Wall decoration with pvc wall panels. How do-it-yourself wall cladding with plastic panels is done. Prices for mixtures for leveling walls and ceilings

When designing interior finishing work, the question often arises of choosing a material for such work. Today, the construction market is represented big choice finishing materials. But it is worth remembering that the material for such work is selected based on the use of the premises, and the use of the wrong type can lead to destruction or rapid damage to the appearance of the entire finish as a whole. One of the universal finishing materials are PVC panels. During the appearance of this material, this finish is quite popular for a number of reasons.

Polyvinyl chloride (PVC) panels are a type of finishing material made on the basis of polyvinyl chloride with the addition of different kind additives. In hardware stores, these plastic panels are called lining. It is used for finishing any building elements, as well as premises in general. The use of PVC panels is mainly used in places where a dry finish is required, and this material can also be used for both indoor and outdoor work.

Plastic PVC panels

Types of PVC panels

Such finishing material can be divided into two types:

- Ceiling panels;

- Wall panels;

Their difference is that shelf panels are thinner . This is due to the fact that when mounted on the ceiling, the lining will not carry any loads, so the ceiling finish will not require the manufacture of panels with a large thickness. Also, the ceiling lining is much less in weight, and this greatly facilitates the installation process, and at the same time, the weight of the entire suspended structure is reduced.

Also, PVC panels can be divided according to the method of connecting the lamellas:

- Seamless;

- Embossed;

- Chamfered slats;

Pros and cons of PVC panels

When choosing a material for finishing, you should know and take into account all the positive and negative qualities. PVC panels can be noted such positive traits :

- Ease of installation;

- Long service life;

- Availability;

- Large selection of colors;

- Does not require special care;

- This material is suitable for finishing any room;

Along with the positive qualities, there are also a number of shortcomings that you should pay attention to when choosing it:

- Low impact resistance;

- This material is not resistant to ultraviolet radiation. That is, it is not advisable to mount the lining in places that are constantly under the sun;

It is worth noting that such shortcomings can be removed depending on the pricing policy. Therefore, when choosing PVC panels, these parameters should be given great attention.

Surface mounting methods

Before starting the installation of PVC panels in the room, it is necessary to determine the method of fastening. Here you should know that the panels can be attached in three ways.

- Vertical mount;

- Horizontal mount;

- Diagonal mount (rare);

The method of fastening must be determined in advance based on design features premises. This is necessary in order to properly mount the frame. In some cases, if it is required to sheathe a column, then only diagonal fastening is used. In most cases, when installing a lining, the method of fastening depends only on the wishes of the customer.

Panel fixing tools

When self-attaching PVC panels, you will need a tool that you need to prepare in advance so as not to interrupt the sequence of work for a long period. To complete the work you will need:

- Perforator or drill;

- Bulgarian (UShM);

- Rule;

- Level;

- Roulette;

- stapler;

Any of these tools is necessary, because when performing some tasks manually, the quality of the entire finish as a whole can be seriously affected, which will entail additional costs for the purchase of material. Therefore, do not neglect such nuances.

Choosing a frame for PVC panels

In order to qualitatively perform all installation work, you should initially familiarize yourself with preparatory work. The installation of wall or ceiling panels is 90% dependent on a well-made frame for them. It is intended for fastening panels, since fastening of such material is not used on the main surface. In some cases, it also performs the function of leveling the main surface.

The frame can be made from wooden slats or from a metal profile. This profile is used for plasterboard work. The difference between these materials is primarily in the pricing policy. But, it is also worth noting other nuances.

wooden frame it is made faster and will cost a little less, but before it is mounted, additional costs and time will be required for fire-prevention treatment of wood. Also, if the rail was purchased raw, after its installation, it may change shape. As a result, more dowels will be required for its fastening.

Main advantage metal frame is its durability and ease of use. It does not require any additional work with it.

It is also worth noting that with unevenness on the walls of the wooden lath, more metal profiles will go away. A metal frame is simply necessary in places with high humidity, since a tree under such conditions can infect a fungus and the entire frame can collapse in a short period.

To choose the right material for the frame, you will also need to take into account the location and type of wiring if the work is carried out indoors.

To properly install PVC panels, you first need to make a crate (frame). This is done in the following way. To begin with, a visual inspection of the surface where the panels will be installed is carried out. At this stage, it is necessary to identify wall defects and, if any, they need to be eliminated. After that, an unevenness check is carried out. This will require a rule and a level. To determine the inclination of the sheathed surface, you can also use a plumb line.

Wall unevenness check

At the next stage, it is necessary to decide on the method of fastening the lining sheets. If horizontal fastening of the panels was chosen, the frame rails must be installed vertically. When panels are mounted vertically, rails are mounted horizontally. Marking is also carried out, how many rails will be required on the sheathed surface. Reiki should be placed at a distance of no more than 50 cm from each other. Necessary condition is that the first and last rails should be placed in the corners of the sheathed surface.

When all the nuances are determined, you can proceed to the direct execution of work. The first rail is installed from the corner and is attached to the wall with dowels. During installation, it is required to strictly control the evenness of the installation using a level. The next rail is mounted in the opposite corner. After that, a thread is pulled between them, and all subsequent rails are mounted along it. The end result will be a frame on which PVC panels can be fastened.

Before mounting the panel sheets, corner moldings are initially installed, which are stapled to the frame. In another embodiment, starting moldings can be attached around the perimeter of the sheathed surface, if the sheathed area has no corners.

PVC panels are mounted using a stapler. Their connection to each other occurs with the help of side lamellae.

