Maximum length of the underfloor heating circuit pipe. Warm water floor - the maximum length of the pipeline. What should be the diameter of the pipes from the boiler to the collector

The device of warm water floors in a private house has many nuances and other important points that need to be considered. In this article I will tell you how to make the right warm water floor. I will describe the main points that installers and customers miss.

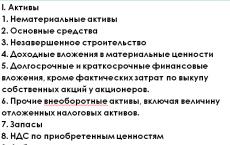

Content

1. The thickness of the screed for a warm water floor

Pipe manufacturers are misleading people by offering 25, 30 or 35 mm screed height over the pipe. Installers are confused in the testimony. As a result, the underfloor heating does not work correctly.

Remember: According to SP 29.13330.2011 clause 8.2, the optimal thickness of the cement screed should be at least 45 mm above the pipeline.

Simply put, if we use a RAUTHERM S 17x2.0 pipeline with a height of 17 mm, then 45 mm above the pipe should be a screed. The minimum thickness of the screed for underfloor heating above the insulation is 62 mm.

With a decrease in the thickness of the screed, the risk of cracks and chips increases. Underfloor heating pipes expand and contract under the influence of temperature. With the height of the screed, we compensate for such temperature deformations. In practice, reducing the height of the screed leads to a sensation of temperature differences on the floor surface. One section of the floor is hotter, the other is colder.

Some of my customers want to play it safe and increase the maximum thickness of the screed to 80 mm, thereby greatly increasing the inertia of the system and heat consumption. The warm floor reacts with a great delay to changes in the air temperature in the room and consumes more heat to warm up additional centimeters of the screed. By the way, for the underfloor heating system, I recommend using a concrete grade not lower than M-300 (B-22.5).

2. Insulation for a warm water floor

In a warm water floor system, it uses only 1 of 3 types of insulation: extruded polystyrene foam with a density of more than 35 kg / m 2. When purchasing, be sure to check the type and density of the insulation. It is important!

Regular polystyrene foam is not suitable for underfloor heating. It is very brittle, has a lower density than polystyrene foam. The use of foam in a warm water floor system will cause the screed to sag. The use of foam as a heater is prohibited.

Foamed heaters will not withstand the weight of the screed and will shrink from 10 cm to 1-2 cm. Sometimes installers advise expanded clay backfills instead of insulation for underfloor heating. The option is working, but significantly increases the load on the floors. Expanded clay is 12 times heavier than expanded polystyrene, and retains heat 5 times worse. The mass of 40 mm expanded clay backfill is 3.7 kg / m 2.

The task of the insulation in the underfloor heating system is not so much in thermal insulation as in compensating for thermal expansion of pipes. The pipe is pressed into the insulation under the influence of temperature and does not deform the screed.

The underfloor heating cake is determined by the thickness of the insulation. The height of the insulation must be at least 50 mm in private houses. In the interfloor ceilings of apartments, a warm floor is often mounted on a foil substrate - multifoil without using a full-fledged layer of insulation.

3. Deformation joint in the floor screed

The expansion joint in the floor screed is used in rooms with an area of more than 40 m 2 where one of the sides of the room is more than 8 m.

In such rooms, the distribution of the contours of the warm floor is carried out depending on the placement of expansion joints. The expansion joint must not cross the underfloor heating loops and can only pass through the supply pipes.

At the intersection of expansion joints, the pipes are laid in a corrugated pipe-sleeve 1 meter long. The separation of the room with expansion joints starts from the corners of the room, narrowing places and columns.

4. Floor covering for underfloor heating

The floor covering directly affects the heat transfer and the operation of the system. You can make a mistake with the thickness of the insulation, screed, laying step, but a mistake in choosing a floor covering will be fatal.

In I have already given calculations why a warm floor cannot be used for heating. And the main reason is all kinds of shelters, carpets, sofas, furniture.

For example: Ceramic tiles are 7 times better at dissipating heat than laminate and 20 times better than any textile flooring.

Porcelain stoneware coating in most cases compensates for errors with the choice of thickness of insulation, screeds, incorrect pipe laying steps and much more. Porcelain stoneware gives off heat 2.5 times better than ceramic tile, 15 times better than resin flooring and 17 times better than laminate.

When choosing flooring for underfloor heating, ask for a certificate marked "underfloor heating". This means that the material is certified for use with a warm water floor. Otherwise, if the coverage is chosen incorrectly, The floor dries out, the smell is released.

5. Pipe for a warm water floor

The heat-insulated floor does not allow joints and couplings. Loops of a heat-insulated floor keep within an integral section of a pipe. Therefore, the pipe is sold in coils of 60, 120 and 240 meters. Polypropylene pipes, pipes with threaded, coupling connections in underfloor heating systems for installation in a screed are strictly prohibited!

I am often asked which pipe to choose for a warm water floor. Cross-linked polyethylene is used as a material for underfloor heating pipes. I recommend 3 brands of underfloor heating pipe manufacturers for installation: Uponor - pePEX pipe, Rehau - Rautherm S, STOUT - PE-Xa / EVOH

The PEX pipe for underfloor heating is more plastic than its counterpart for heating.

