

Iron and wood deck

In the event that you make a porch with your own hands from wood or metal, you can attach it directly to the plinth. At the same time, bars or a metal corner are nailed to the wall during construction. A wooden frame or an iron frame of the upper platform is attached to them with one edge.

You can build a metal porch by attaching it directly to the house

What can be the foundation of the porch

How to properly attach a porch to the house with your own hands, we hope now you understand. Only one question remained unconsidered, namely, what should be its foundation. Under the street stairs, you can make a base of different types.

concrete pad

Under light wooden and metal stairs during their construction, a small concrete cushion is usually arranged. Next, let's see how to fill in such a support. They do not lay it on the entire width of the porch, but only under the first step of the march. Thus, it serves as a support for stringers or bowstrings. Its installation is carried out as follows:

- In the place where the ends of the stringers will subsequently be located, a square pit is dug out to the width of the porch. Its depth depends on the weight of the structure of the outdoor ladder and is usually 30-40 cm;

- Formwork from boards is installed in the pit. Further, sand or gravel is poured on its bottom with a layer of 10 cm;

Do-it-yourself porch. Photo of the process of arranging a concrete cushion for a march

- After that, the bottom is poured with a three-centimeter layer of cement mortar;

- A reinforcing cage is installed on the resulting support, which can be made from a 12mm bar;

- Next, the formwork is filled with concrete mix. At the same time, four parts of sand and the same amount of crushed stone are taken for one part of cement grade 300-400.

- At the last stage, the surface of the filled pillow is carefully leveled. In this case, it will be possible to build the most stable porch.

If a wooden or metal staircase has a very wide or long flight, it is worth building a thicker pillow. Wooden or concrete pillars the upper platform should at the same time have a thickening at the very bottom.

The concrete pillow under the porch can be quite large. You can build it, including the number and steps

Column foundation under the porch to the house

Sometimes wooden ladders are simply supported on poles during construction. At the same time, in addition to the supports of the upper platform, two more wooden posts are dug into the ground under the march (instead of a concrete cushion). In the same way, you can make supports for the bowstrings of a metal staircase from pipe segments. Such a foundation is cheaper than a pillow and its construction is simpler, but at the same time it is less reliable.

You can build a porch with different types pillars

Strip foundation

The porch device is technologically rather complicated if it is built into the veranda. In this case, most often during construction, a strip foundation is completely poured under the entire structure.

Do-it-yourself porch. Photo of a foundation pit for a strip foundation

This event consists of several stages:

- After the markup is made, a trench is dug around the perimeter of the veranda;

- Sand is poured on its bottom;

- Further, formwork is installed along the edges, which can be made from a board;

- Then, bars 5 cm thick (reinforcement supports) are laid at the bottom of the trench;

- The armature is knitted from a 12mm rod;

- After it is installed in the formwork, the latter is poured with a concrete mixture of the same composition as for a simple concrete pad;

- Formwork can be removed a day after pouring.

How to build a porch. Filling the strip foundation

Important: The veranda and the march itself are erected no earlier than two weeks after the foundation is laid.How to build a slab foundation

Let's see how to make slab foundation under the street stairs. This type of foundation is arranged under heavy structures - concrete and brick. He represents himself monolithic slab under the entire area of the stairs. It is poured in about the same way as a pillow. The depth of laying depends on the depth of the foundation of the building. Usually it is 50-70cm.

The slab foundation under the porch is not very difficult to make.

On a note: The thickness of the sand or gravel layer according to SNiP must be at least 10 cm.So, now you know how to build a porch with your own hands. Depending on its type, different methods can be applied. Under light street stairs, you can make the foundation cheaper and simpler. Heavy structures require more reliable foundations.

Any happy owner of a suburban area rejoices at the opportunity to take a break from the bustle of the city in nature. For creating comfortable conditions existence, you need a beautiful, warm, spacious house, a bathhouse, outbuildings.

Without the construction of a structure, it will not work out. The appearance of the building largely depends on how the entrance group is framed. Consider what the porches of houses can be, what they can be built from, and also we will analyze how to make a porch in the country with your own hands.

Finished building

For almost all buildings, the front door to which rises above the ground, the porch in front of it is required attribute. It should perform two functions: decorative ̶ to be a decoration of the facade and practical ̶ to ensure comfortable and safe movement, as well as protect the entrance group from the influence of adverse external factors.