You can also watch a video instruction for mounting the batten and fixing PVC panels in the video:

Installation of PVC panels on the ceiling is carried out in the same way as on the walls. A significant difference is that all work is carried out above head level. At the initial stage, it is necessary to assemble the frame for the ceiling finish. In such cases, it is more advisable to use wooden slats, since it will be a little easier to work with them, but do not forget that the metal crate will still last longer, so you can choose it. Also, before starting work, the method of fastening the sheets is determined. For such work, any method of fastening may be suitable. This parameter is more dependent on the design of PVC panels.

The frame for the ceiling sheathing is made in the same way as for the walls. When constructing a ceiling lathing, laying should be taken into account electrical wires. Since PVC ceiling sheets are thinner than wall sheets, it is required to provide additional elements for a chandelier or spotlights in the frame.

Also, as in the wall version, moldings (ceiling skirting boards) are attached around the perimeter of the ceiling.

Installation of ceiling plinths on the crate

Fastening is carried out on staples using a stapler for wooden crates and on self-tapping screws for metal.

You can also watch some videos with instructions on how to PVC installation ceiling panels:

Fastening PVC panels to columns

Sometimes there is a need that it is necessary to sheathe the column with PVC panels. This is a rather laborious task if the column has round shape. But such work can also be done independently. For sheathing the column, you will need to calculate the required amount of a metal profile, since a wooden frame cannot be used. The whole point of the column sheathing lies in correct installation frame.

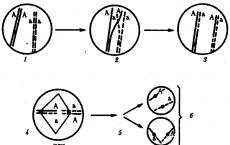

The metal profile has a U - shaped shape. Along its edges, triangles are required on both sides. This can be done with a grinder or metal shears. Thus, this profile can be bent into a perfect circle. Its fastening is carried out using special metal plates, which are initially fastened around the entire circumference. Then the profile is mounted on these plates.

The fastening of the lining in such cases is usually used diagonally, since the panels have a rectangular shape and can be easily attached to a round surface.

You can also watch a video on this topic:

Fastening PVC panels to a metal profile

To install PVC panels on a metal frame, the first thing you need is to correctly calculate the required number of profiles. To begin with, along the entire perimeter of the sheathed surface, it is required to fix the profile guides (UD). Their installation is carried out along a pre-marked line. If available laser level these jobs can be done much easier and faster.

The next step will be the installation of wall profiles (CD), they are located at a distance of 50 cm from each other along the guide profiles. When the installation of wall profiles is made, they are fixed with the help of mounting plates every 30 - 40 cm. Such a frame is in many ways reminiscent of a crate for drywall.

Installation of a metal crate under PVC panels

At the next stage, PVC panels are cut and installed. They are fastened with self-tapping screws to the profile. It is important not to forget that when assembling the lathing, wall profiles must always be mounted perpendicular to the direction of fastening of the panels.

As with timber framing, starting moldings are also required if the surface has no corners or turns.

Fastening PVC panels to a metal crate

An unpleasant moment when working with metal profiles is the fastening of panels to them. This process is very labor intensive and time consuming.

How to fix PVC panels without crates

Sometimes there are cases when PVC panels are fixed without a frame. But such fastening does not find great popularity, since the lining sheets will repeat all the irregularities of the sheathed surface. But for decoration, the following method is used. A sheet of plywood, chipboard or chipboard is initially attached to the sheathed surface. This is necessary in order to level and strengthen the entire sheathed surface. Further, according to the given dimensions, a lining sheet is cut out and attached to a wooden base using a stapler or self-tapping screws.

Today we will analyze in detail for you: how to finish the walls with PVC panels, how to build a frame for this and how to make slopes correctly.

More and more often you can find on the walls in houses and apartments, not wallpaper - which are familiar to us, but PVC plastic panels. And now they make such panels in which the seams at the junctions are completely invisible, which gives a solid surface. Previously, PVC panels could be found in the kitchen or in the bathroom. However, they often trim the walls in other rooms. PVC panels for walls have a completely different color and you can choose any pattern you are interested in.

In general, we will do everything with our own hands so that the whole structure looks dignified and beautiful, as if a real professional did all the work. As a result, a spectacular wall should be obtained, on which PVC panels will look not only as a decoration, but also as a full-fledged detail of the composition.

Useful information:

A few words about plastic and its properties

The first thing I want to note right away is that PVC plastic panels are absolutely harmless. Modern technologies made it possible not only to reduce the cost of production, but also to remove all harmful substances. That is why the installation of PVC panels on the wall can be done absolutely in any room, and even in the nursery. It's good when you also have . It can be perfectly combined with the walls.

Now the choice of PVC panels is so wide that absolutely any design elements in the interior can be created from them. Another not unimportant factor is that the panels are really beautiful and look very decent on the walls. For example, here are a few interiors where the walls are finished with PVC panels. It looks beautiful and dignified, which means that PVC wall panels are actually a great replacement for even the most expensive wallpaper.

Volumetric PVC panels in the interior

It is noteworthy that any image that will be of excellent quality can be applied to PVC panels. They can be easily pasted over with ordinary self-adhesive, this allows you to achieve any desired effect. It is very fashionable to put 3D images on the wall. In general, fantasy can be limitless.

Finishing with PVC panels allows you to hide any wall defects. With their help, you can beautifully finish any niche where, for example vinyl wallpapers, it is quite difficult to glue end-to-end. And the end result and the quality of the finish is really impressive.

Indeed, without understanding the specific points of installation, without reading the advice of professionals, you should not take up work on your own. The work itself is quite delicate and requires professionalism not only in the hands, but also in the head.

