Where Isover Used? Isover - insulation: technical characteristics of thermal insulation, density standard. Scope and properties

Today, construction markets are simply crammed with a variety of thermal insulation materials that differ in price, types of forms, installation method and, of course, quality. Competing firms create new models of insulation, only to occupy the highest sales bar in the construction markets. There are materials that always remain in the lead. One of these materials is Izover. This is a heater that specifications achieve simply colossal quality in the thermal insulation of a room or building.

In terms of properties, Izover is very close to mineral wool, and also has its pros and cons. The material is produced in the form of pressed rolls with a rigid and soft structure, so it is excellent for insulating roofs, facades on buildings, ceilings and walls inside a room. The basis of the Izover material is fibers, which have a length of about 100-150 microns and a thickness of 5 microns. This quality and dimensions increase the level of elasticity and resistance to load transfer. external factors.

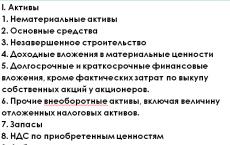

Technical characteristics of Izover

The Izover material is made of the highest quality fiberglass, and this is achieved through the use of TEL technology. Izover has no analogues on the construction market today. Izover has the following advantages:

Technical characteristics of insulation Izovol

The technical characteristics of the insulation have not only positive qualities associated with thermal insulation. There are also secondary advantages, such as service life, environmental friendliness and the weight of the insulation, which play a big role during installation.

Insulation release form

In order to increase the usability of Izover, many companies produce material in several forms. These can be rolls, slabs, and mats, which in their structure have different rigidity for insulating the outer or inner side of the wall surface in buildings, and the price also differs depending on the choice of form type.

In order to increase the usability of Izover, many companies produce material in several forms. These can be rolls, slabs, and mats, which in their structure have different rigidity for insulating the outer or inner side of the wall surface in buildings, and the price also differs depending on the choice of form type.

Also distinguish single layer and double layer Izover. In the first case, the thickness reaches 5-10 centimeters. The two-layer material does not differ too much in thickness, since here the dimensions of one layer are about 5 centimeters. Plates can be about a meter in size, or rather, speaking, this is the standard that can most often be found on the construction market, but there are exceptions when ordering insulation on websites or from dealers.

One roll of Izover insulation is about 16–20 square meters, that is, quite large sizes. The width of the roll reaches 1.2 meters, while its length can vary from 7 to 14 meters. It goes without saying that the specifications will be slightly different depending on the choice of material size.

Varieties of Izover models

As mentioned above, the isover material has many models and this is not surprising, because its application has a fairly wide coverage. Heater can be used indoors, which means that the model will already be, it does not have such a rigid structure due to minimizing the impact of external factors, but when insulating the external surfaces of buildings, most often Izover already has a different structure. In fact, there is a whole list of models of insulation.

Model Isover KL34

Most often, this model is used for warming the facade and masonry of the building, which has several layers at once. Distinctive feature such a model is that it has a size of 5–10 centimeters in thickness, but it does not require additional fasteners, and installation is carried out only on a pre-installed frame.

Model Isover KL37

This model is produced in the form of rolls, which have a pressed structure. That is why the material can be used indoors, but the main thing is the almost identical installation feature. There is also no need to use additional fasteners, but it is important to install the insulation on the frame so that it fits well to the surface. Most often, this model is used for attic insulation in private homes.

Model Isover KL40

The KL 40 model differs in that it has two layers in its structure at once. Izover technical characteristics of this model allow the use of insulation for installation on horizontal surfaces, that is, it is actually most often installed in the form of a floor or ceiling material. If the dimensions on the floor or ceiling do not allow the use of a two-layer material, it can be easily divided and only one layer installed. The price of such a heater is relatively lower than other models.

Disadvantages of using Izover

The main drawback of Izover insulation, which many sites are silent about, is of course fiberglass structure, which has very fine glass chips. Because of it, installing a heater is quite inconvenient and dangerous, because when it hits a large number such glass dust into the body, unwanted Negative consequences for the body.

The main drawback of Izover insulation, which many sites are silent about, is of course fiberglass structure, which has very fine glass chips. Because of it, installing a heater is quite inconvenient and dangerous, because when it hits a large number such glass dust into the body, unwanted Negative consequences for the body.

In order for there to be no health consequences when installing insulation, you need use gloves, goggles and a respirator. Many may think that this is an extra security measure, but just look at the fiberglass under a good sunlight to see all the glass dust.

Conclusion

Isover - great material, which surpasses in quality a large number of analogues in the modern construction market. Due to all its advantages, the insulation is deservedly in the first place in terms of the number of purchases and popularity.

Izover insulation

Market building materials replete with a variety of insulation and soundproof materials for buildings. As a rule, the main difference between them is the form of manufacture and the composition of the base, but the country of origin, the reputation of the manufacturer and the possibilities of application also play a significant role.

Insulation usually costs a significant amount, so in order not to get into a mess, you need to bet on a guaranteed quality product, for example, products from Isover. According to experts and customer reviews, it occupies a leading position in such characteristics as service life, reliability and efficiency.

Peculiarities

Isover insulation is used both in residential buildings and in public institutions and industrial buildings. This product is produced and sold by a company that is part of the international association Saint Gobain- one of the leaders in the building materials market, which arose more than 350 years ago. Saint Gobain is known for its innovative designs, applications modern technologies And high quality its products. All of the above points also apply to Isover heaters, produced in various modifications.

Isover products share many of the pros and cons of mineral wool as they exhibit similar properties. On the market, they are sold in the format of slabs, rigid and semi-rigid, and mats rolled into rolls according to their own patented technologies in 1981 and 1957. This insulation is used for processing roofs, ceilings, facades, ceilings, floors and walls, as well as ventilation pipes. Isover is based on glass fibers. Their length is from 100 to 150 microns, and the thickness is from 4 to 5 microns. This material is resilient and resistant to stress.

Isover insulation is tear-resistant, which means it can be placed on complex structures. For example, these include pipes, elements of production lines, industrial equipment, and others.

When using Isover as a heater or sound insulator, it must be protected from moisture.

Usually, vapor barrier and waterproofing films are used for this. It is customary to install a vapor barrier from the inside of the house to protect it from condensation. The waterproofing film is placed outside, saving from rain and melting snow. As a rule, Isover is mounted without the use of fasteners, the only exception may be the insulation of the ceiling - in this case, dowels-"fungi" are used.

Under the "cap" of the brand, a lot of heaters are produced, which have various purpose and perform various functions. They are divided into two groups: for industrial and domestic use. In private housing construction, the Classic material, marked with the letter K, is most often used.

The price of Isover insulation may vary in different regions of our country. Usually the average indicator varies from 120 to 160 rubles per square meter. In some areas, it is more profitable to purchase it in packages, and somewhere in cubic meters.

The subtleties of manufacturing

Saint Gobain has been operating on the Russian market for more than 20 years and is engaged in the production of materials at two factories: in Yegoryevsk and Chelyabinsk. All enterprises undertake to pass the certification of the international environmental management standard, which makes Isover insulation an environmentally friendly product that is on par with cotton and linen in terms of environmental performance.

As part of different types Isover contains both glass and basalt fibers. This structure is the result of processing glass cullet, quartz sand or mineral rocks of the basalt group.

- It is in Isover that mineral raw materials are used. Its constituents are melted and drawn into fibers following the TEL technology. As a result, very thin threads are obtained, which are interconnected using a special composition of resins.

- The composition of cullet, limestone, quartz sand and other minerals is carefully mixed beforehand.

- To obtain a homogeneous fluid mass, the resulting mixture must be melted at a temperature of 1300 degrees.