The calculation of pipes for a warm water floor is reduced to determining the length of the circuit, the diameter and the pitch of the pipe, depending on the hydraulic balancing of the circuits.

The maximum length of the underfloor heating circuit should not exceed 80 meters. This pipe length corresponds to the maximum area of one underfloor heating circuit - 9 m 2 with a step of 150 mm, 12 m 2 - with a step of 200 mm, or 15 m 2 with a laying step of 250 mm.

At the same time, the minimum length of the underfloor heating circuit must be more than 15 meters, which corresponds to a floor area of 3 m 2. This requirement is very relevant for small bathrooms and bathrooms, where Customers try to make a separate circuit, and then wonder why the warm floor is either hot or completely cold. The underfloor heating thermostat for such circuits works jerkily and quickly fails.

The diameter of the pipe for a warm water floor is determined comprehensively for each collector cabinet, based on the requirements for pressure drop in the circuit - no more than 12-15 kPa and surface temperature - no more than 29 ° C. If one underfloor heating circuit turns out to be significantly longer than the other, then we can balance such circuits by changing the pipe diameter.

For example, our warm floor consists of 5 circuits 80 meters long, and 1 circuit - only 15 meters. Therefore, in a 15-meter circuit, we must significantly narrow the pipe diameter so that the pressure loss in it is comparable to 80-meter circuits. As a result: we mount 5 circuits with a diameter of 20 mm, and a 12-meter circuit with a 14 mm pipe. To calculate the underfloor heating system, they usually contact me.

6.Temperature regulator for water floor heating

The room thermostat in the underfloor heating system can be regulated both “by air” in the room, and “by water” - with a floor sensor. There are combined thermostats on sale that provide increased control accuracy, but also have increased requirements for the installation site.

A room thermostat for underfloor heating can control from 1 to 4 circuits, depending on the characteristics of a particular model. The thermostat is connected to the servomotors of the manifold assembly and regulates the power supply, due to which the servomotor opens and closes, regulating the flow of water in the underfloor heating circuit.

"Warm floors" are no longer perceived as a kind of exotic - more and more homeowners are turning to this technology for heating their residential properties. Such a system can fully take on the function of a full-fledged home heating, or work in tandem with classic heating devices - or convectors. Naturally, these features are taken into account in advance, at the stage of general design.

There are more than enough proposals for project development, installation and debugging of systems. And yet, many homeowners, according to the good old tradition, strive to do everything with their own hands. But such work "by eye" is still not done - one way or another, calculations are required. And one of the key parameters is the total allowable length of pipes of one circuit.

And since, in the conditions of an ordinary average private residential building, as a rule, a pipe with a diameter of 16 mm is quite enough for laying, we will focus on it. So, we are considering the question of what can be the maximum length of the underfloor heating circuit with a 16 pipe.

Why is it better to use a pipe with an outer diameter of 16 mm?

To begin with, why is a 16 mm pipe being considered?

Everything is very simple - practice shows that for "warm floors" in a house or apartment of this diameter is enough. That is, it is difficult to imagine a situation where the circuit does not cope with its task. This means that there is no really justified reason to use a larger, 20-millimeter one.

And, at the same time, the use of a 16 mm pipe provides a number of advantages:

- First of all, it is about a quarter cheaper than the 20mm counterpart. The same applies to all the necessary fittings - the same fittings.

- Such pipes are easier to lay, with them it is possible, if necessary, to perform a compact step of laying out the contour, up to 100 mm. With a 20mm tube, there is a lot more fuss, and a small step is simply impossible.

- The volume of coolant in the circuit is significantly reduced. A simple calculation shows that in a linear meter of a 16 mm pipe (with a wall thickness of 2 mm, the inner channel is 12 mm) holds 113 ml of water. And in 20 mm (inner diameter 16 mm) - 201 ml. That is, the difference is more than 80 ml per just one meter of pipe. And on the scale of the heating system of the whole house - this literally translates into a very decent amount! And after all, it is necessary to ensure the heating of this volume, which entails, in principle, unjustified energy costs.

- Finally, a pipe with a larger diameter will also require an increase in the thickness of the concrete screed. Like it or not, but at least 30 mm above the surface of any pipe will have to be provided. Let these "unfortunate" 4–5 mm do not seem ridiculous. Anyone who was involved in pouring the screed knows that these millimeters turn into tens and hundreds of kilograms of additional concrete mortar - it all depends on the area. Moreover, for a 20 mm pipe, it is recommended to make the screed layer even thicker - about 70 mm above the contour, that is, it turns out to be almost twice as thick.

In addition, in residential premises very often there is a “struggle” for every millimeter of floor height - simply for reasons of insufficient “space” to increase the thickness of the overall “pie” of the heating system.

A 20 mm pipe is justified when it is necessary to carry out a floor heating system in rooms with a high load, with a high intensity of people's traffic, in gyms, etc. There, simply for reasons of increasing the strength of the base, it is necessary to use more massive thick screeds, for the heating of which a large heat exchange area is also required, which is exactly what a pipe of 20, and sometimes even 25 mm, provides. In residential areas, there is no need to resort to such extremes.