Necessary good tool. With a square, a saw for metal and a drill, the whole result will not be called a finish, but a “lining”. Even though the panels are easy to care for, they are not considered to be the ideals of hygiene. Don't do wall cladding plastic panels in the bedroom, since plastic does not breathe at all, and this will negatively affect healthy sleep. The maximum that can be done is a kind of panel on part of the wall.

In any light, the plastic glare is quite strong. And this is undesirable for the child's psyche. This is recommended not only by psychologists, but also by medicine. It is also necessary to take into account the moment that the panels inside are hollow and any living creatures can start in them. Many "specialists" try to seal holes with silicone during installation. I must say right away that you should not do this, because during thermal deformation, individual panels can lead and all work will again turn into a “lining”.

There is one more minus. The panels burn excellently and at the same time emit quite toxic gases. Of course, you can’t light them with a lighter or a match, but in an open fire they flare up perfectly.

However, despite all this, PVC wall panels are the ideal solution for the implementation of some individual idea. And all this looks quite beautiful and interesting. Drawings on panels can be further projected onto floors, which can also be done with 3D drawings.

Let's see what experts say about plastic panels:

- When decorating walls with PVC panels, it is necessary to take into account the coefficient of their expansion. After all, materials such as polyvinyl chloride expand quite strongly when heated. Therefore, when decorating walls with PVC panels, thermal clearances must be made for a width, or rather, half the width of the installation profile. The installation of the panels to the crate itself must also allow some deformations in the plane of the panels themselves.

- If you are going to install the panels on a soft crate using staples or on a wooden crate, then it is advisable to use thermal washers together with self-tapping screws. This will slightly complicate the installation of PVC panels on the wall, but will save all your work in the future. In the heat, some panels can simply pop out of the overall structure and such moments happen quite often.

- If you take the laying of the laminate on the walls, then during installation special brackets are provided - clamps that fix the panels on the crate of any kind and design. At the same time, each panel is able to move a little, which allows it to expand freely with a rise in temperature.

Instructions for fixing PVC panels on the wall

All panel elements are fastened easily and quite simply. The most basic and time-consuming part is the creation of a high-quality crate. Since it is the main bearing part, it must be done very accurately, but more on that later, but now let's take a closer look at the elements of the PVC panels themselves.

- To the crate number 8 it will fit exactly the mounting large shelf. It is attached with screws or staples.

- In order for the fastening small shelf to firmly dock with the large shelf, it is equipped with a longitudinal protrusion, which should hang over the crate.

- To finish the walls with PVC panels, you will need a start and finish profile. In the picture, this is a profile under number 7, with its help it is possible to frame the entire structure of PVC panels. It is the wide shelf that will be attached to the crate itself, and the narrow one is necessary in order to hold the panels themselves. There are also special finishing profiles, and they can be detachable. With them, a narrow shelf can be removed and put back, this allows you to make special latches.

- Under number 4 and 5 inside and outside corners are shown. During installation, you will need these elements in the decoration of some niches, or corners. Here you need to know that the corners are purchased a size larger than the size of the PVC panels themselves.

- Under number 1 we have a connecting profile. It is necessary in cases where you want to sheathe the walls with PVC panels that have different colors, or their length is not enough for the entire structure. It is mounted like a normal installation profile.

- Under number 2 plinth shown. It is also often called a fillet. It is usually mounted with glue and has a facing function.

- Under number 6 the installation combined profile is shown. It is necessary in order to insert the ends of the panels into it, and the plank that runs perpendicular is closed with a plinth. Usually it is used only at perfectly even angles. Otherwise, unpleasant dirt will accumulate in the cracks.

- All corners that overlap another material can be hidden using F-corners. We have them under number 3 attached with regular glue.

PVC wall cladding tool

- Circular saw or electric jigsaw. The saw will be preferable because the jigsaw can play on the stiffeners and the cut itself will not be as smooth as we would like. I used a metal file, since the ends are still sewn up with a plinth or profiles. You can also use a hacksaw, the main thing is that there are small teeth.

- If you need to cut different angles, then it is advisable to purchase a miter box. It should have 45 and 90 degree angles.

- It is very convenient to use a construction stapler when sheathing walls with PVC panels if the construction of the crate is wooden.

- Convenient to use as well rubber mallet. It is often used when laying laminate. It is quite convenient for her to get the bar of the panel, which is stuck in the grooves. Otherwise, you may damage the cladding profile or crate.

- If the finishing profile is not collapsible, you will also need a plastering spatula. When you install the last panel, you need to bend the profile with something. So the spatula is the most suitable tool.

Installation of PVC plastic panels on the wall

It is better to watch the whole process in the video below, and in the description we will talk about the main stages of work that must be followed when decorating walls with PVC panels.

- First of all, we make a wooden crate.

- It is necessary to immediately fix the guide profiles, starting and finishing.

- We insert the first panel into the installation profile, which will be at the bottom. We bend the panel with an arc and bring the upper end into the upper profile. Remember that you must bring the mounting small shelf into the starting profile.

- With the help of a rule and a mallet, we drive the profile tightly into the groove. The bar should be firmly in place. Next, the panel is additionally fixed on the crate. This is done with the help of brackets, which are driven through a large mounting shelf. In this sequence, each PVC panel is installed, up to the penultimate plank.

- The last panel must be evenly cut from the side of the large mounting shelf in width and always in size. Moreover, it is necessary to leave a few millimeters for thermal expansion.

- Using a spatula, we bend the shelf in the finishing profile and insert the lower end of the PVC plank into the groove. And we start immediately in the finishing profile and in the installation. It is advisable to do this work together in order to fully control the process of installing the last bar in place.