- After that, the "liquid glass" falls on a rapidly moving bowl, in the walls of which holes are made. Thanks to physics, the mass flows outward in the form of threads.

- In the next step, the fibers must be mixed with a polymer adhesive that has a yellow tint. The resulting substance enters the furnace, where it is blown with hot air and moves between steel shafts.

- The glue sets, the layer is leveled and glass wool is formed. It remains only to send it under the circular saws in order to cut it into fragments of the required size.

When buying Isover, you can see the quality certificates. When the material is produced under license, the seller provides documents confirming the EN 13162 and ISO 9001 standards. These become a guarantee that the Isover is made of safe materials and there is no prohibition on its use indoors.

Varieties

There are different types of insulation, depending on whether they are sold in a roll format or in slabs. Both varieties can have different sizes, and different thicknesses, and different laying technology.

Heaters are subdivided and depending on industries of application. They are universal or suitable for individual areas - walls, roofs or saunas. Often the purpose of the insulation is encrypted in its name. In addition, it is worth adding that the materials are divided into those used indoors and on the facades of buildings.

It is also worth adding that Isover are divided according to the stiffness of the material. This parameter, related to the characteristics of GOST, is indicated on the package and is closely related to the density, compression ratio in the package and thermal insulation properties.

Advantages and disadvantages

All Isover heaters have similar positive and negative characteristics. If we talk about the pros, then the following are distinguished:

- The material has low thermal conductivity. This means that the heat stays in the room for a long time, so it is possible to spend less on heating, thereby saving significant amounts.

- The insulation demonstrates a high ability to absorb noise due to the presence of an air gap between the fibers, which absorbs vibrations. The room becomes as quiet as possible, protected from external noise.

- Isover has a high level of vapor permeability, that is, the material breathes. It does not retain moisture and the walls do not begin to dampen. In addition, the dryness of the material increases its service life, because the presence of moisture negatively affects the thermal conductivity.

- Thermal insulators are completely non-flammable. According to the flammability scale, they received the highest rating, that is, the best resistance to fire. As a result, Isover can be used to build wooden buildings.

- Plates and mats are lightweight and can be used in buildings that do not tolerate excessive load.

- Service life can reach 50 years.

- Heaters are treated with compounds that increase moisture resistance.

- The material is easy to transport and store. The manufacturer compresses Isover 5-6 times when packing, and then it completely returns to its shape.

- There are product lines with different technical characteristics, designed for different areas of construction.

- Isover is highly resilient. The insulation is superior to other mineral wools in this indicator due to the special TEL technology, according to which it is produced.

- 5 centimeters of mineral wool are equal in thermal conductivity to 1 meter brickwork.

- Isover is resistant to biological and chemical attack.

- Isover has quite affordable price especially when comparing it to other alternatives.

- The material demonstrates high rates of density and rigidity, which allows it to be mounted without additional fasteners.

However, there are still a few downsides:

- A relatively complex installation process, during which it is necessary to additionally protect the respiratory system and eyes.

- The need to lay an additional layer of waterproofing during construction. Otherwise, it will absorb moisture, which will violate the thermal insulation characteristics. In winter, mineral wool can even freeze, which is why it is important to leave a ventilation gap.

- Some types still do not belong to non-combustible, but to self-extinguishing - in this case, you will additionally have to comply with fire safety requirements.

- The soft structure of cotton wool limits the scope.

- The only negative for industrial enterprises is that when the temperature rises to 260 degrees, Isover loses its properties. Namely, there such a temperature is quite possible.

Specifications

Isover is produced using a special patented TEL technology and has excellent technical characteristics.

- Coefficient of thermal conductivity very small - only 0.041 watts per meter / Kelvin. A big plus is the fact that its value does not increase over time. Insulation retains heat and retains air.

- As for soundproofing, indicators different models different, but always at a high level. This means that any kind of Isover will somehow protect the room from external noise. All this is ensured by the air gap between the glass fibers.

- With regard to combustibility, then Isover varieties are either non-combustible or low-flammable and self-extinguishing. This value is determined by the relevant GOST and means that the use of almost any Isover is absolutely safe.

- Vapor resistance of this insulation ranges from 0.50 to 0.55 mg / mchPa. When the insulation is moistened by at least 1%, the thermal insulation will immediately deteriorate by as much as 10%. To prevent this from happening, it is necessary to leave a gap of at least 2 centimeters between the wall and the insulation for ventilation. Glass fibers will return moisture and thus maintain thermal insulation.

- Isover can serve up to 50 years and for a rather impressive period not to lose their thermal insulation qualities.

- In addition, the heater contains water-repellent components which makes it inaccessible to mold.

- It is also important that in fiberglass material bugs will not be able to settle and other pests. In addition, the density of Isover is approximately 13 kilograms per cubic meter.

- Isover considered environmentally friendly insulation and absolutely safe for human health.

- It is much lighter than the competition, therefore, it can be used in rooms made of fragile materials or in which it is forbidden to create excessive loads. The thickness of a single-layer Isover can be either 5 or 10 centimeters, and in a two-layer Isover, each layer is limited to 5 centimeters. Slabs are usually cut meter by meter in size, but there are exceptions. The area of one roll varies from 16 to 20 square meters. Its standard width is 1.2 meters, and the length can vary from 7 to 14 meters.

Isover produces not only universal heaters, but also narrowly focused actions that are responsible for specific elements of the building. They differ in size, functions and technical properties.

Isover can be produced for light thermal insulation (wall and roof insulation), general building insulation (soft slabs for frame structures, medium hard slabs, mats without fasteners and mats with foil on one side) and special purposes (for pitched roofs).

Isover has a special marking where:

- KL are plates;

- KT - mats;

- OL-E - mats of special rigidity.

The numbers show the class of thermal conductivity.

The packaging also indicates where one or another type of insulation can be used.

- "Isover Optimal" It is considered a universal material that is used to process ceilings, walls, partitions, roofs and floors along logs - that is, all parts of the house, except for the foundation. The material has low thermal conductivity and retains heat in the house, it is elastic and non-combustible. Installation is very easy, does not require additional fasteners, and, given the versatility, all of the above points make "Optimal" one of the most popular representatives of Isover.

- "Isover Pro" It is also a versatile insulator. It is sold in the form of rolled mats and is used for roofs, walls, ceilings, ceilings and partitions. "Profi" has one of the lowest thermal conductivity and is very convenient to cut. The insulation can be 50, 100 and 150 mm thick. Just like "Optimal", "Profi" belongs to the NG class in terms of combustibility - that is, it is absolutely safe in a fire situation.

- "Isover Classic" is chosen for thermal and sound insulation of almost all parts of the house, except for those that experience the greatest load. The "exceptions" include the basement and foundation. The material is sold both in rolls and plates and has low rigidity. The porous structure makes it an excellent insulator. However, this type does not differ in strength and durability, which means it is not suitable for installation under a screed and for finishing walls under plaster. If, nevertheless, there is a desire to use it for facade insulation, then only in combination with siding, clapboard or facade panels fixed on the crate. "Classic" insulates the house very well and allows you to reduce heating costs by almost half. In addition, it is a good sound insulator and protects the building from unnecessary noise.

- "Isover Warm house-Stove" and "Isover Warm House" used in the installation of most parts of the house. They have almost the same technical characteristics, with the exception of volume and linear dimensions. However, it is customary to use plates in one area, and mats in another. "Warm House-Stove" is selected for the insulation of vertical surfaces, inside and outside the house, as well as frame buildings. "Warm House", which is sold in the form of rolls of mats, is used to insulate interfloor ceilings and the floor above the basement (installation takes place between the lags).