It may be objected that in order to "push" the coolant through a thinner pipe, it will be necessary to increase the power indicators of the circulation pump. Theoretically, the way it is - the hydraulic resistance with a decrease in diameter, of course, increases. But as practice shows, most circulation pumps are quite up to the task. Below, attention will be paid to this parameter - it is also linked to the length of the contour. This is what calculations are made in order to achieve optimal, or at least acceptable, fully functional performance of the system.

So, let's focus on the pipe exactly 16 mm. We will not talk about the pipes themselves in this publication - that is a separate article of our portal.

What pipes are optimal for a water "warm floor"?

Not all products are suitable for creating a floor heating system. Pipes are embedded in the screed for many years, that is, their quality and performance characteristics there are special requirements. How to choose - read in a special publication of our portal.

How to determine the length of the contour?

The question seems to be quite simple. The fact is that on the Internet you can find a lot of recommendations on this matter - both from pipe manufacturers, and from experienced craftsmen, and from, let's be honest, absolute amateurs who simply "tear" information from other resources, not particularly going into subtleties.

So, in the installation instructions that manufacturers often accompany their products, you can find the established limit for the length of the circuit for a 16 mm pipe reaches 100 meters. Other publications show a border of 80 meters. Experienced installers recommend limiting the length to 60 ÷ 70 meters.

It would seem, what else is needed?

But the fact is that the contour length indicator, especially with a vague definition of “maximum length”, is very difficult to consider in isolation from other system parameters. Lay out the contour "by eye", just so as not to exceed the recommended limits - an amateurish approach. And with such an attitude, it is quite possible to soon encounter deep disappointments in the operation of the system. Therefore, it is better to operate not with an abstract “permissible” contour length, but with an optimal one corresponding to specific conditions.

And it depends (more precisely, it does not depend as much as it is closely interconnected) on a host of other parameters of the system. This includes the area of the room, its purpose, the estimated level of its heat loss, the expected temperature in the room - all this will allow you to determine the step of laying the circuit. And only then it will be possible to judge its resulting length.

So we will try to “unravel this tangle” in order to come to the optimal length of the contour. And then - check the correctness of our calculations.

A few basic requirements for the parameters of the "warm floor"

Before proceeding with the calculations, it is necessary to familiarize yourself with some of the requirements that a water floor heating system must meet.

- "Warm floor" can act as the main heating system, that is, fully provide a comfortable microclimate in the premises of the house and compensate for heat losses. Another option, more rational - it acts as an "assistant" to ordinary radiators or convectors, taking on a certain share in common work systems, increasing the overall comfort in the home. In this case, the calculation should be carried out in close relationship - the owners must decide in advance in what proportion the overall system will work. For example, 60% is taken over by the high-temperature radiator system, and the rest is given to the "warm floor" circuits. It can also be used autonomously, for example, maintaining comfort in the premises during the off-season, when it still (or already) does not make sense to “drive the entire heating system to full”.

- The temperature of the coolant at the supply to the "warm floor" is limited - a maximum of 55 degrees. The temperature difference at the inlet and return must be in the range from 5 to 15 degrees. A drop of 10 degrees is considered normal (optimally, it is desirable to bring it up to 5 - 7).

The following modes of operation are usually taken into account.

Table of modes of operation of the water "warm floor"

- There are quite strict restrictions on the maximum surface temperature of the "warm floor". Overheating of floors is not allowed for a number of reasons. This is an uncomfortable feeling for a person’s legs, and difficulties in creating an optimal microclimate, and possible damage to the finish.

The following limit values for surface heating have been established for different rooms:

- Before starting the calculations, it is advisable to immediately draw up an approximate diagram of the layout of the circuit in the room. There are two main pipe laying patterns - "snake" and "snail" with multiple variations.

A - the usual "snake";

B - double "snake";

B - angular "snake";

G - "snail".

The usual "snake" seems to be laid out easier, but it turns out too many 180-degree turns, which increases the hydraulic resistance of the circuit. In addition, with this layout, a temperature difference can be clearly felt from the beginning of the circuit to the end - this is well shown in the diagram by a color change. The disadvantage can be eliminated by laying a double snake, but such installation is already more difficult to perform.

In the "snail" heat is distributed more evenly. In addition, 90-degree turns predominate, which reduces head losses. But laying such a scheme is still more difficult, especially if there is no experience in such work.

The circuit itself may not occupy the entire area of \u200b\u200bthe room - often pipes are not laid in those places where it is planned to install stationary furniture.

However, many masters criticize this approach. Stationarity of furniture - the value is still quite arbitrary, and the "warm floor" is laid for decades. In addition, the alternation of cold and heated zones is an undesirable phenomenon, at least from the point of view of the possible appearance of pockets of dampness over time. Unlike electrical systems, water floors are not threatened by local overheating due to closed areas, so there should be no concerns from this side.