- In the same way, we will start the panel at the top. We bend the profile bar with our spatula and drive the board into place.

- The edge bar is also attached to the crate with brackets. This is done easily. You just need to bend the profile a little and drive the brackets into the necessary places.

- Skirting boards are installed at the very end.

If you are using a finishing special profile, then the most important thing is to apply and then snap the shelf.

If you purchased a cheaper profile, then after all the manipulations with it, it may remain bent. This is also fixable: the profile is heated with a household hair dryer, and then the curved place is smoothed out with a cold iron.

The gaps between the profiles, especially in the corners, can be covered with homemade grout. Mix sawdust with PVA glue until the dough is thick. Or you can choose the color of the silicone profile.

Pay due attention to the crate. If it turned out to be careless, then the last plank of the PVC panel will definitely show this. Most often, the edge begins to bend outward. The result is a "line".

How to make a crate for PVC panels

The crate can be made both wooden and using a metal profile - C. The advantage of the crate is that. Moreover, the insulation will be quite significant. If you are constantly cold, then this will help correct the situation. It is best to use mineral wool mats for insulation. For those who like to listen to quite loud music, you can put a layer of soundproofing on the walls.

The crate itself is attached to the walls with dowels or self-tapping screws. If the walls are curved, then the vertical strips are installed using a plumb line or level. For the substrate, you can use pieces of rubber, trimming the panels themselves.

The most convenient crate is the usual linear one. The maximum step for PVC panels is 50 cm. The minimum step is 30 cm. All protrusions, openings, window slopes, the corners of the walls must be made framed. Lathing battens should not be with hanging ends. The only exception would be the protrusion of your window sill. For it, a special recess is cut out in the panel that will adjoin it.

Video on wall decoration with PVC panels

As you can see, the panels are quite easy to work with, and most importantly, all the work goes quickly. The main thing is to assemble the crate, and the installation of panels is an easier and rather fun task.

How to sheathe slopes with plastic

Slopes are the most a big problem faced by plastic finishers. After all, specially made obtuse corners are not produced, and if they were produced, then finding slopes with clear angles is also a problem. Many get out of this situation in different ways, but they all go to the fact that as a result the angle is straight when the slope itself narrows inward. Along with this, there is a fairly simple way to finish the slopes with plastic.

- We sew up to the corner the two sides of our slope. You can allow an indent of exactly half the width of our corner shelf.

- We begin to cut the right corner along the length from the side of the slope, leaving a margin of up to 6 cm in two directions.

- We carefully cut one of our shelves on the corner on both sides equally. We try to cut exactly along the very edge of the corner.

- Next, you need to draw a straight line from the corner at an angle of 45 degrees. At the place of the cut, we cut off the extra piece with a pruner or with the help of garden shears.

- Along the very edge of our corner, it is necessary to make an incision with a knife at half the thickness of our facing profile and apply glue from the inside.

- Then it remains to impose, and press until our corner opens as we need. And it remains only to wait until the glue grabs.

The final rounding

We install PVC panels on a soft crate

Here it probably became interesting to everyone: “How can you finish the walls with PVC panels for soft facing? - after all, it will never withstand the weight of the entire structure. Trust me, all the cladding on the soft crate that the beginners made stand for 15 years, and without any signs of damage.

According to its properties, soft lathing has the same thermal expansion as PVC panels. The adhesive base itself stretches quite well. It turns out that the board on it begins to stretch, and then falls into place. But in order for everything to actually work out, you need to do some preparatory work:

First you need to remove the wallpaper from the wall. The surface itself must be leveled with a very strong putty. You can use "Prospector" or "Hercules". The putty layer should be at least 3 - 4 millimeters. This is necessary so that if there are protrusions or irregularities in the wall somewhere, then a sufficient layer of putty will stabilize everything and the normal thickness will remain to hold the PVC panels on the wall.

Only high-quality finishing profiles are required. Without them, you will not be able to make wall cladding with PVC panels, but on a soft crate.

In order for the panels themselves to hold firmly on the crate, it is necessary to reduce the contact of the adhesive layer with air. Therefore, you need to glue everything quickly enough and also systematically.

From the beginning of the tape, remove the protective layer by 3 centimeters, and cut off the tape itself. The initial end is pressed to the top point on the wall, and the bottom end to the bottom point. It is convenient to do it with only two people. As a result, we begin to peel off the bottom layer of the protective tape, and the adhesive tape itself is immediately firmly pressed against the wall. At the very end, you must also leave the tail of the tape about 3 centimeters. In the same way, we make a crate around the entire perimeter or the intended area.

Installation of PVC profiles on a soft crate

To begin with, we lay our installation top profile, which we pull out the entire protective tape horizontally and from under it. At this moment, the second assistant presses the profile tightly against our double-sided tape. The bottom profile for the panels is also glued according to this principle.

After that, vertical profiles are installed in the same way, without taking long breaks between gluing the profile and opening the adhesive base. It is more convenient to do everything from the bottom up. Thus, your profile will not hang on tape. After that, we fix the finishing profile.

All PVC panels must be accurately cut to size. The slightest jamming between the profiles must not be allowed. In place, each panel is placed consistently and simultaneously from above and below. Here it is already forbidden to use a mallet or a rule.

All protective film, namely, its tails are cut or re-glued as installation work progresses PVC profile on the wall. One of the shelves in the panel must be cut to 10 mm, and this cut piece is glued to our edge board. The result is a durable construction that will serve you for years. But according to my principles, I have a negative attitude towards a soft crate. I just don't trust double sided tape.