- "Isover Extra" It is made in the form of plates with increased elasticity and 3D effect. The latter means that after compression, the material expands and occupies all the free space between the surfaces that require insulation. The plates are tightly connected to each other and just as tightly adjoin to the surfaces. "Extra" is also universal, but is usually used for wall insulation indoors. It is worth adding that it can also be used for thermal insulation of facades in the case of subsequent cladding with bricks, clapboard, siding or panels, and for roofs. "Isover Extra" is considered one of the most effective heat preservation materials.

- "Isover P-34" It is produced in the form of plates, the thickness of which can be 5 or 10 centimeters. They are mounted on a frame and are used to insulate ventilated parts of the house - facade or multilayer masonry. It is possible to insulate both vertical, and horizontal, and inclined surfaces, since the model is very elastic. "P-34" is easily restored after deformations and is resistant to shrinkage. It is completely non-combustible material.

- "Isover Frame P-37" used for insulation of floors between floors, roof slopes and walls. It is important to consider that the material must fit snugly against the surface. "Isover KT37" also adheres tightly to the surface and is used for insulation of floors, partitions, attics and roofs.

- Isover KT40 refers to two-layer materials and is sold in the form of rolls. It is used exclusively on surfaces located horizontally, that is, for ceilings and floors. In case of insufficient depth of the cavity, the material is divided into two separate layers of 5 centimeters. The material has a high vapor permeability and belongs to non-combustible materials. Unfortunately, it cannot be used on surfaces with difficult wet conditions.

- Isover Styrofoam 300A requires mandatory fasteners and is available in the form of plates. The material has increased moisture resistance and thermal insulation due to the presence of extruded polystyrene foam in the composition. Such insulation is used to treat walls inside and outside the premises, floors and flat roofs. It is possible to apply plaster on top.

- "Isover Ventiterm" has a somewhat unusual scope. It is used for ventilated facades, pipes, plumbing, as well as to protect precision instruments from the cold. You can work with it both with and without fasteners. Such a heater is produced in the form of plates. Its technical characteristics are quite serious, especially in terms of strength - an order of magnitude better than that of ordinary mineral wool.

- "Isover Frame house» It is used to insulate walls from the outside and from the inside, pitched roofs and attics, as well as ceilings and partitions. In general, it is suitable for improving any frame structures in the house. The elasticity of the material helps to retain its shape during operation and installation, while the stone wool fibers provide additional noise protection.

Roofing

For roof insulation, some universal varieties of Isover are used, for example, "Optimal" and "Pro", as well as highly specialized "Isover Warm roof" and "Isover Pitched roofs and attics". Both materials are designed for the same purpose, but have different characteristics: they differ in the form of release, linear dimensions and the material used. They also undergo a special treatment that gives the products increased moisture resistance.

- "Warm Roof" produced in the form of mats rolled up. They are sold in plastic packaging with markings that allow you to cut the material according to its width. "Pitched roofs" are sold in the form of slabs, pressed and packed in polyethylene. They are used in the case of insulation of pitched and mansard roofs, as well as for surfaces inside and outside the building.

- "Isover Pitched Roof" used exclusively for roof insulation. It is moisture resistant, does not let in sounds, has high vapor permeability and is non-flammable. As a rule, it is recommended to use it in two layers, with the top one covering the joints of the bottom one - this way the material will retain heat even better. "Pitched Roof" is available in the form of slabs with a width of 61 centimeters and a thickness of 5 or 10 centimeters. "Pitched Roof" has a high hydrophobicity - it does not absorb moisture, even if immersed in water for a long time. This allows the material to be used in difficult conditions that are not suitable for other heaters.

- "Isover Ruf N" is a heater for flat roof. It has the maximum level of thermal protection and is compatible with any building materials.

- "Isover Master of Warm Roofs" also has a high rate of thermal protection. Due to its vapor permeability, it eliminates the accumulation of moisture in the wall. In addition, when insulated from the outside, the plate will retain its properties in any weather.

- "Isover OL-P" is a special solution for flat roofs. It has ventilated grooves to remove moisture and is created using the tongue-and-groove technology, which increases the tightness of the mineral wool layer.

Facade under plaster

To insulate the facade for the purpose of further coating with plaster, the following types of Isover are used: "Facade-master", "Plaster Facade", "Facade" and "Facade-Light". All of them are sold in the form of plates and are non-combustible material.

- "Facade-Master" p It is used for insulation of facades of residential buildings up to 16 meters high. The plaster must be applied in a thin layer.

- "Plaster Facade", which is an innovative material, costs much less than the previous one, but performs the same functions and is applied under the same conditions.

- "Facade" used for subsequent coating with decorative plaster.

- "Facade-Light" used for houses with a small number of floors and for subsequent finishing with a thin layer of plaster. For example, this option is chosen by the owners country houses. Such material is strong, rigid, but light in weight.

For soundproofing buildings

In order to protect the house from various noises, both external and internal, "Isover Quiet House" and "Isover Sound Protection" are used. Besides, you can also use universal heaters - "Classic" and "Profi".

- "Quiet House" has a high ability to absorb noise, so it is often chosen for soundproofing walls and partitions between rooms. Plates are also used for horizontal surfaces - for logs, beams, spaces between the suspended ceiling and the original one. The material performs two functions, so the home becomes quiet and warm.

- "SoundProtection" has high elasticity, therefore it is often mounted inside the frame crate, which acts as a partition or is fixed on the wall (in the case of facade coatings). The material can be used in combination with other heaters and thus create a double layer that retains heat and does not let in sounds. Such a solution will be especially effective for creating frame partitions and attic floors.

Wall insulation inside

For thermal insulation and sound insulation of the walls of buildings inside and outside, Isover Profi, Isover Classic Slab, Isover Warm Walls, Isover Warm and Quiet Wall and Isover Standard are recommended. These heaters are sold both in mats in rolls and in the form of saws.

- "Standard" usually selected for thermal insulation structures consisting of many layers. In this case, siding, lining, brick, block house and other materials can be used as a finish. In addition, these plates are suitable for thermal insulation of frame structures, for mansard and pitched roofs. Due to the medium density, the material is not suitable for further plastering of walls. "Standard" has good elasticity, which means a snug fit to surfaces and structures. The plates are fixed using special clamping fixtures.

- « warm walls» - these are plates that are also made of glass fibers, but in addition are reinforced with a water-repellent treatment. This variety is also used for thermal and sound insulation of walls inside and outside, installation in a frame, insulation of roofs, loggias and balconies. Increased moisture resistance becomes an additional plus in the last two examples. The material is resilient and elastic, does not slip or break.

- "Warm and Quiet Wall" It is sold both in the form of plates and rolls. The material has a porous structure, which allows it to perform two functions. In addition, this variety is characterized by increased vapor permeability and, as it were, “breathes”. This allows you to create a comfortable environment in residential premises. The plates are elastic and do not even need to be additionally fixed - they themselves will qualitatively “spread” inside the frame.

- "Warm and Quiet Wall Plus" has similar characteristics to the "Heat and Quiet Wall", which will be discussed a little later, but has a lower thermal conductivity and better sound insulation. The slabs are used for walls inside the building, walls outside under siding or facade coverings and, with additional protection, for warming frame structures.

Floor insulation

To insulate floors with high quality, you can choose two specialized materials - "Isover Floor" and "Isover Floating Floor", which have slightly different technical and operational characteristics, which, however, combine damping properties and mechanical characteristics. Both types are easy to install, but using different technologies. In addition to insulation, these materials are also distinguished by high-quality bilateral sound insulation.