Components:

- Ladder. This is the main element of the porch structure.

Requirements for stairs and their components are prescribed in SNiP 31-02-2001 "Single-apartment residential houses", GOST 8717-2016 "Concrete and reinforced concrete steps", SNiP II-25-80 " wooden structures”, GOST 23120-2016 “Stairs marching platforms and steel railings”.

In individual buildings it is allowed to deviate from the current standards. With their device, the owners can focus on their own taste and ease of use for family members and guests.

The parameters of the stair elements, allowing you to move comfortably along it, are as follows:

- Ladder width: at least 90 cm.

- Step depth: 25-33 cm.

- Riser height: 15-20 cm.

- The angle of inclination of the stairs should not exceed 45 degrees.

- Area.

The platform must be below the edge front door by 5 cm. Its dimensions for convenient opening of the door: length not less than 1 m, width ̶ one and a half widths of the door leaf.

- Canopy or roof.

The canopy must withstand wind and snow loads, protect people and the entrance group from precipitation and the scorching rays of the sun.

- Walling.

Fencing must be continuous, equipped with handrails at a height of at least 0.9 m, withstand loads of 0.3 kN / m. When installing baluster racks, it is recommended to leave a distance of no more than 20 cm between them, and in the presence of small children, no more than 15 cm.

There are many manufacturing options, however, a staircase, even if it consists of two or three steps, and a small platform must be present.

The main elements of the porch structure are shown in the photo:

Components

Kinds

Let's take a look at the various options.

Structures can be classified according to the following criteria:

Construction example

- According to the foundation. The building can be built on a common foundation with the building or be an extension on a separate one.

Building on a separate foundation

- By design form.

There are a huge variety of species: from simple, rectangular or semicircular, to the most complex, sometimes even bizarre shapes.

- By operating time. The building can be built for a while, for ease of lifting into a building under construction or as a durable structure.

Temporary facility

- Organization of entry in the building of the structure can be made with one or two side lifts.

But the most popular options are with a front entrance to the house.

Straight lift option

- According to the degree of protection of the site in front of the door. Buildings can be equipped with sheds, fences, have completely blank or only partially closed walls.

Fully enclosed type

The choice of design is often determined by the material capabilities of the owners, the requirements that apply to the porch structure (provide protection from falls, bad weather, prying eyes).

Open with canopy

The site can be used not only to enter the building, but also to create additional recreation areas. If size allows, the building can be turned into a cozy terrace or veranda for gatherings with family or friends.

Terrace option

By equipping the terrace with wicker furniture, decorating with decorative elements: curtains, flowers, lanterns, you can completely transform the look of the building.

- Looks like stairs. It can be monolithic or arranged on guides (kosoura and bowstrings).

These elements can be replaced by a frame or a cast structure made of reinforced concrete.

- According to the material from which the structure is made.

The design of the building must be in harmony with architectural style the entire building. You can immediately choose the right materials and not use the cladding, or first make the base structure, which is then finished in accordance with the overall design of the facade.

Materials for porch structures

Here are the most used materials for stairs by builders:

- Wood. This material is still one of the most popular for summer cottages. Its great advantage is accessibility, aesthetics and the ability to make a porch on your own.

wooden type

A wooden structure is the best fit for a building also built of wood.

Important! Particular attention should be paid to the careful treatment of wood from fire, moisture and insect damage.

- Metal. The structure of this material has many significant advantages. Structures made of it are strong, durable, but do not forget about periodic corrosion treatment.

This type can be ordered from the manufacturer, however, if you have an idea about the operation of the welding machine, then it is quite affordable to build a simple structure with your own hands. Without finishing, the metal does not look very attractive.

For cladding, wood, WPC, tiles of various types are often used. Forged elements give a special charm.

metal application

- Brick. Another type of material, the use of which will ensure the durability of the extension to the house. With ideas about brickwork, a beautiful brick structure with your own hands in the country is quite simple to build.

Application of brick

The brick structure will look perfect on the facade of a building lined with bricks or blocks. A very interesting option would be to move away from straight lines in the form of steps.

- Blocks. Blocks of various types are less commonly used in the construction of porches, but this option also has a right to exist.

application of blocks

The porch, built of blocks (like the whole house), needs to be finished, because of the not very attractive appearance.