In conclusion, I want to add a few brief recommendations on PVC wall panels and their installation:

- The best option would be to finish the bathroom, as well as a balcony or your loggia. PVC wall panels feel great in the hallway, which is connected to the living room. PVC panels in general help to relieve the entire interior.

- If you decide to sheathe the room with seamless panels, it would be better to install an air conditioner for this, or ventilate the room more often, since the panels are not able to pass air.

- You can also install PVC panels on the wall in the bedroom, but this is done only as a kind of panel. It is not recommended to use such a finish in the kitchen and in the children's room.

As a result, PVC wall panels look quite effective if they were installed by a really master. A good repair in an apartment is not only sticking new wallpapers and painting the ceiling, but also some decorative elements that are easy to do with plastic panels.

Following our advice, wall decoration with PVC panels will not be a burdensome task for you, and the result itself will please long years. Trust an experienced plastic specialist!

tweet

Pin it

Like

The modern market offers a huge number of varieties, sizes and design options for PVC panels, so they can be matched to any interior style. PVC panels are inexpensive, quickly mounted, operated for a long time, and most importantly, they will help to equip a unique, unlike anything room design. How to fix plastic panels to the wall: on glue, on screws, on the crate? Which panels to choose and which installation method to prefer, we will analyze all these issues in detail in our article.

Why PVC bathroom panels have become the number one competitor to tiles? It's all about ease of installation. Put tile even on the most even basis, it is beyond the power of a person who has never done this. You will need the services of a specialist to level and strengthen the base, mark the wall and lay out the tiles row by row, observing the levels and width of the tile joint. In addition, the cutting of tiles itself, if necessary, requires special tools and certain skills.

With PVC panels, everything is much simpler. They have a lot of advantages:

- Light in weight: their transportation to the house and installation do not cause any difficulties.

- Exists several mounting methods from simple wall stickers to purlin systems, each of which can be handled even by a layman.

- Panels biologically sustainable and during operation, the appearance of fungus on them is excluded.

In addition, it is possible to note such advantages of plastic products as moisture resistance, hygiene, duration of operation And inexpensive cost. Of course, they also have their own characteristics. For example, despite the presence of stiffeners in the design of the product and the thickness of the plastic, which is quite large for some manufacturers, the panels are quite brittle material. and with an accidental strong point impact, they can break through. Therefore, when buying, you need to choose the most durable products of European manufacturers.

However, if the lining good quality, then when bathing, for example, you can rely on it as much as you like: it has sufficient flexibility and elasticity to support the weight of a person.

When choosing products, you should look at such specifications, how:

- plastic thickness (the more, the more reliable);

- the presence and number of stiffeners;

- when viewed under artificial lighting on the front plane, transverse ribs should not be visible;

- the surface must be intact, undamaged, not scratched, the film on the front plane must not be damaged;

- plastic from the ends should not be with burrs and microcracks.

There are several types of PVC panels, differing in size and other parameters.

Table 1. Types of PVC panels.

| Name | Peculiarities | Dimensions |

|---|---|---|

| Ceiling | Thinner thicknesses up to 5 mm | |

| Wall | Thicker and tougher up to 10mm thick | width 15-50 mm, length 90-300 mm |

| Rack | Narrow planks with shaped edges, similar to lining, have a thorn-groove locking connection | width 13-50 mm, length 90-300 mm |

| leafy | Large rectangular sheets with a relief or pattern on the outside | width 50-122 mm, length 30-98 mm |

| Tiled | Tile | width 30-98 mm, length 30-98 mm |

| Sandwich | Double-layer, with a heat-insulating layer, the thickness can reach 4 cm | width 90-150 mm, length 300 mm |

In width, standard wall panels are most often found 25cm and 37cm, length - 2700cm, 3000cm. Different manufacturers may produce products of different sizes. The price difference depends on various factors: the quality and thickness of the plastic, the type of decor printing, its complexity, etc.

Polyvinyl chloride panels are divided into several types according to their coating. They are:

- monochrome;

- colored, with a dye added to the mass;

- mirror;

- with an image pasted on a thermal film;

- with a pattern applied by offset;

- with one image spaced into several panels, forming a panel.

According to the method of connection, the products can be seamless and with a recess. Of course, when joining seamless panels, the seam still remains visible, but hardly noticeable. If the products are chamfered, then the seams are more highlighted and create a certain geometry of the room.

In addition, a wide range of accessories for fastening elements is offered: start and F-shaped profiles, internal and external corners, joint profiles, skirting boards. The use of fittings allows you to give an aesthetic appearance to the joints, and of course it is used for a more reliable and simple fastening.

Find out what types, and also check out step by step instructions for finishing, in a special article on our portal.

Prices for popular finishing wall panels

Wall panels

Mounting

To carry out the calculation, you first need to determine the direction of installation. Products can be attached horizontally And vertically. Vertical placement is preferred for small spaces such as hallways, kitchens, and bathrooms. With this method of finishing, the ceiling visually rises due to vertical lines. Horizontal installation is more often used for finishing spacious rooms, for example, at camp sites, in hostels. It resembles a traditional horizontal finish, especially if the panels are matched, for example, under a tree.

Panels can be fixed in three ways:

- on any adhesive composition;

- on self-tapping screws;

- on the crate.

The first method is the easiest, simplest and fastest, but only applies if the base is sufficiently level. The second is also not particularly difficult, but requires skill in handling a screwdriver. In this case, the panels can be dismantled over time and moved to another location. The method of fastening to the crate is the most durable, time-consuming and capital. Thus, the cladding can be firmly mounted on uneven surfaces.