- "Flor" used for the construction of floating floors and structures along the logs. In the first case, the material covers the entire surface and creates a warm and quiet floor. Due to the adaptation to high loads, the insulation can also be placed under a concrete screed.

- "floating floor" always used to create a concrete screed that will not be connected to the walls and the base, in other words, for a "floating" floor. The plates are always laid out on a perfectly flat surface and connected using a technique called the “thorn groove”. Due to the fact that the fibers are arranged vertically, this type of insulation demonstrates outstanding strength characteristics.

Bath thermal insulation

For warming baths and saunas, Isover has special solutions - mats rolled up and called "Isover Sauna". This coating has a foil layer on the outside, which reflects heat and creates a vapor barrier.

"Sauna" consists of two layers. The first is mineral wool based on fiberglass, and the second is foil. It should be noted that mineral wool is a non-combustible material, and the foil coating has a flammability class G1. It can withstand temperatures up to 100 degrees due to the presence of glue, and at a higher temperature it can ignite and die out on its own. To avoid an accident, the foil layer is additionally covered with clapboard.

"Isover Sauna" on the one hand performs the functions of thermal insulation, and on the other hand, it is a barrier to steam so that the mineral layer does not suffer from a large amount of evaporation. The foil reflects heat away from the walls in the room and increases the level of heat retention.

Installation nuances

The first step is to choose the right type of Isover, for this it will be enough just to look at the existing markings. Each product is assigned a class and number of stars, and these data are contained on the packaging. The more stars, the better the heat-shielding properties of the material.

To insulate a house without special requirements, two stars are enough; for increased thermal protection and ease of installation, three stars are selected. Four stars are assigned to the product of the latest generation with increased thermal protection. In addition, each package has a label with precise data regarding thickness, length, width, package volume and number of pieces.

Mineral wool insulation is mounted in the same way as any other heat-insulating material. When insulating the walls inside the room, the first thing to do is to make a crate of wooden or metal planks. Drywall will be attached to them later. The walls are pre-primed, and a heat-reflecting coating is fixed on those that border the street.

When installing the battens, it is necessary to observe a step corresponding to the width of Isover, slabs or mats. At the next stage, the insulation sheets are glued to the wall, if necessary, a water-repellent film is fixed and horizontal strips are stuffed.

Wall insulation outside the building begins with the fact that a wooden frame is attached to the wall.

- It is usually made from bars measuring 50 by 50 millimeters, which are attached vertically.

- Insulation can be mounted in one or two layers. It is placed in the structure so as to fit snugly against the wall and frame without gaps and cracks.

- Further, the bars are again attached on top, but already horizontally. The distance between the horizontal bars should be the same as between the vertical ones.

- With two-layer insulation, a second layer of thermal insulation is placed in a horizontal crate, moreover, overlapping the joints of the first.

- To protect against moisture, a hydro-windproof membrane is placed outside, the necessary ventilated gap is created, and after that you can proceed to the cladding.

Roof insulation begins with the fact that a hydro-windproof membrane, which is also produced by Isover, is stretched along the upper edge of the rafters.

- It is fastened with a construction stapler, and the joints are glued with reinforced mounting tape.

- Further, it is recommended to start the installation of the roofing - a gap is formed on top of the membrane with the help of a pressure bar, and then the coating is installed on the counter-lattice of bars 50 by 50 millimeters.

- The next step is to install the heat insulator directly. With a standard distance between the rafters, the insulation will need to be cut into 2 halves and each installed in the frame. Most often, one piece manages to insulate the entire length of the roof slope. If the distance between the rafters is non-standard, then the dimensions of the thermal insulation boards are determined independently. We must not forget that their width should be at least 1-2 centimeters more. Thermal insulation should fill the entire space without gaps and cracks.

- Next, a vapor barrier membrane is installed along the lower plane of the rafters, which will protect against moisture inside the room. Joints are glued with vapor barrier tape or reinforced construction tape. As always, a gap is left and the installation of the inner lining begins, which is attached to the crate with nails or self-tapping screws.

Floor insulation along the lags is selected in two cases: attic ceilings and ceilings above basements with no heating.

- First, logs are installed and laid with roofing material to prevent rotting and destruction of the structure.

- Then the heat insulator material is installed inside. For cutting, a knife with a blade length of more than 15 centimeters is used. The roll is simply rolled between the lag so as to close the entire space, and no additional fixing actions are required. During installation, moisture of the material should be avoided.

- The next step is to install the overlapping vapor barrier membrane, the joints are glued as usual with reinforced mounting tape or vapor barrier tape. A base is installed on top of the vapor barrier, which is attached with screws to the logs.

- Everything ends with finishing: tiles, linoleum, laminate or carpet.

When carrying out activities for the purpose of soundproofing partitions the first step is the marking and collection of guides and their further installation.

- At a free-standing partition, it is necessary to veneer one side with drywall, and you can begin to create sound insulation.

- Isover mounts between metal frame posts without fasteners, fitting snugly to the structure and filling the entire space without gaps or gaps.

- Then the partition is sewn up on the other side with drywall, and the seams are puttied using paper reinforcing tape.

Thermal insulation of baths and saunas begins with the creation of a wooden frame from bars measuring 50 by 50 millimeters.

- The bars are mounted horizontally.

- The insulation is cut with a knife into two halves and installed in the frame, while the foil layer should be turned inside the warm room. As usual, the material is installed without gaps and cracks.

- The joints are well glued with foil tape, as is the outer surface of the crate. All this will create a sealed vapor barrier circuit.

- A crate is placed over the horizontal bars to create an air gap. It will speed up the warm-up and increase the life of the skin.

- At the final stage, the inner lining is installed.

One of the main mistakes when using Isover is choosing the wrong material width.

If the insulation roll lies freely between, for example, beams, then the main goal will not be achieved. It will be quite costly to cut it into several rows, and leaving it in this state, despite the gaps and gaps, is completely pointless. Therefore, it is extremely important to calculate all the necessary dimensions for the work surface, taking into account the length, depth and width of the beams or battens.

In the event that the insulation is in direct contact with wires or pipelines, it is necessary to check the tightness of communications. In terms of electricity, the situation is not very dangerous, but in the second case it is better to isolate communications with a corrugated pipe.

In addition, all materials must be absolutely dry before the start of the insulation process. If the surface for which Isover is intended is wet, then you will either have to wait for it to dry, or dry the room with a hair dryer or gun.

But the worst mistake, of course, will be the lack of waterproofing and vapor barrier. If you miss these moments, then the material will be wasted, and the thermal insulation effect will not be achieved.

How to calculate: instruction

It is very important to be able to correctly calculate the required thickness of the insulation to create and maintain a comfortable temperature in the room. To determine it, it is necessary to reproduce the heat engineering algorithm, which exists in two versions: simplified - for private developers, and more complex - for other situations.

The most important quantity is the resistance to heat transfer. This parameter is referred to as R and is defined in m2×C/W. The higher this value, the higher the thermal insulation of the structure. Specialists have already calculated the recommended average values for various regions of the country, which differ climatic features. When building and insulating a house, it must be taken into account that the resistance to heat transfer must be at least normalized. All indicators are specified in SNiP.

When building and insulating a house, it must be taken into account that the resistance to heat transfer must be at least normalized. All indicators are specified in SNiP.

There is also a formula that shows the relationship between the thermal conductivity of the material, the thickness of its layer and the resulting thermal resistance. It looks like this: R = h / λ. R is the heat transfer resistance, where h is the layer thickness and λ is the thermal conductivity of the layer material. Thus, if you find out the thickness of the wall and the material from which it is made, you can calculate its thermal resistance.