So there is no strict framework in this regard. It is possible, in order to save material, to leave unfilled areas, or to lay the contour completely over the entire area. But if at some site it is planned to install pieces of furniture or plumbing fixtures that require fastening to the floor (for example, fastening the toilet with dowels or anchors), then this place, of course, remains free from the contour. There is simply a high probability of damaging the pipe when installing fasteners.

Which contour laying scheme is better to choose?

More details about the choice of laying schemes, with theoretical justifications, are described in a separate article on our portal.

- The pipe laying step can be from 100 to 300 mm (usually it is a multiple of 50 mm, but this is not a dogma). Less than 100 mm is neither possible nor necessary. And with a step of more than 300 mm, the “zebra effect” can be felt, that is, the alternation of warm and cold stripes.

But which step will be optimal - the calculations will show, since it is closely related to the expected heat transfer of the floor and the temperature regime of the system.

- One more caveat - all subsequent heat engineering calculations are shown for the optimal size of the "pie" of the floor heating system.

It was said above that the thickness of the screed should be at least 300 mm above the surface of the pipes. But to ensure full accumulation and uniform distribution of heat, it is recommended to adhere to a thickness of 45-50 mm (namely for a pipe with a diameter of 16 mm).

Learn how to do it right, choose mixtures, prepare a solution, and also get acquainted with the technology of pouring water and electric underfloor heating.

And so that the generated heat is not wasted on heating the floor or other base of the "warm floor", a thermal insulation layer is necessarily provided under the pipe circuit. Usually, expanded polystyrene with a density of about 35 kg / m³ is used for this (extruded is better, as it is more durable and efficient). The minimum thickness that ensures the correct operation of the "warm floor" should be:

| Features of the base of the "warm floor" | The minimum thickness of the thermal insulation "cushion" |

|---|---|

| Floor over the ceiling above the heated room, the temperature in which is ˃ 18 °C | 30 mm |

| 50 mm | |

| Floor over the ceiling above the heated room, the temperature in which is from 10 to 17 °C | 70 mm |

| Floor on the ground, including in basements or basements with a depth from ground level up to 1500 mm. | 120 mm |

| Floor in basements or basements with a depth from ground level of more than 1500 mm | 100 mm |

Required condition- the floor heating system must be laid on a carefully insulated base, otherwise the heat will be spent extremely inefficiently

Required condition- the floor heating system must be laid on a carefully insulated base, otherwise the heat will be spent extremely inefficiently All these last remarks have been made because the following calculations will be valid precisely for such recommended "ideal" conditions.

Carrying out calculations of the main parameters of the contour

In order to lay the pipe contour with the optimal pitch (and its total length will subsequently depend on this), it is first necessary to find out what heat transfer is expected from the system. This is best shown by the specific heat flux density g, calculated per unit floor area (W/m²). Let's start with this.

Calculation of the specific density of the heat flux of the "warm floor"

Calculating this value, in principle, is not difficult - you just need to divide the required amount of thermal energy needed to replenish the heat loss of the room by the area of \u200b\u200bthe "warm floor". This does not mean the entire area of \u200b\u200bthe room, namely the “active”, that is, involved in the heating system, on which the circuit will be laid out.

Of course, if the "warm floor" will work in conjunction with a conventional heating system, then this is also immediately taken into account - only the planned percentage of the total heat output is taken. For example, 1.5 kW is required to heat a room (replenish heat loss), and the share of "warm floor" is assumed to be 60%. So, when calculating the specific heat flux density, we operate with the value 1.5 kW × 0.6 = 0.9 kW

Where can we get the indicator of the total required power to compensate for heat losses? There are many recommendations based on the ratio of 1 kW of energy per 10 m² of floor space. However, this approach turns out to be too approximate, not taking into account a lot of important external factors and features of the room. Therefore, it is better to carry out a more thorough calculation. Don't worry - with our calculator it won't be too difficult.

Calculator for calculating the specific heat flux of "warm floor"

In order to avoid unnecessary costs and technological errors that can lead to a partial or complete alteration of the system with your own hands, the calculation of a water-heated floor is made in advance, before laying. The following inputs are required:

- The materials from which the housing is built;

- Availability of other sources of heating;

- Room area;

- The presence of external insulation and the quality of the glazing;

- Regional location of the house.

You also need to determine what maximum air temperature in the room is required for the comfort of residents. On average, it is recommended to design the contour of the water floor at the rate of 30-33 ° C. However, such high performance during operation may not be necessary, a person feels as comfortable as possible at temperatures up to 25 degrees.

In the case when additional heat sources are used in the house (air conditioning, central or heating system etc.), the calculation of the warm floor can be oriented to the average maximum values of 25-28 ° C.

Advice! It is strongly not recommended to connect warm water floors with your own hands directly through central system heating. It is advisable to use a heat exchanger. The ideal option is completely autonomous heating and connecting underfloor heating through a collector to the boiler.

The efficiency of the system directly depends on the material of the pipes through which the coolant will move. 3 types are used:

- Copper;

- Polyethylene or cross-linked polypropylene;

- Metal-plastic.

At copper pipes maximum heat transfer, but rather high cost. Polyethylene and polypropylene pipes have low thermal conductivity, but are relatively cheap. The best option in terms of price and quality is metal-plastic pipes. They have a low heat transfer consumption and an acceptable price.