The selected mounting option does not affect the order of events when mounting the plates directly:

- fittings are installed: initial and finishing strip, internal and external corners;

- fittings are installed along the openings;

- the panel is inserted with a narrow shelf into the fastening element. Fastened from the side of a wide shelf with self-tapping screws. Elements must be mounted tightly;

- the final panel must be squeezed between the one in front of it and the finishing element of the row. The excess can be trimmed neatly along with a knife;

- joints with the ceiling are covered with ceiling, joints with the floor - with floor plinths.

How to glue panels

Bonding - most easy way finishing the room with panels, which is allowed either in the event that when the wall is perfectly flat or when the leased premises are being renovated according to the principle and so it will do, clean and okay. It will be quite difficult to dismantle such a finish in the future and it certainly will not be possible to use it for re-assembly.

The panels are glued to a flat or slightly uneven base. Previously, to improve adhesion, it is necessary to remove and clean out all the bumps and weak layers of the previous finish. Then plaster and putty uneven places. Then prime the surface to improve adhesion. The finished base for gluing the cladding must be even, dry, clean.

Apply the adhesive to the wall, spread it evenly with a notched trowel and gently press the panel against the wall. The duration and force of pressing usually depend on the adhesive and are indicated on the packaging or in the instructions for use. Also apply glue to the next panel, then it should be carefully docked with the previous one and pressed to the base. Thus, you can quickly get a beautiful decorative coating.

Video - Installation of PVC panels with glue

As for the adhesive for panels, modern manufacturers offer just a huge selection of adhesives. You can list the most popular:

- quality liquid nails;

- liquid nails and Titan Wild glue;

- Emfikol 34012A;

- Kleiberit 636.

Prices for liquid nails

Liquid Nails

The above adhesives are resistant to high humidity and temperature fluctuations. The facing materials glued to them will hold for the entire period of operation.

Advice! If there is a choice, it is better to choose the most quickly setting adhesives - for example, liquid nails. Then you don't have to wait for a while until the first panel grabs to start gluing the second one.

Installation of PVC panels on self-tapping screws

This mounting method also includes a sufficiently level base. Although the requirements for the surface condition are less than when working with glue. No need to remove greasy stains from the wall and treat it with a primer to increase adhesion. However, to improve the quality of work and increase the speed of installation, a screwdriver is required. However, today screwdrivers can be bought even for one and a half thousand rubles, so this installation method can be called quite budgetary.

As for self-tapping screws, you can opt for wood screws with a wide notch. Length 16 mm will ensure proper fixation to the wall. If finishing is planned bathroom, you should opt for galvanized, that won't rust during operation. Do not choose self-tapping screws with a wide hat, it can interfere with docking.

The process itself is extremely simple. From the inside, the screws are screwed into the bottom of the lock, where they will not interfere with the fixation of the next panel. The next strip is inserted into the lock, pressed and fastened with self-tapping screws from the inside. All subsequent parts are attached in the same way.

Attention! Be sure to check where the wiring goes in the wall. To do this, you can use inexpensive devices such as indicator screwdrivers, signaling devices or metal detectors.

Prices for popular models of screwdrivers

Screwdrivers

How to fix panels to an uneven wall on a crate - step by step instructions

If the wall is very uneven, and living in the apartment is supposed to be long, you can’t do without crates. There are 3 types of crate systems: wooden, metal and plastic. Wooden - this is an option for the most extreme case. The tree is not suitable for the bathroom - it will swell from moisture, for the same reason you should not use it on the loggia. That's why the best way- galvanized profiles for plasterboard width 40mm.

The only drawback of the traditional crate fastening is that it eats 3-4 cm of usable area at each wall. But under it, you can lay communication cables, as well as make a soundproof layer in the apartment or a heat-insulating layer on the loggia.

A good variety of a convenient and easy-to-assemble crate system is plastic mounting strips and plates - kleimers. This is a special fastening system designed for PVC cladding. Fastening is carried out as quickly and simply as possible: the plate snaps into the groove on the profile with clamps. No other fastener is used. If necessary, such a finish is instantly disassembled: just pry it with a screwdriver. Installation of the entire cladding in a room of 15 squares with such a system will take no more than a day.

The advantages of plastic crates are obvious. Firstly, in case of damage to one panel, it can be pulled out and replaced for this no need to disassemble the whole structure. Secondly, if the house is shrinking, or if it Vacation home, as well as during seasonal shifts cladding will retain its solidity. Thirdly, such a crate eats only 1 centimeter from every wall.

For bathrooms and kitchens, the best option is a ready-made plastic crate system sold in construction departments. It does not deform due to high humidity and temperature fluctuations, does not rot or crack. Galvanization is also a great solution to the problem. It is also permissible to use wood blocks, but before starting work, they must be treated several times with special impregnations from decay.

Let's take a step-by-step look at how to mount the crate:

Step 1. We clean the wall from crumbling old finishes. You don't need to level it.

Step 2 We process the surface of the wall with antifungal compounds.

Step 3 We mark the places for the slats of the crate structure. They should be perpendicular to the PVC panels. If they are mounted vertically, then the crate is mounted horizontally. The spacing of the bars should be 30-35 cm.

Step 4 We fasten the bars at the beginning and at the end of the wall, around openings, niches and other structural elements rooms. Then the rest. The whole system is attached to the dowels. IN concrete put 6*40mm, in brick 6*60mm in increments of about 60cm.