If there are several layers, the resulting figures will have to be summed up. Then the obtained value is compared with the normalized values for the region. It turns out the difference that the heat-insulating material will have to cover. Knowing the coefficient of thermal conductivity of the material chosen for insulation, it is possible to determine the required thickness.

It is worth remembering that in this algorithm it is not necessary to take into account layers that are separated from the structure by a ventilated opening, for example, determined by the type of facade or roof.

This happens because they do not affect the overall resistance to heat transfer. In this case, the value of this "excluded" layer is equal to zero.

It must be remembered that the material in the roll is cut into two equal parts, usually 50 millimeters thick. Thus, having identified the required thickness of the insulation squares, the product should be laid in 2-4 layers.

- To calculate required amount standard packages for roof insulation, you will have to multiply the area of \u200b\u200bthe roof to be insulated by the planned thickness of the thermal insulation and divide by the volume of one package - 0.661 cubic meters.

- To calculate the number of packs to be used for facade insulation for siding or lining, the area of \u200b\u200bthe walls will have to be multiplied by the thickness of the thermal insulation and divided by the volume of the package, which can be equal to 0.661 or 0.714 cubic meters.

- To determine the number of Isover packs required for floor insulation, the floor area is multiplied by the thickness of the thermal insulation and divided by the volume of one package - 0.854 cubic meters.

Safety

When working with insulation, consisting of fiberglass, be sure to use goggles, gloves and bandages made of gauze or a respirator. Clothing should be with long sleeves and trousers, in addition, do not forget about socks. It is better, of course, to play it safe and wear protective overalls. Otherwise, installers expect unpleasant consequences - itching and burning all over the body. By the way, this requirement applies to all types of work with any mineral wool.

To protect the inhabitants of the house from glass dust, it is recommended to put a special film between the insulation and the top layer, for example, clapboard.

Even if it gets hurt wood panel, insulation particles will not be able to penetrate the room. Material can be cut with simple knife, but it should be sharpened as sharply as possible, in extreme cases, you can use a fairly sharp chisel.

The insulation must always be stored in a dry, closed place, and the packaging must only be opened at the installation site. The room should be well ventilated, and after completion of work, all waste should be collected and discarded. Also, after completing the installation, you must take a shower or at least wash your hands.

Isover mineral wool is one of the leading manufacturers of mineral wool fiberglass heat-insulating materials in the world. These heaters have established themselves as high-quality products with an optimal ratio of price and performance.

Rolled mineral wool Izover

From this article you will learn what types of Izover thermal insulation exist, their characteristics, and how they differ from each other. We will also study the reviews and find out why these mineral wool heaters are better than similar products on the market.

1 Scope of thermal insulation Izover

Thermal insulation materials from the French company Izover, in addition to excellent insulating abilities, also have good noise-reducing properties, which greatly expands their scope.

Izover pierced mineral wool mats are widely used both in industrial construction, for insulation of interfloor ceilings, and free space inside hollow brick walls, and in household thermal insulation of residential premises. According to the reviews, Izover heaters in practice perform much better than the products of the main competing manufacturers - Ursa and Rockwool.

With the help of Izover mineral wool insulation, any surface can be thermally insulated. The company produces materials for internal and external thermal insulation walls, insulation of attic floors, pitched and straight roof ceilings.

An important advantage of Isover thermal insulation is such characteristics as flexibility, resistance to deformation, and tensile strength, which allows it to be installed on structures of complex shape, such as pipes, industrial equipment, elements of production lines, etc.

As already mentioned, Izover mineral wool from the French company Saint-Gobain has, like Isobox stone thermal insulation, soundproofing properties. It is often used for isolation industrial premises And apartment buildings. Mineral wool qualitatively protects the room from any shock and airborne noise.

2 Varieties and technical characteristics of Izover heaters

Under the Isover brand, a very large number of mineral wool heaters differing from each other with different functional purposes are produced. The company divides its products into two categories - for industrial and domestic use.

Consider the most popular types of thermal insulation materials Izover.

3 Isover KL 34

Plate insulation, the thickness of which can be 5 or 10 centimeters. This material is intended for frame mounting, and does not require mandatory fixing with dowels. Model KL34, according to reviews, is characterized by high elasticity, which makes it possible to install it on any surface.

KL34 boards are delivered in double-pressed packages, after opening which, the material immediately takes its original shape. The thermal conductivity of Izover KL34 is 0.034 W / mk, the vapor permeability is 0.53 mg / mchPa.

Among the advantages of this model, it is worth highlighting the restoration after any deformation and resistance to shrinkage. The nominal compressibility of KL34 under a specific load of 2000 Pa is 60% as for Ecover insulation, and the return after compressive loads is 98%.

KL34 corresponds to the flammability class NG - completely non-combustible material, and can be operated in the temperature range from -70 to +250 degrees. Moisture absorption KL34 when fully immersed in water for 72 hours is 5% of the total weight of the board, with partial immersion for 24 hours - 1%.

Izover K line of heaters (l - slab, t - roll)

4 "Pitched Roof"

A material designed to insulate the inner surface of the roof of a house. Release form - plates with a thickness of 5 or 10 centimeters, a length of 117, and a width of 61 cm.

The advantages of Pitched Roof wool include high hydrophobicity - the material practically does not absorb moisture even when completely immersed in water for a long time, which allows it to be effectively used in difficult wet conditions in which other heaters would lose their thermal insulation abilities.

The technical characteristics of Izover "Pitched Roof" are as follows:

- thermal conductivity coefficient - 0.035 W / mK as for the Izba insulation;

- steam conductivity coefficient - 0.55 mg / mchPa;

- Moisture absorption with partial immersion in 25 hours - 0.08 kg / m².

The density of this material is 15 kg / m3, it shows good rebound deformation properties. In terms of combustibility, "Pitched Roof" belongs to the class of non-combustible materials NG, which makes it possible to use it for thermal insulation of industrial premises.

The area of the plates in one package of such insulation is 14.27 m², the weight of the package itself is 10.8 kg.

5 Isover KT37

Izover KT37 - rolled heat-insulating material for insulation internal parts buildings made of concrete, brick, wood and aerated concrete. Consumer reviews indicate that it is perfect for insulating walls from the inside, attic or interfloor ceilings and lag floors.

KT37 belongs to the category of soft thermal insulation, the material has a density of 15 kg / m3, which does not allow the use of this material on surfaces that experience serious mechanical stress.

Compared with the initial volume of the roll, the packed KT37 is compressed almost 2 times, which greatly simplifies its transportation, the volume of one package is 0.16 cubic meters, after opening - 0.71 cubic meters.

The thermal conductivity of Izover KT37, as well as Rockwool Wired Mat 80 plates, is comparable with other heaters of this company, it is 37 W / mk, which makes even single-layer insulation with this mineral wool quite effective.

The thickness of the KT37 roll can be 50 or 100 mm, length - 630 cm, width - 60 cm. The roll form of the insulation makes it possible to cover large surfaces much faster than it can be done with plate material. In terms of combustibility, the product is classified according to the European standard A1, which corresponds to our NG class (non-combustible material).

6 Isover KT40

Isover KT40 is a two-layer heat-insulating material produced in the form of a roll, designed for insulating the walls of frame houses, mounting in the middle of false walls and thermal insulation of free space inside hollow brick walls.

Two-layer Izover KT40

The thickness of the roll KT40 is 100 mm, while due to the two-layer design, the product can be divided into two rolls of 50 mm. The overall characteristics of KT40 are as follows: roll length - 700 cm, width - 61 cm, the area of \u200b\u200bone package of insulation is 17.08 m².