Experienced specialists primarily take into account the following parameters:

Experienced specialists primarily take into account the following parameters:

- Determining the value of the desired t in the room.

- Correctly calculate the heat loss of the house. To do this, you can use calculator programs or invite a specialist, but it is also possible to make an approximate calculation of heat losses yourself. An easy way to calculate a warm water floor and heat loss in a room is the average value of heat loss in a room - 100 W per 1 sq. meter, taking into account the ceiling height of not more than 3 meters and the absence of adjacent unheated premises. For corner rooms and those in which there are two or more windows, heat losses are calculated based on a value of 150 W per 1 sq. meter.

- Calculation of how much heat loss of the circuit will be for each m2 of the area heated by the water system.

- Determination of heat consumption per m2, based on decorative material coatings (for example, ceramics have a higher heat transfer than laminate).

- Calculation of surface temperature taking into account heat loss, heat transfer, desired temperature.

On average, the required power for every 10 m2 of paving area should be about 1.5 kW. In this case, point 4 in the above list must be taken into account. If the house is well insulated, the windows are made of a high-quality profile, then 20% of the power can be allocated for heat transfer.

Accordingly, with a room area of 20 m2, the calculation will take place according to the following formula: Q = q * x * S.

3kW*1.2=3.6kW, where

Q is the required heating power,

q \u003d 1.5 kW \u003d 0.15 kW is a constant for every 10m2,

x = 1.2 is the average heat loss coefficient,

S is the area of the room.

Before starting the installation of the system with your own hands, it is recommended to draw up a plan, accurately indicate the distance between the walls and the presence of other heat sources in the house. This will allow you to accurately calculate the power of the water floor. If the area of \u200b\u200bthe room does not allow the use of one circuit, then it is correct to plan the system, taking into account the installation of the collector. In addition, you will need to mount a cabinet for the device with your own hands and determine its location, distance to walls, etc.

How many meters is the optimal length of the circuit

H2_2Often there is information that the maximum length of one circuit is 120 m. This is not entirely true, since the parameter directly depends on the diameter of the pipe:

- 16 mm - max L 90 meter.

- 17 mm - max L 100 meter.

- 20 mm - max L 120 meter.

Accordingly, the larger the diameter of the pipeline, the lower the hydraulic resistance and pressure. And that means a longer contour. However experienced craftsmen recommend not to "chase" the maximum length and choose pipes D 16 mm.

You also need to take into account that thick pipes D 20 mm are problematic to bend, respectively, the laying loops will be more than the recommended parameter. And this means a low level of system efficiency, because. the distance between the turns will be large, in any case, you will have to make a square contour of the cochlea.

If one circuit is not enough to heat a large room, then it is better to mount a double-circuit floor with your own hands. In this case, it is strongly recommended to make the same length of the contours so that the heating of the surface area is uniform. But if the difference in size still cannot be avoided, an error of 10 meters is allowed. The distance between the contours is equal to the recommended step.

Hydraulic pitch between coils

The uniformity of surface heating depends on the pitch of the coil. Usually 2 types of pipe laying are used: snake or snail.

The uniformity of surface heating depends on the pitch of the coil. Usually 2 types of pipe laying are used: snake or snail.

The snake is preferably done in rooms with minimal heat loss and a small area. For example, in a bathroom or corridor (since they are located inside a private house or apartment without contact with the outside environment). The optimal loop pitch for a snake is 15-20 cm. With this type of laying, the pressure loss is approximately 2500 Pa.

Snail loops are used in spacious rooms. This method saves the length of the circuit and makes it possible to evenly heat the room, both in the middle and closer to the outer walls. The loop pitch is recommended within 15-30 cm. Experts say that the ideal step distance is 15 cm. The pressure loss in the cochlea is 1600 Pa. Accordingly, this do-it-yourself installation option is more profitable in terms of system power efficiency (you can cover a smaller usable area). Conclusion: the snail is more efficient, the pressure drops less in it, respectively, the efficiency is higher.

The general rule for both schemes is that closer to the walls, the step should be reduced to 10 cm. Accordingly, from the middle of the room, the contour loops are gradually compacted. Minimum paving distance up to outer wall 10-15 cm.

Another important point- Do not lay the pipe on top of the seams of concrete slabs. It is necessary to draw up a diagram in such a way that the same location of the loop between the joints of the plate on both sides is observed. For do-it-yourself installation, you can draw a diagram in advance on a rough screed with chalk.

How many degrees are allowed for temperature changes

System design, in addition to heat and pressure losses, implies temperature differences. The maximum difference is 10 degrees. But it is recommended to focus on 5 ° C for uniform operation of the system. If the desired comfort temperature of the floor surface is 30 °C, then the direct pipeline should supply about 35 °C.

Pressure and temperature, as well as their losses, are checked during pressure testing (checking the system before finishing pouring the finishing screed). If the design is done correctly, then the specified parameters will be accurate with an error of no more than 3-5%. The higher the difference t, the higher the power consumption of the floor.