Step 5 We align the crate with a plumb line in one plane. To do this, at first the fasteners are not completely twisted, and if necessary, thin plywood is stuck under the planks to the required level. After alignment, the fasteners can be tightened. For attachment, you can use hangers for plasterboard. With them it is easier to level the surface of the crate.

Step 6 If the system is assembled from plastic elements, it is necessary to check their perpendicularity to the PVC panels, otherwise there is a risk that the locks will not snap into place. It will be more convenient to work with a plastic crate if wooden bars are installed around the perimeter of the entire wall being trimmed along the thickness of the guides.

Prices for building levels

Building levels

Now you can consider how the panels are attached to the crate:

- Starting and ceiling plinths and fastened with appropriate fasteners to the system. The result is a frame. It is necessary to strictly check the verticality and horizontality of this frame, and then the plane of the cladding in terms of level, since even a millimeter deviation can cause a blockage in the future.

- Elements are cut to length with a hacksaw. A protruding spike is cut off from the first panel, then the cut side is inserted into the corner, and the edges are tucked into the profiles. The bar is driven all the way and fixed to each crossbar.

- Joining subsequent panels.

- The latter is cut to width and inserted into profiles.

Video - Installation of PVC panels on the crate

Note! Some craftsmen prefer to work without corner profiles. The panel that goes into the corner can be cut from the back and gently bent so as not to break. This usually succeeds the first time, since plastic for the manufacture of panels is used quite flexible and elastic. From the front side, such a fold will look nice and neat.

Features of fastening in different rooms

Pay attention to the article - where we analyzed interesting options installation of panels in the restroom.

The following features of the finishing device in different rooms can be distinguished:

- In the bathroom and high humidity and temperature fluctuations often occur, so it is better to take a crate system made of plastic or stainless steel. If the wall is without special bumps and pits, you can glue the cladding on liquid nails or even mounting foam. Mounting on self-tapping screws (also made of stainless steel) is acceptable.

- For finishing loggias or balconies it is better to take sandwich panels and lay them on the crate, under which you can place a layer of thermal insulation.

- For finishing living rooms take decorative panels with patterns, drawings or with a 3D effect. Installation should be carried out taking into account the condition of the walls. If there are a lot of wires in the room, it is better to use a crate for which they can be hidden. In the rooms, you can arrange a more economical wooden crate, since the humidity drops are small here.

- For decoration rooms country houses , used only in the season, as well as terraces and verandas, you should use any crate, except for wood, since during an unheated period, humidity may increase in them.

- In addition, the panels are used for finishing administrative premises, offices, trade departments and supermarkets.

Many have seen how to install plastic panels on the wall, but not everyone knows how to do it correctly. It is how to install plastic on the walls that we will consider today. After all, there is different types panels and their installation is done in different ways. In the video in this article, you can get acquainted with the types of panels and see the individual points of installation.

Installation of plastic panels on the wall will depend on the type. There are two main divisions.

This:

PVC panels for outdoor decoration | These panels are made thicker, because they must withstand external influences. They are more difficult to process and have a less elegant appearance. |

PVC panels for interior decoration | This plastic is thinner and much easier to process. More susceptible to external influences. But its production is more accurate. Panels with a flat wall can simply be glued flat. |

How to properly install plastic panels on the walls will depend on their appearance. After all, they are mainly attached to the crate, and the number of rails will depend on the shape of the panels.

Here they are:

Sheet panels | This option is suitable for a large area of \u200b\u200bfinishing. It fits perfectly, and you can do the finish in a short time. But this is for interior work. After all, this option is not thick and will not withstand external influences. |

Panels for lining | For exterior finish Panels are basically made like this. Compliance with three points will help to qualitatively perform a soft crate:

Below is the essence of the technology:

Installing profilesThe installation process should be as fast and accurate as possible. It is necessary to minimize the contact of adhesive tape with air. To do this, it is enough to know and follow a few simple rules.

Panel mountingThe panel device technology practically does not differ from the installation of the profile. Exceptions are a few of the following.

About the finish profileThe device of this element is the final stage in working with PVC panels. It is very important to correctly and accurately install the profile. It gives completeness and aesthetics to the entire construction process. In many ways, the type of completed section depends on the installation of this element. This element is often replaced with a corner or part of it. This is due to the inflated price of the profile.

Now you know how to install plastic panels on walls. The main thing is to use high-quality and proven materials. And you can do everything quickly and efficiently. The instructions will help you not to make mistakes. |

How to sheathe walls with plastic panels? If there are bumps, potholes or hard-to-remove mold foci on the walls, which are difficult to remove from the surfaces with plaster and putty, the most rational solution is to decorate the walls with plastic panels with your own hands.

A properly installed wall frame allows you to make the coating perfectly even, get the plane solid, mask all defects. The article will tell you how to do it correctly.

Plastic wall panels are products made from polyvinyl chloride (PVC) by extrusion.

During this process:

- The molten dense mass of the composition is squeezed out through the dies on special equipment corresponding in shape to the profile of the panels.

- Workpieces are cooled at a certain temperature.

- Cut to required sizes.

- The standard panel thickness is:

- 5 millimeters;

- from 8 to 10 millimeters. Despite fluctuations in thickness, this is a single standard size, for which component elements, such as moldings, are made the same.

- The width of plastic sheets for wall decoration ranges from 20 to 37 centimeters- These are fairly wide plastic wall panels.

- Standard element length:

- 2.6 meters;

- 2.7 meters;

- 3 meters.

The advantages of PVC panels are:

- Security. Do not emit harmful elements when heated to a temperature (+80°C).