In terms of thermal insulation properties, KT40 is somewhat inferior to the rest of the company's products; its thermal conductivity coefficient is 0.04 W / mk. The material has a high vapor permeability (about 0.5 Mg / MPa), which makes it the best option for insulating the walls of wooden and frame houses.

According to the standards of combustibility GOST 30225 KT40 belongs to the class of non-combustible materials NG. This mineral wool is not intended for thermal insulation of surfaces with difficult wet conditions.

Moisture absorption of the material during partial immersion is about 15% of the total mass, as a result of which it is better to install an additional waterproofing layer when installing KT40.

7 Izover "Venti"

Ecowool Izover Venti is a slab mineral wool insulation designed for thermal insulation of ventilated facades. The technical characteristics of Venti are quite serious, especially in terms of strength - an order of magnitude better than that of ordinary mineral wool.

Specifications: "Venti" density is 88 kg/m³, compressive strength - 20 kPa, perpendicular tension - 4 kPa. The thermal insulation coefficient of this material is 0.035 W / mk, and the vapor permeability is 0.3 mg / MPa.

Water absorption of the material when fully immersed for 24 hours does not exceed 1% of the total mass, fire resistance class - NG.

8 "Standard"

Mineral wool "Standard" is a universal option for non-loaded thermal insulation of any surfaces. This is an excellent solution for insulating walls and facades of buildings made of any materials - wood, brick, concrete, gas silicate blocks.

With the help of Standard type plates, you can successfully insulate the roof, attic, roof, floor or ceiling of the house.

The structure of mineral wool Izover “Standard

This insulation has a density of 38 kg / m3, which allows it to be used as facade thermal insulation for the subsequent application of wet plaster.

Technical characteristics of cotton wool Standard are as follows:

- Thermal conductivity coefficient according to GOST 7076-99 - 0.035 W / mk;

- Steam conductivity coefficient - 0.3 Mg / MPa;

- Water absorption at partial immersion for 24 hours is 1% of the total weight of the plate;

- Nominal compressibility under a load of 2 kPa - 8%;

- Flammability class according to GOST 30244-94 - NG (completely non-combustible material);

- Permissible temperature mode of operation - from - 80 to +700 C.

Izover "Standard" is produced in the form of plates, the width of which is 60 cm and the length is 120 cm. The thickness is 5 or 10 cm.

9 Product Reviews

Finally - a few reviews from those who are familiar with the material firsthand.

I am a foreman in a team that performs insulation of low-rise works. Previously, we used Rockwool mineral wool, but we have been working with Izover for a year now. I can say that he is better than Rockwool in all respects. We hear only positive feedback from our clients. In general, I recommend.

Victor, 35 years old, Rostov:

I recently insulated the facade of the house with Izover. For a long time I chose between him and Rockwool mineral wool, in the end deciding that Rockwool was not worth the money they were asking for him, and settled on Izover. Didn't regret it.

I did all the work myself, I can say that it is quite easy to work with slab insulation. I think that in this price category there are no heaters better than Izover.

Technical characteristics of insulation Izover

Technical characteristics of Izover - description of the material, list of variations. Advantages of using Izover thermal insulation.

Isover insulation (isover) - types and characteristics

Modern Izover insulation is produced in the base with basalt or glass fibers. The material is obtained by processing quartz sand, mineral rocks of the basalt group and broken glass. The components are mixed, melted at ultra-high temperatures in special furnaces, and then drawn into fibers of different lengths and thicknesses, fastened with a special type of resin.

Isover insulation is produced in two versions: plates and rolls using our own patented technologies in 1981 and 1957.

The main characteristics of the insulation

Thermal insulation materials of the Isover brand from mineral wool inspire confidence and are in stable demand. Moreover, both slabs and rolls are considered to be among the best thermal insulation on the market.

The main characteristics of the heater include:

- Thermal conductivity.

- Soundproofing.

- Flammability.

- Vapor permeability.

- Long service life.

- Environmental friendliness.

- Convenient release form.

- Light weight.

As a heat insulator, Izover insulation managed to prove itself from the best side precisely due to the thermal conductivity coefficient equal to 0.041 watts per meter per Kelvin. The coefficient does not change during the operation of the insulation throughout the entire period, the fibers do an excellent job of accumulating and retaining air, preventing heat loss.

The material has excellent sound insulation performance. Fiberglass insulation with an air gap absorbs noise, guaranteeing optimal level silence, especially if you use specially adapted types of insulation for the sound insulation layer.

Flammability is also important. Thermal insulation materials with technical characteristics indicating a density of up to 30 kilograms per cubic meter are classified as non-combustible. The materials are successfully used in rooms of any type and purpose, without fear of the spread of fire in the event of a fire.

Thermal insulation boards made of mineral wool with special technical characteristics indicating the presence of an additional layer based on aluminum foil or fiberglass are classified as low combustible.

Such materials are used subject to certain restrictions, which in fact are nothing more than a convention. In practice, insulators are appropriate almost everywhere, the main thing is to follow the fire safety requirements for structures prescribed in the SNIp.

An important item from the list of technical characteristics of thermal insulation is vapor permeability. The insulation is able to maintain functionality even after contact with moisture. Unlike many modern analogues for thermal insulation, Izover products based on stone wool simply and effectively cope with the problem of moisture penetration into the thermal insulation layer.

The insulation gives off the absorbed moisture as quickly as it receives, the main thing is to leave a small gap (2-3 cm) between it and the wall to maintain ventilation.

Neglecting this simple rule will lead to a violation of the material's ability to remove moisture, which over time will negatively affect the ability to retain heat. Izover heaters have optimal vapor permeability - from 0.50 to 0.55 mg / mchPa.

Analysis of the technical characteristics of the material implies the mention of such an important parameter as the service life. The material not only does not transmit heat, but is also able to serve properly for several decades. The manufacturer claims a service life for heat-insulating plates and rolls of 50 years with full preservation of functionality.

A feature of the material is the water repellents included in the composition, capable of repelling moisture, preventing the reproduction of insects, fungi and the formation of mold, which in turn ensures safety throughout the entire period of use.

Among the technical characteristics of the insulator, environmental friendliness and complete safety for health play a special role. Izover materials do not pose any risk to life and health, as they are made from natural raw materials.

The light weight of the insulation is not just one of the characteristics, it is a clear and undeniable advantage. If we compare the insulator with analogues, then its weight is an order of magnitude less, which in turn allows us to expand the scope of application by combining the insulation with surfaces made of not the most durable materials.

An excellent bonus from a manufacturer that focuses on improving the technical characteristics of the finished product can be considered the release form. Insulations are available in several versions - rolls, plates, less often - in mats (for example, ISOVER ISOTEC KIM-AL).

The average thickness of a single-layer insulation ranges from 50 to 150 mm. The two-layer insulation has a fixed thickness of 5 cm with standard sizes 1 m by 1 m. The roll is produced with an area of 16 to 20 square meters with a constant width of 1.2 meters and a length ranging from 7 to 14 meters.

The technical characteristics in relation to the combustibility of the heat-insulating material should include the following parameters:

The combustibility of thermal insulation boards and rolls based on mineral wool varies within 30 kg/m3, if we are talking about a group of non-combustible materials. Semi-rigid and rigid boards coated with film and foil from the group of low combustible are taken out into a separate category.

Varieties and application of insulation

The description of the main technical characteristics of the material confirms the fact that as a heater it is practically out of competition. Plates and rolls are used for internal and external insulation, practicing the device of a heat-insulating layer of rooms and structures different type and appointments. A heat insulator is presented in a fairly wide range in order to select the most appropriate option.

Thermal insulation for pitched roofs - the most suitable option for isolation:

- pitched roof from the inside;

- house insulation for siding;

- outside pitched roof insulation.