- Concrete. The concrete structure, made according to the technology, will last a long time. It is durable, safe, weather-resistant. The appearance of such structures, of course, leaves much to be desired, however, when using facing materials, you can get a real work of art.

concrete type

Cladding materials

Facing material serves to give the extension an attractive appearance, and also ensures its durability. It must be durable, unaffected by the weather, safe (non-slip).

As finishing materials, you can use: siding, WPC, wood, brick, tiles of various types, panels, natural and artificial stone.

Materials for fences and canopies

- Railing. Fences for the porch structure perform a protective and decorative function. They protect people from falling and give attractiveness.

Fences can be screen and lattice. The materials for their device can be: glass, WPC, PVC, metal, polycarbonate, wood, stone.

- Roofs and awnings. To ensure a comfortable stay of people in any weather, as well as to protect the entrance group from precipitation and sunlight, visors or roofs are installed over the structure.

Canopies are mounted either directly to the facade or supported by vertical supports. The type of fastening depends on the area and weight of the structure itself and the condition of the building wall (the ability to withstand loads).

The frame of the canopies is usually made of wood or metal, and the canopies themselves can be made of glass, polycarbonate, metal, metal tiles, slate, soft roofing materials.

When arranging a canopy, a drainage system should be provided to protect against excess moisture and provide comfort to people.

Having familiarized ourselves with the possible designs of the porches and the materials for their manufacture, we will consider options for how to make a building in the country.

Construction

For a more complete acquaintance with how to make an extension of this type to a country house yourself, a video is offered in this article:

So:

- Preparatory work. You should start with preparation, which includes: choosing a design (including the type of foundation), taking measurements, selecting materials, making a drawing, clearing the territory.

Sketch example

- Purchase of materials.

- Foundation device. The foundation can be pile, slab, tape and columnar. When choosing the type and depth, the type of soil, the level of groundwater, and the massiveness of the structure should be taken into account. It should be noted that for concrete structures and brick porches, the foundation must be solid. On top of the finished foundation, you must not forget to lay waterproofing.

Strip foundation

Important! The foundation must not come into contact with the foundation of the house. For insulation, a special layer is used, for example, from mineral wool.

- We are building. Consider the most popular options.

wooden porch

Manufacturing instructions:

- For work you will need: bars for supports (100x150 mm), logs (their thickness is determined by the size of the platform and the load on it), boards for stringers (50x300 mm) and steps (35-40 mm in thickness), material for flooring the platform, balusters, handrails, fasteners. All wooden parts must be impregnated with flame retardants and antiseptics.

- The platform frame is mounted. For this, vertical supports are installed, as shown in the photo. When the supports are immersed in the ground, in dug pits (at least 50 cm deep), a pillow of sand and gravel is arranged, then flat stones are laid. Beams are installed according to the level. After that, the remaining space is filled with cement mortar.

Important! The solution must be completely dry.

The height of the vertical beams is leveled. Logs are laid on the supports using a spike / groove connection or special stainless steel brackets.

- A ladder is being installed in the country house. Stringers are attached (with pre-cut recesses for treads and risers). The upper end of the stringers is fixed on the beam, the lower end is best attached to the foundation.

Design

- Risers and treads are fixed to the stringers with self-tapping screws (you can additionally smear the joints with glue).

- With the help of self-tapping screws, the platform flooring is laid.

- Railings are being installed. To do this, support poles are mounted in the corners. A bar is stretched between them, to which racks are attached, fixed from above by handrails.

- If required, a canopy is installed.

wooden view

concrete type

Building a concrete porch takes a lot of time, so you have to be patient.

For its manufacture, you can use a ready-made solution or prepare a mixture yourself. The problem of how to make a pouring solution with your own hands is not difficult to solve: you will need a concrete mixer, cement grade not lower than M400, river sand, crushed stone and water. The mixture is diluted with water, starting from the ratio: cement (part), sand (2 parts), crushed stone (2 parts).

- Formwork installation. This is the most important point in the manufacture of concrete extensions. Boards, plywood, chipboard, sheet metal or plastic are used (if rounded shapes are required). Formwork elements must be firmly fixed. wooden elements it is recommended to cover with drying oil to facilitate dismantling.

formwork

- Reinforcement. For this, reinforcing bars with a diameter of 10 mm are used, which are connected to each other at a distance of 10-15 cm, or metal grid. In order for the armature to be in the "body" concrete structure, it should be laid on stands, the role of which can be played by broken bricks. Broken stones and bricks can also be placed inside, they will increase strength and save mortar. If railings are subsequently installed, embedded elements can be installed.