- Aesthetics. No seams at the joints, a variety of colors and patterns. On PVC panels, you can apply photo images by thermal printing, paint them, decorate them with a self-adhesive film. This allows you to use the material:

- in the bathroom (see Facing the bathtub with plastic panels: doing it right);

- loggias (see Finishing a loggia with PVC panels: installation instructions);

- living room.

Separate panels are sheathed on the walls in the bedroom for adults.

- Durability, over 10 years, and high durability, despite the dampness in the bathroom and temperature fluctuations on the balcony.

- Practicality, ease of maintenance. It is enough to periodically remove dust.

Along with this, finishing with PVC panels has a number of disadvantages, which are due to chemical composition and material properties.

These include:

- Low hygiene. Plastic does not breathe, it does not allow steam to pass through, which requires restrictions on its use in the bedroom. The kitchen should be well ventilated and a powerful extractor fan should be installed in the room to remove fumes and soot. Glare from a glossy surface from the sun's rays and polarization adversely affects the psyche of the child.

Tip: You can’t decorate a children’s bedroom with plastic glossy panels.

- Burning toxicity. When ignited, PVC burns actively with the release of gases with very serious consequences. Because of this, the kitchen is not completely sheathed with plastic panels: at risk is a section of the wall above gas stove. Finishing should not have contacts with wiring, heating, lamp housings.

What elements are needed for mounting panels

Before sheathing the walls with plastic panels, it is necessary to purchase additional moldings - fixing and at the same time decorative elements that give the cladding a final look. Profiles come in several types, shown in the photo.

They may be:

- Starting.

- Finishing.

- Guides: top and bottom. These are installation moldings that create a frame around the perimeter of the entire surface being trimmed.

- Corner outdoor. With its help, protruding corners of the room are formed.

- Corner internal, mounted along the internal corners.

- Connecting. Designed for end connection of elements, with combined finishing of panels of different colors.

- Skirting boards or fillets. Fixed with glue.

- Simple corners. Used for finishing corners, glued to the skin.

The panels are fastened to the wooden frame with staples and a construction stapler, to the metal frame - with self-tapping screws.

Tip: Polyvinyl chloride has a high coefficient of thermal expansion, which means that during installation, the fasteners must be made with a small gap for elastic deformation of the plastic panel. At the same time, the staples make it possible for the plastic to move, but the “flea” screws do not. In this case, it is necessary to use thermal washers with self-tapping screws, consisting of a sealing ring, a cover and a washer with a leg. There must be a gap of at least 1.5 millimeters between the wall of the hole in the plastic and the leg of the washer.

Before sheathing walls with plastic panels, a video lesson will tell you the nuances of the work.

How to make a crate for panels

Plastic wall cladding begins with the manufacture of a frame for panels or wall battens. This will allow in the future to quickly replace, if necessary, plastic panels and securely fasten them.

For the crate are used:

- Wood bars.

- Metal profile - less often.

In this case, small cells located behind the structure can be used for laying insulating materials. On the surface of the wall, the crate is fastened with clamps or self-tapping screws in dowels.

The fastening elements of the crate are installed in increments of up to 0.5 meters. The distance between the bars is chosen so that the laying of the insulating material is as simple as possible.

How to install pvc panels

One of the main features of the material is ease of installation.

Wherein:

- Plastic panels for walls, wide mounting shelves are fixed to the crate with brackets or self-tapping screws.

- On the other side of the part there is a small mounting shelf hanging over the crate.

Before sheathing the walls with plastic, the necessary tools are purchased:

- Electric jigsaw, for adjusting the dimensions of the mounted elements.

- Construction stapler, for attaching plastic fragments to a wooden crate.

- Miter box, for reliable fixation of the tool when cutting panels.

- Plaster spatula, to facilitate the bending of a part of the finishing profile.

- A rubber mallet helps to easily pull the panel into place.

Installation instructions for plastic panels after the installation of the crate:

- Profiles installed:

- guides;

- starting;

- finishing.

- The first sheet of the panel is installed in the lower profile, the element is bent in an arc and installed in the upper profile.

- With the help of a mallet, the sheet is pressed tightly against the starting profile.

- The rest of the plastic elements are attached in the same order, except for the last one.

Tip: When installing the remaining element, you should be very careful.

- The last panel is cut from the side of the large fastener shelf. A small reserve is being made for its expansion.

- The panel of the finishing profile is bent, the lower part of the last element is installed so that it fits snugly into the profile. For this:

- part of the finishing element is taken away;

- the panel starts up to the upper corner;

- the shelves of the finishing and mounting profiles are bent, and the plastic fragment is finally fixed.

- The panel and the finishing profile are attached to the crate with a construction stapler.

- Skirting boards are being installed.

How to glue pvc panels

In this way, you can finish smooth, dry surfaces.

Wherein:

- The surface must be free of dust, dirt and grease.

- Glue is used special - "liquid nails". Do not use adhesives containing cleaners or solvents.

- When sheathing the shower wall, a small gap of up to three millimeters is left at the bottom to prevent a “gust” of material when expanding the pallet.

- Seams must be filled with silicone sealant.

How to care for panels

Caring for plastic is quite simple:

- Wash panels with a soft cloth

- Use for washing special products that do not contain solvents or abrasive particles. Most often, ordinary soapy water is sufficient.

- At the end, the surface is washed with plain clean water.

How we sheathe the walls with plastic panels can be seen in the video in this article. Wall cladding with plastic panels great option, helping to save enough money and make the room comfortable. The price of PVC panels in the repair of premises and wall decoration is very different, there is always the opportunity to choose the best option that satisfies the quality and cost.