This type of material is characterized by improved moisture resistance, which allows it to be used for insulation of roofs operated in conditions of high humidity.

Another option for stone wool insulation is to improve the quality of sound protection. The material is suitable for insulating partitions, insulating structures for siding, insulating floors along logs and walls inside the house.

Izover for soundproofing has excellent soundproofing properties, indispensable for improving the properties in partitions and other structures.

Another type of stone wool insulation is Izover Classic Plus. The material is suitable for insulation of almost all types of surfaces, has a thermal insulation coefficient of 0.041 W.

It is sold in the form of lightweight plates with a thickness in two versions: 50 mm and 100 mm, in packs of 7 and 14 pieces. Plates Classic are easy to use, suitable for installation in rooms with a limited area. The material does not require the use of special fasteners, it is used to isolate partitions, suspended ceilings and other surfaces. You can buy Izover Classic Plus plates at an affordable price.

Unlike the Classic Izover Sauna slabs, the material is based on fiberglass wool with an additional layer of foil. Products are produced with a thickness of 50 mm and 100 mm, with a width of 1200 mm and a length in two versions - 625 mm and 12500 mm.

From the name it is clear that the insulation is designed primarily for use in saunas, where stable high temperatures are maintained and additional protection against abundant steam is needed.

The heat-insulating material is safe, durable, sold in packages that are convenient for transportation with a thickness of plates of 50 mm, 100 mm, 150 mm.

Izover Profi also has technical characteristics different from the Classic insulator, which is also produced in the form of rolls and plates. The insulation has a 3D effect, which allows you to insulate surfaces with a snug fit to the base and consoles. In terms of thermal protection, it is the Profi that is considered the most effective and has an indicator of 0.037 W.

The material is available in two thicknesses: Profi boards 50 mm and Izover Profi insulation 100 mm (in rare cases up to 150 mm).

For the insulation of ventilated facades, special heaters are suitable. These are models for warming the outer layer in the case of a two-layer thermal insulation device, guaranteeing minimal heat loss with high thermal protection.

Complete with insulation for the upper layer, Izover VentFacade Bottom is also used for the lower layer, also with excellent thermal performance. The thickness of the plates (50 mm or 100 mm) is determined on the basis of a thermal calculation.

For insulation of single-layer ventilated facades, Izover Facade Mono and VentFacade Optima for low-rise buildings are used.

Another type of plate with a thickness of 50 and 100 mm (in isolated cases 150 mm) is Isover KL34. The materials are tightly mounted on the frame without the use of additional fasteners. The slabs, like the Classic, are suitable for insulating both ventilated facades and multi-layer brickwork, while it will equally effectively insulate horizontal and vertical planes.

Isover KL37 is a heater sold in tightly pressed packs. Just like the previous options, it does not need additional fasteners, it is suitable for installation between floors, roof and wall insulation with maximum adhesion to the surface.

A variation of the previous model - Isover KT37, produced in compressed rolls. Installation of insulation for thermal insulation does not require additional fasteners, the elements fit perfectly to the surface. Used for insulation of roofs, interfloor ceilings, attics and partitions.

Isover KT40 is a two-layer insulation in compressed rolls, suitable for thermal insulation of both vertical and horizontal surfaces.

Isover STYROFOAM 300A - insulation for thermal insulation, the installation of which is complicated by the use of fasteners. Produced in hard rough slabs, excellent adhesion to concrete. The composition includes extruded polystyrene foam, due to which insulated cells are formed that improve moisture resistance. Insulate material both horizontal and vertical surfaces inside and out.

Another variety of ISOVER ISOTEC KIM-AL material in the form of fiberglass thermal insulation mats. The material is developed using a special technology of vertical fiber formation, additionally covered with a layer of aluminum foil to improve vapor barrier and increase service life.

Mats ISOVER ISOTEC KIM-AL are used to insulate air ducts of supply and exhaust ventilation system, technological equipment, fittings, flange connections pipelines, etc.

The main advantages of ISOVER ISOTEC KIM-AL include a special arrangement of fibers, due to which the material during installation retains its original shape unchanged, adhering as closely as possible to the surface. In addition, the insulation increases the level of sound insulation in the room, suitable for thermal insulation of pipes inside buildings.

The advantage of ISOVER ISOTEC KIM-AL is also resistance to chemicals. If we compare KIM-AL with other heaters based on stone wool, then its superiority is obvious - the material is not susceptible to moisture and aggressive environments.

Using material for insulation (it doesn’t matter if Classic is Facade, Pro or soundproofing plates), you need to protect your hands and eyes with gloves and goggles.

Characteristics and types of insulation Izover

The main characteristics of thermal insulation Izover. Its varieties, areas of application. Advantages and disadvantages of Isover material.

You can easily get lost in the trade names of building materials, especially when you deal with them from time to time. In addition, all the names are very often similar. This also applies to Isover insulation, which was originally produced and developed in France, and came to us about 25 years ago. It was first used in the mid 1930s light hand Saint Gobain. As before, this is a material based on fiberglass and mineral fibers, but thanks to localized production, the price of the material has ceased to be European with a fairly good quality.

What is Izover

Izover insulation, the technical characteristics of the photo, the price of which will be shown below, can be supplied in a wide variety of shapes and formats. It depends on where it is used. Only one thing remains unchanged - it is an insulating material based on mineral fibers and fiberglass. The first quality of any insulation should be the minimum coefficient of thermal conductivity. The tables show the characteristics of several types of material and the maximum thermal conductivity of the universal Isover. It is about 0.036 W / m³ and may fluctuate depending on the density of the material.

The material itself is a fiber structure. The length of the fibers can be from 120 microns, and the thickness is not more than 4 microns. It is these indicators that guarantee the material high strength with minimal thermal conductivity and a sufficient amount of air held inside the material. The production technology is patented and not a single material can simply physically have the characteristics that Izover of any type declares.

Characteristics of Izover

Minimal heat loss guaranteed simple property air placed in the closed space between the fibers of the material, this is what makes the material so warm. In addition, Izover can also be used as a sound insulator and the company declares it as absolutely safe for health. It can be used not only for external insulation of facades, but also internal insulation rooms of a residential building, including children's rooms.

The vapor permeability of the material also has great importance, since the accumulation of moisture in the structure of the material leads to the loss of thermal properties. However, when Izover insulates foundations, plinths and facades, experts recommend leaving at least 2 cm for sufficient ventilation. For water repellency, the material is impregnated with water repellents, which guarantee the absence of not only moisture, but also biological threats. Therefore, the manufacturer can guarantee a 50-year service life of the material.

Safety, weight and price

According to GOST, Izover is considered non-combustible when used in the form of clean slabs, mats and rolls. In combination with aluminum foil or film, it can be considered low-flammable, but this is enough from a safety point of view to calmly insulate with material internal walls residential buildings, not to mention facades. Izover in this sense has no restrictions on the use.

One of the distinguishing qualities of the material is its very light weight. This is important if you take into account the cost of equipping the battens, fastening materials and additional elements that are used during installation. Also, the low weight of the insulating structure reduces the load on floors, walls or roofs. The price of the material is also quite worthy. With a high level of localization of production, it was possible to achieve the price level of domestic materials, and this is about 130-180 rubles per square meter of insulation. Packing an insulator can cost from a thousand to 1,500 rubles, depending on the brand.

Dimensions, density and types of insulation

The density of a material can play a decisive role when it is used in certain conditions. For example, the densest insulation has a density of 120 to 160 kg / m³ and is used for roofing, and the least dense with an indicator of 28-38 kg / m³ can be used for both walls and facades. Izover for the floor has a density of 150-165 kg / m³.