By warm floor it is pleasant to walk, there is no discomfort from the cold underfoot and stuffiness in the upper part of the room. A well-equipped system allows you to evenly heat all areas of the rooms, creating comfort and saving money on heating. Installation of a warm floor is relatively simple, but the efficiency of the heating circuit depends entirely on the correct calculations in the preparation of the project.

In order for the warm floor to create the desired climate and not cause inconvenience or utility accidents, the room in which this heating circuit will be installed must meet the following requirements:

- the height of the ceilings from the subfloor should be such that its reduction by 20 cm does not cause discomfort;

- the doorway must have a height of at least 2.1 m;

- the subfloor must be strong enough to withstand the cement screed, which will close the thermal circuit;

- if the subfloor is laid on the ground or there is an unheated room under the insulated room, it is necessary to lay an additional layer of insulation with a shielding coating;

- the surface on which the installation of the thermal circuit and all components of the “pie” of the warm floor is planned must be flat and clean.

If the above requirements are met, the underfloor heating system will be installed without problems. However, its effectiveness depends not only on the size of the room, but also on its other features, which will be taken into account by the following recommendations:

- Walls are the main source of heat loss, therefore, before calculating and installing the heating system, it is necessary to at least roughly calculate the amount of heat that is spent on heating the street. If the figure obtained is higher than 100 W per square meter, it is advisable to insulate the walls so as not to overpay for heating;

- The heating circuit should not fall under the installation sites of massive furniture and heavy stationary equipment. Constant high pressure on the floor will damage the pipes or cables of the heating system and disable it.

- For uniform heating of the room, it is necessary that such unheated zones occupy no more than 30% of the floor area. Therefore, before making calculations, a drawing of the room is made on a scale, and places on this drawing are marked that should be left unheated. Then the total working area is calculated - it should be 70% or more of the total.

- It is necessary to calculate the optimal shape, length and step of the thermal circuit and its power, as well as draw a drawing indicating the points of connection to the heating system, the direction of the coolant flow.

Ways to install the "warm floor" system

For the proper functioning of this heating system, a clear sequence of layers of the so-called "pie" of the warm floor is important.

The thermal circuit is laid on a previously heat- and waterproofed surface, and on top it is poured or covered with a cement screed, on top of which the finishing layer is laid. flooring. The above layers - the shell of the pie - are required in both cases. They protect the system from external influences and increase its efficiency.

1. What temperature should the coolant be in the warm floor and how can its temperature be controlled?

The temperature should not be higher than 55 ° C, and in some cases not higher than 45 ° C.

To put it even more precisely: the temperature should be in accordance with the temperature calculated in the project, which takes into account the need for a particular room in heat and the material from which the finished floor is made.

You can control the temperature with the help of such a thermometer, and preferably two.

You can control the temperature with the help of such a thermometer, and preferably two.

One thermometer shows the temperature of the heating medium at the supply of the underfloor heating (mixed water temperature), and the other - the return temperature.

If the difference between the readings of two thermometers is 5 - 10 ° C, then the underfloor heating system is working correctly for you.

2. What should be the temperature on the surface of the warm floor?

The surface temperature of a working underfloor heating must not exceed the following values:

29 ° C - in the premises of long-term stay of people;

35 o C - in the boundary zones;

33 o C - in bathrooms, bathrooms.

3. What forms of pipe laying are used for underfloor heating?

For laying underfloor heating pipes, different forms are used: snake, corner snake, snail, double snake (meander).

|

|

|

|

Also, when laying one contour, you can combine these forms.

For example, the edge zone can be arranged with a snake, and then the main part can be passed with a snail.

4. What is the best installation for underfloor heating?

For large rooms square, rectangular or round shape without a geometric exclusive, it is better to use a snail.

For small rooms, rooms with complex shapes or long rooms, use a snake.

5. What should be the laying step?

The laying step must be designed in accordance with the calculations.

For edge zones, a step of 10 cm is used. For other zones with a difference of 5 cm - 15 cm, 20 cm, 25 cm. But not more than 30 cm.

This limitation is due to the sensitivity of the human foot.

With a larger pipe pitch, the foot begins to feel the temperature difference in the floor sections.

To do this, you can use a very simple formula: L=S/N*1.1, where

S is the area of \u200b\u200bthe room or circuit for which the pipe length is calculated (m 2);

N - laying step;

1.1 - pipe margin of 10% for turns.

To the result, do not forget to add the length of the pipe from the collector to the underfloor heating, including supply and return.

For example, consider a problem in which you need to calculate the length of a pipe for a room in which the floor occupies a usable area of 12 m 2. The distance from the collector to the warm floor is 7 m. The pipe laying step is 15 cm (do not forget to convert to m).

Solution: 12 / 0.15 * 1.1 + (7 * 2) = 102 m.

7. What is the maximum length of one loop?

Everything depends on the hydraulic resistance or pressure losses in a particular circuit, which, in turn, directly depend on both the diameter of the pipes used and the volume of coolant that is supplied through the cross section of these pipes per unit time.

In the case of a warm floor, (if you do not take into account the above factors), you can get the effect of the so-called locked loop. A situation in which no matter how powerful the pump you install in terms of pressure, circulation through this loop will be impossible.