- Pouring concrete. The prepared concrete is poured into the formwork. To compact the mixture, it is worth processing with a deep vibrator. The surface is leveled by the rule.

After that, the structure should be covered with a film. Formwork material can be dismantled a week after pouring, all other work must be left until the structure is completely dry (one month).

Concrete view

For finishing a concrete structure, materials are used, which were described above. If planned by the project, fences and a roof are installed.

The article reviewed possible options devices of porches for summer cottages, as well as tips on how to build a porch at the dacha with your own hands.

A wooden porch is considered the best solution for your home. A wooden porch is relatively inexpensive and easy to manufacture in relation to porches made of other materials. But very often people wonder, how to make wooden steps for the porch of the house with your own hands?

And in this case there are some nuances that must be taken into account when designing and building. We'll talk about this further.

- Open.

This staircase design does not have a riser

This design creates a feeling of airiness and stairs.

- Closed.

This design of the stairs has risers.

This design assumes steps closed in height.

- Straight staircase. This type of staircase has the most simple form and standard steps.

- winder ladder.Steps have an uneven tread size.

- Radial. This type of staircase has steps round shape, they increase in length relative to the central axis.

Step calculation

- grinding machine;

- a circular saw;

- pencil;

- ruler.

The thickness of the boards for steps should be from 30 to 40 millimeters.

We make steps from wood

Do-it-yourself steps made of wood for the porch, cut out according to a template, put it on the board and circle it with a pencil. Only after that, the same steps are cut out with an electric saw.

After completion of the work, wear-resistant is applied to the finished steps. Then proceed to the collection of the stairs themselves.

Steps for a wooden outdoor porch can be attached:

- to stringers;

- to bowstrings;

- patients. This is the most difficult way, which requires a certain skill.

When assembling stairs with your own hands, it is best to use the first two methods of fastening steps.

Fastening steps to stringers

Fastening steps to stringers, suggests a number of options for:

Fastening steps to the bowstring

If you fasten the steps to the bowstring, they fixed in the following ways:

- With the help of wooden bars;

- With the help of metal corners;

- into deep grooves. Steps for the porch, at the joints are glued with glue.

Wooden steps on a metal staircase

Installation of wooden steps on a concrete staircase

A concrete staircase is a reliable and durable construction, but not distinguished by its beautiful appearance. Wood cladding allows you to give the design an excellent decor.

But in this case, the product turns out to be quite expensive, twice as expensive as completely made from solid wood.

But in this case, the product turns out to be quite expensive, twice as expensive as completely made from solid wood.

Before making a porch with steps made of wood on, it is necessary to correctly calculate the stairs, including the dimensions of wooden boards in the overall dimensions of the structure.

To facilitate installation, it is necessary to carefully prepare the formwork.

Features of mounting steps on a concrete base are as follows:

The frame from should dry well. The raw composition, due to high humidity, may begin to deform, and crumble after drying;

The frame from should dry well. The raw composition, due to high humidity, may begin to deform, and crumble after drying;- After manufacturing, the ladder should remain at rest, preferably 90 days;

- After complete drying, the lining of the structure is performed;

- All irregularities, distortions are leveled with a screed. If the irregularities are too large, self-leveling compounds are used;

The surface is thoroughly cleaned and primed;

The surface is thoroughly cleaned and primed;- Sheets are glued, which will finally level the concrete surface and provide moisture-proof insulation. Plywood is glued with a special mastic and fixed with dowels;

- Wooden steps are being installed. To connect the tread and riser, grooves are cut in each part;

- The installation of steps begins with the first, lowest riser. To fix it on the floor, bolts are screwed into the end of the step so that they protrude by 6 cm;

Hats are cut off;

Hats are cut off;- Bolt installation locations are marked on the floor;

- Holes are drilled and filled with epoxy;

- Risers are fixed;

- From above, on the plywood previously smeared with glue, a tread is placed with the next riser attached and fixed with self-tapping screws and glue;

- A load is placed on the step until the glue hardens.

Decorating wooden steps

Wood is the most capricious building material.

In addition to ecological cleanliness and beauty, it also has significant shortcomings:

To increase the service life, steps should be treated with all kinds of compounds.

The order of work is as follows:

Wooden steps for the porch, with their own hands and on any basis, allow the design to give an attractive and original look. And additional processing with protective coatings will increase their service life.