The size of the material and the form of release can be very different, depending on the scope of application. For example, for a foil moisture-resistant Izover for wet rooms, it can be produced in rolls with a thickness of 50 to 100 mm, and the length of the unfolded roll will be within 1.25 m. Universal insulation can be up to 100 mm thick and produced in the form of plates of various sizes, at the same time, the material is perfectly cut and processed, and the size of the plate is selected based on the size and surface area, so as not to allow a large amount of waste.

Areas of application for insulation

Given the universal properties, low price and various forms of release, the use of the material can be very versatile. For example, the main areas of use of Izover are:

- For baths and saunas, a foil isover is used.

- Ceilings, interfloor ceilings are insulated with a less dense material.

- Izover of increased density is used for floors and roofs.

- It is used when installing plastic windows.

- For insulation of balconies.

- For insulation of basements and basements.

- Interior partitions are insulated, taking into account the fact that the material has good sound insulation.

- For facade insulation.

Reliable and durable material (the manufacturer declares 50 years of warranty operation) can be an excellent insulation not only for a private house, but also for an apartment, as well as for non-residential buildings. Good luck to everyone and warm homes!

Izover insulation: specifications, photo, price

You can easily get lost in the trade names of building materials, especially when you deal with them from time to time. In addition, all the names are very often similar. This also applies to Isover insulation, which was originally produced and developed in France, and came to us about 25 years ago. It was first started

Izover insulation: technical characteristics, disadvantages and advantages

The most popular roll and tile insulation is isover. It bears the name of a company that patented the production of a material from sand, limestone and soda, while being able to retain heat. Thanks to these properties, ISOVER provides high thermal insulation as well as sound insulation. It can be used for insulation, both indoors and outdoors.

Technical characteristics of insulation ISOVER

Glass fibers are the basis of ISOVER. The length of one of the thousand fibers reaches 150 microns with a thickness of 5 microns. These parameters make the material very elastic and durable.

Glass fibers are the basis of ISOVER. The length of one of the thousand fibers reaches 150 microns with a thickness of 5 microns. These parameters make the material very elastic and durable.

ISOVER can be used at any stage of building erection. Manufacturers promise thermal protection of the highest level.

ISOVER specifications are as follows:

- Low thermal conductivity. It provides a high degree thermal protection

- Excellent sound reduction properties. Provides significant noise reduction

- High environmental friendliness of the material. Can be used to warm any room

- Durability. This material can last at least 5 decades

- Fire resistance. It does not really burn, but at high temperatures it can melt

- Lightness of weight. Thanks to this indicator, isover can even be used for insulation of stacked structures.

Density of airtight ISOVER at the level of 13 kg/m3. During installation, it is possible (due to the softness of the material) to reduce the density of adhesion to the wall.

Types of insulation ISOVER

The manufacturer does not produce universal material. Given the high manufacturability of the production process, Isover can be manufactured for:

The manufacturer does not produce universal material. Given the high manufacturability of the production process, Isover can be manufactured for:

- Light thermal insulation. By production the TEL technology is used. Slabs and mats are produced. Can be used as wall insulation wooden house or brick, for roof insulation, should not be used for insulation of foundations and floors

- General construction insulation. There are also several varieties:

Soft fiberglass slabs for frame structures,

Roll mats are used without fasteners,

Mats, one side of which has a foil base,

Slabs of medium hardness

- The products are special. It's about about ISOVER for pitched roofs. Such material has high hydrophobic characteristics, it does not burn and it has a high level of vapor permeability.

The ISOVER marking for civil engineering is as follows:

- KL - plates

- KT - mats

- OL-E - mats of special rigidity

- The numbers indicate the thermal conductivity class

ISOVER application

The scope of ISOVER is the most diverse. It can be used for insulation

The scope of ISOVER is the most diverse. It can be used for insulation

roofs, attics, building facades, interiors, suspended ceilings, floors, plinths and foundations.

- ISOVER KT40 is recommended for use in ceiling and floor insulation. This is a material consisting of two layers that can be easily separated. Installation of horizontal surfaces does not require additional fixing

- ISOVER STYROFOAM 300A is a tile material that must be fixed when installed on vertical surfaces. Can also be used successfully on horizontal surfaces

- ISOVER KL 34, ISOVER KL 37 - boards that are released in pressed rolls. The material is used as insulation for walls inside the apartment, for insulation internal partitions, for thermal insulation of ceilings, attics

When using ISOVER indoors, a vapor barrier will be required.

How to insulate walls and floors with Izover?

You need to work with this material in the same way as with any other insulation. The main thing to know is that high-quality insulation is a multilayer cake. And then there will be a positive result when the order of the layers of this pie is observed.

Wall insulation

In order to mount Izover on the wall, you need to make a crate. It can be wooden planks or metal. Then drywall will need to be attached to them.

In order to mount Izover on the wall, you need to make a crate. It can be wooden planks or metal. Then drywall will need to be attached to them.

The technique for performing work can be as follows:

- Walls need to be primed

- Attach heat reflective sheet. This should only be done for walls that border the street.

- Make a vertical crate. It can be a full-fledged frame, but it can also be ordinary wooden planks. The step between the planks should be done according to the width of ISOVER

- Lay sheets of insulation, gluing them to the wall

- Attaching the moisture-repellent film

- Now you need to fill the horizontal bars

Ceiling insulation

It is necessary to insulate the ceiling, practically, using the same technology as the walls. The only difficulty is that you have to mount over your head.

Disadvantages of ISOVER

Even modern materials cannot be absolutely perfect. But with regard to ISOVER, he can say that his two shortcomings can be leveled out.

Even modern materials cannot be absolutely perfect. But with regard to ISOVER, he can say that his two shortcomings can be leveled out.

- ISOVER - it pricks and causes irritation. This can be avoided by wearing gloves.

- ISOVER is afraid of moisture and under its influence it loses all its positive qualities. This means that the material cannot be used outside (except for those types that have additional protection in the form of foil layers)

ISOVER cost

Roll standard ISOVER, which is used for wall and ceiling insulation, has an area of 20 m2. The thicker the sheet, the better the technical characteristics of the isover insulation, the price is also higher, respectively.

Roll standard ISOVER, which is used for wall and ceiling insulation, has an area of 20 m2. The thicker the sheet, the better the technical characteristics of the isover insulation, the price is also higher, respectively.

So, ISOVER KT 40 has the fortieth thermal conductivity class, a sheet thickness of 10 cm, belongs to non-combustible materials and costs 750 rubles.

ISOVER sheet, which can be used for pitched roofs, has dimensions of 100 / 1170 / 610 millimeters. Packing area from 14 to 17 m2 depending on sheet thickness. The cost is about 800 rubles.

Isover insulation: technical specifications and installation features

Isover insulation: specifications, types of material, prices and applications. How to insulate them with walls and ceilings and where it is used. As well as

is one of the leading manufacturers of mineral wool fiberglass thermal insulation materials in the world. These heaters have established themselves as high-quality products with an optimal ratio of price and performance.

From this article you will learn what types of Izover thermal insulation exist, their characteristics, and how they differ from each other. We will also study the reviews and find out why these mineral wool heaters are better than similar products on the market.

1 Scope of thermal insulation Izover

Thermal insulation materials from the French company Izover, in addition to excellent insulating abilities, also have good noise-reducing properties, which greatly expands their scope.

3 Isover KL 34

Plate insulation, the thickness of which can be 5 or 10 centimeters. This material is intended for frame mounting, and does not require mandatory fixing with dowels. Model KL34, according to reviews, is characterized by high elasticity, which makes it possible to install it on any surface.