In practice, it has been found that pressure losses of 20 kPa or 0.2 bar just lead to this effect.

In order not to go into calculations, we give some recommendations that we use in practice.

For metal-plastic pipe With a diameter of 16 mm, we make a contour no more than 100 m. Usually we stick to 80 m.

The same applies to polyethylene pipes. For 18 XLPE pipes, the maximum loop length is 120 m. In practice, we adhere to 80 - 100 m. For 20 metal-plastic pipes, the maximum loop length is 120 - 125 m.

8. Can there be underfloor heating contours of different lengths?

The ideal situation is when all loops are the same length. You don't need to balance or adjust anything.

In practice, this can be achieved, but most often it is not advisable.

For example, at the facility there is a group of rooms where you need to make a warm floor. Among them there is also a bathroom, the usable floor area of which is 4 m 2 . Accordingly, the length of the pipeline of this circuit, together with the length of the pipes to the collector, is only 40 m.

Do all rooms really need to be adjusted to this length, splitting the usable area of the remaining rooms by 4 m 2?

Of course not. This is not advisable. And then what is the balancing valve for, which is precisely designed to help equalize the pressure loss along the contours?

Again, you can use the calculations through which you can see to what maximum limit you can allow the spread of pipe lengths of individual circuits at a particular facility with this equipment.

But again, without plunging you into complex boring calculations, let's say that at our facilities we allow a spread in the lengths of pipes of individual circuits of 30 - 40%. Also, if necessary, you can "play" with pipe diameters, laying steps and "cut" the areas of large rooms not into small or large, but into medium pieces.

9. How many circuits can be connected to one mixing unit with one pump?

This question is physically similar to the question: "How much cargo can be taken away by car?"

What else would you like to know if someone asked you this question?

Absolutely correct. You would ask: "What car are we talking about?"

Therefore, in the question: “How many loops can be connected to the underfloor heating collector?”, It is necessary to take into account the diameter of the collector and what volume of coolant is able to pass through the mixing unit per unit of time (it is customary to consider m 3 / hour). Or, which is also equivalent, what kind of heat load can the mixing unit of your choice carry?

How to find out? Very simple.

For clarity, let's show an example.

Let's say you have chosen Valtec's Combimix as your mixing unit. What heat load is it designed for? We take his passport. See the clipping from the passport.

|

|

What do we see?

Its maximum flow rate is 2.38 m 3 /hour. If we put the Grundfos UPS 25 60 pump, then at the third speed with this coefficient this unit is able to "drag" a load of 17000 W or 17 kW.

What does this mean in practice? 17 kW is how many circuits?

Imagine that we have a house in which there are some (unknown) rooms of 12 m 2 of usable floor space in each room. Our pipes are laid in increments of 20 cm, which leads to the length of each circuit, taking into account the length of the pipes from the warmest floor to the collector, 86 m. In accordance with the design calculations, we also found that the heat removal from each m 2 of this warm floor gives 80 W , which leads us respectively to the thermal load of each circuit

12 * 80 = 960 W

How many rooms or similar circuits can our mixing unit provide with heat?

17000 / 960 = 17.7 similar circuits or rooms.

But this is the maximum!

In practice, in most cases, it is not necessary to calculate the maximum performance. So let's stick with number 15.

Valtec itself has a collector with the maximum number exits - 12.

10. Is it necessary to make several underfloor heating circuits in large rooms?

In large rooms, the design of the warm floor must be divided into smaller areas and several contours should be made.

This need arises for at least two reasons:

limiting the length of the circuit pipe is necessary in order not to get the effect of a "locked loop", in which there will be no coolant circulation through it;

the correct operation of the cement slab itself, the area of \u200b\u200bwhich should not exceed 30 m 2. Withthe ratio of the lengths of its sides should be 1/2 and the length of one of the edges should not exceed 8 m.

11. How do I know how many underfloor heating circuits I need for my house?

In order to understand how many loops of a warm floor will be needed and, on the basis of this, to choose a suitable collector with the same number of outlets, you need to start from the area of \u200b\u200bthe premises themselves in which this system is planned.

After that, you calculate the useful area of \u200b\u200bthe warm floor. How to do this is described in question 12 " How to calculate the usable floor area?".

Then, use the following method: starting from the step of the warm floor, break the usable area of the warm floor in each room into the following dimensions:

- step 15 cm - no more than 12 m 2;

- step 20 cm - no more than 16 m 2;

- step 25 cm - no more than 20 m 2;

- step 30 cm - no more than 24 m 2.

If the floor area in the room is less than the specified dimensions, then it does not need to be broken.

We recommend reducing these values by 2 m 2 if the length of the pipe connection from the underfloor heating to the collector exceeds 15 m.

When dividing the useful floor area in the premises, also try to ensure that the length of the pipes in these circuits is either the same, or the difference between the individual circuits does not exceed 30 - 40%.How to find out the length of pipes in each circuit, read question 6 " How to calculate pipe length?".

Step back 30 cm from each of the walls of the room. Shade the resulting space. Mark on the plan the areas where the furniture will constantly stand: a refrigerator, furniture wall, sofa, large closet, etc. Shade these areas as well. The unshaded part of the room plan will be the usable floor area you are looking for.

For clarity, let's calculate the useful area of the dining room, where there will be a warm floor. The total area of the dining room is 20 m 2, the length of the walls is 4 m and 5 m, respectively. The kitchen will have kitchen set, refrigerator and sofa, which we will mark on the plan. Let's not forget to step back from the walls by 30 cm. Let's shade the occupied areas. See drawing.

And now let's calculate the usable floor area.

13. What is the total thickness of the underfloor heating cake?

It all depends on the thickness of the insulation, since the remaining values \u200b\u200bare known.

With the next thickness of the insulation, you will get the following values (the thickness of the finishing coating is not taken into account):

- 3 cm - 9.5 cm;

- 8 cm - 14.5 cm;

- 9 cm - 15.5 cm.

14. What do you use to calculate the water floor heating system?

For calculation as systems radiator heating, and for underfloor heating systems we use the company's Audytor CO program.

Below we post a screenshot of the module of this program for the preliminary calculation of a warm floor and a screenshot of the module for calculating the layers of a warm floor cake.

|

|

Upon careful consideration of these screenshots, you can understand how serious the correct calculation of the warm floor is.

You can also see the work of the program itself, which makes it possible to carry out visual control over such important parameters as the length of the pipe, pressure losses, temperature on the floor surface, heat going down uselessly, useful heat flow, etc.

15. How to determine the dimensions of the collector cabinet in order to place all the necessary components in it?

Determining the dimensions of the collector cabinet is not difficult. We again suggest using Valtec products and their ready-made recommendations presented in the table, provided that you use ready-made underfloor heating units manufactured by this manufacturer.

Determining the dimensions of the collector cabinet is not difficult. We again suggest using Valtec products and their ready-made recommendations presented in the table, provided that you use ready-made underfloor heating units manufactured by this manufacturer.

Linear dimensions of manifold cabinet

(SHRN - external; SHRV - internal)

| Model | Length, mm | Depth, mm | Height, mm |

|---|---|---|---|

| SHRV1 | 670 | 125 | 494 |

| SHRV2 | 670 | 125 | 594 |

| SHRV3 | 670 | 125 | 744 |

| SHRV4 | 670 | 125 | 894 |

| SHRV5 | 670 | 125 | 1044 |

| SHRV6 | 670 | 125 | 1150 |

| SHRV7 | 670 | 125 | 1344 |

| SHRN1 | 651 | 120 | 453 |

| SRN2 | 651 | 120 | 553 |

| SHRN3 | 651 | 120 | 703 |

| SRN4 | 651 | 120 | 853 |

| SHRN5 | 651 | 120 | 1003 |

| SHRN7 | 658 | 121 | 1309 |

Selection of manifold cabinet

Collector groups 1 |

cabinet model |

cabinet model SHRN/SHRV + Dualmix + ball valve |

cabinet model SHRN / SHRV + crane |

| Collector 1*3out | SHRN3/SHRV3 | SHRN4/SHRV4 | SHRN1/SHRV1 |

| Collector 1*4out | SHRN3/SHRV3 | SHRN4/SHRV4 | SHRN2/SHRV2 |

| Collector 1*5out | SHRN4/SHRV3 | SHRN5/SHRV4 | SHRN2/SHRV2 |

| Collector 1*6out | SHRN4/SHRV4 | SHRN5/SHRV5 | SHRN3/SHRV3 |

| Collector 1*7out | SHRN4/SHRV4 | SHRN5/SHRV5 | SHRN3/SHRV3 |

| Collector 1*8out | SHRN5/SHRV4 | SHRN6/SHRV5 | SHRN3/SHRV3 |

| Collector 1*9out | SHRN5/SHRV5 | SHRN6/SHRV6 | SHRN4/SHRV4 |

| Collector 1*10out | SHRN5/SHRV5 | SHRN6/SHRV6 | SHRN4/SHRV4 |

| Collector 1*11out | SHRN6/SHRV5 | SHRN7/SHRV6 | SHRN4/SHRV4 |

| Collector 1*12out | SHRN6/SHRV6 | SHRN7/SHRV7 | SHRN5/SHRV5 |

16. At what height should the manifold cabinet be installed?

There are no specific rules in this regard, but there are recommendations.

On the one hand, it is clear that when mounting a collector cabinet, it is necessary to take into account the height of the future screed and finish, so that a situation does not turn out when it will not even be possible to open the cabinet door.

On the other hand, it is necessary to take into account the ease of maintenance and the need for the possible replacement of individual elements of the system with the likelihood of disconnection of the pipeline.

The shorter the pipe section, the greater its rigidity and vice versa.

Considering this factor, it is possible to raise the collector cabinet by 20 - 25 cm from the level of the finished floor.

However, we must not forget about a very important design element. If lifting the cabinet leads to an unacceptable violation of the design and it is impossible to solve this problem in another way, lower the cabinet to the floor level, but in such a way that it can open.